Bi2O2Se-based thermoelectric material and preparation method thereof

A technology of thermoelectric materials and bulk materials, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high sintering energy consumption, high operation difficulty, long reaction time, etc., and achieve short sintering time and performance change Obvious effect of improving ZT value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a Bi 2 O 2 The preparation method of Se-based thermoelectric material includes the following steps:

[0033] 1) First press Bi 2-x Sn x O 2 The stoichiometric ratio of Se, when x=0, weigh Bi 2 O 3 , Bi and Se powder; when 0 2 O 3 , Bi, Se and SnO 2 Powder

[0034] 2) After mixing the powder in step 1), vacuum seal the tube, encapsulate the powder in a vacuum quartz glass tube, and calcinate at 475°C to 525°C to complete the phase formation phase. The calcining time is 6h~ 24h;

[0035] 3) Put the calcined powder into the graphite mold, after compaction, SPS spark plasma is used to sinter into a bulk material, the sintering temperature is 525℃~575℃, and the heating rate of sintering is generally 119℃ / min~131℃ / min , The holding time is 5min~30min, the sintering pressure is 30MPa~80MPa, then the required Bi 2 O 2 Se-based thermoelectric material.

Embodiment 1

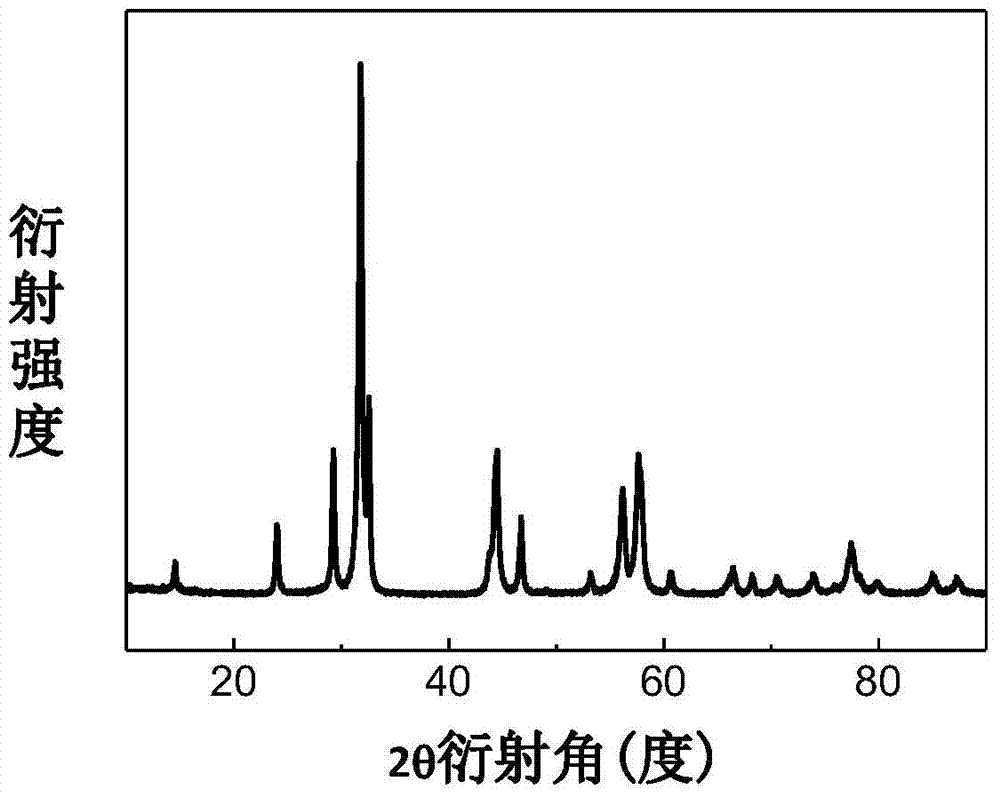

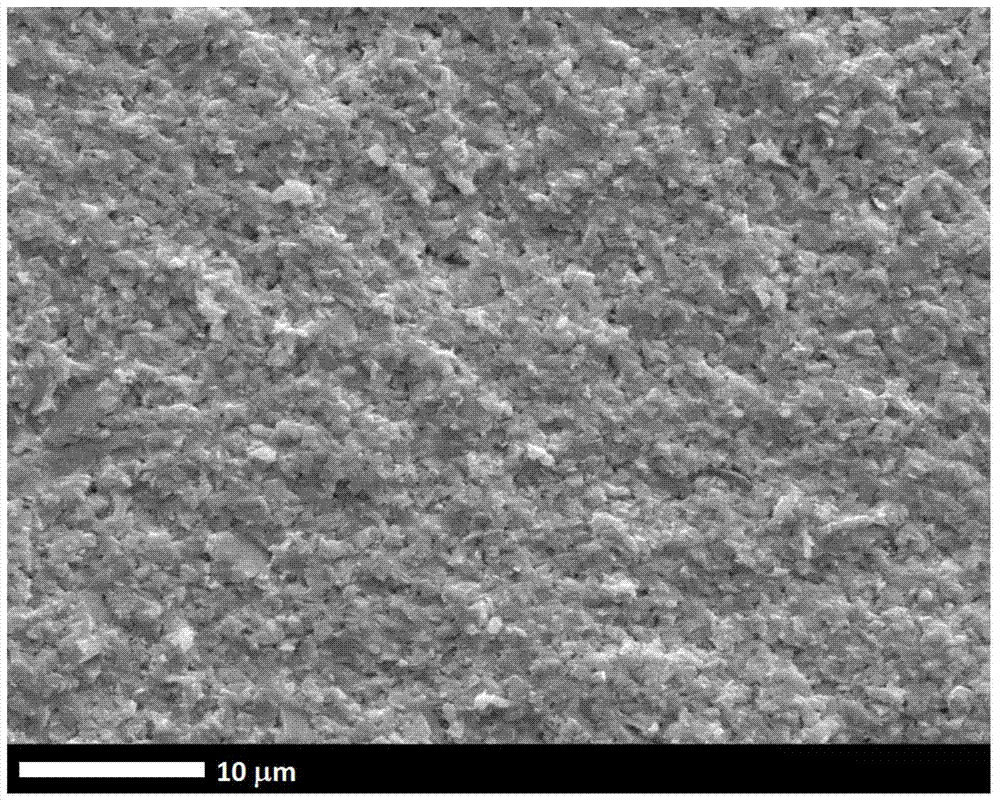

[0038] Follow Bi 2 O 2 The proportion of Se, weighed Bi 2 O 3 , Bi and Se powders, after mixing, vacuum sealing the tube and then calcining, sintering in air at 525°C for 24 hours to complete the phase formation stage of the material phase. Then crush, mix, and use SPS spark plasma sintering furnace to sinter at 575℃, sintering pressure is 50MPa, heating rate is 131℃ / min, and holding time for 5min can obtain Bi 2 O 2 Se-based thermoelectric material. It is characterized by figure 1 , 2 shows. Its ZT value can reach 0.065 at 500°C.

Embodiment 2

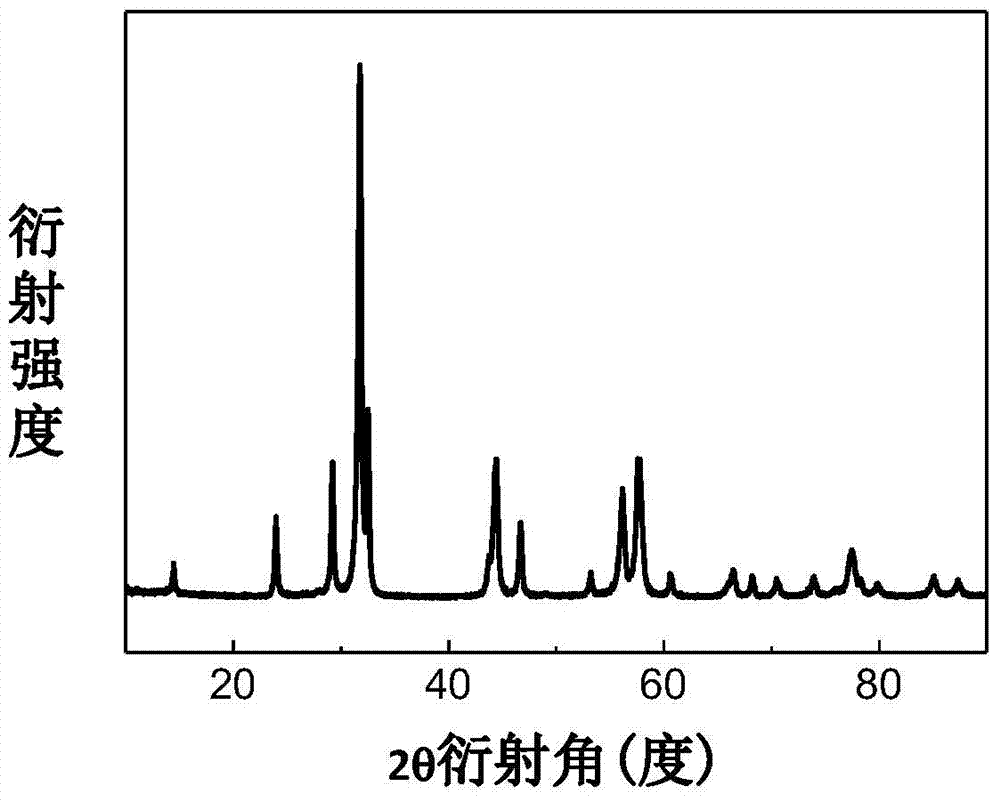

[0040] Follow Bi 2 O 2 The proportion of Se, weighed Bi 2 O 3 , Bi and Se powders, after mixing, vacuum sealing the tube and then calcining, sintering in air at 500℃ for 12h, complete the phase formation stage of the material phase. Then crush, mix, and use SPS spark plasma sintering furnace to sinter at 550℃, sintering pressure is 80MPa, heating rate 125℃ / min, heat preservation 15min can obtain Bi 2 O 2 Se-based thermoelectric material. It is characterized by image 3 , 4 shows. Its ZT value can reach 0.054 at 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com