A bi2o2se-based thermoelectric material and its preparation method

A thermoelectric material and bulk material technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high sintering energy consumption, long reaction time, and high difficulty in operation, and achieve short sintering time and improved ZT value. , the effect of obvious changes in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a Bi 2 o 2 The preparation method of Se-based thermoelectric material comprises the following steps:

[0033] 1) First press Bi 2-x sn x o 2 The stoichiometric ratio of Se, when x=0, weigh Bi 2 o 3 , Bi and Se powder; when 02 o 3 , Bi, Se and SnO 2 powder;

[0034] 2) Mix the powders in step 1) and vacuum seal the tubes, encapsulate the powders in a vacuum quartz glass tube, and calcinate at 475°C to 525°C to complete the phase formation stage, and the calcining time is 6h to 24h;

[0035] 3) Put the calcined powder into a graphite mold, and sinter it into a bulk material with SPS discharge plasma after compaction. The sintering temperature is 525°C~575°C, and the heating rate of sintering is generally 119°C / min~131°C / min , the holding time is 5min~30min, and the sintering pressure is 30MPa~80MPa, that is, the required Bi 2 o 2 Se-based thermoelectric materials.

Embodiment 1

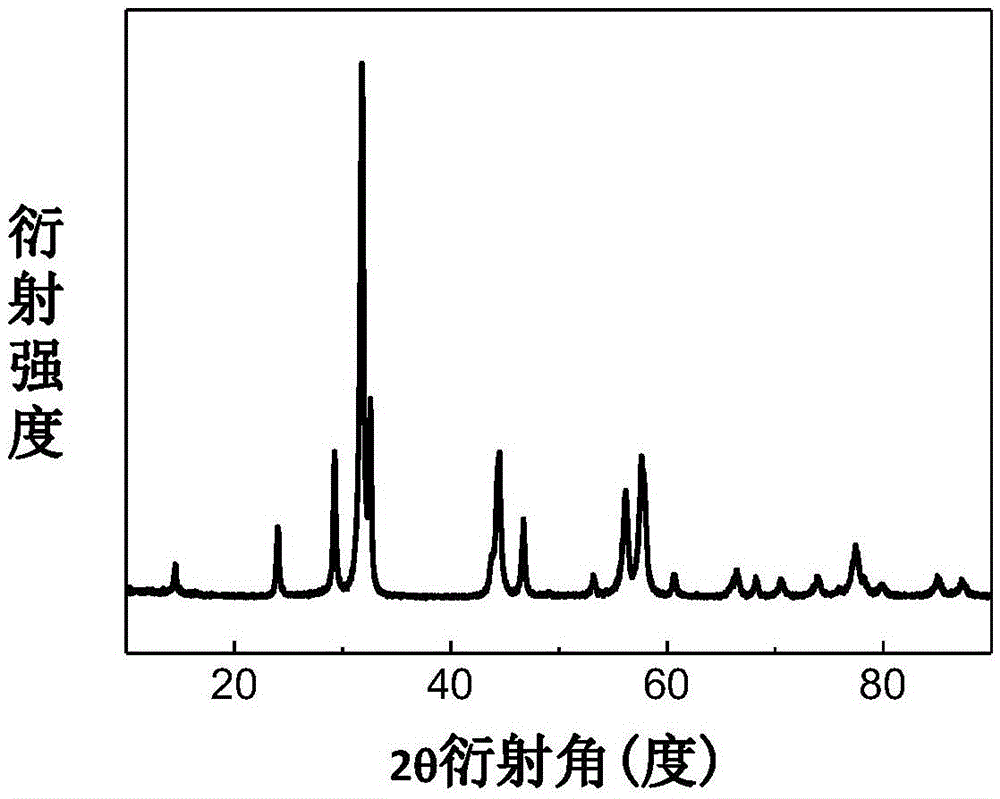

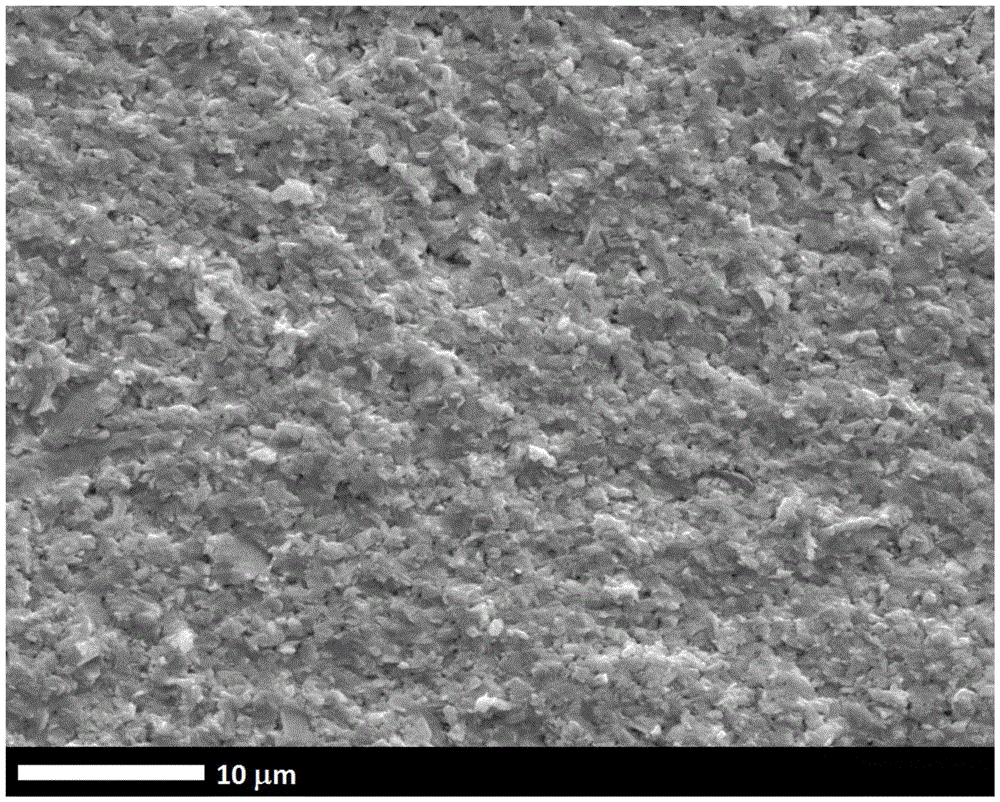

[0038] According to Bi 2 o 2 The ratio of Se, weigh Bi 2 o 3 , Bi and Se powders, after mixing, seal the tube in vacuum and then calcine, and sinter in air at 525°C for 24h to complete the phase formation stage of the material phase. Then crush, mix, and sinter in SPS discharge plasma sintering furnace at 575°C, the sintering pressure is 50MPa, the heating rate is 131°C / min, and the temperature is kept for 5min to obtain Bi 2 o 2 Se-based thermoelectric materials. It is characterized by figure 1 , 2 shows. Its ZT value can reach 0.065 at 500°C.

Embodiment 2

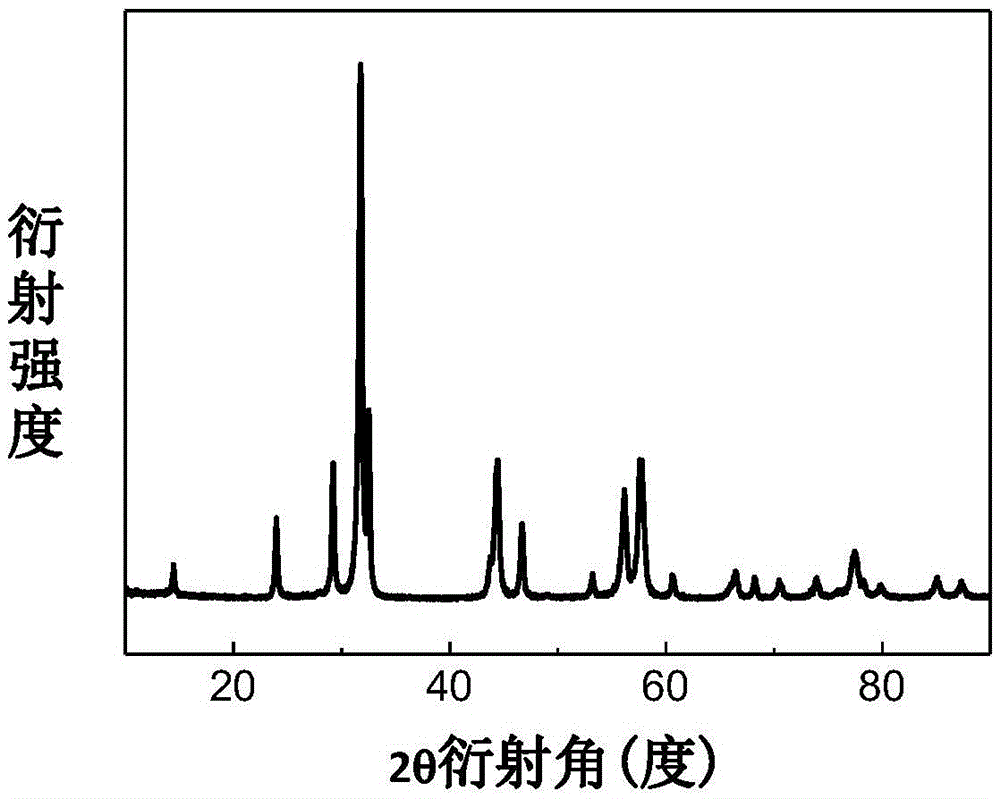

[0040] According to Bi 2 o 2 The ratio of Se, weigh Bi 2 o 3, Bi and Se powders, after mixing, seal the tube in vacuum and then calcine, and sinter in air at 500°C for 12 hours to complete the phase formation stage of the material phase. Then crush, mix, and sinter in SPS discharge plasma sintering furnace under the condition of 550°C, the sintering pressure is 80MPa, the heating rate is 125°C / min, and the temperature is kept for 15min to obtain Bi 2 o 2 Se-based thermoelectric materials. It is characterized by image 3 , 4 shows. Its ZT value can reach 0.054 at 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com