Zinc antimony based porous p-type thermoelectric material and preparation method thereof

A technology of porous structure and thermoelectric material, which is applied in the field of porous structure p-type zinc-antimony based thermoelectric material and its preparation, semiconductor thermoelectric power generation and refrigeration materials, and achieves the effect of shortening the preparation period and shortening the preparation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

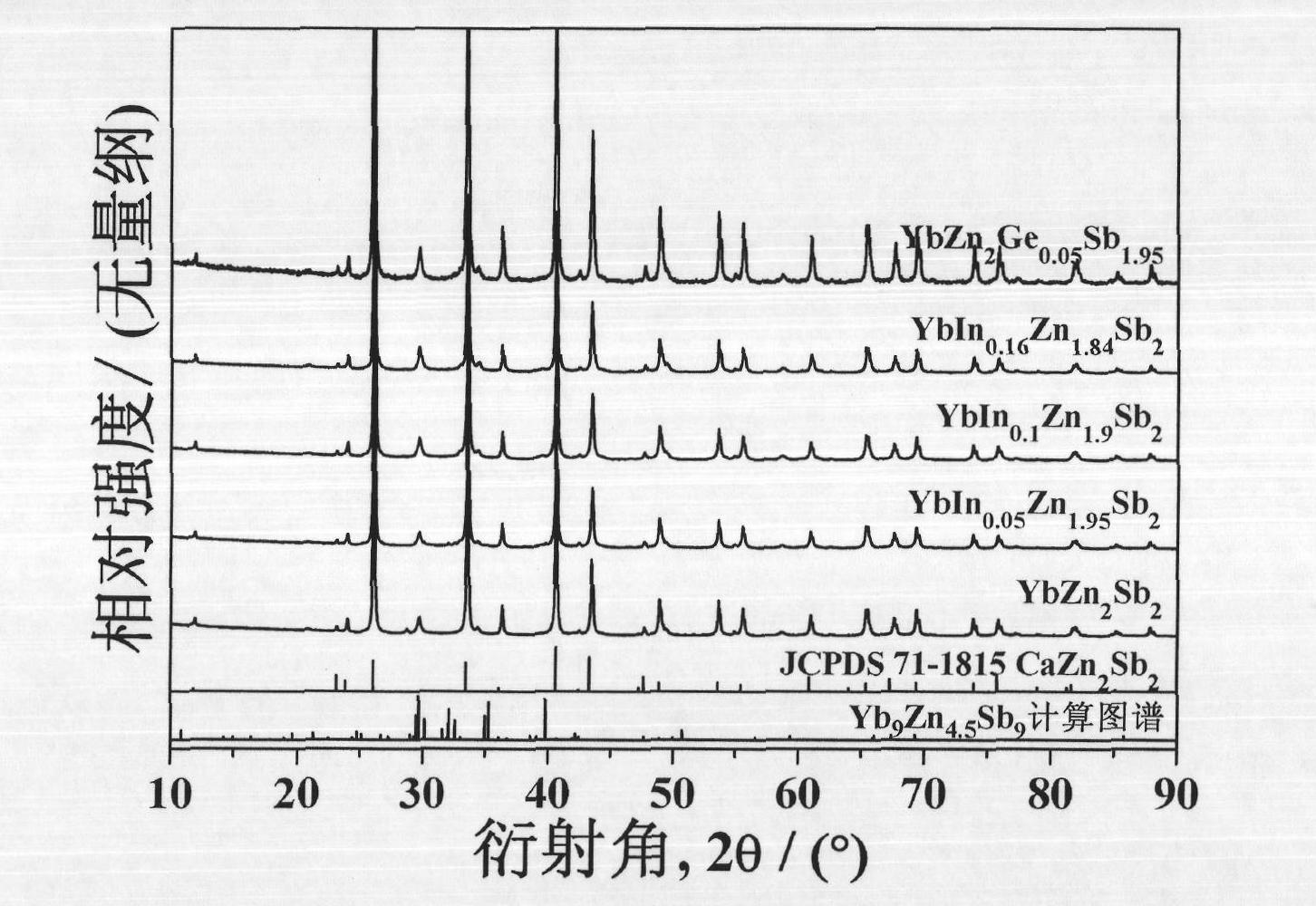

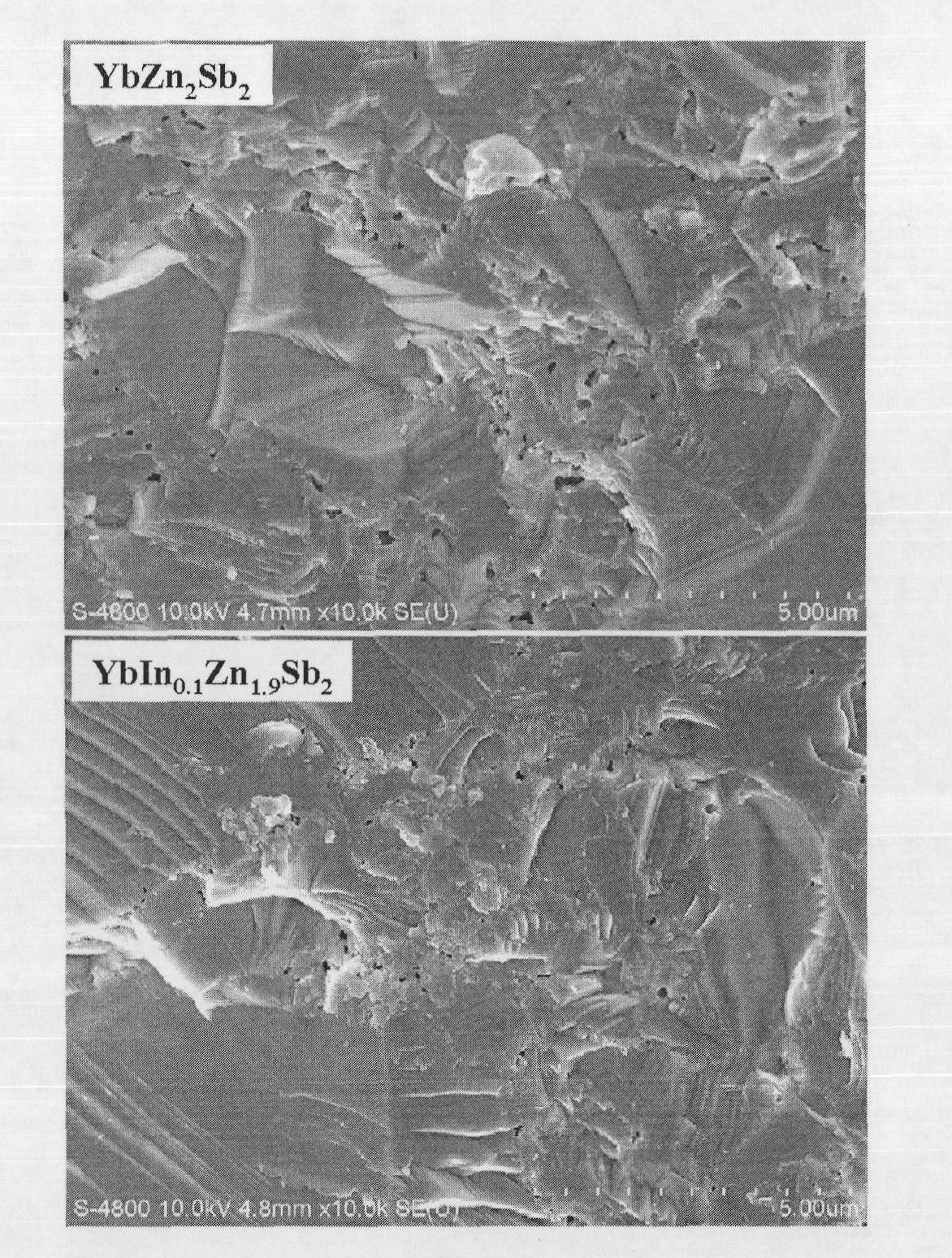

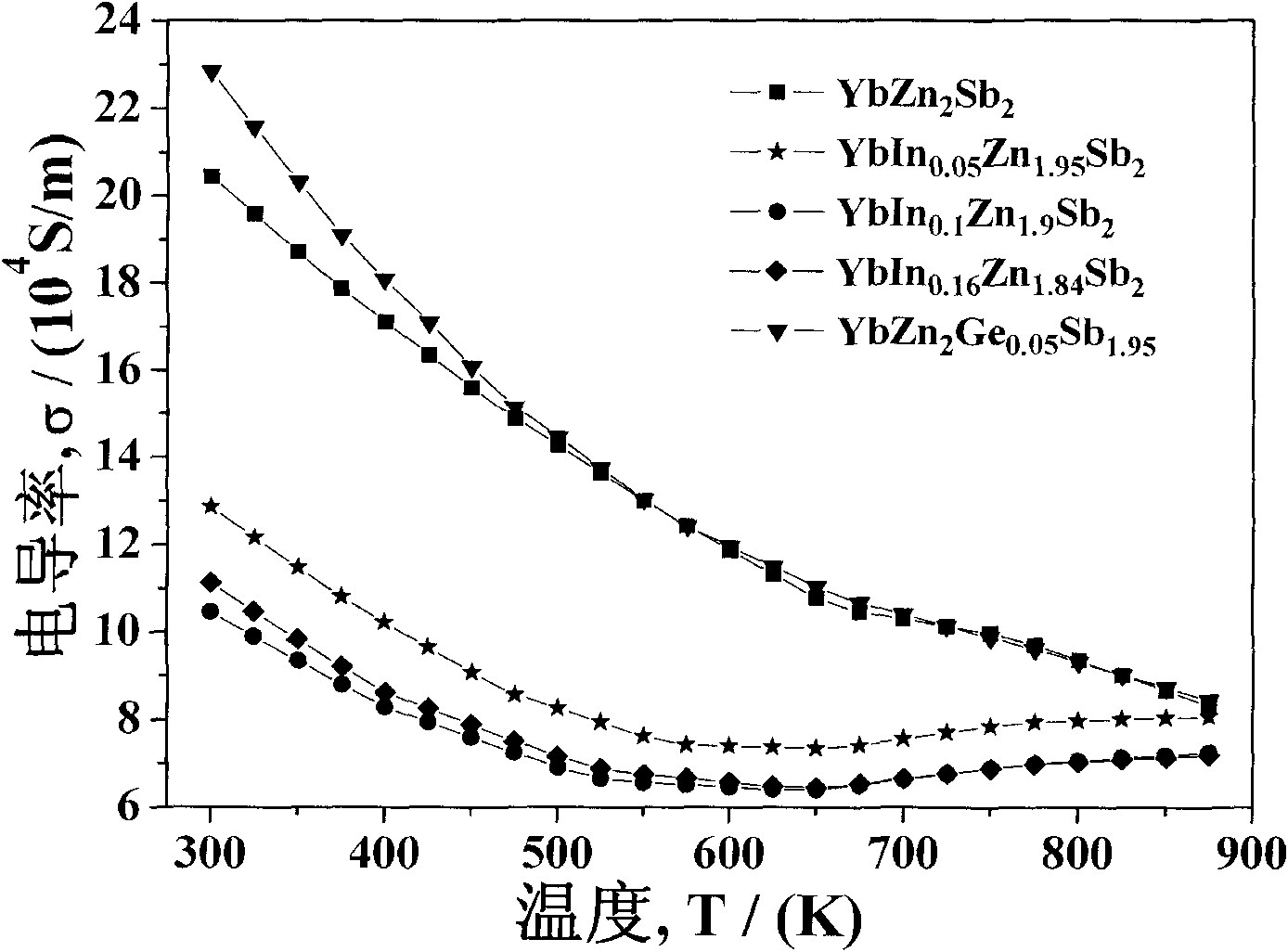

[0037] Example 1: Porous structure p-type YbZn 2 Sb 2 Material

[0038] (1) According to the nominal composition, it is YbZn 2 Sb 2 The stoichiometric ratio of high-purity Yb block (purity 99.995%) 2.8451g, Zn powder (purity 99.99%) 2.1507g and Sb powder (purity 99.999%) 4.0044g are accurately weighed, and the three raw materials are loaded into In the graphite crucible, and seal the graphite crucible in a vacuum degree less than 10 -1 In a vacuum quartz tube of MPa;

[0039] (2) Place the above-mentioned vacuum quartz tube in a programmed temperature-controlled melting furnace, and raise the temperature from room temperature to 850°C at a rate of 3°C / min. After vacuum melting for 6 hours, the master alloy melt is quenched in oil to obtain YbZn 2 Sb 2 Quenched castings of master alloys;

[0040] (3) The above-mentioned YbZn 2 Sb 2 The quenched casting of the master alloy is ground and passed through a 400-mesh sieve to obtain YbZn 2 Sb 2 quenched powder of the ma...

Embodiment 2

[0043] Example 2: Porous structure p-type YbIn 0.05 Zn 1.95 Sb 2 Material

[0044] (1) Composed as YbIn by name 0.05 Zn 1.95 Sb 2 The stoichiometric ratio accurately weighs 2.8323g of high-purity Yb block (purity 99.995%), In powder (purity 99.99%) 0.0940g, Zn powder (purity 99.99%) 2.0875g and Sb powder (purity 99.999%) 3.9864g, Put the four ingredients into In the graphite crucible, and seal the graphite crucible in a vacuum degree less than 10 -1 In a vacuum quartz tube of MPa;

[0045] (2) Place the above-mentioned vacuum quartz tube in a programmable temperature-controlled melting furnace, and raise the temperature from room temperature to 850°C at a rate of 5°C / min. After vacuum melting for 8 hours, the master alloy melt is quenched in water to obtain YbIn 0.05 Zn 1.95 Sb 2 Quenched castings of master alloys;

[0046] (3) The above-mentioned YbIn 0.05 Zn 1.95 Sb 2 The quenched casting of the master alloy is ground and passed through a 400-mesh sieve to obt...

Embodiment 3

[0049] Example 3: Porous structure p-type YbIn 0.1 Zn 1.9 Sb 2 Material

[0050] (1) Composed as YbIn by name 0.1 Zn 1.9 Sb 2 The stoichiometric ratio accurately weighs 2.8197g of high-purity Yb block (purity 99.995%), In powder (purity 99.99%) 0.1871g, Zn powder (purity 99.99%) 2.0249g and Sb powder (purity 99.999%) 3.9686g, Put the four ingredients into In the graphite crucible, and seal the graphite crucible in a vacuum degree less than 10 -1 In a vacuum quartz tube of MPa;

[0051] (2) Place the above-mentioned vacuum quartz tube in a programmable temperature-controlled melting furnace, and raise the temperature from room temperature to 900°C at a rate of 7°C / min. After vacuum melting for 10 hours, the master alloy melt is quenched in oil to obtain YbIn 0.1 Zn 1.9 Sb 2 Quenched castings of master alloys;

[0052] (3) The above-mentioned YbIn 0.1 Zn 1.9 Sb 2 The quenched casting of the master alloy is ground and passed through a 400-mesh sieve to obtain YbIn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com