Flame-retardant temperature-regulating environment-friendly non-woven fabric and preparation method thereof

A non-woven and environment-friendly technology, applied in the field of flame-retardant and temperature-adjusting environment-friendly non-woven fabrics and their preparation, can solve the problems of decreased use performance, affected use experience, disappearance, etc., and achieves increased thermal stability and compactness. The effect of improving thermal stability, thermal stability and densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

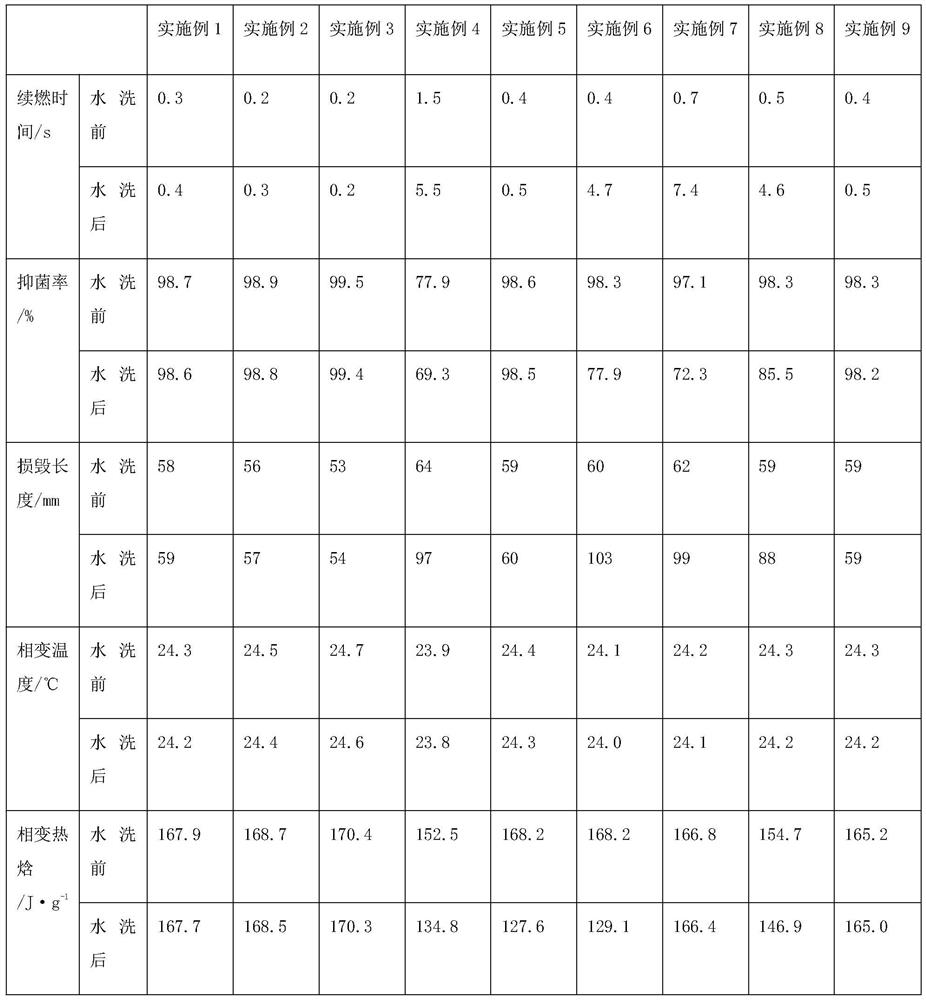

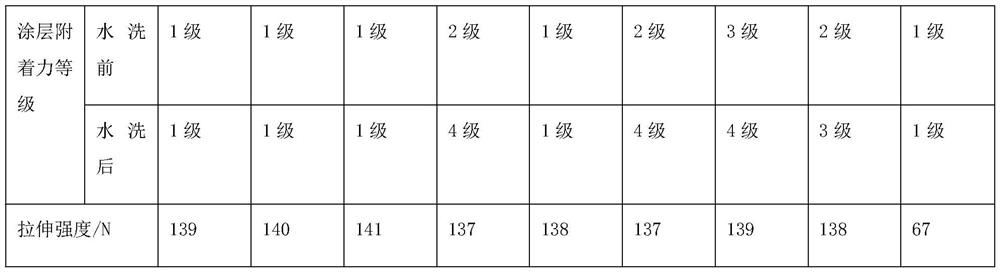

Examples

Embodiment 1

[0056] A flame-retardant temperature-regulating environment-friendly non-woven fabric, the raw material components are as follows: in parts by weight, 80 parts of non-woven fabric substrate, 30 parts of modified temperature-regulating capsule coating, and 28 parts of anionic flame-retardant coating , Cationic flame retardant coating 28 parts.

[0057] The non-woven fabric substrate includes various raw material components as follows: in parts by weight, 80 parts of degradable polymer and 20 parts of modified carbon nanotubes.

[0058] The modified temperature-regulating capsule coating includes the following raw material components: in parts by weight, 27 parts of butyl stearate, 18 parts of n-octadecane, 8 parts of pentaerythritol triacrylate, 15 parts of acrylate monomer, 15 parts of propylene glycol monomer, 14 parts of emulsifying and dispersing agent, 9 parts of diethylenetriamine, 10 parts of sodium tetrahydroxyaluminate, and 20 parts of graphene oxide.

[0059] The raw...

Embodiment 2

[0076] A flame-retardant temperature-regulating environment-friendly non-woven fabric, the raw material components are as follows: in parts by weight, 100 parts of non-woven fabric substrate, 35 parts of modified temperature-regulating capsule coating, and 30 parts of anionic flame-retardant coating , Cationic flame retardant coating 30 parts.

[0077] The non-woven fabric substrate includes various raw material components as follows: in parts by weight, 100 parts of degradable polymer and 25 parts of modified carbon nanotubes.

[0078] The modified temperature-regulating capsule coating includes the following raw material components: in parts by weight, 33 parts of butyl stearate, 20 parts of n-octadecane, 10 parts of pentaerythritol triacrylate, 16 parts of acrylate monomer, 16 parts of propylene glycol monomer, 16 parts of emulsifying dispersant, 13 parts of diethylene triamine, 12 parts of sodium tetrahydroxyaluminate, and 22 parts of graphene oxide.

[0079] The raw mate...

Embodiment 3

[0096] A flame-retardant temperature-regulating environment-friendly non-woven fabric, the raw material components are as follows: in parts by weight, 120 parts of non-woven fabric substrate, 40 parts of modified temperature-regulating capsule coating, and 32 parts of anionic flame-retardant coating , Cationic flame retardant coating 32 parts.

[0097] The non-woven fabric substrate includes various raw material components as follows: in parts by weight, 120 parts of degradable polymer and 30 parts of modified carbon nanotubes.

[0098] The modified temperature-regulating capsule coating includes the following raw material components: in parts by weight, 37 parts of butyl stearate, 22 parts of n-octadecane, 12 parts of pentaerythritol triacrylate, 18 parts of acrylate monomer, 18 parts of propylene glycol monomer, 18 parts of emulsifying dispersant, 15 parts of diethylene triamine, 14 parts of sodium tetrahydroxyaluminate, and 24 parts of graphene oxide.

[0099] The raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com