Novel heat dissipation insulating composite material and preparation method therefor

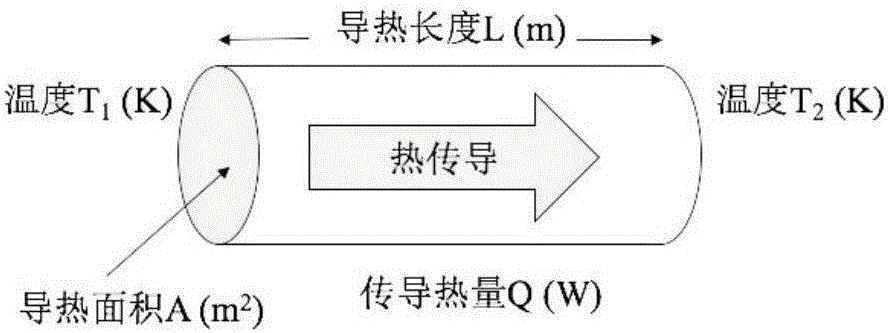

An insulating composite material, a new type of technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced LED life, low thermal conductivity, reduced thermal conductivity, etc., to achieve great market competitiveness, low thermal expansion coefficient, The effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

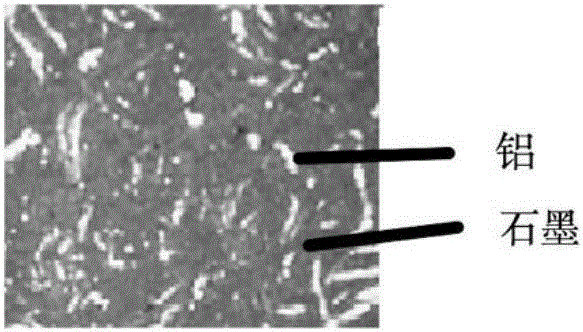

[0047] Example: preparation and performance testing of new thermal insulation composite materials.

[0048] The artificial graphite purchased on the market is pretreated by conventional methods, and cut into 300mm × 240mm × 140mm block graphite preforms (density is 1.8g / cm 3 ; The average interplanar spacing d002 is 0.32nm; the pore diameter is 2μm; the porosity is 15%).

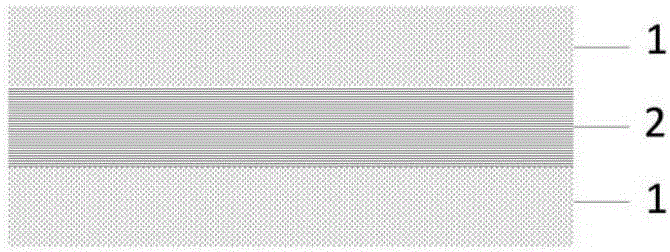

[0049] Cut the above-mentioned massive graphite preform into 240mm (long) * 140mm (wide) * 1.5mm (thick) graphite sheets (200 sheets) along the 300mm direction, buy 240mm (long) * 140mm (wide) * 0.38 from the market mm (thick) alumina ceramic sheets (100 pieces), and arrange them into a sandwich structure in the way of 2 layers of graphite sheets sandwiching 1 layer of alumina ceramic sheets, and use iron plates (thickness 0.2mm) to isolate multiple sandwich structures , after fixing the whole body with a metal frame (such as Figure 5 shown) placed in the mold.

[0050] Heat the metal aluminum in a cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com