Battery protection system and vehicle

A technology for protecting systems and batteries, applied to secondary batteries, battery pack components, and isolation of batteries from their environment. The probability of diffusion and the effect of accelerating cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

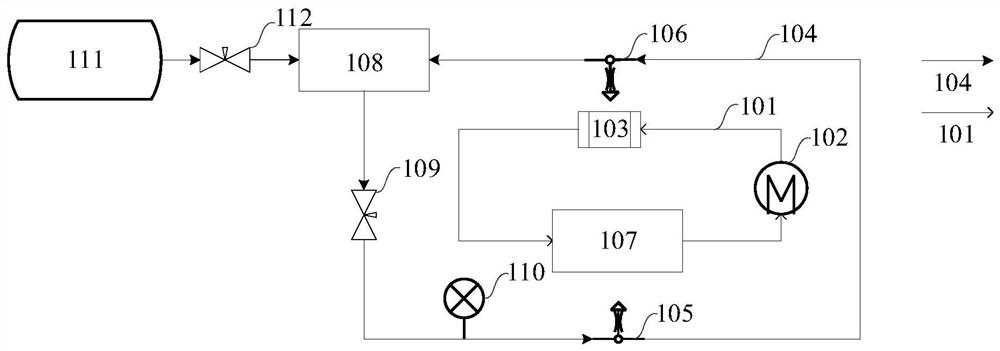

[0033] One of the core concepts of the embodiment of the present invention is to provide the battery assembly 107 with a first pipe 101 connected to it and loaded with cooling liquid, a fluid drive assembly 102 and a heat conduction assembly 103 arranged on the first pipe 101, and a second The pipeline 104, the first nozzle 105 and the second nozzle 106 arranged on the second pipeline 104; the second pipeline 104 is used to transfer the cold medium; the first nozzle 105 is arranged opposite to the battery assembly 107, The second spray head 106 is arranged opposite to the heat conduction assembly 103; when it is determined that the battery assembly 107 meets a preset thermal runaway condition, the first spray head 105 is used to sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com