Nanofiber-based biomedical non-woven fabric and preparation method thereof

A biomedical and nanofiber technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of poor protection treatment, hot and uncomfortable, difficult preparation, etc., to resist the invasion of microorganisms and pathogens, improve Effects of wearing comfort and improving spinning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

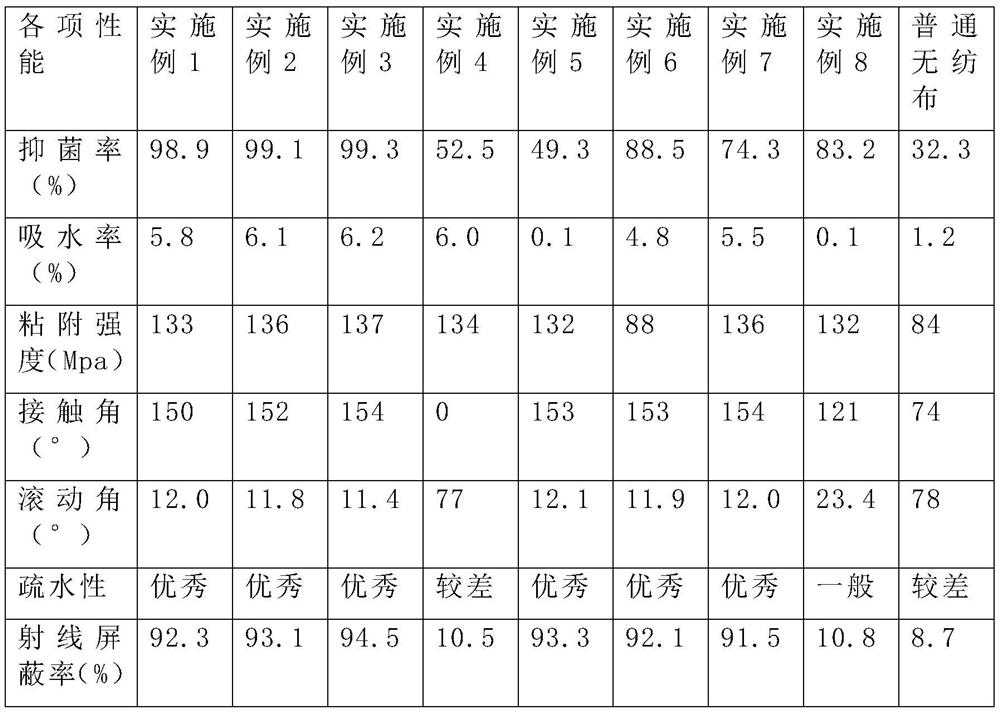

Examples

Embodiment 1

[0060] (1) Preparation of adhesive: Add carboxymethyl starch to deionized water and stir evenly, gelatinize at 50°C for 45 minutes, add acrylamide and stir, adjust the pH value to 7.8, add ammonium persulfate under nitrogen atmosphere and keep stirring for 3 hours , get adhesive;

[0061] (2) preparing the first non-woven fabric;

[0062] A. Preparation of antibacterial capsules:

[0063] a) Preparation of nanoparticles A: Mix zinc nitrate and seaweed dry powder evenly, add deionized water and stir to dissolve, raise the temperature to 75-85°C and continue stirring for 1.5h, cool to room temperature, add sodium hydroxide, stir evenly, and let stand After 10 h, the nanoparticle A was obtained by suction filtration and drying.

[0064] b) Prepare solution A: add polyvinyl alcohol to deionized water to dissolve, add nanoparticles A, and ultrasonically disperse for 1 hour to obtain solution A;

[0065] c) Place ethyl cellulose in dichloromethane and acetone and stir to dissolve...

Embodiment 2

[0086] (1) Preparation of adhesive: Add carboxymethyl starch in deionized water and stir evenly, gelatinize at 55°C for 50 minutes, add acrylamide and stir, adjust the pH value to 8.0, add ammonium persulfate under nitrogen atmosphere and keep stirring for 5 hours , get adhesive;

[0087] (2) preparing the first non-woven fabric;

[0088] A. Preparation of antibacterial capsules:

[0089] a) Preparation of nanoparticles A: Mix zinc nitrate and seaweed dry powder evenly, add deionized water and stir to dissolve, raise the temperature to 80°C and continue stirring for 2h, cool to room temperature, add sodium hydroxide, stir evenly, let stand for 13h, pump Nanoparticles A were obtained by filtration and drying.

[0090] b) Prepare solution A: add polyvinyl alcohol to deionized water to dissolve, add nanoparticles A, and ultrasonically disperse for 1.5 hours to obtain solution A;

[0091] c) Place ethyl cellulose in dichloromethane and acetone and stir to dissolve it, add it to...

Embodiment 3

[0112] (1) Preparation of adhesive: Add carboxymethyl starch in deionized water and stir evenly, gelatinize at 60°C for 65 minutes, add acrylamide and stir, adjust the pH value to 8.8, add ammonium persulfate under nitrogen atmosphere and keep stirring for 7 hours , get adhesive;

[0113] (2) preparing the first non-woven fabric;

[0114] A. Preparation of antibacterial capsules:

[0115] a) Preparation of nanoparticles A: Mix zinc nitrate and seaweed dry powder evenly, add deionized water and stir to dissolve, raise the temperature to 85°C and continue stirring for 3.5h, cool to room temperature, add sodium hydroxide, stir evenly, and let stand for 15h, Nanoparticles A were obtained by suction filtration and drying.

[0116] b) Prepare solution A: add polyvinyl alcohol to deionized water to dissolve, add nanoparticles A, and ultrasonically disperse for 2 hours to obtain solution A;

[0117] c) Dissolve ethyl cellulose in dichloromethane and acetone, stir and dissolve it, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com