Method for preparing high-hardness wear-resistant powder metallurgical rolling sleeve

A powder metallurgy and wear-resistant technology, which is applied in the field of shaft sleeves, can solve the problems of reducing the macroscopic hardness and strength of materials, and the performance of powder metallurgy roller sleeves or shaft sleeves is difficult to meet the requirements of compressor use, and achieves the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: The preparation method of the high-hardness and wear-resistant powder metallurgy roller sleeve in this embodiment is manufactured by powder metallurgy technology, and specifically includes the following steps in sequence:

[0031] ①Powder mixing, mixing iron powder, carbon powder, chromium powder or ferrochrome powder, and lubricant, and ensuring the percentage by weight of the total composition of iron, carbon, and chromium: carbon is 0.3-2%, and chromium is 0.5% ~ 4%, lubricant 0.1 ~ 2%, unavoidable impurities not exceeding 2%, the balance is iron;

[0032] ② Forming, the density after forming is greater than 6.8g / cm 3 ;

[0033] ③ Sintering at a temperature of 1000-1350°C, preferably 1150-1350°C, for at least 20 minutes;

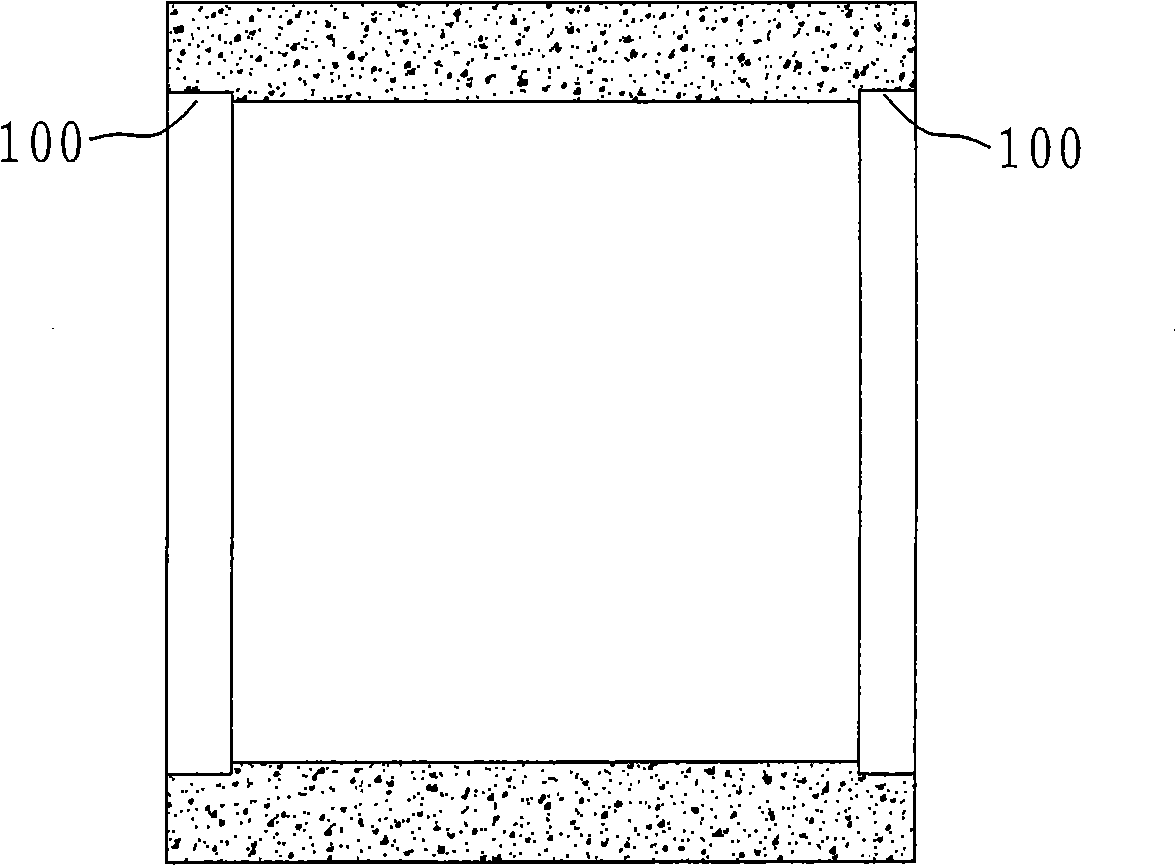

[0034] ④ Machining, for the part 100 that is difficult to form through the mold (such as figure 1 shown in ), such as mounting grooves, etc., are processed by machining, and machining can be turning, milling, grinding, drilling, bori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com