Ceramizable heat-preservation fireproof coating and preparation method thereof

A kind of technology of fireproof coating and ceramicization, which is applied in the field of heat preservation and fire prevention to achieve the effect of improving mechanical properties, good protection effect and excellent heat preservation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

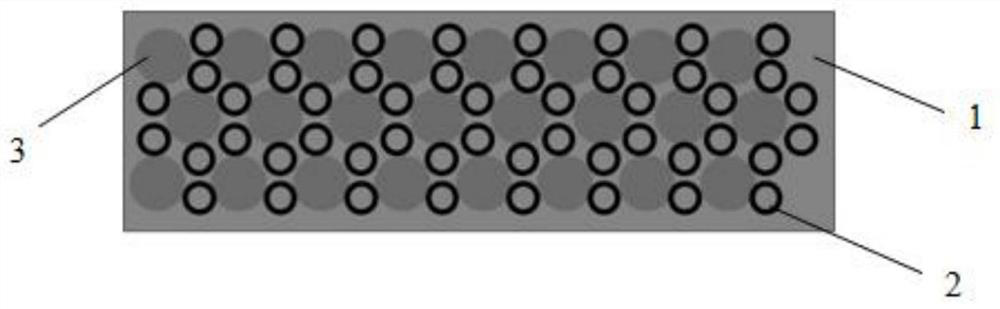

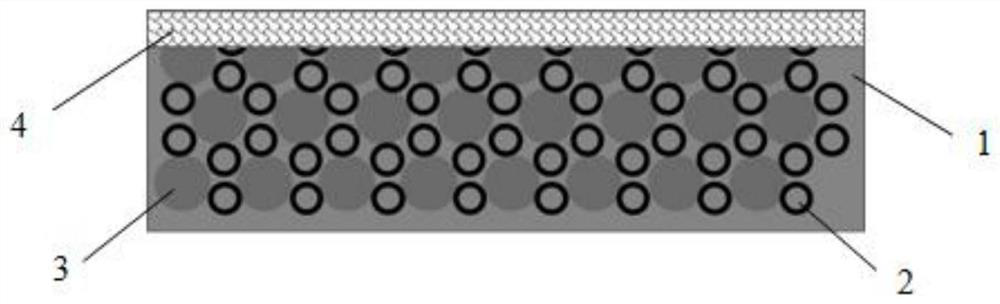

Method used

Image

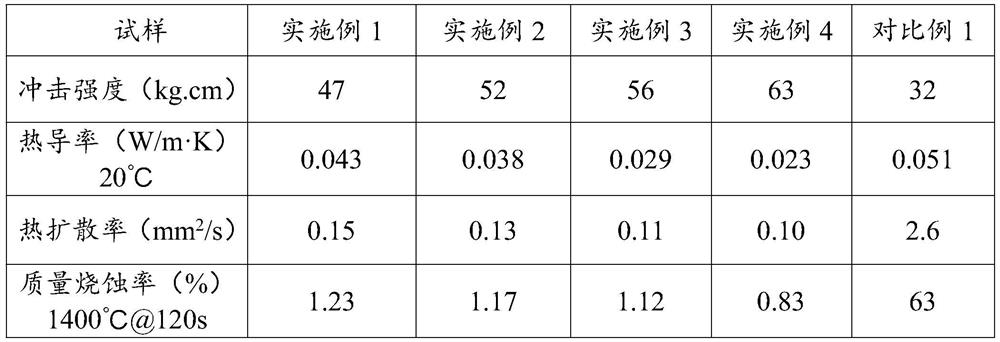

Examples

Embodiment 1

[0023] A ceramicized thermal insulation and fireproof coating, in parts by weight, its preparation raw materials include the following components: 15 parts of high temperature resistant silicone resin, 35 parts of thermal insulation fillers, 5 parts of other functional fillers, 2 parts of auxiliary agents, and 50 parts of dilution solvent .

[0024] Wherein, the high temperature resistant silicone resin is methyl silicone resin (SH9502); the insulating filler is hollow ceramic microspheres with a particle size of 5 μm; other functional fillers, in parts by weight, include: 5 parts of carbon black, 5 parts of white 5 parts of carbon black, 1 part of zinc oxide; the auxiliary agents, in parts by weight, include: 1 part of siloxane coupling agent KH5501, 1 part of dispersant, 1 part of defoamer; A mixture of toluene.

[0025] The preparation method of the ceramizable thermal insulation and fireproof coating comprises the following steps: (1) mixing and stirring the high temperat...

Embodiment 2

[0027] A ceramicized thermal insulation and fireproof coating, in parts by weight, its preparation raw materials include the following components: 25 parts of high temperature resistant silicone resin, 50 parts of thermal insulation fillers, 10 parts of other functional fillers, 4 parts of auxiliary agents, and 200 parts of dilution solvent .

[0028] Wherein, the high temperature resistant silicone resin is methyl phenyl silicone resin (Rhodia 6405); the insulating filler is hollow glass microbeads with a particle size of 50 μm; other functional fillers, in parts by weight, include: carbon 8 parts of black, 10 parts of white carbon black, 3 parts of zinc oxide, 5 parts of titanium oxide; the auxiliary agents, in parts by weight, include: siloxane coupling agent KH5502 parts, dispersant 1.5 parts, defoamer 1.5 parts parts; the diluting solvent is No. 120 mineral spirits.

[0029] The preparation method of the ceramizable thermal insulation and fireproof coating comprises the ...

Embodiment 3

[0031] A ceramicized thermal insulation and fireproof coating, in parts by weight, its preparation raw materials include the following components: 30 parts of high temperature resistant silicone resin, 75 parts of thermal insulation fillers, 15 parts of other functional fillers, 5 parts of auxiliary agents, and 500 parts of dilution solvent .

[0032] Wherein, the high temperature resistant silicone resin is methylphenyl silicone resin (SH9603); the insulating filler is hollow ceramic microspheres with a particle size of 100 μm; other functional fillers, by weight, include: 10 parts of carbon black , 15 parts of white carbon black, 5 parts of zinc oxide, and 10 parts of titanium oxide; the additives, in parts by weight, include: siloxane coupling agent KH5503 parts, dispersant 2 parts, defoamer 2 parts; The diluting solvent is banana water.

[0033] The preparation method of the ceramizable thermal insulation and fireproof coating comprises the following steps: (1) mixing and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com