Patents

Literature

203 results about "Iron(II) sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) sulfide or ferrous sulfide (Br.E. sulphide) is one of a family chemical compounds and minerals with the approximate formula FeS. Iron sulfides are often iron-deficient non-stoichiometric. All are black, water-insoluble solids.

Preparation method and applications of ferrous sulfide/biological carbon composite material

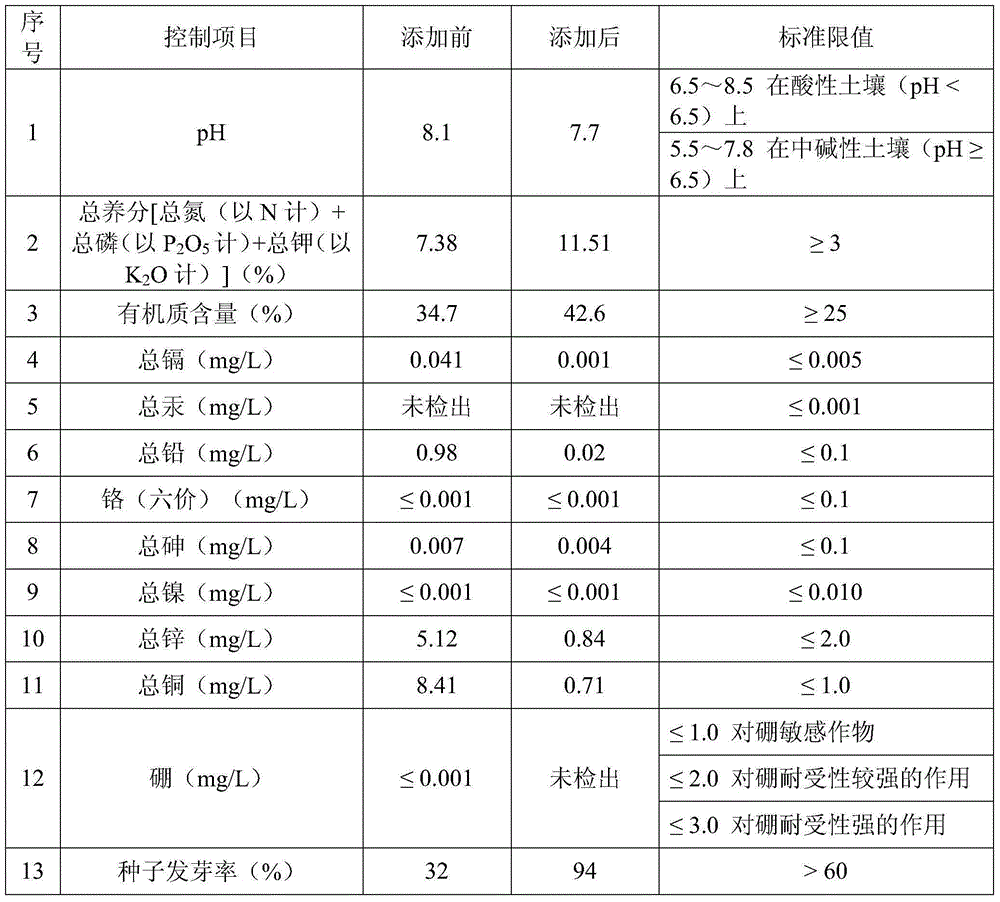

ActiveCN106966456ALow biological toxicityEfficient removal abilityWater contaminantsWater/sewage treatment by sorptionCarboxymethyl celluloseSulfate

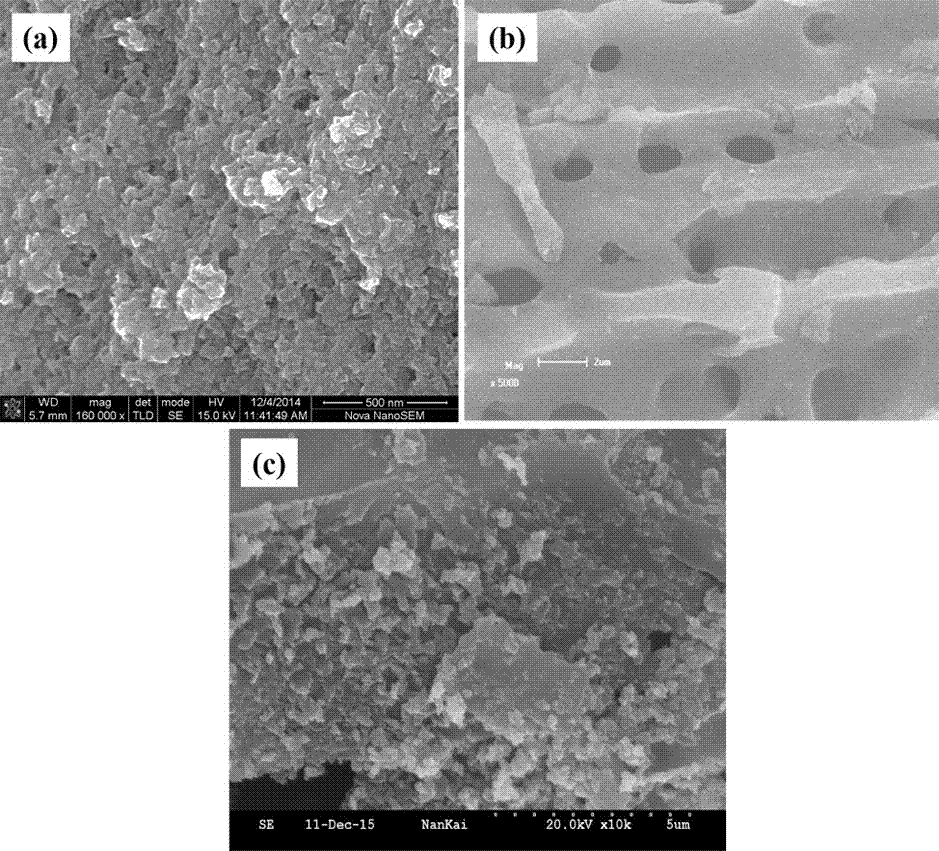

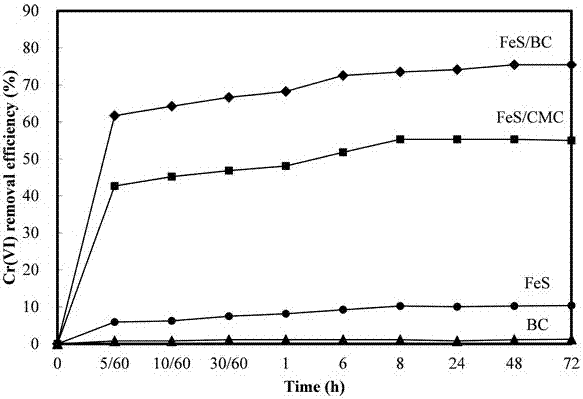

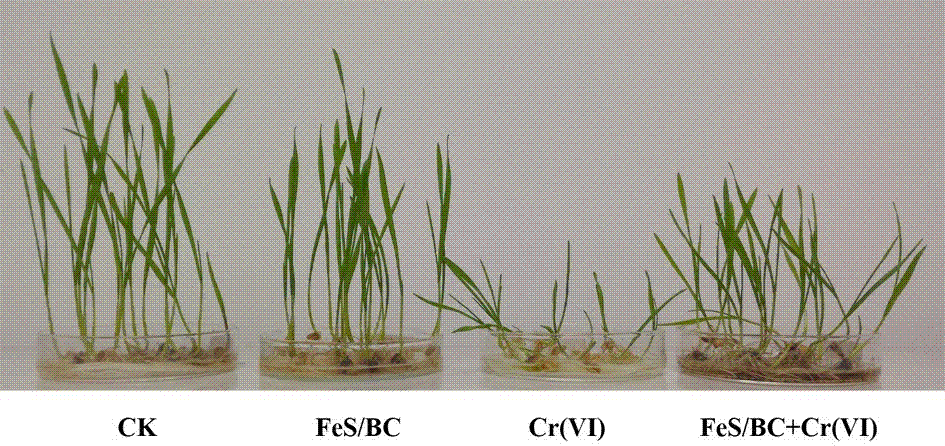

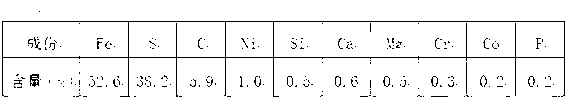

The present invention discloses an efficient ferrous sulfide / biological carbon composite material and a preparation method thereof, and applications of the ferrous sulfide / biological carbon composite material in repair of heavy metal pollution water bodies. According to the present invention, biological carbon is adopted as a carrier, a ferrous sulfate solution and the biological carbon are mixed, sodium carboxymethyl cellulose is added as a stabilizer and a dispersant, a sodium sulfide solution is added to the system in a dropwise manner under the nitrogen protection, and vigorous stirring is performed to make the generated ferrous sulfide nanoparticles uniformly grow on the surface of the biological carbon, such that the disadvantage that the ferrous sulfide nanoparticles are easily agglomerated is substantially improved so as to increase the effective contact area between the ferrous sulfide nanoparticles and the pollutant, and the adsorption ability and the oxidation reduction ability of the ferrous sulfide and the biological carbon are integrally combined so as to improve the pollutant removal ability; the preparation method has advantages of simple and rapid process, low production cost, environmental protection and no secondary pollution; and the efficient ferrous sulfide / biological carbon composite material can strongly repair the Cr(VI) polluted water body, can effectively reduce the biological toxicity of the Cr(VI) on wheat seeds, and has wide application prospects in the fields of repair of organic pollution and inorganic pollution in environments.

Owner:NANKAI UNIV

Method for synchronously removing nitrogen and phosphorus in sewage containing nitrogen and phosphorus

InactiveCN102603064AAchieving natural fusionWide variety of sourcesTreatment with anaerobic digestion processesActivated sludgeThiobacillus

The invention discloses a method for synchronously removing nitrogen and phosphorus in sewage containing nitrogen and phosphorus, belonging to the field of sewage treatment. The method comprises the steps of (1) screening thiobacillus denitrificans: screening thiobacillus denitrificans from anaerobic activated sludge and taking as target strain, wherein thiobacillus denitrificans utilizes sulphur source in ferrous sulfide to conduct autotrophic denitrification; (2) preparing fillers of a reactor: directly adding ferrous sulfide with the particle size smaller than 25mm in a reaction container; (3) adding sewage: feeding sewage to be treated into the reaction container, wherein the sewage to be treated is the sewage containing nitrogen and phosphorus with the pH value of 5.0-9.0; (4) conducting the autotrophic denitrification process: conducting the mixed reaction for 2 to 6d at the temperature of 10 DEG C-40 DEG C under the anaerobic condition in the reaction container, reducing NO2<-> and NO3<-> in water to be N2 by thiobacillus denitrificans while simultaneously oxidizing ferrous sulfide by thiobacillus denitrificans, and simultaneously, precipitating phosphorus in water by utilizing iron ions (being oxidation products); and (5) separating solid and liquid. According to the method, the technology for removing nitrogen by utilizing thiobacillus denitrificans and the technology for removing phosphorus by using iron ions are fused naturally, the reaction cost is low, and the processing effect is good.

Owner:NANJING UNIV

Ferrous sulfide dirt neutral complexing cleaning agent and preparation method thereof

ActiveCN103194325ATo achieve the purpose of safe productionImprove anti-corrosion performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsChemical industrySodium acetate

The invention relates to an equipment cleaning agent which is used in the field of petroleum and chemical industry, in particular to a ferrous sulfide dirt neutral complexing cleaning agent which is used for washing a synthesized ammonia low-temperature methanol washing unit system in the petroleum chemical industry and the coal chemical industry. The ferrous sulfide dirt neutral complexing cleaning agent is prepared from the following raw materials in parts by weight: 5 to 8 parts of sodium gluconate, 7 to 11 parts of sodium salicylate, 20 to 26 parts of gadoliniam diethylene triamine pentaacetic acid, 20 to 26 parts of sodium ethylene diamine tetracetate, 40 to 46 parts of propenoic acid-itaconic acid copolymer, 25 to 32 parts of disodium polyepoxysuccinicate, 12 to 15 parts of sodium hydroxyphenylace, 3 to 7 parts of triethanolamine, 3 to 7 parts of hydrogen peroxide, 0.1 to 0.3 part of lauryl sodium sulfate, 0.1 to 0.3 part of polydimethyl siloxane fluid and 40 to 45 parts of water. The ferrous sulfide dirt neutral complexing cleaning agent is free from generating hydrogen sulfide when cleaning the ferrous sulfide dirt and corroding the equipment and has strong capacity for complexing the iron ions, the removal speed is fast, the decontamination rate is more than 98 percent, the neutralization and passivation are unnecessary to carry out after the chemical washing, and the equipment can be put into operation immediately.

Owner:GANSU HEIMA PETROCHEM ENG

Preparation method for battery grade ferrous sulfate heptahydrate crystal

The preparation method for battery grade ferrous sulfate heptahydrate crystal of the present invention includes using ferrous sulphate which is the by-product in the titanium dioxide production as raw material, using the operation of purification, filtration, crystallization and dryness, and preparing ferrous sulfate heptahydrate by using the difference of the solubility of ferrous sulphate changing with the temperature. The operation of purification includes performing reduction of ferric iron in ferrous sulphate which is the by-product in the titanium dioxide production to ferrous iron by using a reducing agent, adding ferrous sulfide to remove the heavy metal ions such as cobalt, nickel, zinc, copper, plumbum and cadmium, and using fluoride to remove calcium and magnesium ions. The preparation method uses vacuum drying and packaging, and the main content of ferrous sulfate heptahydrate in the dried material is more than 99.7%. The preparation method has simple technology and low cost, can recycle fluorinion by precipitation conversion, and can reduce the discharge of hazardous waste. Moreover, the prepared product has high purity, low impurity and ferric iron contents, and can be long-term storage. The recovery rate of ferrous sulphate is greatly improved.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Iron-based sulfide electrode material, preparation method and application in solid state battery

ActiveCN106784815AImprove electrochemical performanceIncrease energy densityMaterial nanotechnologyCell electrodesIron(II,III) sulfideSolid-state battery

The invention provides an iron-based sulfide electrode material, a preparation method and application in a solid state battery, and belongs to the technical field of secondary lithium batteries. The iron-based sulfide electrode material which is based on conversion reaction is selected from one or more of ferrous sulfide, ferriferous sulfide and hepta-ferous octa-sulfide. The preparation method of the iron-based sulfide electrode material has the advantages of being simple and short in time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

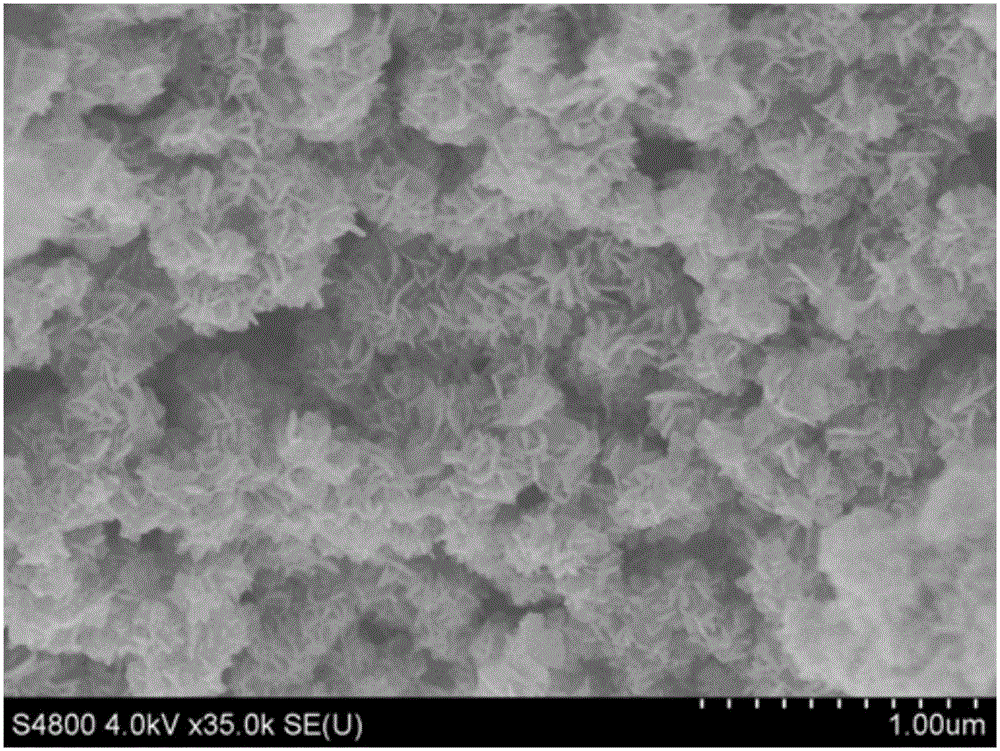

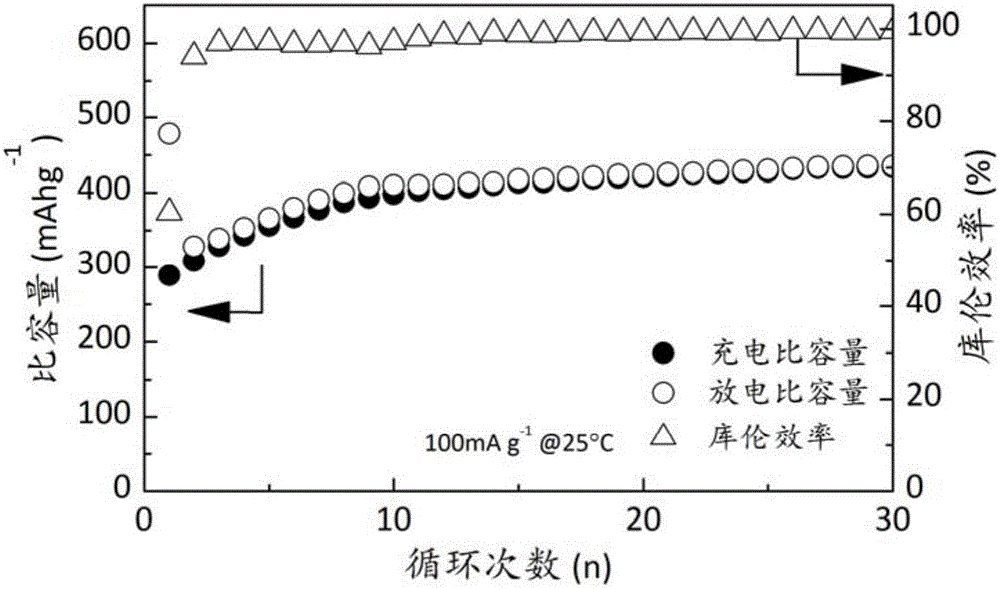

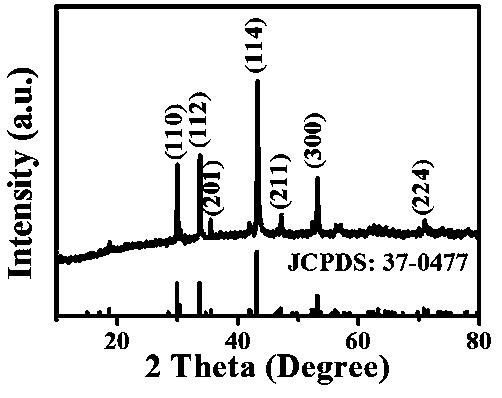

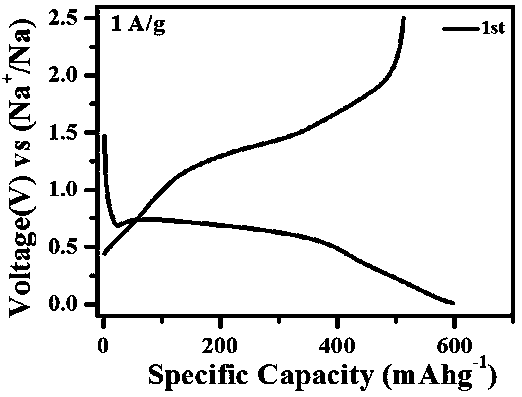

Carbon-coated ferrous sulfide negative electrode material, preparation method and sodium ion battery prepared by the same

ActiveCN109167035AEasy to makeAbundant raw materialsCell electrodesSecondary cellsCarbon coatingElectrical battery

The invention relates to a carbon-coated ferrous sulfide negative electrode material, the preparation method and the prepared sodium ion battery thereof, Carbon-coated ferrous sulfide anode material refers to carbon-coated ferrous sulfide and its doped modified material, wherein the particle size of the ferrous sulfide is 100-500 nm, the mass of the carbon coating layer is 3-30% of the mass of theelectrode material, the doping modification elements are one or several of M=Co, Ni, Mn, Ti, Cu, Mg, Ba, Pb, Al, etc., and the mass of the doping modification elements is 0-30% of the mass of the negative electrode material. A metal sulfate and a carbon source are added into deionized water, stirred and dissolved uniformly at room temperature, freeze-dried to obtain a precursor, and calcined at high temperature in an inert atmosphere to obtain a carbon-coated ferrous sulfide negative electrode material. As that negative electrode material of the sodium ion battery, the invention has the advantage of abundant raw materials, simple preparation, short preparation period, low cost, no pollution, good rate performance and strong cycle stability, and is suitable for large-scale production.

Owner:ZHENGZHOU UNIV

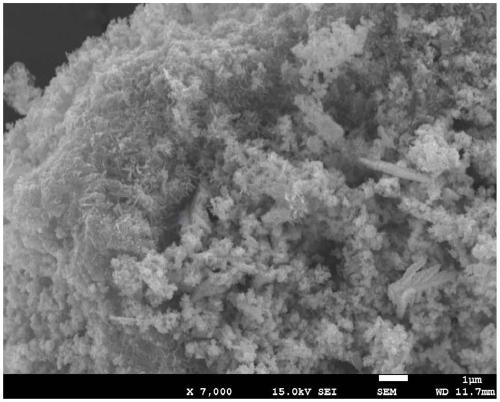

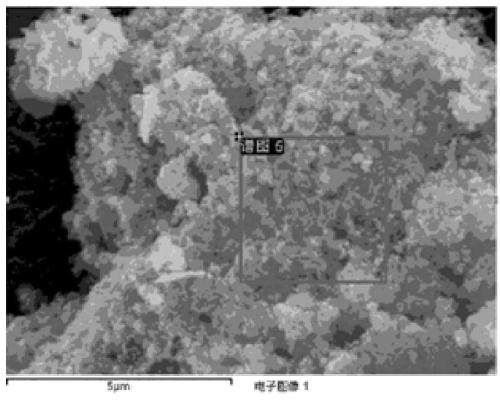

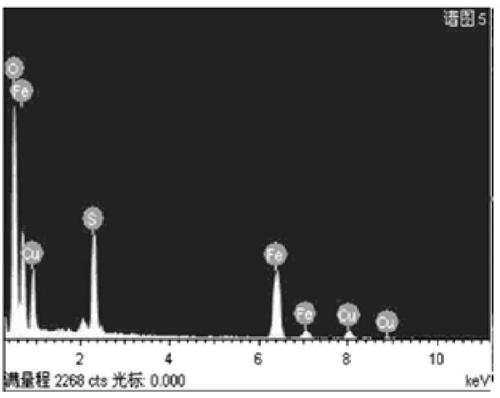

Iron and copper ferrous sulfide loading composite material, preparation method and application thereof

ActiveCN111266572ASlow down the problem of passivation too fastWater Corrosion MitigationWater contaminantsWater/sewage treatmentCu2 ionsIron powder

The invention relates to an iron and copper ferrous sulfide loading composite material, a preparation method and application thereof. The composite material comprises iron and copper and ferrous sulfide loaded to the surfaces of the iron and copper. Copper in the iron and copper is loaded to the surface of iron. The composite material is relatively high in activity and reaction selectivity, and can be used in the fields of chromium containing sewage treatment, chromium polluted underground water repair and the like. The preparation method comprises the following steps of mixing a copper salt solution with iron powder primarily; and then mixing the mixed solution with an alkali metal vulcanized salt solution secondarily to obtain the iron and copper ferrous sulfide loading composite material. The preparation method recovers Fe2<+> generated in a replacement process of copper ions and iron powder and has the advantages of being simple in step and economical and effect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Magnesium based ferrous sulfide composite nanomaterial as well as preparation method and application thereof

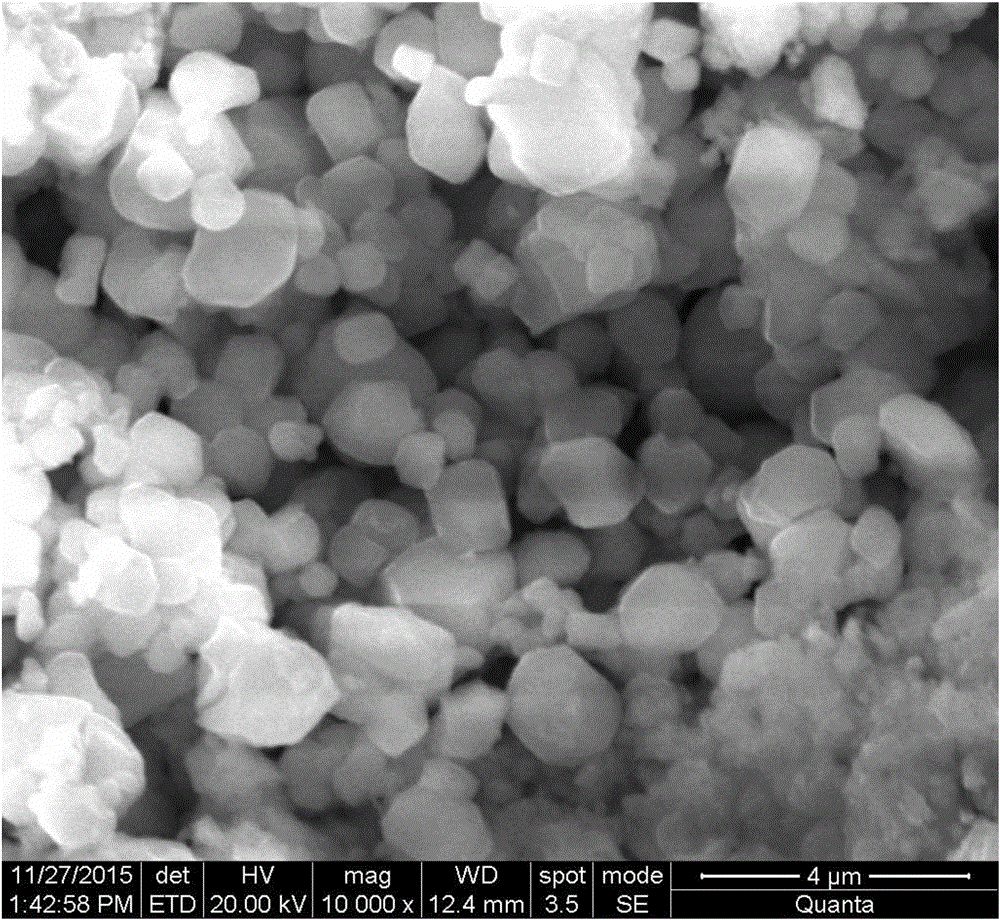

InactiveCN108620047ANo agglomerationHigh reactivityOther chemical processesWater contaminantsPhysical chemistryFerrous

The invention belongs to the field of composite materials and discloses a magnesium based ferrous sulfide composite nanomaterial as well as a preparation method and application thereof. The preparation method comprises the steps: evenly dispersing magnesium based material powder into water to obtain a magnesium based material suspension, wherein a magnesium based material is at least one of magnesium oxide and magnesium hydroxide; then adding a ferrite water solution into the magnesium based material suspension, evenly mixing, dropwise adding a sodium sulfide water solution, reacting to obtainferrous sulfide and standing to obtain the magnesium based ferrous sulfide composite nanomaterial after reaction finishes. According to the preparation method disclosed by the invention, a nano ferrous sulfide material is loaded to the surface of the magnesium based material, and agglomeration of ferrous sulfide particles is inhibited to ensure reaction activity of the ferrous sulfide particles;the active surface of the magnesium based material can efficiently adsorb heavy metal, so that a utilization rate of the ferrous sulfide nanomaterial is improved; meanwhile, a weak-basicity material prepared from the magnesium based material is favorable for stable existence of the nano ferrous sulfide material, so that the composition material is not prone to metamorphosing and is easy to store.

Owner:SOUTH CHINA UNIV OF TECH

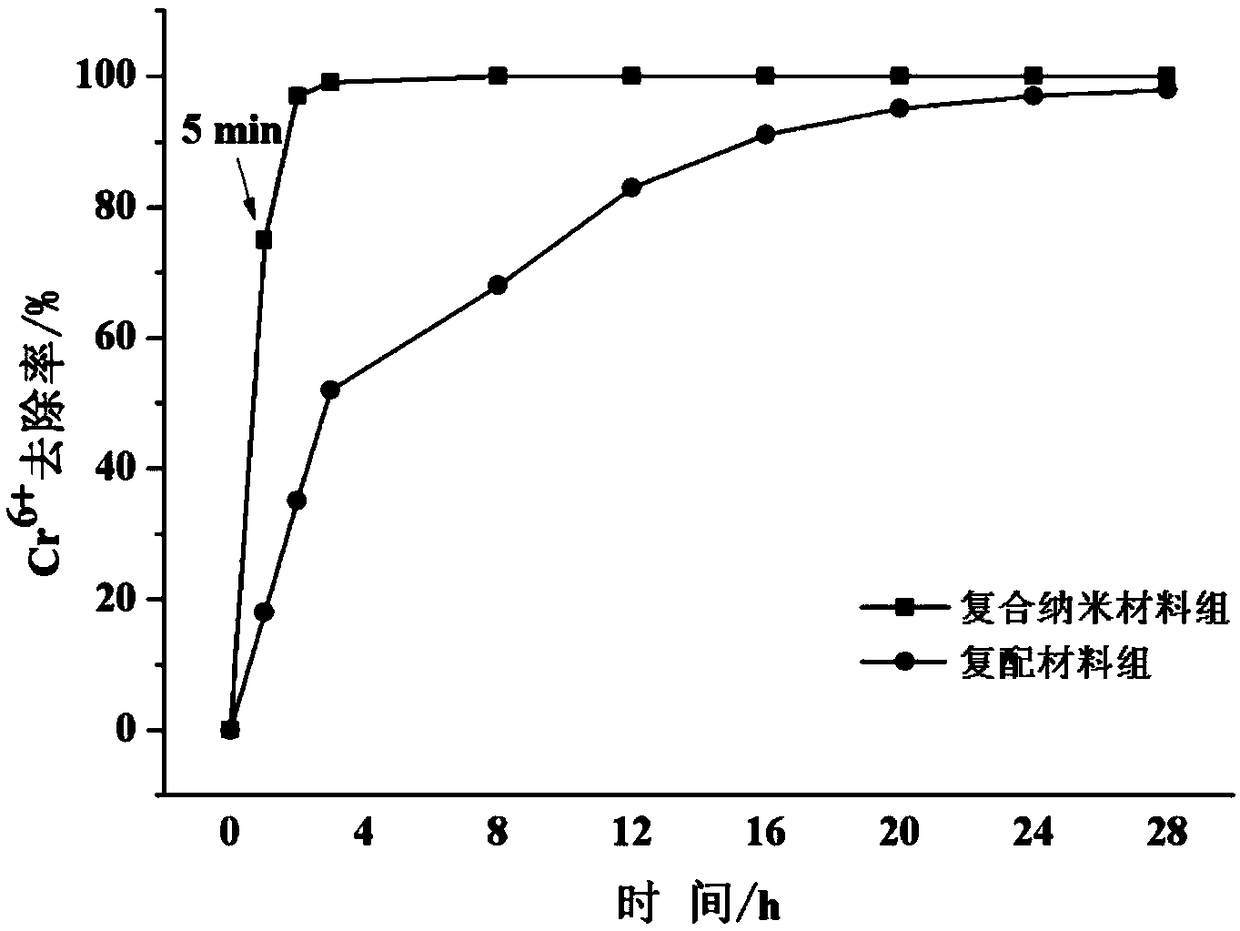

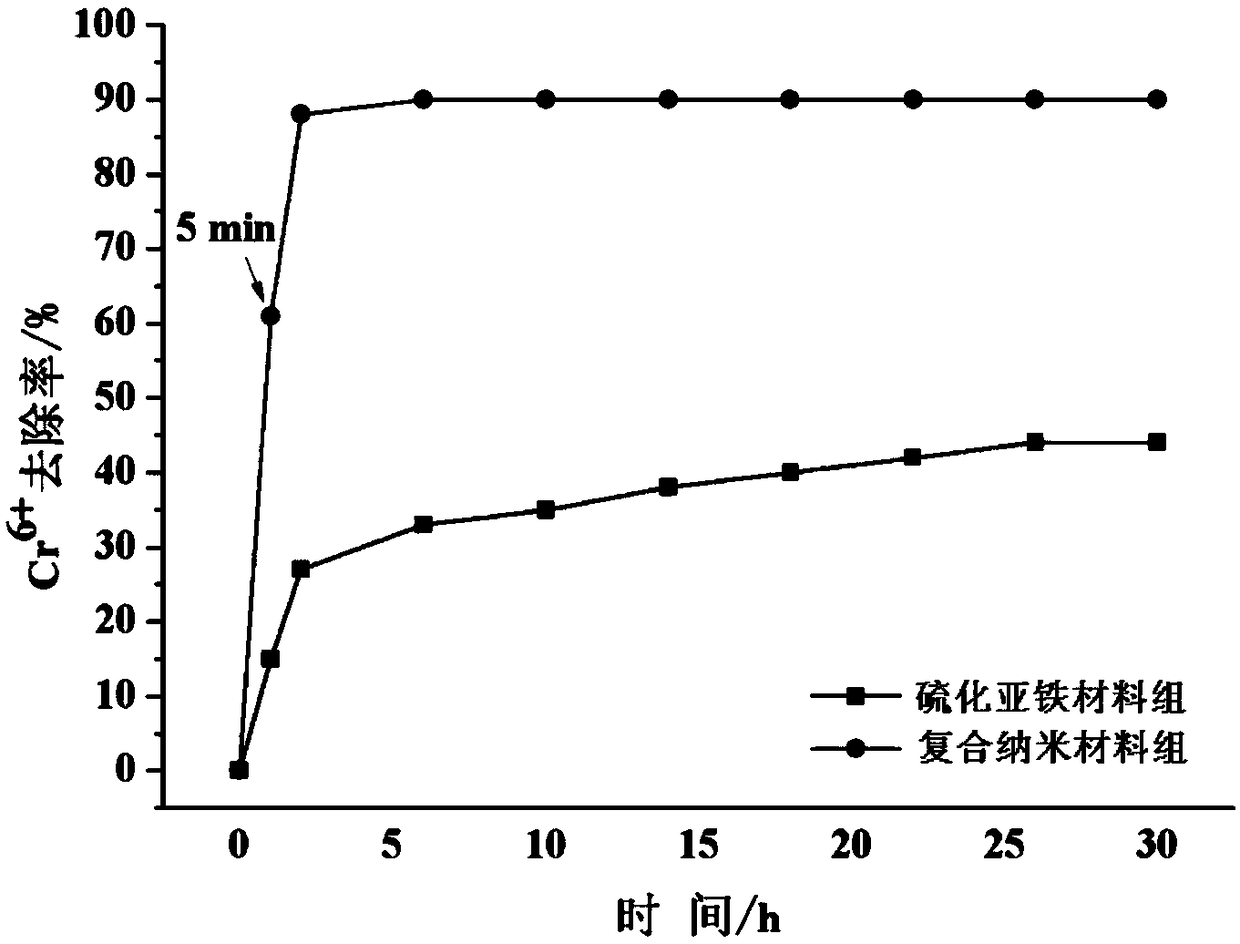

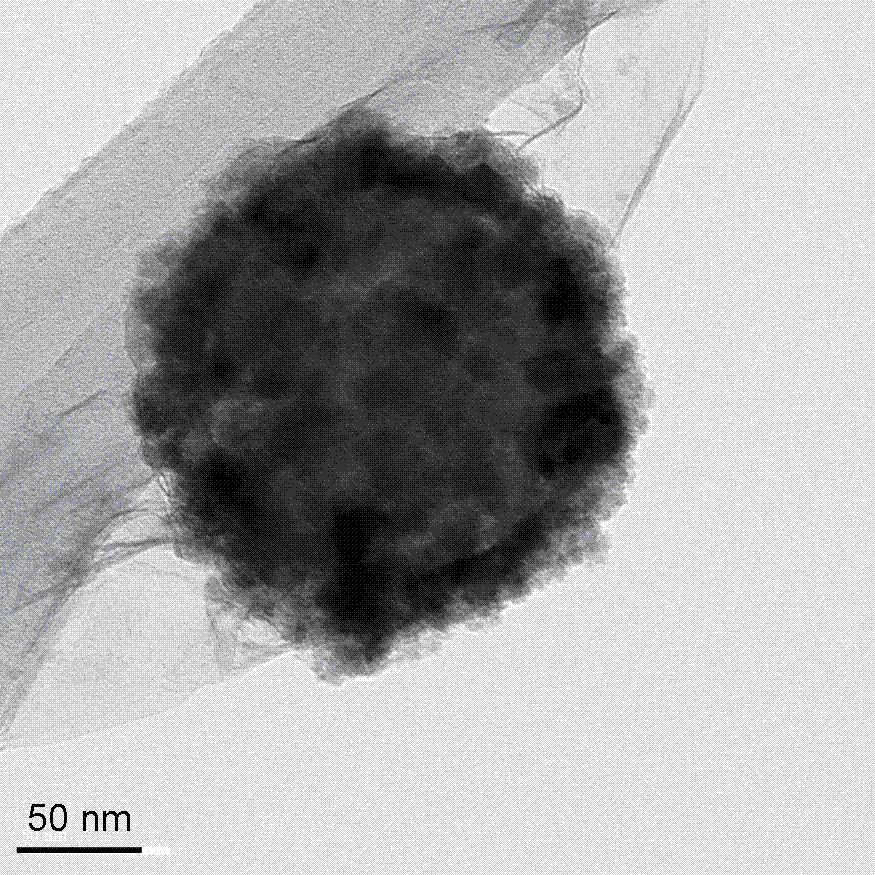

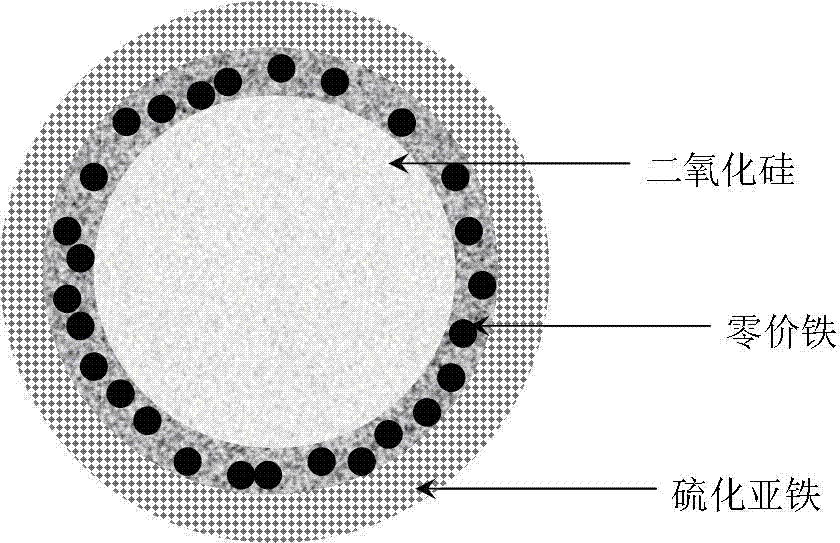

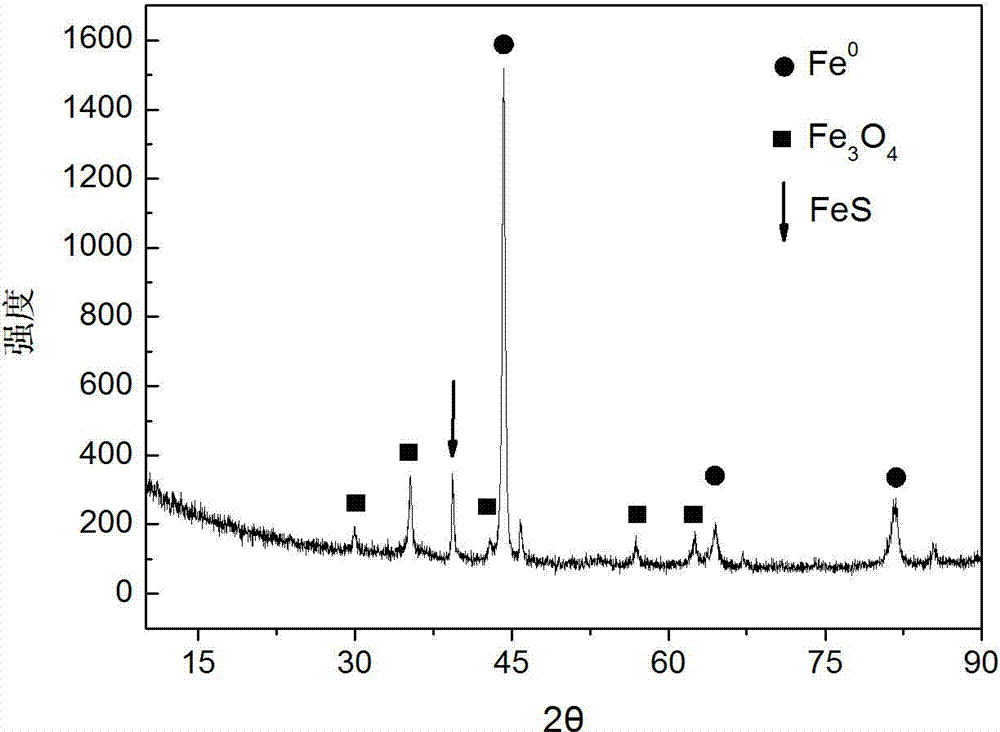

Preparation method and application of nano-silica introduced magnetic vulcanized nanometer zero-valent iron

InactiveCN104492461AEasy to storeGood removal effectPhysical/chemical process catalystsWater contaminantsPeristaltic pumpEngineering

The invention relates to a preparation method of nano-silica introduced magnetic vulcanized nanometer zero-valent iron. The preparation method comprises the concrete steps: (1) adding sodium borohydride and sodium persulfate into water to form a mixed solution; (2) adding nano-silica into a solution containing sodium borohydride and sodium persulfate and continuously stirring; (3) slowly dropwise adding a suspension formed in the second step under the stirring condition into a ferric salt solution by virtue of a peristaltic pump; and (4) after reaction is finished, carrying out solid-liquid separation by utilizing a magnet, respectively cleaning twice by adopting deionized water and anhydrous alcohol, and finally directly storing into a deionized water-alcohol solution, or vacuum drying and then storing in an anaerobic glove box. The invention also discloses environment repairing application of the nano-silica introduced magnetic vulcanized nanometer zero-valent iron. The preparation method is convenient and rapid and is low in cost and technical requirements; the material synthesized by the preparation method has the characteristics of both nanometer zero-valent iron and nanometer ferrous sulfide, is capable of solving the problems that the synthesized material is nonmagnetic, easily oxidized and difficultly applied in the absence of nano-silica, is excellent in inorganic and organic pollutant removing performances and has wide application prospect.

Owner:TONGJI UNIV

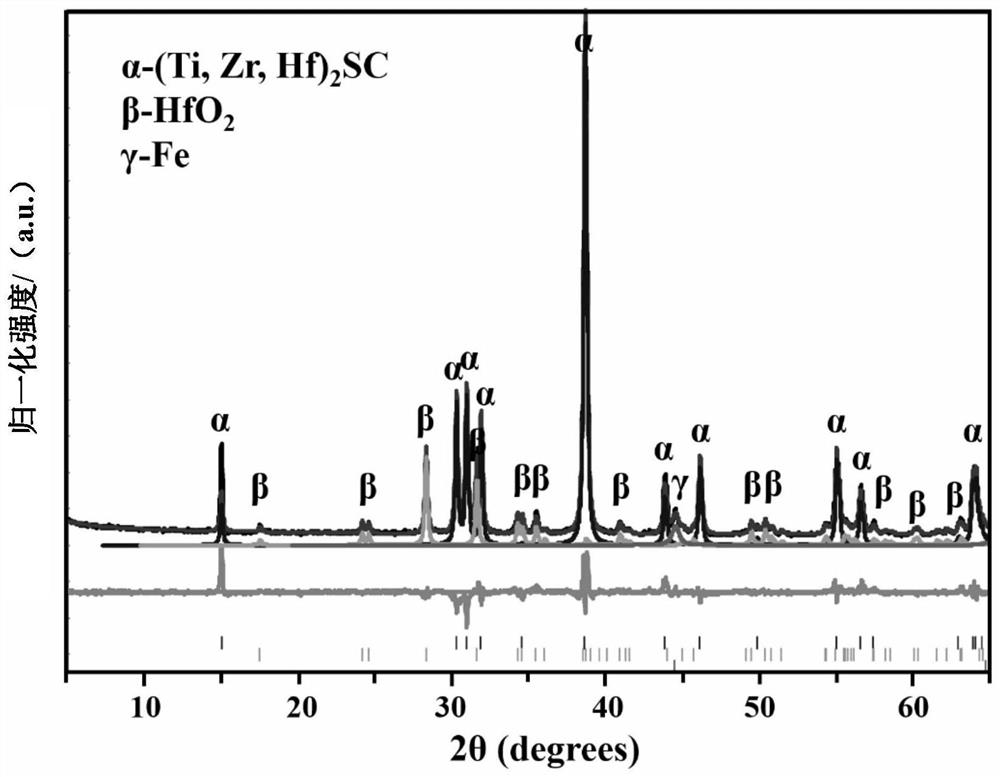

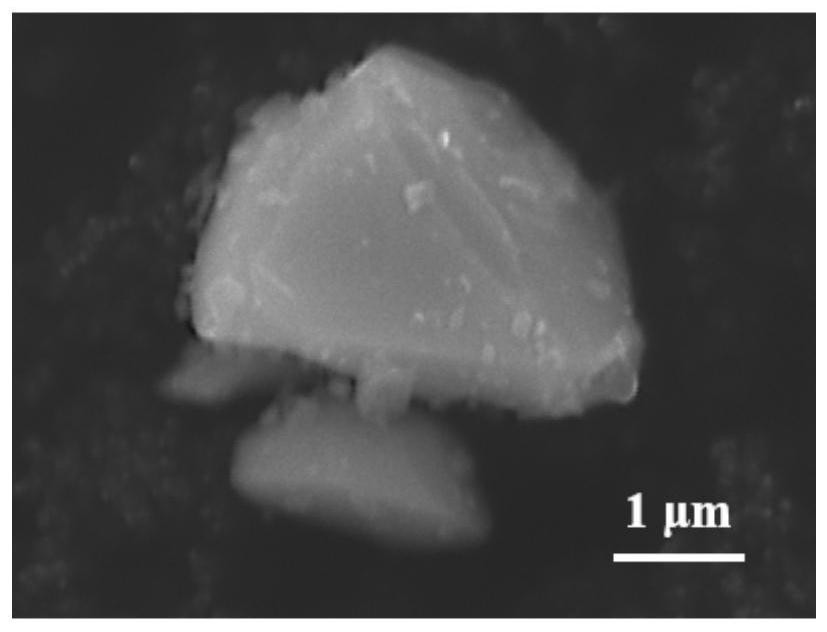

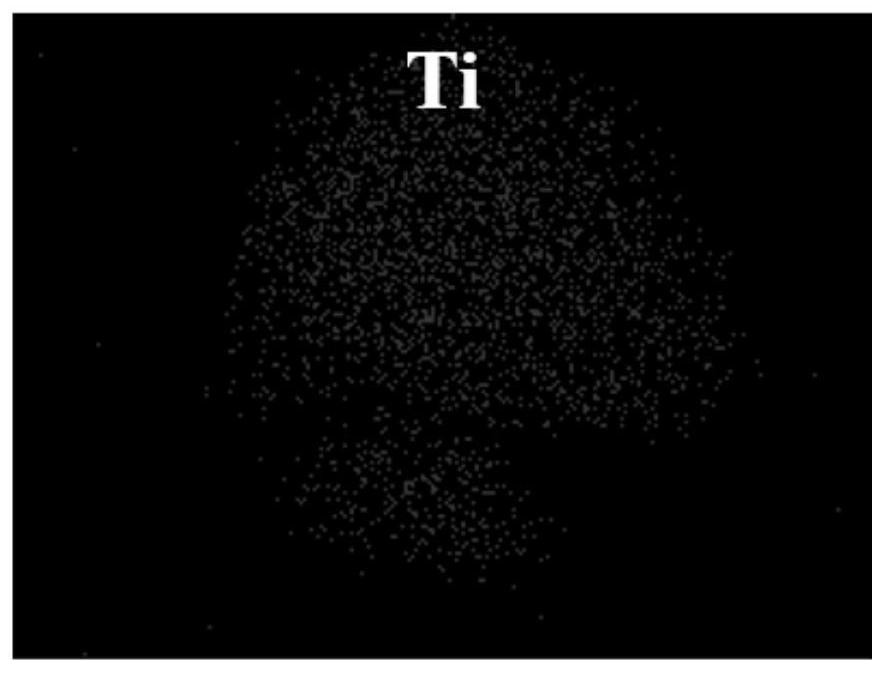

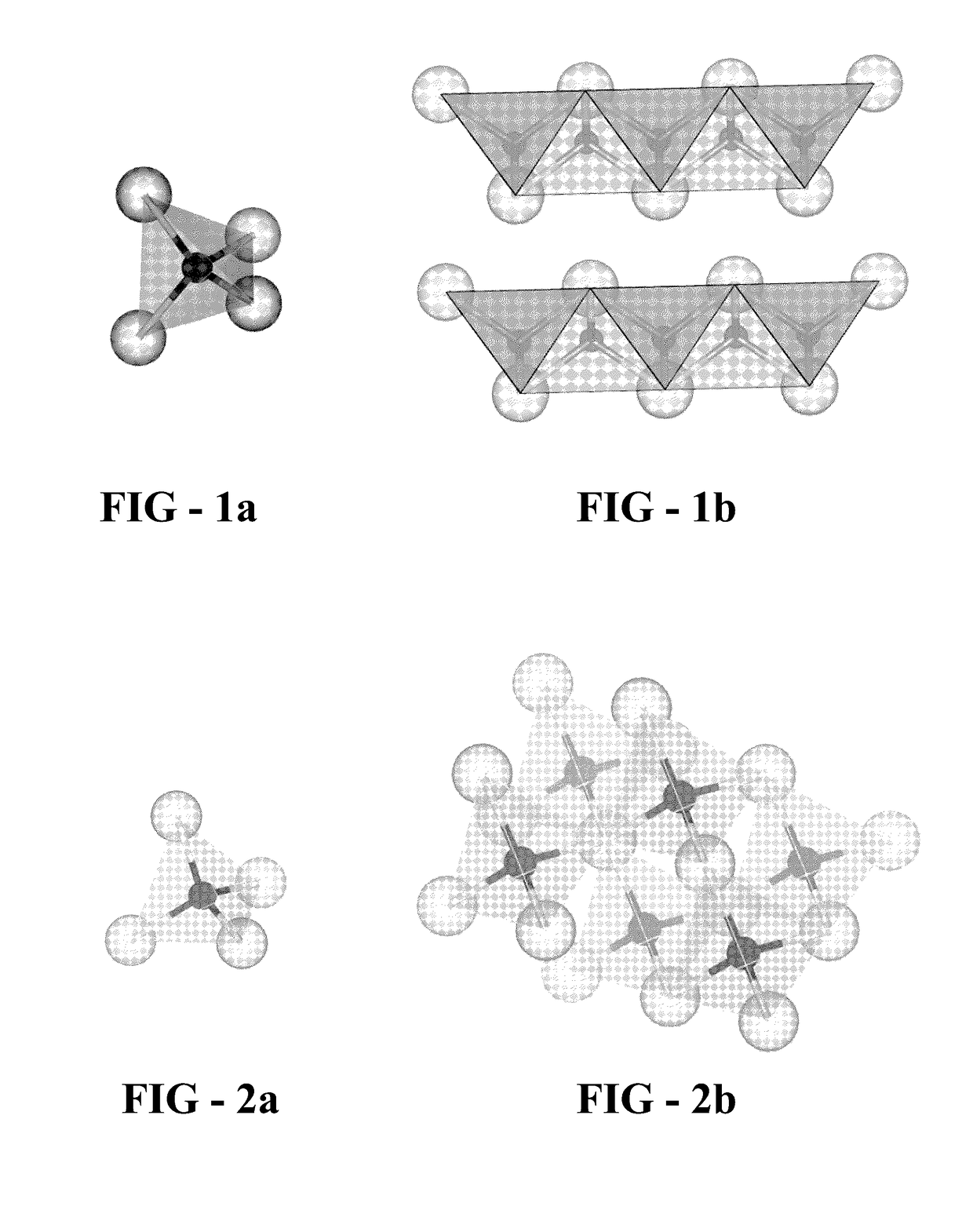

Sulfur-series medium-high entropy MAX phase solid solution material as well as preparation method and application of same

InactiveCN112094121AHigh purityFavorable control of synthetic pathwaysNuclear powerPhysical chemistry

The invention discloses a sulfur-series medium-high entropy MAX phase solid solution material as well as a preparation method and application of the same, wherein the M position of the sulfur-series medium-high entropy MAX phase solid solution material comprises any three or a combination of more than four of transition metal elements Ti, Zr, Hf, V, Nb and Ta, the A position is a sulfur element, and the X position is a carbon element. The preparation method comprises the steps that ferrous sulfide serves as a high-temperature solid sulfur source, transition metal sulfide is obtained through areplacement reaction between transition metal simple substances and the ferrous sulfide, then the transition metal sulfide reacts with metal carbide, and the sulfur-series medium-high entropy MAX phase solid solution material is obtained. The ferrous sulfide sulfur source and the sulfur-containing intermediate product adopted by the invention are both stable metal sulfides, so that volatilizationof elemental sulfur in the high-temperature preparation process is avoided, and the synthesis path of a target phase is favorably controlled. The sulfur-series medium-high entropy MAX phase solid solution material is expected to have a good application prospect in the field of extreme environment structural materials such as nuclear power and high-speed rails.

Owner:宁波材料所杭州湾研究院 +1

Method for treating soil and groundwater containing heavy metals including nickel

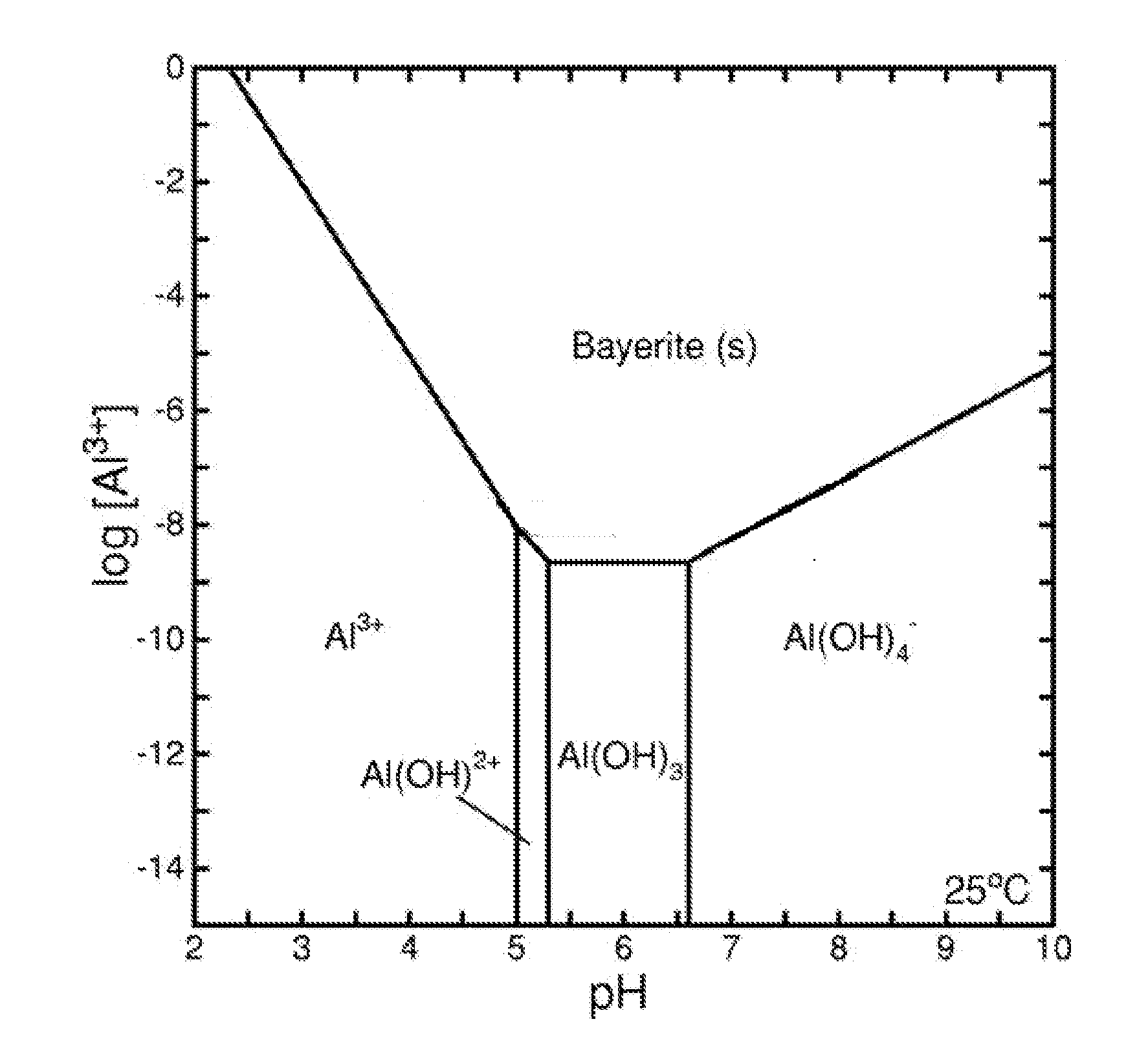

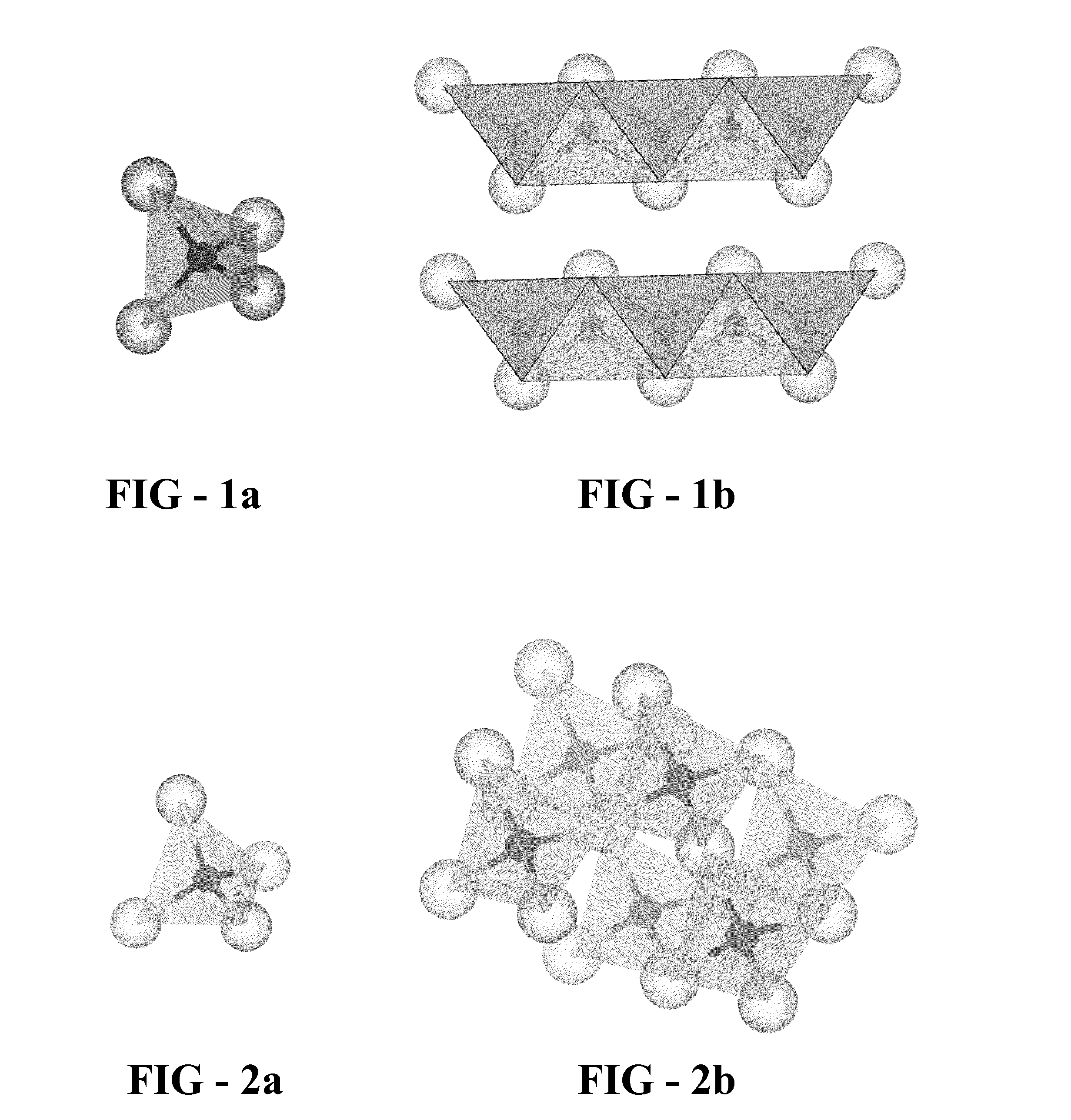

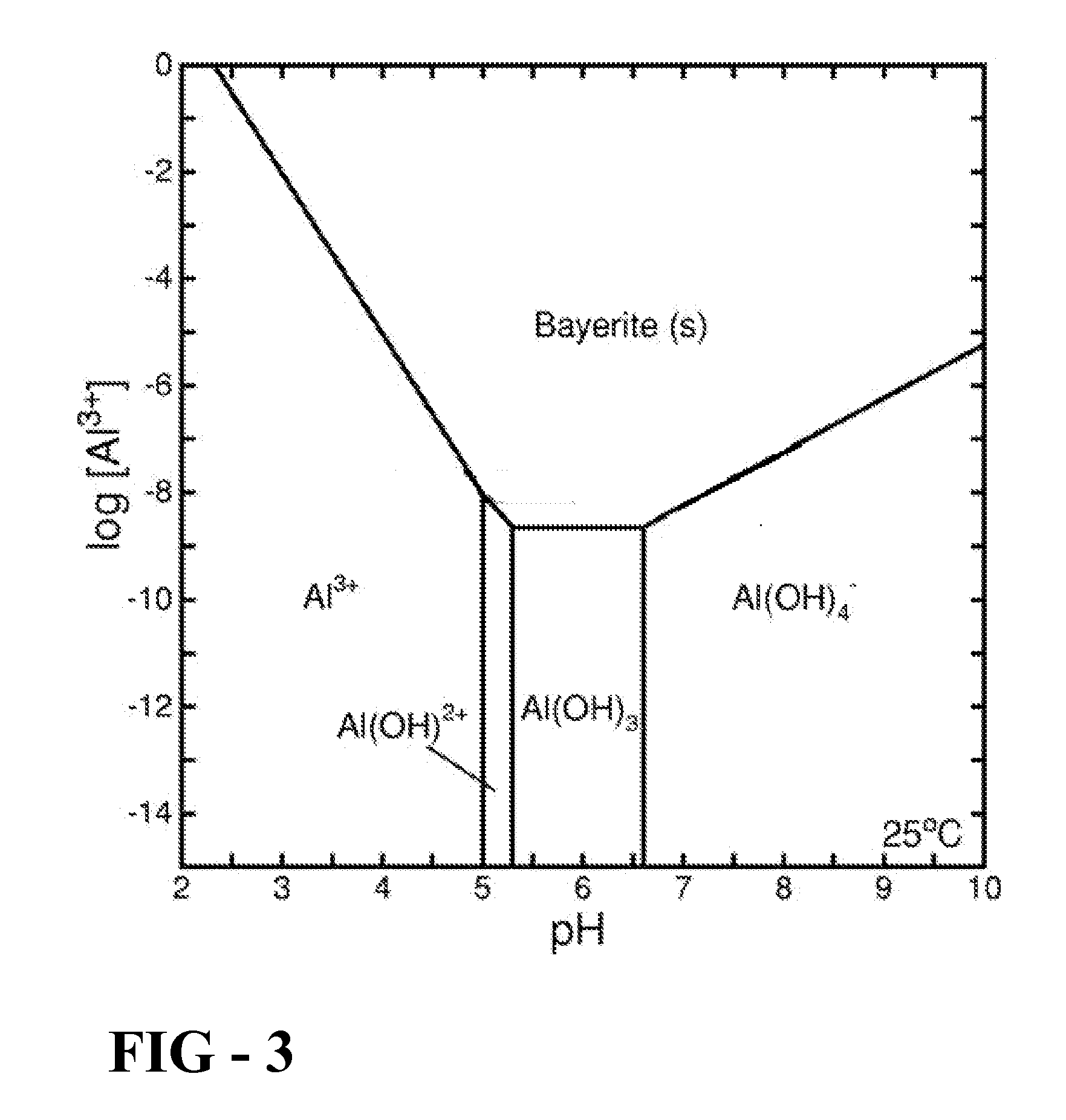

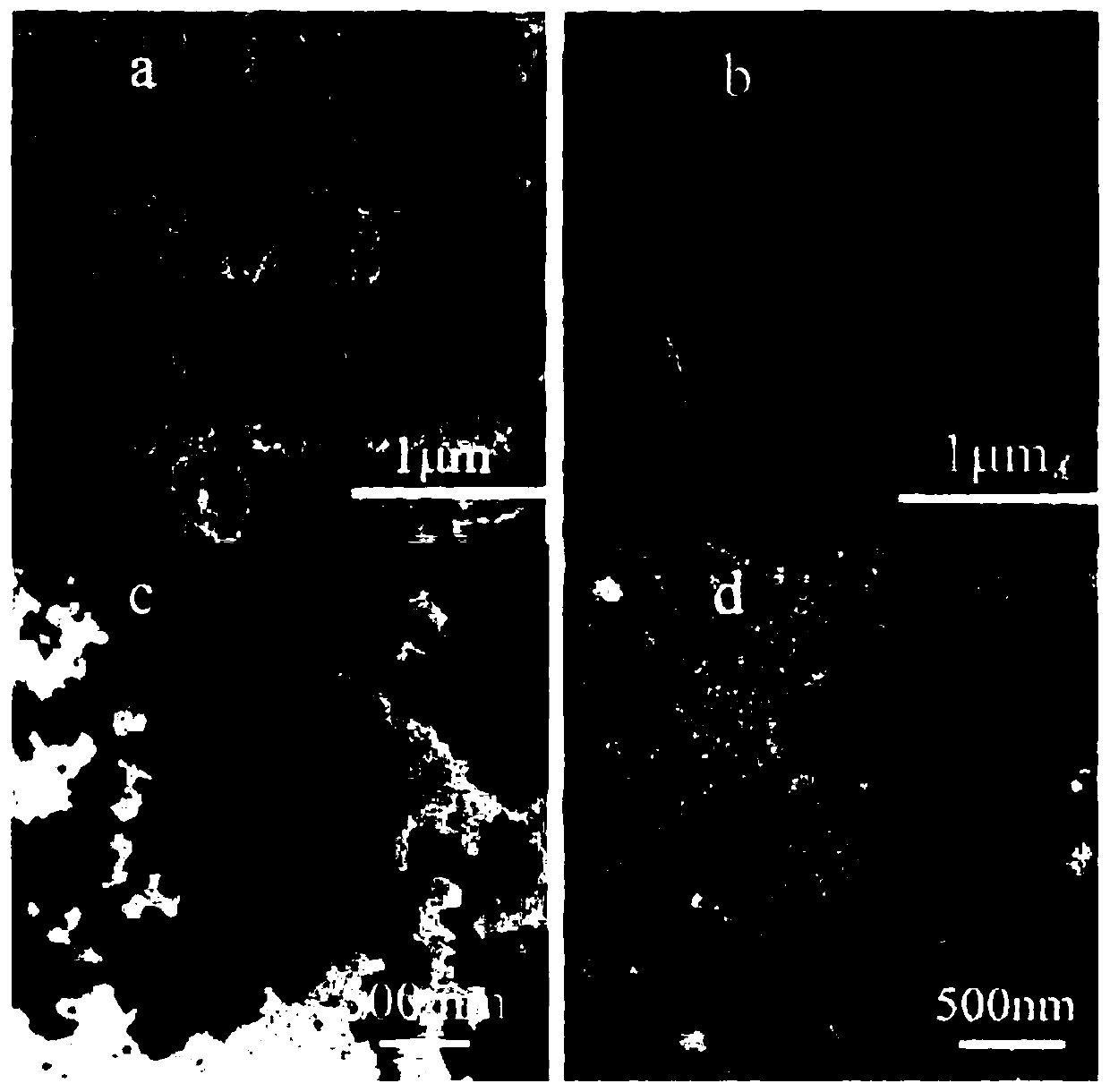

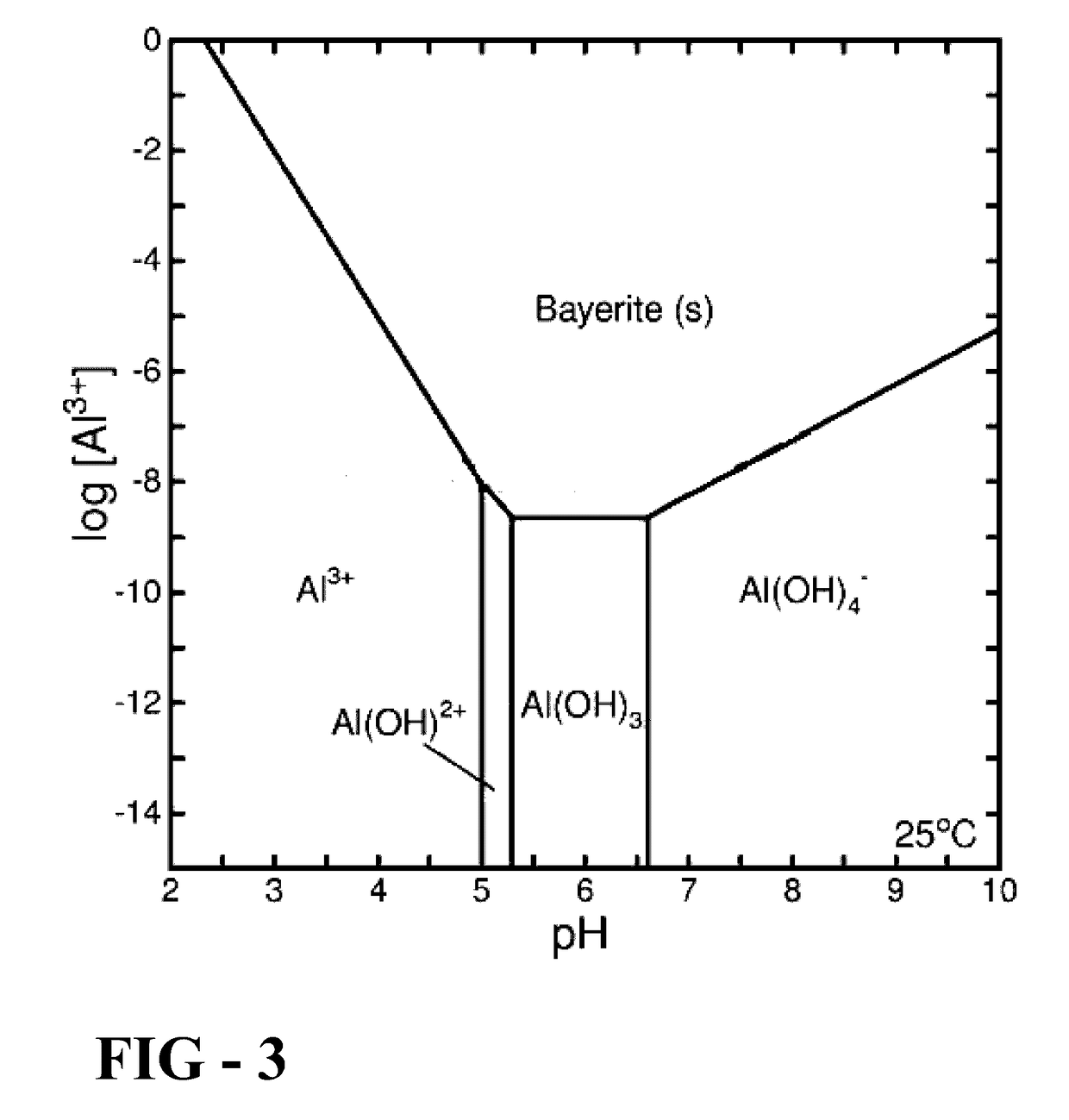

A method of reducing the mobility of metal contaminates in mediums such as soil, groundwater, sludge, etc. that involves contacting the mediums with a reagent that is a ferrous sulfide suspension that contains at least FeS and Al(OH)3. The reagent is produced by reacting a solution that contains at least NaAlO2 and NaOH with a solution that contains FeCl2, HCl and water to form a reaction mixture that contains Fe2+, Cl−, Na+, Al(OH)3 and H2O; and adding NaHS to the reaction mixture. The mobility of the metal contaminates is reduce by adsorption of the metal contaminates in the medium onto the surface of ferrous sulfide or Al(OH)3 in the ferrous sulfide suspension; adsorption of the metal contaminates in the medium onto iron (hydr)-oxides formed in the suspension; and precipitation of the metal contaminates.

Owner:REDOX TECH GRP

Method for preprocessing nitrobenzene-contained waste water by ferrous sulfide

InactiveCN102603050AEasy to operateLow equipment requirementsWater contaminantsWater/sewage treatment by reductionNitrobenzeneWastewater

The invention discloses a method for preprocessing nitrobenzene-contained waste water by ferrous sulfide, which belongs to the technical field of the sewage processing. The method comprises the following steps of: (1) smashing ferrous sulfide until the granularity is 50-60 meshes, causing the fresh surface of the ferrous sulfide to be exposed by washing with water or acid for standby; (2) adding the processed ferrous sulfide into a reacting container; (3) adding the nitrobenzene waste water into the reacting container, wherein the mass concentration ratio of the ferrous sulfide to nitrobenzene in the reactor is not less than 30:1, and the mass concentration of the ferrous sulfide is not lower than 3.6g / L; and (4) putting the reactor into the anaerobic or anoxic environment to mix the ferrous sulfide with the nitrobenzene waste water, and finishing preprocessing the nitrobenzene waste water after mixing and reacting for 60-180min. With the method, cheap FeS is adopted to preprocess thenitrobenzene-contained waste water. The method is easy to operate and has low cost, and the efficient preprocessing effect on the nitrobenzene is realized within short time, the nitrobenzene removal rate can be above 90%, and the processing cost is greatly saved.

Owner:NANJING UNIV

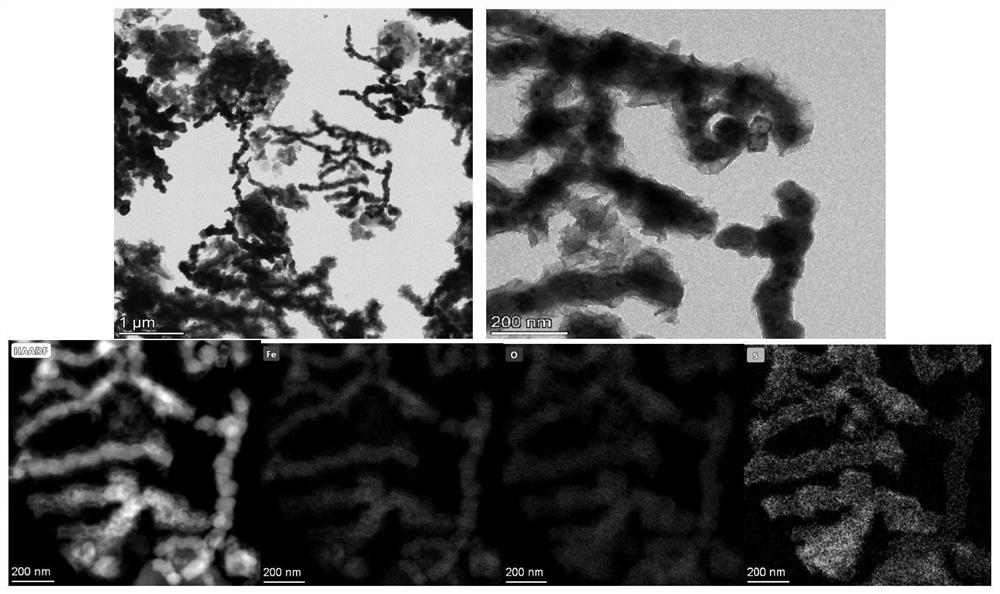

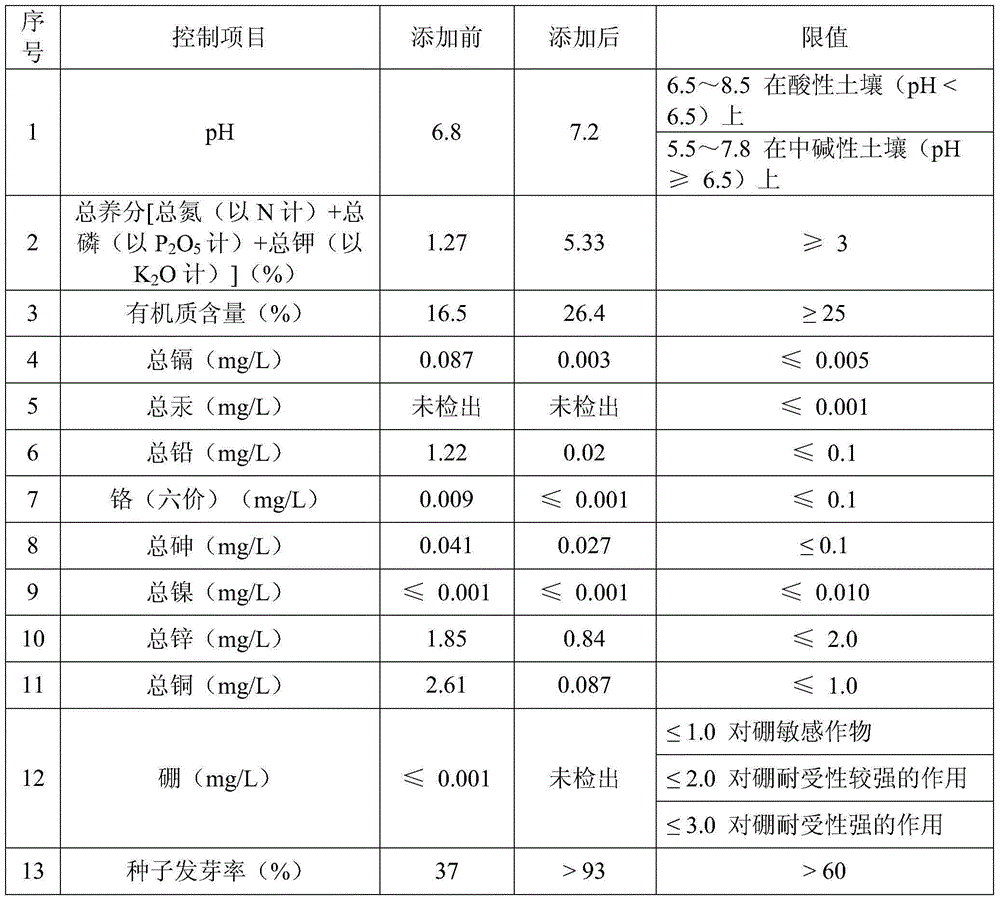

Soil remediation agent, preparation method and applications thereof

InactiveCN110776920AGood dispersionSmall physical and chemical propertiesAgriculture tools and machinesContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a soil remediation agent, a preparation method and applications thereof, wherein the soil remediation agent is a soluble organic matter-ferrous sulfide nanoparticle suspensionliquid, the mass percentage concentration of the soluble organic matter is 0.06-0.4%, the soluble organic matter is one or a plurality of materials selected from humic acid, fulvic acid and tannic acid, and the particle size of the ferrous sulfide nanoparticles is 150-250 nm. According to the invention, the soil remediation agent is applied to remediation of heavy metal contaminated soil, has slow-release removal effect on heavy metals in heavy metal contaminated soil, can efficiently treat soil containing heavy metals such as chromium, arsenic, lead, zinc and the like in a low consumption manner, and has great popularization and application values.

Owner:NANJING NORMAL UNIVERSITY

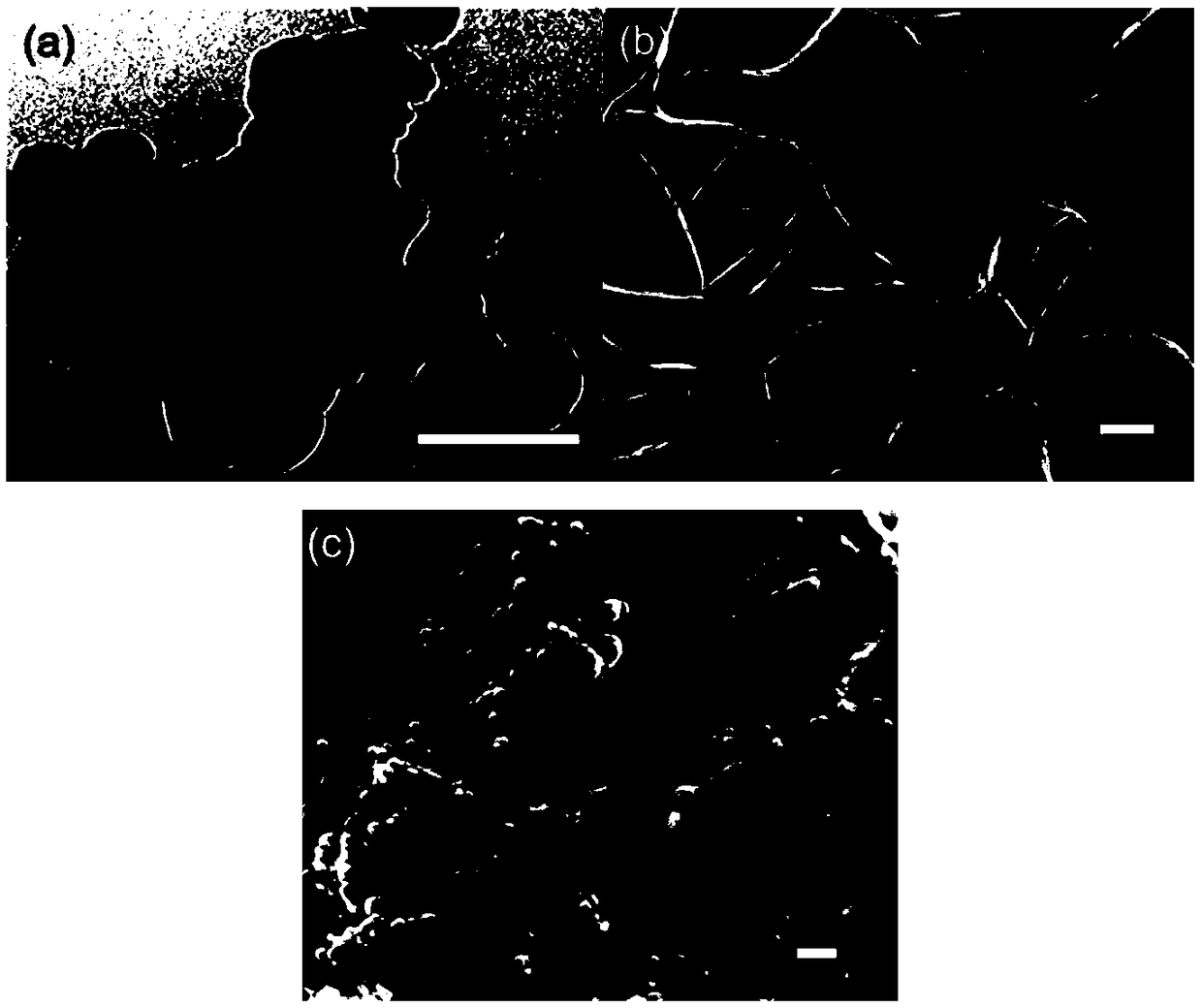

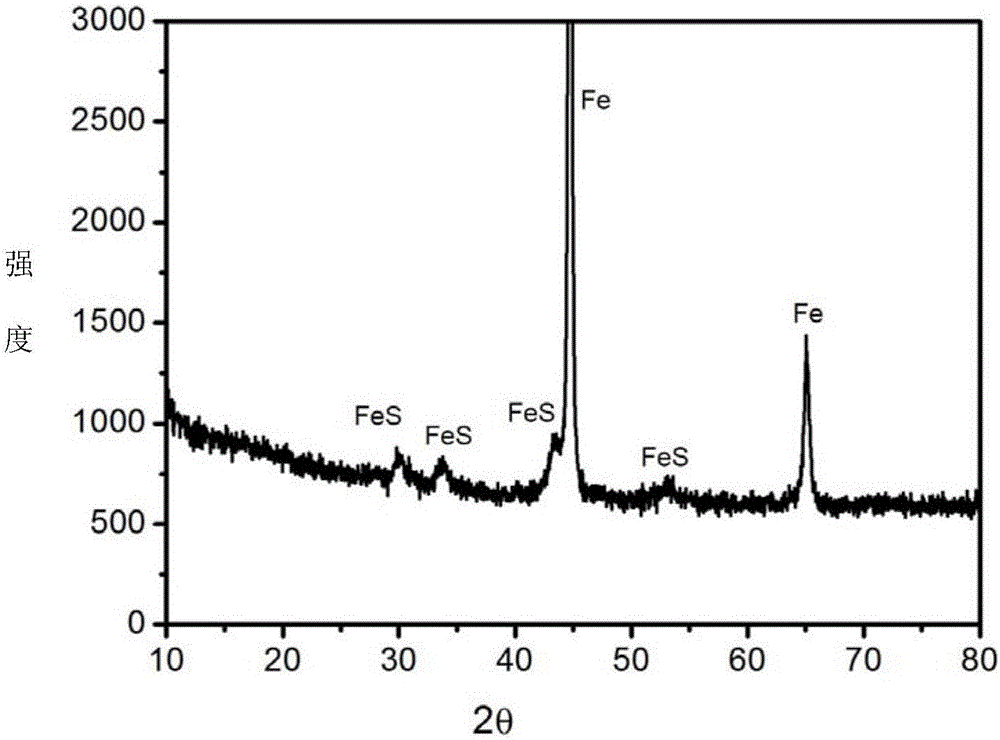

Preparation method for iron-ferrous sulfide composite

The invention discloses a preparation method for an iron-ferrous sulfide composite. The method comprises the steps that elemental sulfur powders and iron sulfide powders are mixed at a a mass ratio of 1: 5-60 or pyrite powders and micron-grade iron powders are mixed at a mass ratio of 1: 5-60; the obtained mixed raw materials are put into a ball mill tank of a ball mill; the ball mill tank is filled with grinding media, and the ball mill tank is in a vacuum environment or inert gas atmosphere; and the ball mill is started, the grinding speed is 400-4000 rpm, the grinding time is 2-30 hours, the grinding media and a product are separated after grinding, and the iron-ferrous sulfide composite is obtained. The grain size of the prepared iron-ferrous sulfide composite is below 10 micrometers. The preparation method is simple, the raw materials are low in cost, and poisonous and harmful dangerous chemicals are not used or generated. The prepared iron-ferrous sulfide composite can efficiently purify chlorine-contained organic pollutants and heavy metals in water, and is especially suitable for in-situ repairing of polluted underground water.

Owner:ZHEJIANG UNIV OF TECH

Method for improving iron powder forming property

A method for improving an iron powder forming property belongs to the technical field of powder metallurgy forming. Pressed blank density can be increased by using good lubricating performance of sulfide. Iron powder and ferrous sulfide powder are mixed in a ball mill and annealed in a hydrogen furnace after being mixed evenly, and the ferrous sulfide is distributed on the surface of the iron powder evenly. In a pressing process, the ferrous sulfide has a lubricating effect, friction condition among powder particles is improved, the forming property is improved, and a blank with the density as 7.2g / cm<3>-7.6g / cm<3> can be obtained. The method has the advantages that the iron powder forming property is good, the blank with higher density can be obtained under low pressing pressure, loss of a grinding tool is reduced, simultaneously sulfur does not affect the performance of iron-based parts, and the process is simple and suitable for industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

Repairing agent for simultaneously repairing As and Cr polluted soil, as well as preparation and application thereof

InactiveCN106957655AShort repair cycleLow costContaminated soil reclamationOrganic fertilisersIron saltsGoethite

The invention discloses a repairing agent for simultaneously repairing As and Cr polluted soil. The repairing agent is prepared from the following components in parts by weight: 25-85 parts of inorganic iron salt, 15-75 parts of clay inorganic minerals, 10-30 parts of silicon dioxide crystallizing agent, 10-30 parts of a magnesium compound and 25-80 parts of sulfide, wherein the inorganic iron salt is one or an arbitrary combination of more than two of ferric sulfate, goethite, ferrous chloride and ferrous sulfide; the magnesium compound is one or an arbitrary combination of more than two of magnesium oxide, dolomite and magnesite; and the sulfide is one or an arbitrary combination of more than two of calcium polysulfide, sodium sulfide and potassium sulfide.

Owner:BEIJING GEOENVIRON ENG & TECH

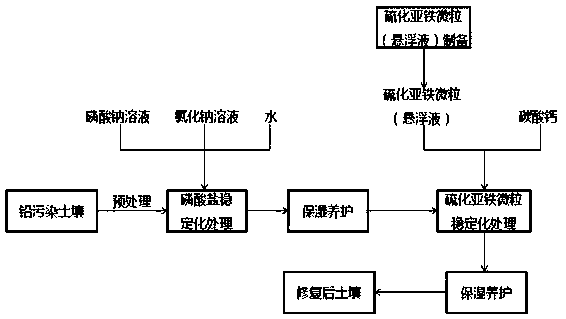

Chemical stabilization repair method of lead contaminated soil

InactiveCN109365514AIncrease negative chargeAchieve stabilizationContaminated soil reclamationTreatment effectSodium phosphates

The invention relates to a chemical stabilization repair method of lead contaminated soil. The chemical stabilization repair method comprises the steps that (1) ferrous sulfide particle suspension liquid is prepared; (2) the lead contaminated soil is pretreated, wherein the lead contaminated soil is crushed and sieved to obtain soil with the particle size smaller than 10 cm; (3) chemical stabilization treatment of the first time is carried out, a sodium phosphate solution and a sodium chloride solution are added into the soil treated through the step (2), the water content of the soil is keptbetween 30% to 50%, and after uniform stirring and mixing, moisture preserving maintenance is carried out for 2 days to 5 days; and (4) chemical stabilization treatment of the second time is carried out, calcium carbonate and the ferrous sulfide particle suspension liquid prepared in the step (1) are added into the soil treated in the step (3), the water content of the soil is kept between 40% to60%, after uniform stirring and mixing, moisture preserving maintenance is carried out for 1 week to 3 weeks, and the repaired soil is obtained. The combined repair method is provided and is combinedwith the advantages of multiple repair agents, the treatment effect of the lead contaminated soil is improved, secondary contamination is relieved, and the TCLP leaching quantity of lead in the treated soil can be reduced to be 0.25 mg / L or below.

Owner:重庆市环境科学研究院 +1

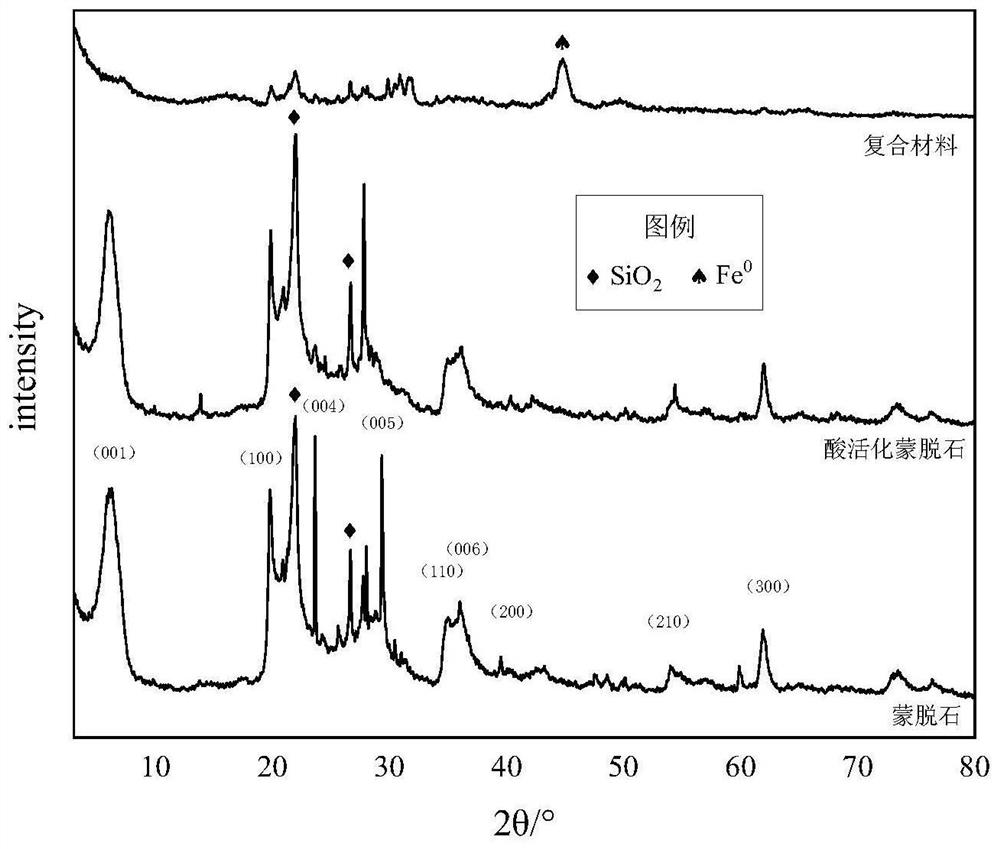

Vulcanized nano zero-valent iron-acid activated montmorillonite composite material, and preparation method and application thereof

ActiveCN111718719AIncrease speedImprove reduction efficiencyOrganic fertilisersSoil conditioning compositionsIn situ remediationMontmorillonite

The invention discloses a vulcanized nano zero-valent iron-acid activated montmorillonite composite material, and a preparation method and application thereof. The composite material is composed of spherical particles with nano zero-valent iron as a core and ferrous sulfide as a shell, is of a nano long-chain structure, has uniformly distributed and highly dispersed iron and sulfur elements, and has typical structural characteristics of silicate and zero-valent iron. The vulcanized nano zero-valent iron-acid activated montmorillonite composite material prepared by the invention is simple in raw material components, green, pollution-free and low in cost; and the product is convenient to transport and store. The prepared vulcanized nano zero-valent iron-acid activated montmorillonite composite material can be applied to in-situ remediation of soil polluted by various alkaline Cr (VI), the process is simple and rapid, the applicability is good, and the remediation effect is good.

Owner:CENT SOUTH UNIV

Process for the detecting of hydrogen peroxide

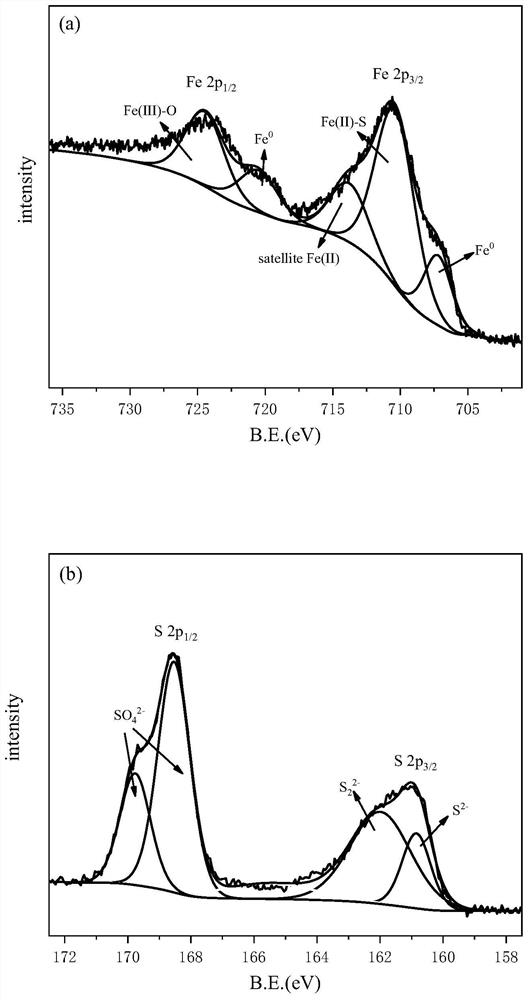

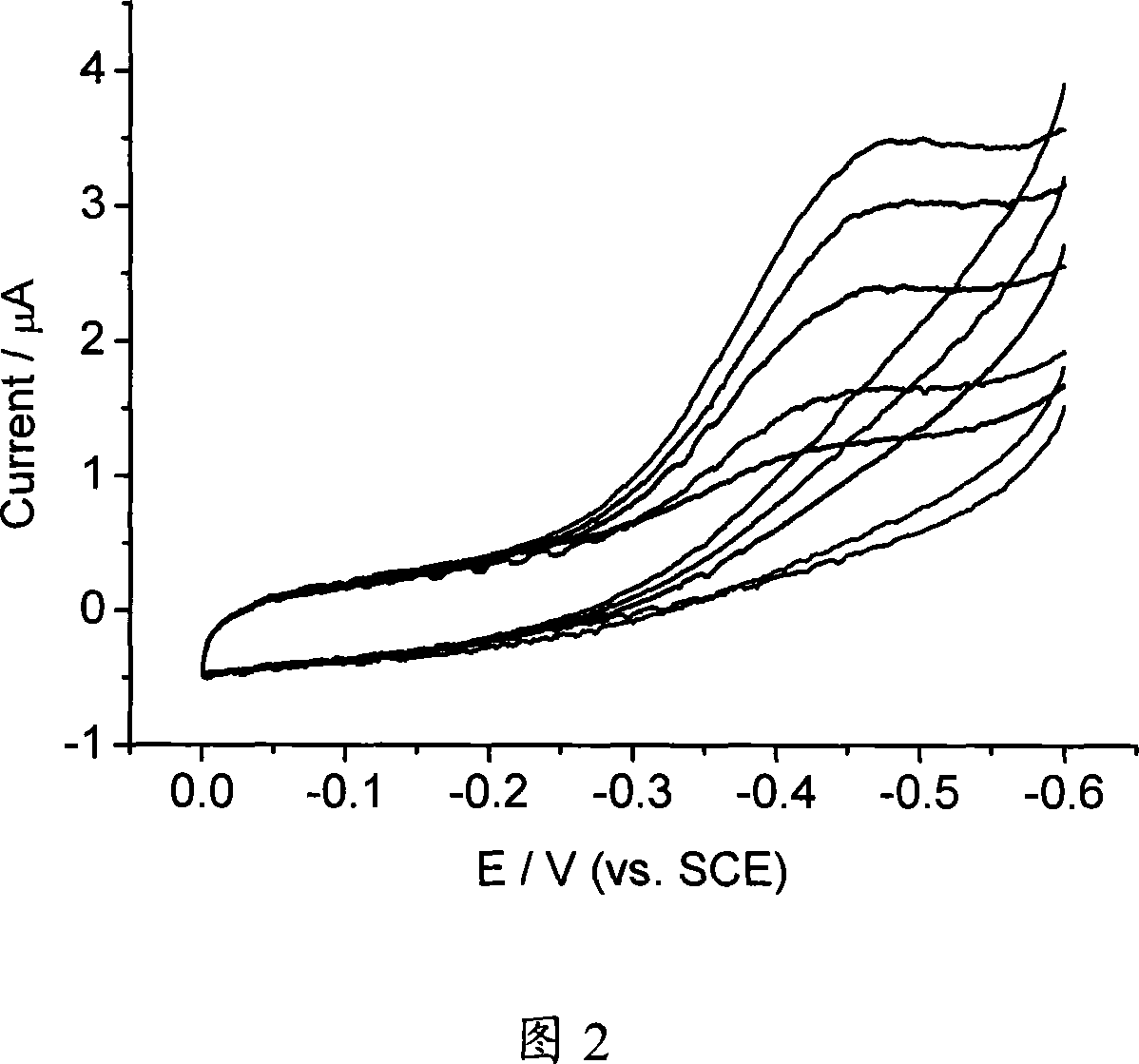

InactiveCN101055264ALarge specific surface areaHigh sensitivityPreparing sample for investigationMaterial electrochemical variablesOxygenVacuum drying

The invention discloses a method of detecting hydrogen peroxide, which includes steps: (1) preparation of nano ferrous sulfide: dissolving ammonium ferrous sulfate into secondary water after removing oxygen by blowing nitrogen, adding mixing solution of sulfide and surfactant into the water solution and mixing at ultrasound condition, after reaction, centrifuge washing, depositing, vacuum drying, and obtaining the nano ferrous sulfide sample; wherein mole ration of the sulfide and the surfactant is 1:1, dosing of the surfactant is 0.014N; (2) checking preparation: dropping and coating suspension and polymer film of the ferrous sulfide nano particles on glass-carbon electrode in turn, airing, and aging; (3) detection of hydrogen peroxide: continuously adding hydrogen peroxide into electrolytic cell to detect the hydrogen peroxide, recording ampere response of the hydrogen peroxide, and obtaining detection result. The invention uses nano ferrous sulfide to replace HRP for detecting hydrogen peroxide, due to nano material having large specific surface area, the method increases sensitivity of detection and is simple, convenient, fast, sensitive and stable.

Owner:NANJING NORMAL UNIVERSITY

Method for improving laterite-nickel ore carbothermic reduction selectivity

The invention discloses a method for improving laterite-nickel ore carbothermic reduction selectivity. A sulfur-containing assistant is added in laterite-nickel ore and the mixture is subjected to carbothermic reduction-sorting process so that a nickel-iron product is obtained. Through action of the sulfur-containing assistant, based on an appropriate carbothermic reduction process, nickel oxide in the laterite-nickel ore is reduced into metallic nickel, iron oxide is reduced into metallic iron and other parts are bonded to sulfur in the assistant so that ferrous sulfide is obtained. The method realizes nickel and iron selective reduction / sulfuration in laterite-nickel ore carbothermic reduction, greatly improves a nickel grade of the reduced product nickel-iron, produces a high-quality nickel-iron product, satisfies requirements on stainless steel smelting raw materials, has the characteristics of strong raw material adaptability, simple processes, good product quality, low treatment cost and good nickel recovery effects, and provides a novel direction for future high-efficiency and low-cost treatment on laterite-nickel ore.

Owner:CENT SOUTH UNIV

Method for treating soil and groundwater containing heavy metals including nickel

Owner:REDOX TECH GRP LLC

Method for eliminating heavy metal in industrial sewage

ActiveCN103641227AMeet the need to remove heavy metalsAvoid it happening againWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationToxic gasSulfate

The invention discloses a method for eliminating heavy metal in industrial sewage. The method comprises the following steps: adjusting the pH value of industrial sewage to be 7-8; subsequently adding sodium sulfide, adjusting the pH value to be 9-10, and reacting sulfur ions with most heavy metal ions so as to generate a precipitate of sulfide, wherein the generation of a harmful gas hydrogen sulfide is effectively prevented; subsequently adding ferrous sulfate while stirring, and reacting with sulfur ions to generate a precipitate of ferrous sulfide and eliminate pollution caused by redundant sulfur ions; adjusting the pH value of the industrial sewage back to be neutral by utilizing the faintly acid of ferrous sulfate, wherein the pollution that a harmful gas hydrogen sulfide can be generated when the pH value is adjusted by using acid is also avoided; press-filtering and subsequently discharging. The method for eliminating the heavy metal in the industrial sewage is simple in process procedure and high in universality, and requirements for eliminating heavy metal in various industrial sewage can be met.

Owner:杭州立佳环境服务有限公司

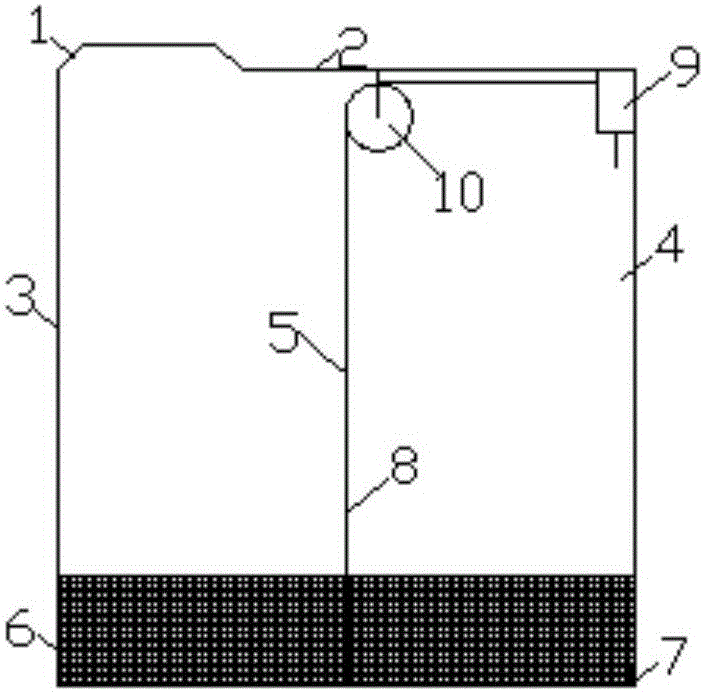

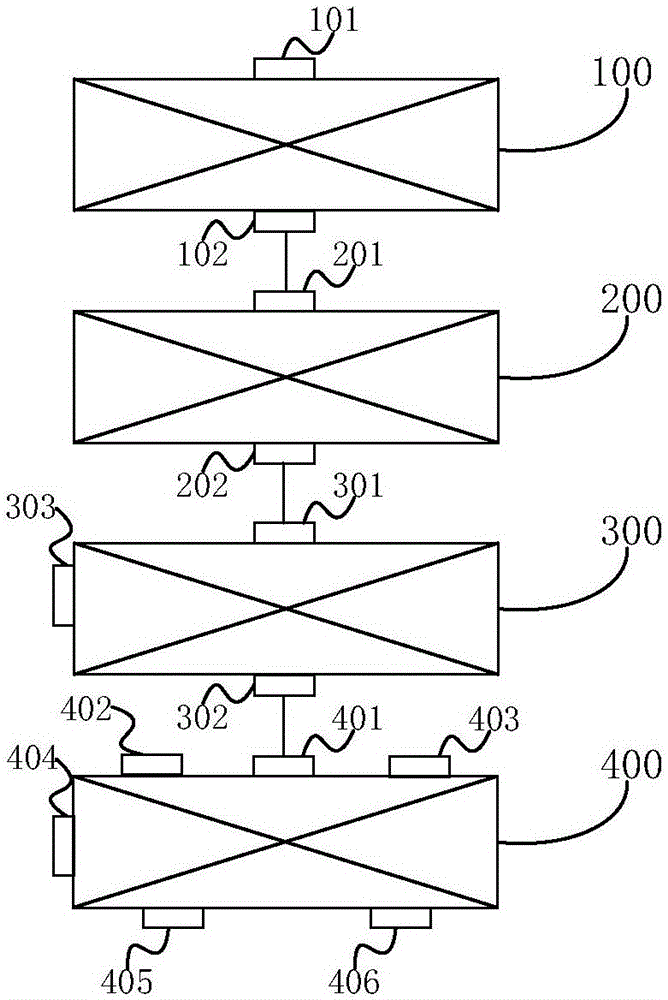

Biological ferrous sulfide and uranium-polluted underground water treatment permeation reaction wall based on same

InactiveCN105819576AHigh yieldSimple and fast operationWater contaminantsRadioactive decontaminationPermeationPollution

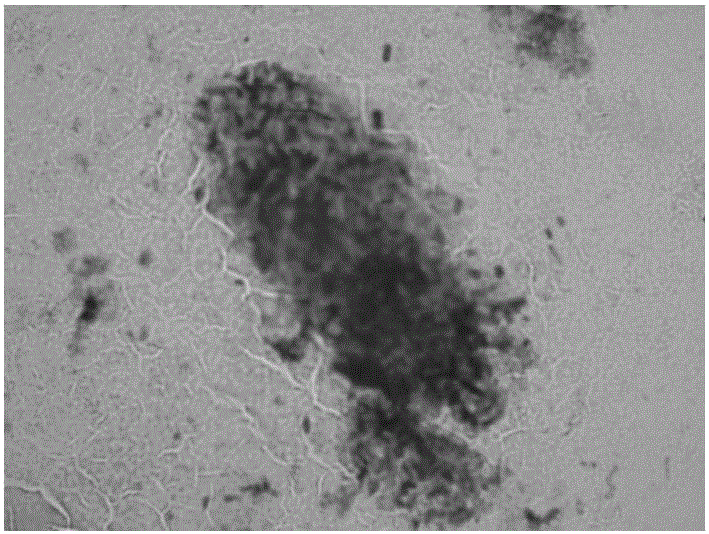

The invention discloses a biological ferrous sulfide composite material which comprises ferrous sulfide and synthetic bacteria bonded to the ferrous sulfide .The ratio of the number of microorganisms of the synthetic bacteria to the ferrous sulfate of unit mass is 3.3*107-5*107 cfu / mg .The synthetic bacteria mainly comprise Desulfovibrio and Clostridium .The invention further discloses a uranium-polluted underground water treatment permeation reaction wall based on the biological ferrous sulfide .The uranium-polluted underground water treatment permeation reaction wall comprises a reaction well and a reaction medium .The reaction well is arranged in soil containing uranium-polluted underground water and located on an underground water flowing path, and the top of the reaction well is flush with the ground and provided with an upward first opening .The reaction medium is arranged in the reaction well and is the biological ferrous sulfide composite material .The prepared material and the device have high removal rate for uranium in water, secondary pollution is avoided, regenerability is good, and the requirements of current underground water uranium-polluted permeation reaction wall materials are met.

Owner:NANHUA UNIV

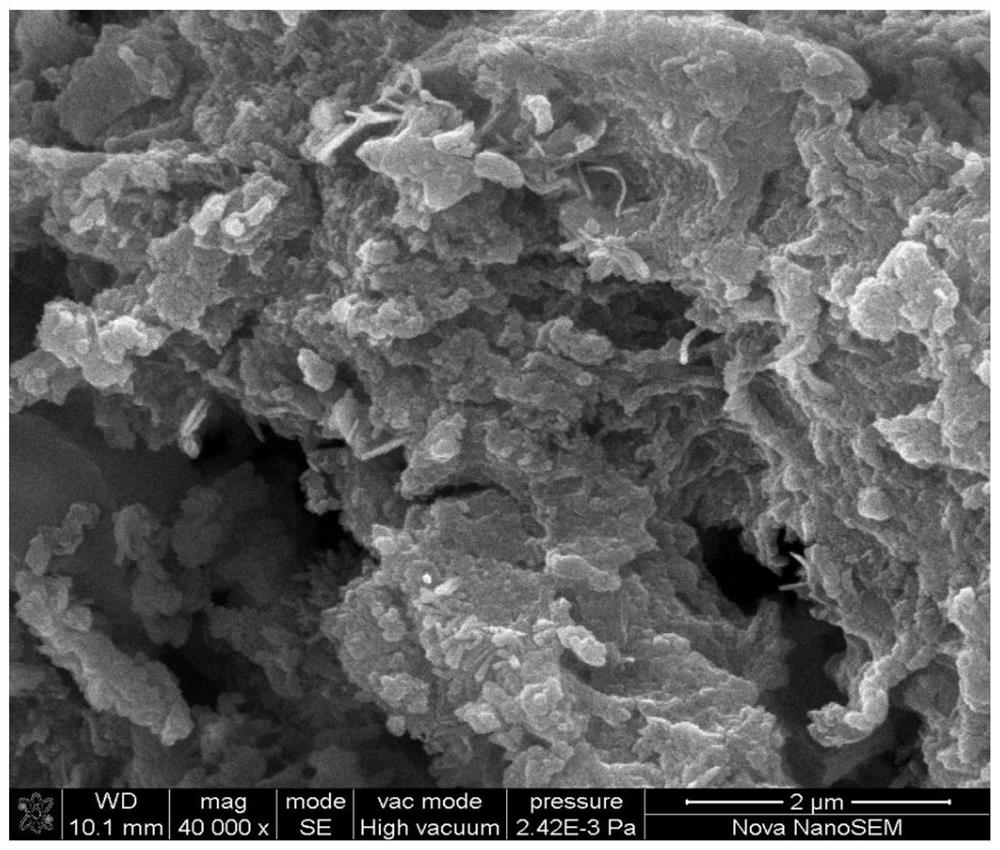

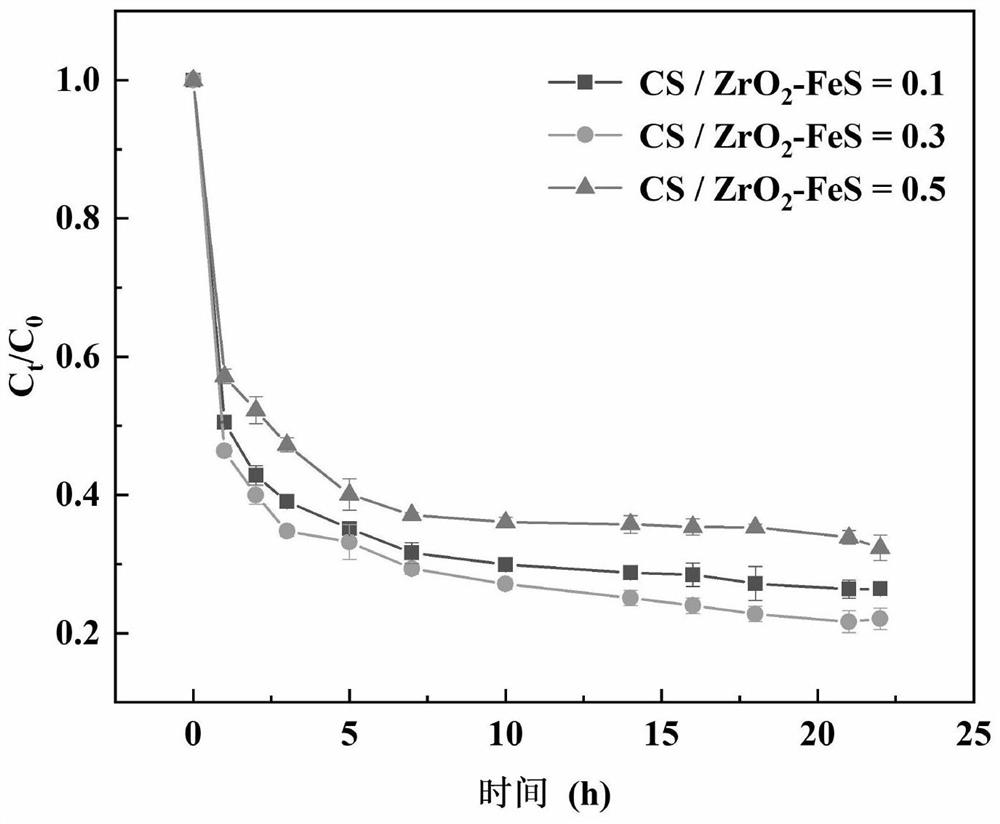

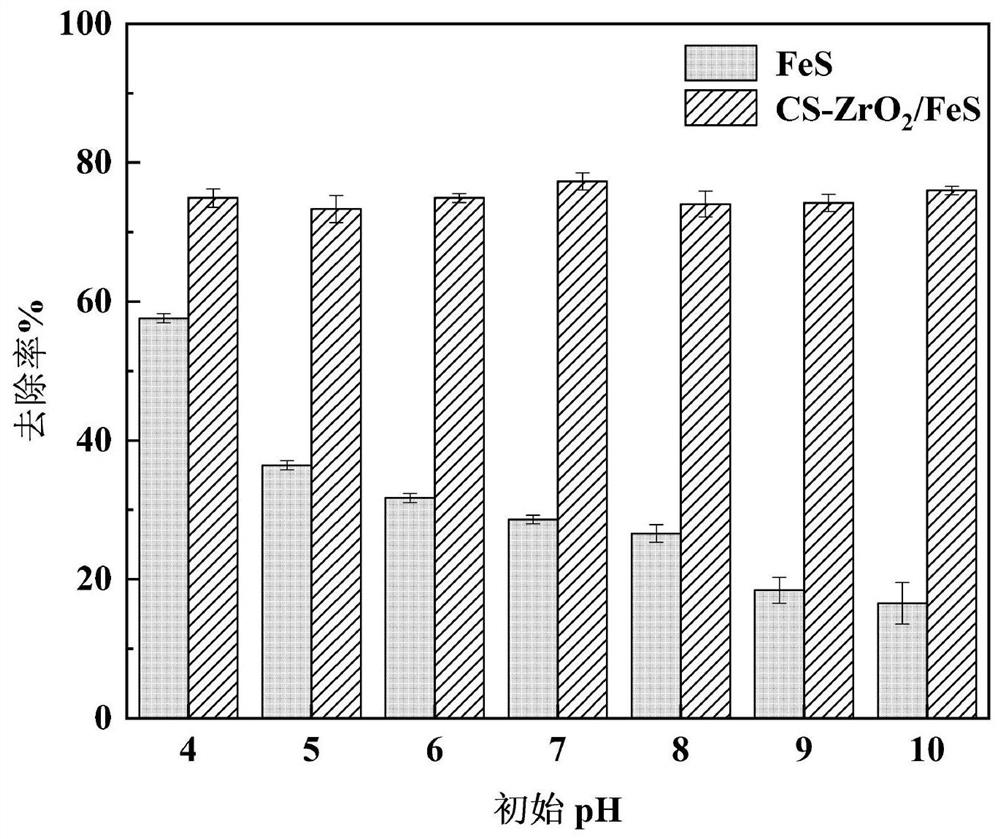

Preparation method and application of chitosan-stabilized zirconium-modified nanometer ferrous sulfide composite material

ActiveCN112844330AGood removal effectSimple preparation processOther chemical processesWater contaminantsWater chlorinationNitrogen gas

The invention provides a preparation method and application of a chitosan-stabilized zirconium-modified nanometer ferrous sulfide composite material, belonging to the technical field of environmentally functional composite nanomaterials. The preparation method specifically comprises the following steps: firstly, preparing zirconium oxide with controllable granularity and relatively high purity by adopting a sol method, and dissolving chitosan by using a dilute acid solution; and adding a ferrous chloride solution into the obtained chitosan solution under the protection of nitrogen, carrying out uniform stirring, adding the zirconium oxide sol, continuing stirring, dropwise adding a sodium sulfide solution, conducting reacting, and performing standing to obtain the chitosan-stabilized zirconium-modified nanometer ferrous sulfide composite material. The material is synthesized by adopting a one-step coprecipitation method, raw material cost is low, a preparation process is simple, the defects that ferrous sulfide is easy to agglomerate, low in reaction activity and poor in stability are overcome, meanwhile, the material has a more stable removal effect on molybdate in water, and the material has a good market application prospect in treatment of molybdenum pollution of surface water and underground water.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

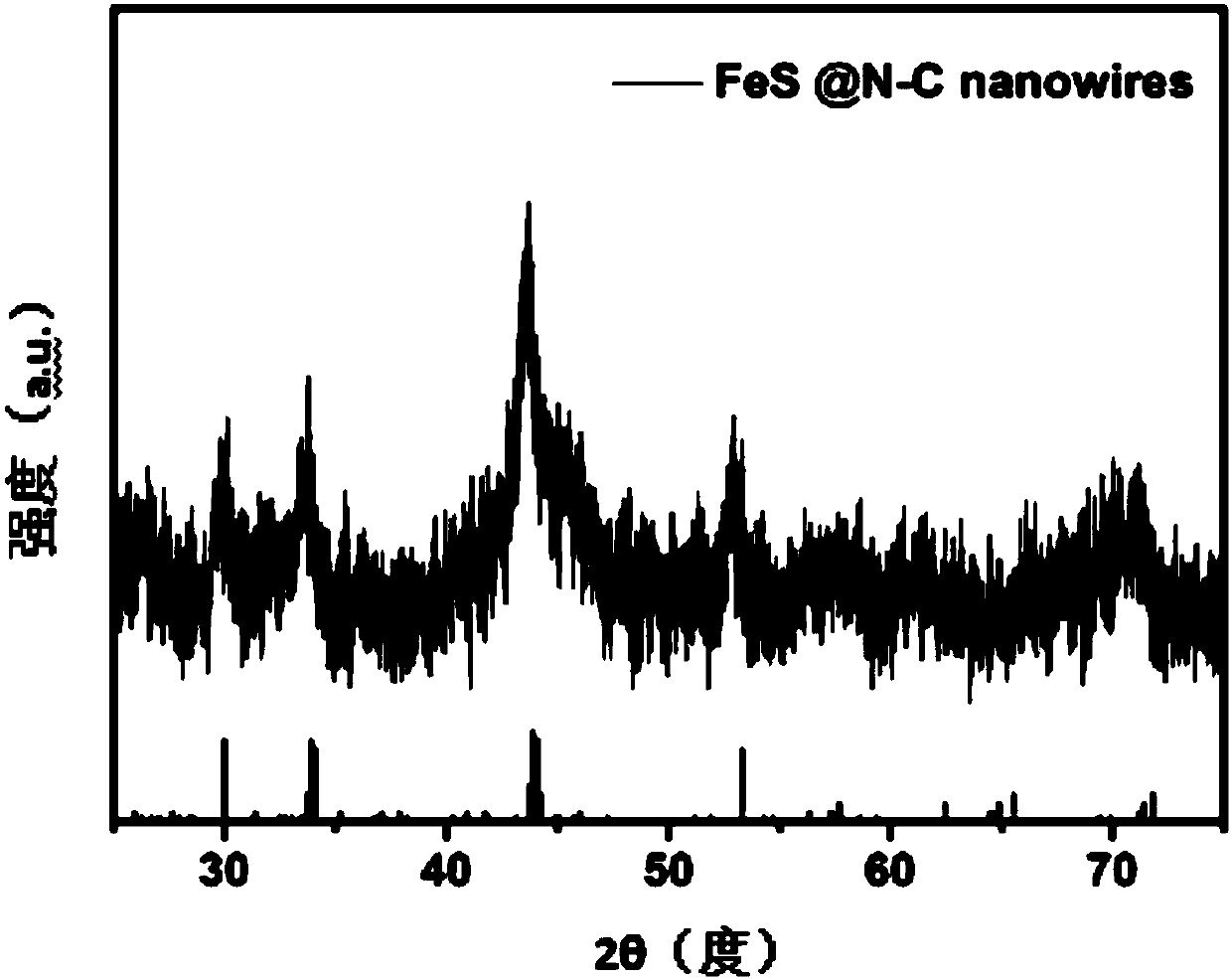

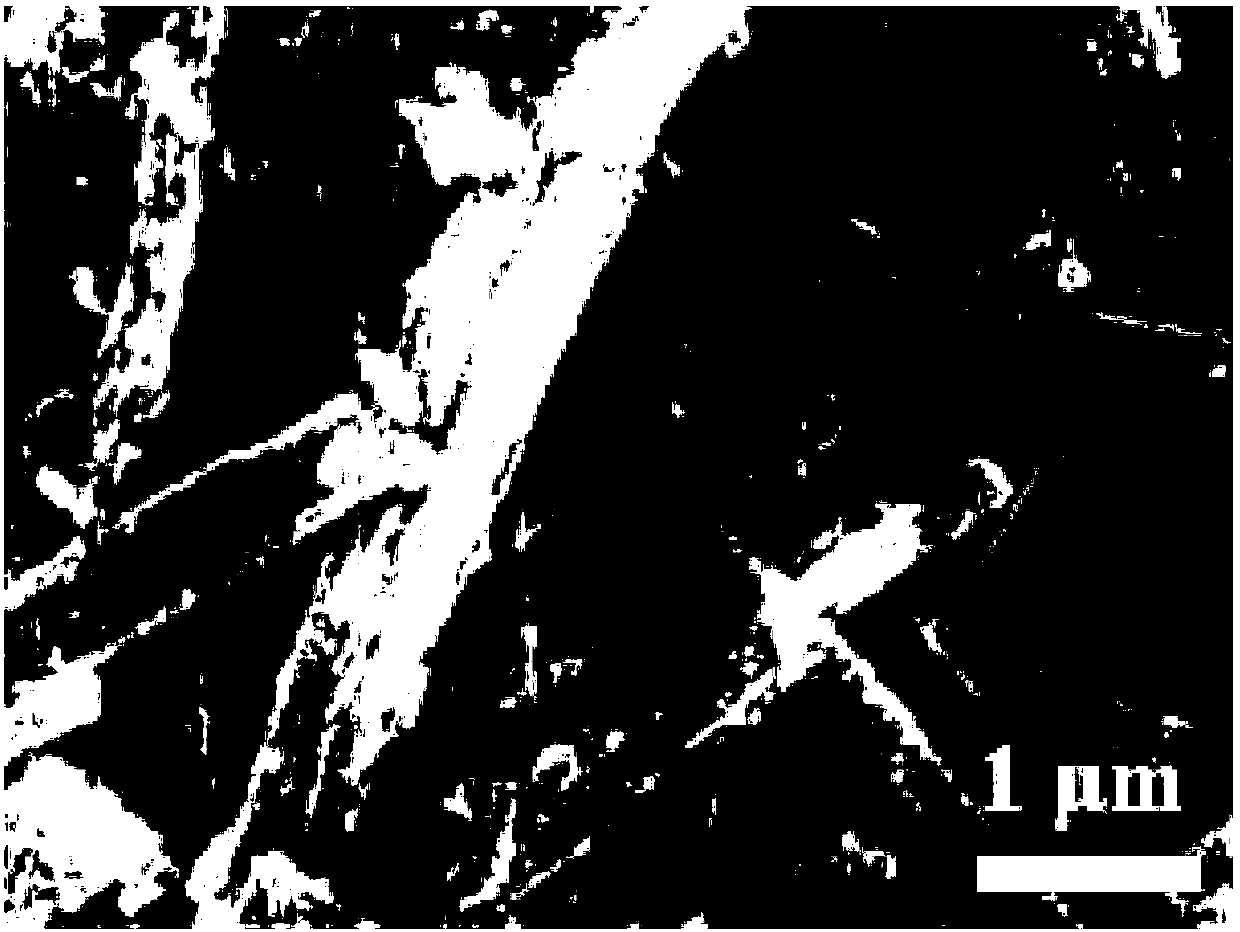

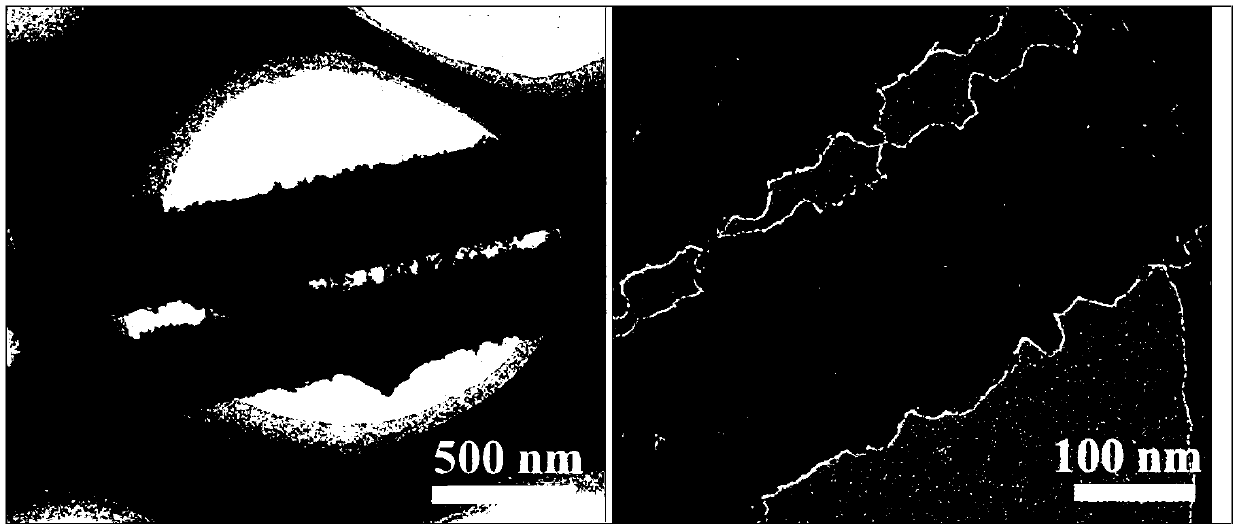

Porous ferrous sulfide nanowires and nitrogen doped carbon composite material and preparation method and application thereof

ActiveCN107634193AHigh yieldGood dispersionMaterial nanotechnologyCell electrodesCarbon compositesNanowire

The invention relates to porous ferrous sulfide nanowires and nitrogen doped carbon composite material and a preparation method thereof; the material can be used as a long-life and high-rate lithium ion battery negative electrode active material, is nanowires formed by compositing an in-situ generated ferrous sulfide nano-crystalline grains and nitrogen doped carbon, has a porous structure, and has the length of 1-10 [mu]m, the width of 100-500 nm and the thickness of 8-15 nm. The composite material has the beneficial effects that the simple hydrothermal and calcining method is only adopted, and the prepared material has high yield and good dispersibility, and makes great efforts to explore large-scale synthesis of nano materials with excellent performance and high rate; the method is simple in process, meets the requirements of green chemistry, has low requirements for equipment and has great potential for application; and the method shortens the diffusion distance of lithium ions andelectrons, buffers the volume change during the cycle process, thereby effectively improving the electrochemical performance of the material.

Owner:WUHAN UNIV OF TECH

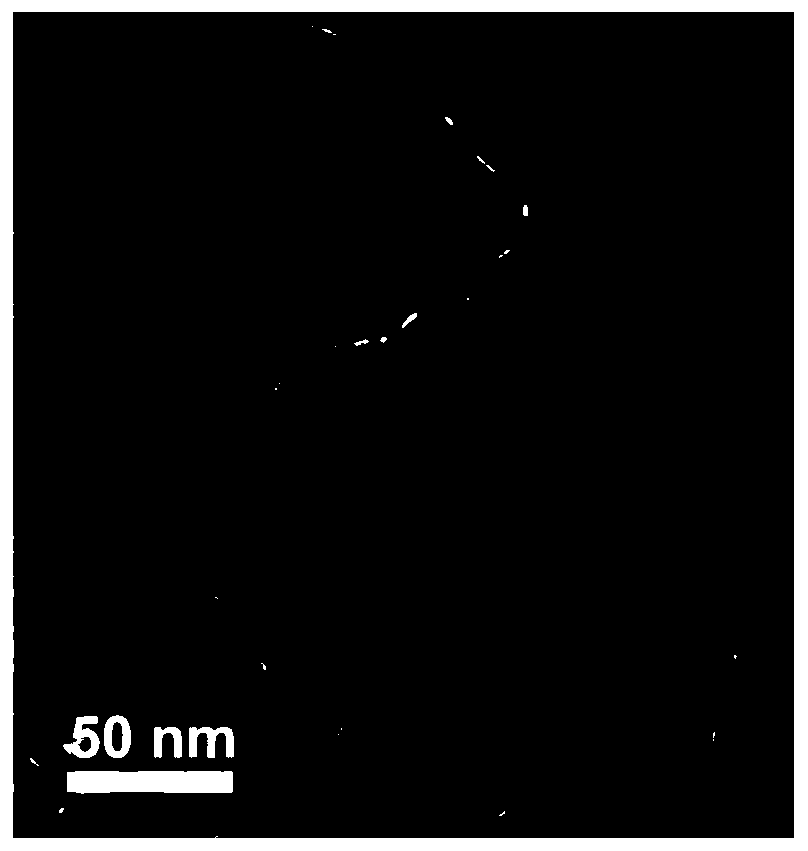

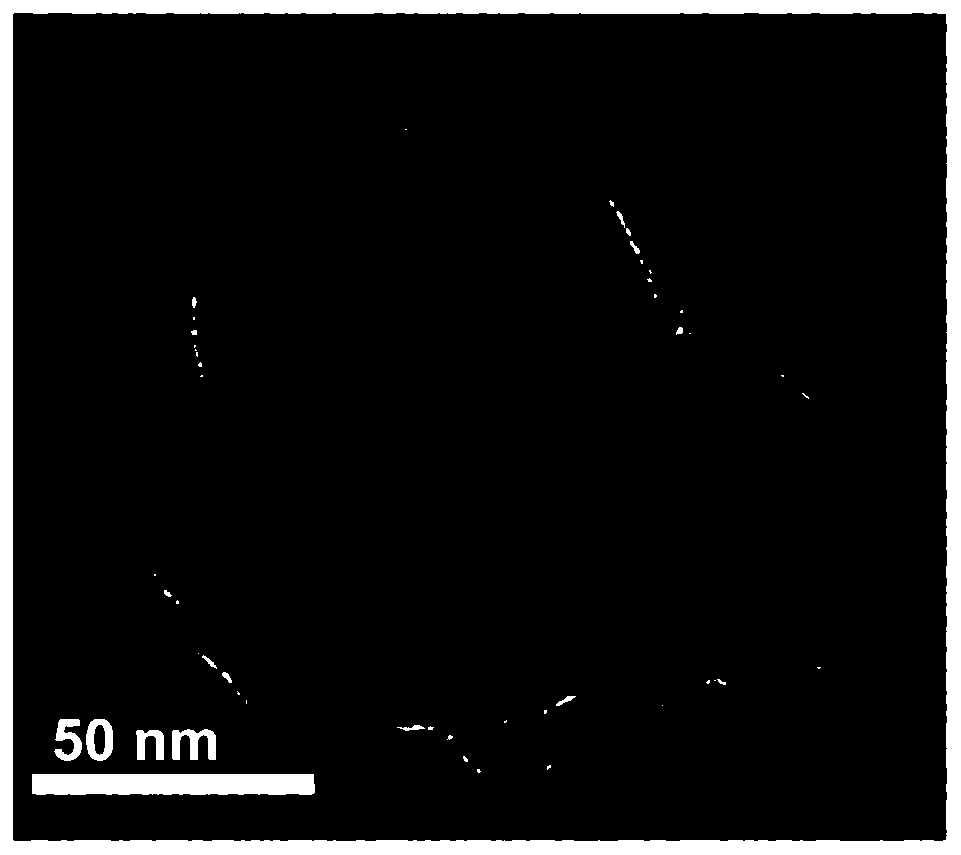

A method for in-situ preparing lithium electrode material carbon-encapsulated ferrous sulfide nanoparticles

InactiveCN109004215ARealize continuous preparationImprove efficiencyCell electrodesPeristaltic pumpVertical tube

The invention provides a method for in-situ preparing lithium electrode material carbon-encapsulated ferrous sulfide nanoparticles. The method includes weighing iron source, A sulfur source and a carbon source, take an inert gas as a carrier gas, input a raw material solution to an injector in a vertical tube furnace through an electronic peristaltic pump, spray that raw material into a high-temperature region of the tube furnace, thermally decompose the raw material to form nano clusters, carry the raw material out of the high-temperature region of the tube furnace with the carrier gas, and then collect the product at the tail of the tube furnace to obtain carbon-encapsulated ferrous sulfide nano core-shell particles. The nano core-shell particles obtained by the method of the present invention can be used as electrode materials for lithium ion batteries. The method of the invention has the advantages of one-step synthesis of core-shell particles, continuous preparation and easy operation, and has broad prospects in industrial application of electrode materials, and is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

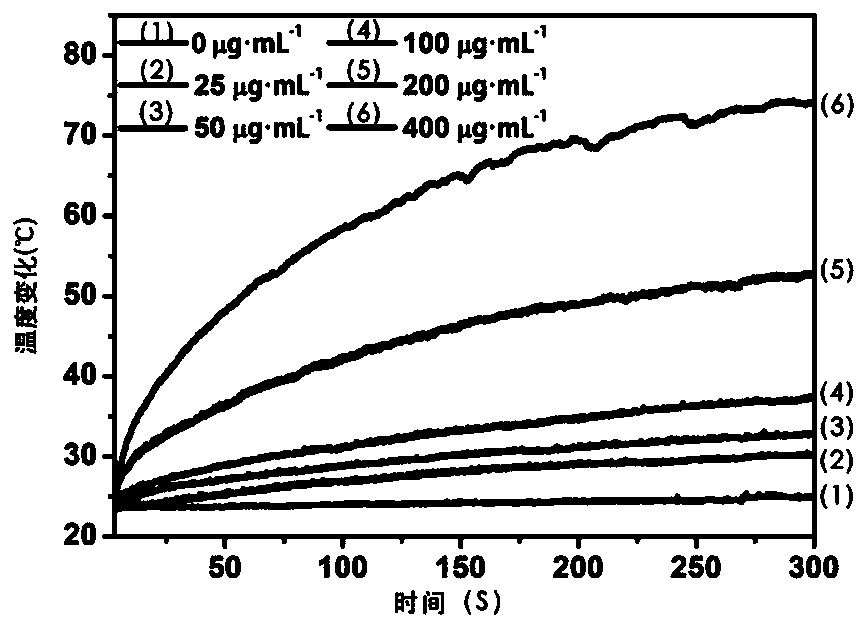

Bismuth-doped metal sulfide nanoflower and preparation method thereof

ActiveCN110101860AEasy to makeLow costOrganic active ingredientsPowder deliveryBismuth sulfideMetallic sulfide

The invention relates to a bismuth-doped metal sulfide nanoflower and a preparation method thereof. The preparation method comprises the steps that a solution system containing both intermediate particles and ammonium thiomolybdic tetrahydrate is subjected to a solvothermal reaction to obtain the bismuth-doped metal sulfide nanoflower; the intermediate particles are generated by mixing an A solution and a B solution, wherein the A solution is mainly composed of BiCl3, MnCl2 4H2O and deionized water, and the B solution is mainly composed of K4[Fe(CN)6] 3H2O, citric acid and deionized water; thefinally prepared bismuth-doped metal sulfide nanoflower is of a nanoflower structure formed by winding and twisting nanosheets, wherein the nanosheets are doping type metal sulfide nanosheets obtained through mutual substitution and mosaicism of elemental bismuth, bismuth sulfide, manganese sulfide, ferrous sulfide and molybdenum sulfide on a two-dimensional structure. The preparation method is simple, the prepared nanoflower can achieve the effect that a single structure has multiple functions, and the photothermal conversion efficiency is higher.

Owner:SHANGHAI UNIV OF ENG SCI

Treatment method of water polluted by mercury

ActiveCN104150634AReduce mercury levelsProcessing speedWater contaminantsMultistage water/sewage treatmentHydrogen SulfateP-tert-Butylphenol

The invention relates to the field of water treatment, and in particular relates to a treatment method of water polluted by mercury. The method comprises the following steps: (1) regulating the pH value of mercury-containing sewage to be 6-6.5, and adding sodium alcohol ether sulfate and sodium hypochlorite into the mercury-containing sewage, wherein the additive amount of sodium alcohol ether sulfate accounts for 1-2 times of the mass concentration of mercury in the sewage, and the additive amount of sodium hypochlorite accounts for 3-5 times of the mass concentration of mercury in the sewage; (2) regulating the pH value of the sewage to be 8-9, and then adding poly p-tert-butylphenol disulfide, ferrous sulfide and sodium hydrogen sulfate into the sewage under the conditions that the mass ratio of p-tert-butylphenol disulfide to ferrous sulfide to sodium hydrogen sulfate is (1-2) to (2-4) to 5, and the mass concentration of poly p-tert-butylphenol disulfide in the sewage is 1-5%; (3) then adding a flocculating agent, calcium oxide and alkylphenol polyoxyethylene into the sewage under the conditions that the mass ratio of the flocculating agent to calcium oxide to alkylphenol polyoxyethylene is 1 to 3 to 2, and the additive quantity of the flocculating agent is 0.1-0.3% of the quantity of the sewage; (4) standing the sewage for 3-5 days in a separation tank, and then performing solid-liquid separation; (5) adsorbing the separated sewage by adopting an activated carbon absorber, and then discharging the sewage.

Owner:ZHEJIANG OCEAN UNIV

Additive for treating sludge and preparing method thereof

ActiveCN105198524AEffective and stableEfficient curingBio-organic fraction processingClimate change adaptationCalcium silicateSludge

The invention discloses an additive for treating sludge and a preparing method thereof and belongs to the technical field of sludge treatment. The additive is prepared from, by weight, 5-25 parts of ferrous sulfide, 30-60 parts of magnesium oxide, 1-15 parts of ammonium bicarbonate, 1-15 parts of urea, 1-15 parts of calcium phosphate, 1-15 parts of calcium silicate, 1-15 parts of potassium sulphate and 5-25 parts of plant ash. The additive has the advantages that municipal sludge and river sediment can be effectively treated, waste materials are recycled, artificial soil is made to be used for landscape planting, mine ecological restoration and other projects, and environment benefits, economic benefits and social benefits are high.

Owner:银发环保股份有限公司

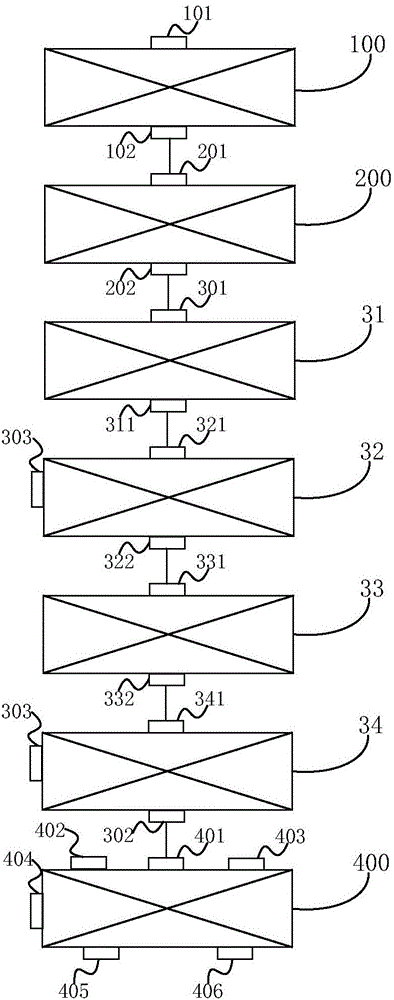

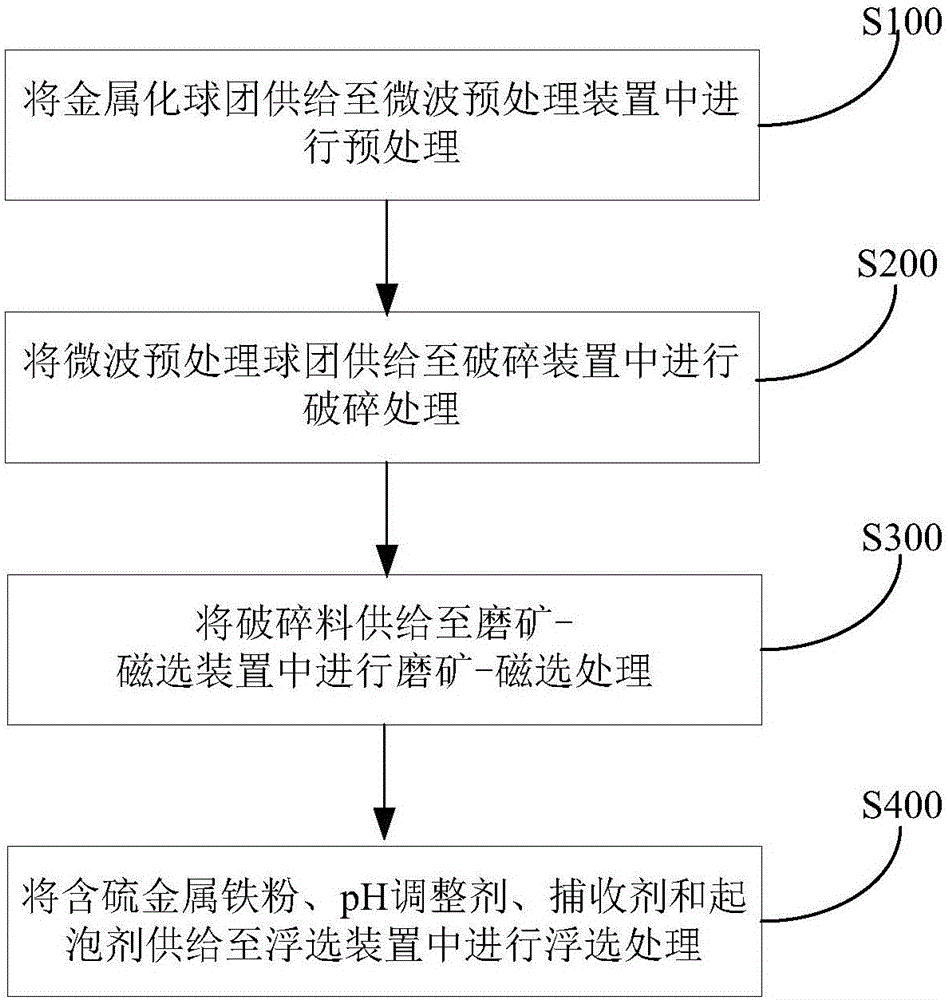

System and method for preparing low-sulfur iron powder

The invention discloses a system and a method for preparing low-sulfur iron powder. The system comprises a microwave pretreatment unit, a crushing device, an ore grinding and magnetic separating unit and a flotation unit, wherein the microwave pretreatment unit is provided with a metalized pellet inlet and microwave pretreated pellet outlet; the crushing device is provided with a microwave pretreated pellet inlet and a crushed material outlet; the ore grinding and magnetic separating unit is provided with a crushed material inlet, a sulfur-containing metal iron powder outlet and a tailings outlet; the flotation unit is provided with a sulfur-containing metal iron powder inlet, a pH regulating agent inlet, a collecting agent inlet, a foaming agent inlet, a low-sulfur iron powder outlet and a ferrous sulfide outlet. The system can be used for treating a metalized pellet to obtain low-sulfur iron powder (the sulfur content can be reduced to about 0.1%), and the product quality is improved, so full utilization of iron-containing resources is widened, and full recycle (the grade and recovery rate of iron can be as high as 90%) of iron element and sulfur element is realized as well.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com