Carbon-coated ferrous sulfide negative electrode material, preparation method and sodium ion battery prepared by the same

A technology for sodium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex synthesis steps, many types of raw materials, and long time consumption, and achieve simple and easy-to-operate preparation methods and strong cycle stability , time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the particle size of the carbon-coated ferrous sulfide substance is 100-500 nm, and the mass of the coating layer is 10% of the mass of the material.

[0028] The synthesis steps of the carbon-coated ferrous sulfide material used in the present invention are as follows:

[0029] (1) Dissolve 0.96 g of ferrous sulfate heptahydrate and 2.18 g of citric acid monohydrate in 7 mL of deionized water, stir and mix well, then freeze-dry at -56°C for 24 hours to obtain the precursor;

[0030] (2) Grind the precursor obtained in step (1) and place it in a tube furnace with an inert atmosphere for calcination at 800 °C for 6 hours, and grind to obtain carbon-coated ferrous sulfide.

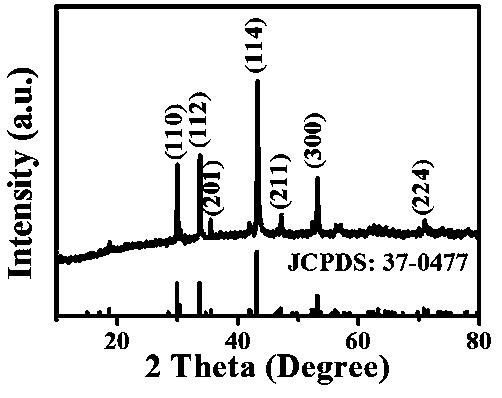

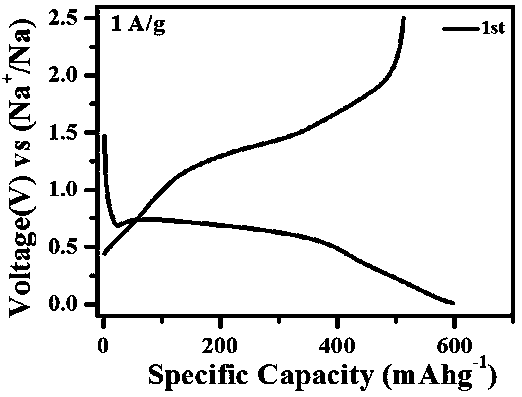

[0031] figure 1 It is the X-ray diffraction (XRD) pattern of carbon-coated ferrous sulfide, which corresponds to the standard card JCPDS 37~0477 of ferrous sulfide, and has good crystallinity. figure 2 It is a scanning electron microscope (SEM) image of carbon-coated ferrous sul...

Embodiment 2

[0034] The preparation of the carbon-coated ferrous sulfide substance in this example is the same as in Example 1.

[0035] The prepared carbon-coated ferrous sulfide was used as the negative electrode active material, and the negative electrode material was mixed with conductive carbon (SuperP Li) and sodium carboxymethyl cellulose at a mass ratio of 80:10:10, and deionized water was used as the dispersant , mix the above mixture evenly, adjust it into a slurry and apply it on the copper foil, dry it at 60°C and cut it to get the negative electrode sheet. The sheet is separated from the metal sodium sheet by Whatman glass fiber membrane, using 1 M NaCF 3 SO 3 Dissolved in diethylene glycol dimethyl ether as the electrolyte, and the stainless steel shell as the shell, assembled into a CR2025 button battery. The battery assembled in the above process was charged and discharged in the potential range of 0.3~2.5 V at room temperature. Its rate performance is as Figure 4 show...

Embodiment 3

[0037] The preparation of the carbon-coated ferrous sulfide substance in this example is the same as in Example 1.

[0038] The prepared carbon-coated ferrous sulfide was used as the negative electrode active material, and the negative electrode material was mixed with conductive carbon (SuperP Li) and sodium carboxymethyl cellulose at a mass ratio of 80:10:10, and deionized water was used as the dispersant , mix the above mixture evenly, adjust it into a slurry and apply it on the copper foil, Na 3 V 2 (PO 4 ) 3 As the positive electrode active material, the positive electrode active material is mixed with acetylene black and polyvinylidene fluoride at a mass ratio of 80:10:10, and 1~methyl~2~pyrrolidone is used as a dispersant, and the above mixture is evenly mixed to form a slurry and coated on On aluminum foil, dry and cut at 60°C to obtain the corresponding negative electrode and positive electrode (the capacity of the positive electrode is much larger than the capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com