Magnesium based ferrous sulfide composite nanomaterial as well as preparation method and application thereof

A composite nanomaterial, ferrous sulfide technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of easy agglomeration, reduced reactivity and stability of ferrous sulfide, etc. It is beneficial to large-scale popularization and use, and the preparation method is simple and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

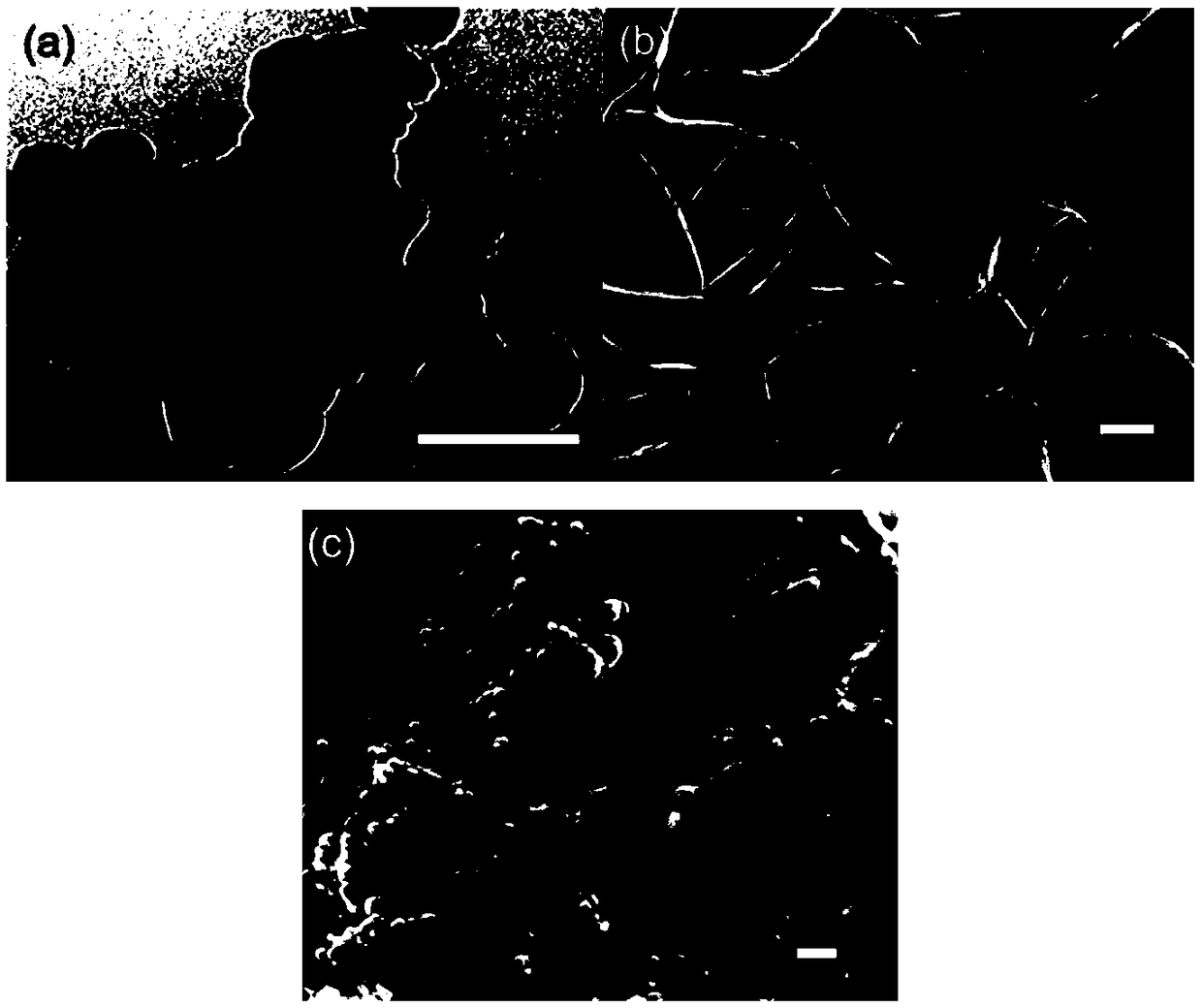

Image

Examples

Embodiment 1

[0032] (1) Deoxygenation treatment of pure water: put 600ml of pure water in the liquid storage bottle, and continuously feed nitrogen gas (500ml / min) for 15-30min to remove dissolved oxygen in the water;

[0033] (2) Utilize the pure water after deoxygenation in step (1) to prepare the ferrous salt solution of 0.043M;

[0034] (3) Utilize the pure water after deoxygenation in step (1) to prepare 0.085M sodium sulfide solution;

[0035] (4) Get 94ml of pure water in step (1), add 0.06g of magnesium hydroxide powder, and utilize ultrasound to disperse magnesium hydroxide in pure water while nitrogen (100ml / min), obtain magnesium hydroxide suspension ;

[0036] (5) under the protection of nitrogen (100ml / min), add ferrous salt solution 16ml that is prepared in step (2) to step (4) gained magnesium hydroxide suspension and mix;

[0037] (6) under the protection of nitrogen (100ml / min), add dropwise the sodium sulfide solution 8ml that is joined in step (3) in the mixed system o...

Embodiment 2

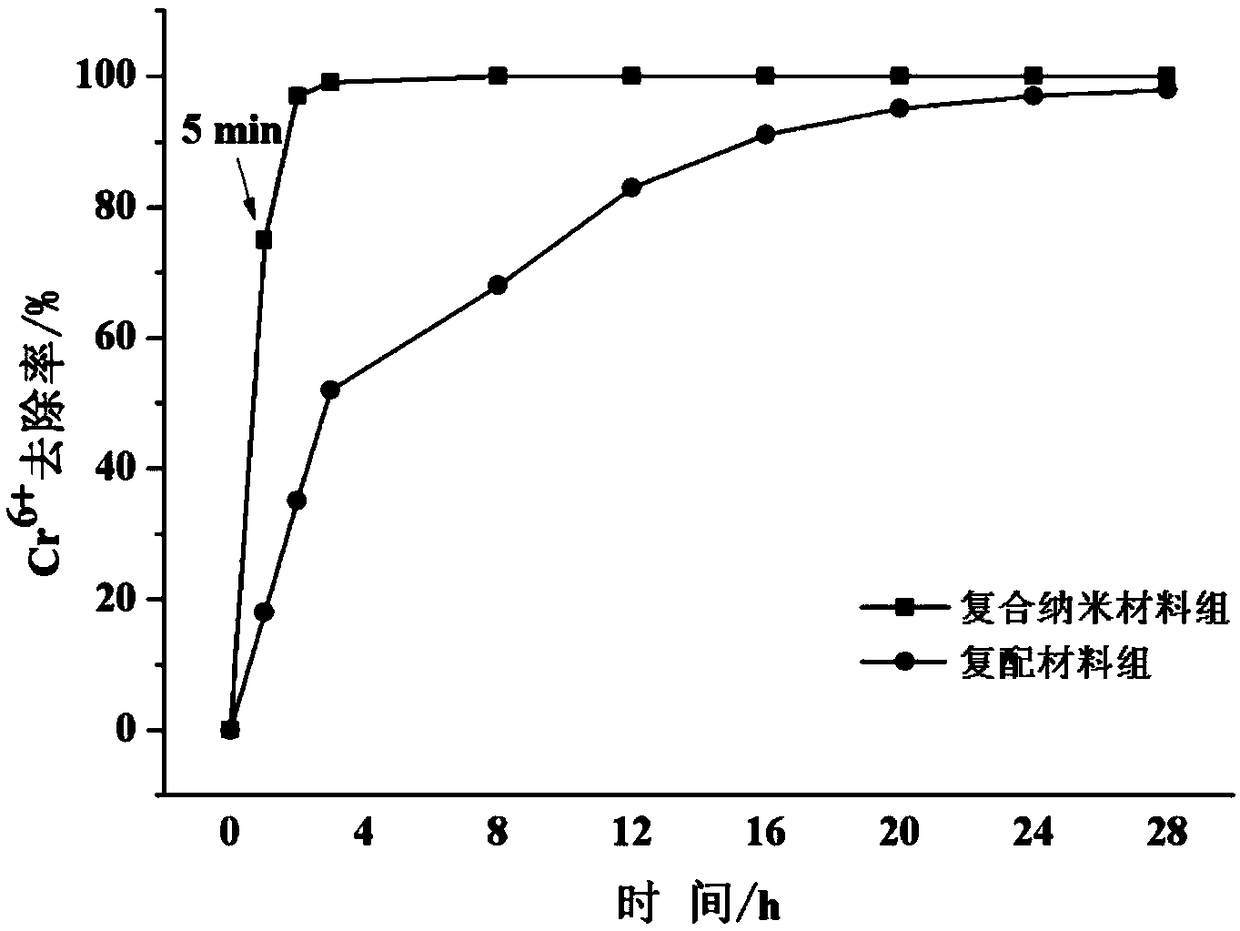

[0041] Gained magnesium hydroxide-ferrous sulfide composite nanomaterials removal experiment of hexavalent chromium in water:

[0042] (1) preparation of hexavalent chromium concentration is 100mg / L, the hexavalent chromium solution of pH=7;

[0043] (2) get the chromium solution prepared in step (1), be divided into three groups (composite nanomaterial group, composite material group, blank group), every group 100ml;

[0044] (3) Add the following materials respectively in the three groups of solutions prepared in step (2): the composite nanomaterial group adds the magnesium hydroxide-ferrous sulfide composite nanomaterial 80ml of embodiment 1 gained 1g / L; Add 40mg of magnesium hydroxide, 40mg of ferrous sulfide, and 80ml of pure water; add 80ml of pure water to the blank group;

[0045] (4) The reaction system in step (3) is sampled respectively at 5min, 30min, 1h, 6h, 8h, 24h, 48h, and 72h after the start of the reaction. Spectrophotometry" detects the concentration of he...

Embodiment 3

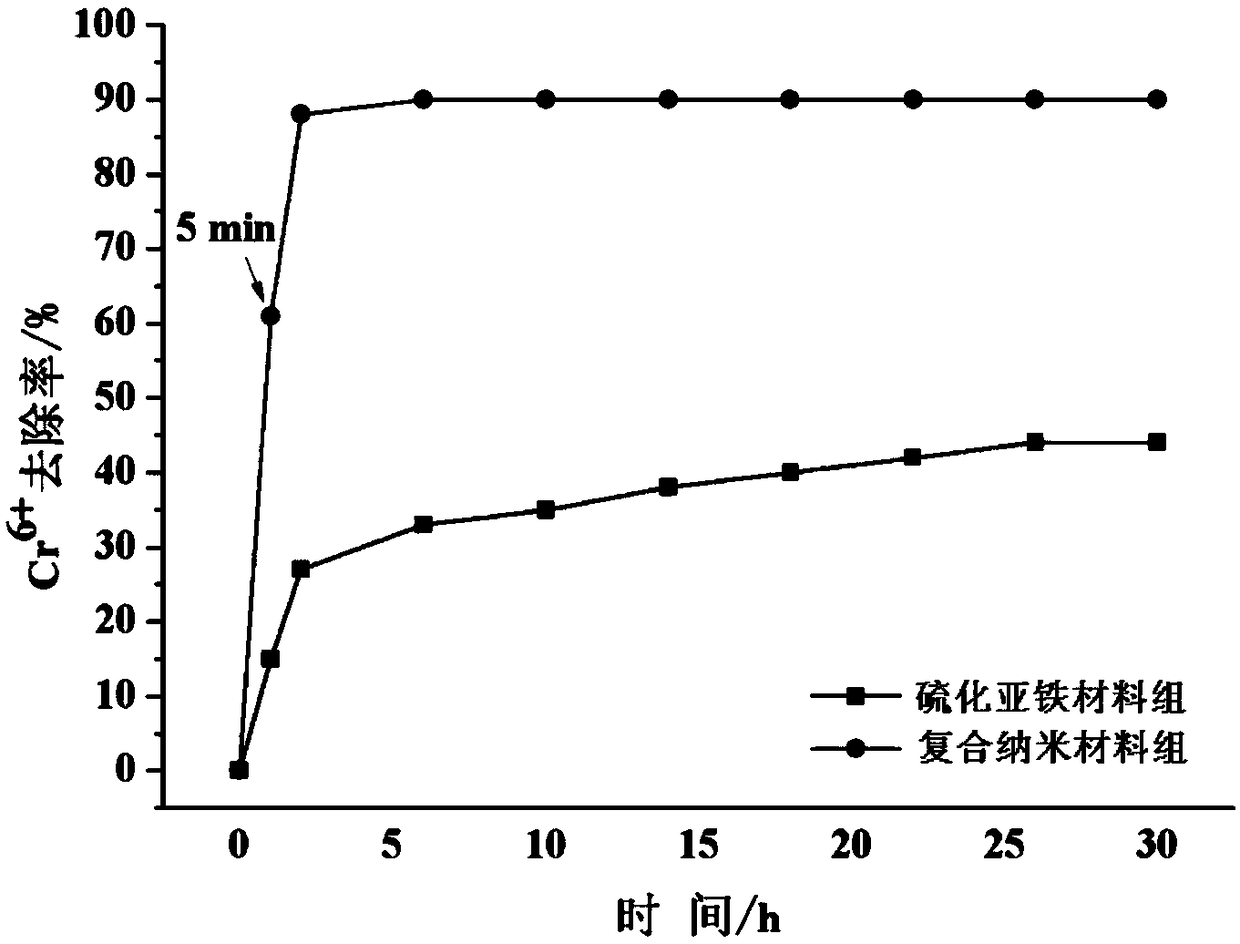

[0048] Gained magnesium hydroxide-ferrous sulfide composite nanomaterials removal experiment of hexavalent chromium in acidic water:

[0049](1) preparation of hexavalent chromium concentration is 100mg / L, the hexavalent chromium solution of pH=3;

[0050] (2) get the prepared chromium solution in step (1), be divided into three groups (composite nanomaterial group, ferrous sulfide material group, blank group), every group 100ml;

[0051] (3) Add the following materials respectively in the three groups of solutions prepared in step (2): the composite nanomaterial group adds the magnesium hydroxide-ferrous sulfide composite nanomaterial 80ml of embodiment 1 gained 1g / L; Ferrous sulfide material 40mg of ferrous sulfide and 80ml of pure water were added to the control group; 80ml of pure water was added to the blank group;

[0052] (4) The reaction system in step (3) is sampled respectively at 5min, 30min, 1h, 6h, 8h, 24h, 48h, and 72h after the start of the reaction. Spectroph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com