Pd/metal-organic framework compound catalyst as well as preparation method and application thereof

A technology of metal-organic frameworks and catalysts, applied in the field of catalysis, can solve the problems of not being universally applicable and time-consuming noble metal/MOFs composite catalysts, achieve high practical value and application prospects, facilitate large-scale promotion, and facilitate separation and treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Pd / MIL-100(Fe) Catalyst

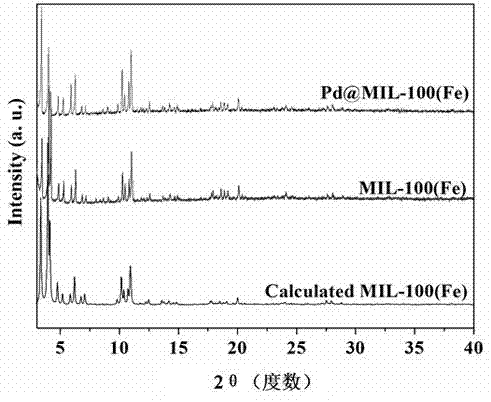

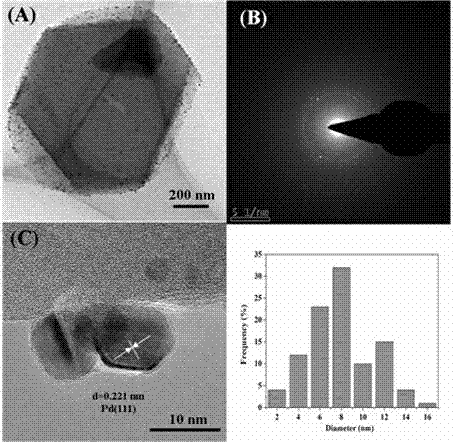

[0024] Mix 5 mL of ethanol, 5 mL of water, 0.333 g of polyvinylpyrrolidone, 294 μL of H 2 PdCl 4 (10 mg / mL) was mixed with 0.1 g carrier, stirred for 30 min to disperse evenly, and then refluxed at 90°C for 3 h. Finally, the obtained product was centrifuged, washed with deionized water to remove excess ions, and vacuum-dried at 60°C to obtain a Pd / MIL-100(Fe) composite material. figure 1 The XRD pattern of the Pd / MIL-100(Fe) catalyst synthesized by this preparation method is shown. figure 2 The transmission electron microscope image of the Pd / MIL-100(Fe) catalyst synthesized by this preparation method is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com