Preparation method for high-strength high-density isotropic impregnation silver carbon/graphite composite material

An isotropic, composite material technology, applied in the field of preparation of immersion silver graphite matrix material, can solve the problems of high manufacturing technical difficulty and high cost, achieve excellent electrochemical resistance, increased bulk density and flexural strength, high corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

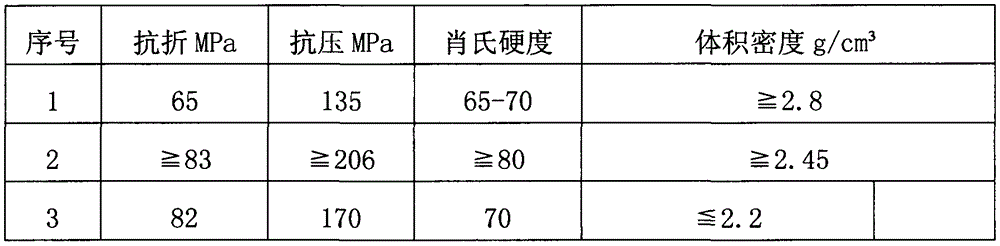

Examples

Embodiment 1

[0056] The first step: kneading of raw materials, kneading needle coke, pitch and catalyst evenly at a certain temperature (asphalt liquefaction temperature, ≯180°C), the best ratio of needle coke and pitch is 40:70, requiring needle coke Pre-crushing, the optimum particle size is 95% of the powder particle size <44μm, the external catalyst is boron carbide, the mass ratio is between 0.5% and 10%; the second step: secondary crushing, cooling the kneaded coke mixture , crushed into powder, the best crushing effect is 95% of the powder particle size <44μm;

[0057] The third step: forming and graphitization, the blank powder is formed by isostatic pressing, and then roasted, the roasting temperature is between 2600 and 3000 °C;

[0058] The fourth step: high-temperature purification, the product obtained by roasting is purified by halogen gas at 2200-2600 °C to remove impurities such as boron, and obtain high-purity and high-isotropy graphite. This embodiment does not require a...

Embodiment 2

[0060] Step 1: Mix raw materials, knead the binder and aggregate in a kneader (kneading temperature ≯ 150°C) at a ratio of (0.3-0.7): 1, and then pulverize to a powder with a particle size of <0.5mm. The binder is the lipid material of pitch, phenolic resin, furfural resin or epoxy resin, and the aggregate is natural microcrystalline graphite, graphite return material, petroleum coke, pitch coke, secondary coke, mesocarbon microspheres, etc. Natural microcrystalline graphite accounts for 30% to 100% of the mass of the aggregate, and the particle size of each aggregate is between 1 and 150 μm; it can also be carried out by using the following steps: first prepare the binder and the corresponding solvent to 5 to 70 wt% Binder solution, then prepare aggregate powder and binder solution at a ratio of 1: (0.5-0.1) to make a slurry, spray dry to obtain a powder with a particle size of <200 μmm, and the spray temperature ≥ the boiling point of the solution;

[0061] The second step: ...

Embodiment 3

[0064] The first step: raw material crushing, select Taixi anthracite raw coal powder with a degree of graphitization > 60%, and crush it, requiring more than 95% of the powder particle size to be ≤ 75 μm;

[0065] The second step: forming, using isostatic pressing, the forming pressure is 100-140Mpa;

[0066] The third step: one-time roasting, the green body is roasted at 800-1400°C, the heating rate is ≤3°C / h, the highest temperature is kept at 18-30°C, and the specific heating system; Stage 1: 100-350°C, heating rate: ≤2.5 ℃ / h, stage 2: 350~400℃, heating rate: ≤1℃ / h; stage 3: 400~500℃, heating rate: ≤0.7℃ / h; stage 4: 500~600℃, heating rate: ≤ 1°C / h; stage 5: 600~700°C, heating rate: ≤1.4°C / h; stage 6: 700~800°C, heating rate: ≤2°C / h; stage 7: 800~1100°C, heating rate: ≤3℃ / h;

[0067]The fourth step: impregnation, preheat the roasted compact to 330°C, then transfer it to a pressure-resistant container filled with coal tar pitch with a softening point of 150°C, and slowly h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com