Bonding agent applicable to copper foil cladding laminated board with full light shading performance

A technology of copper clad laminates and adhesives, applied in the field of electronic information, can solve problems such as accelerating the penetration rate of products, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Additive formula (calculated by weight):

[0046] Nigrosine microsilica powder acetone

[0047] 11 45 45

[0048] 2) Adhesive formula (by weight):

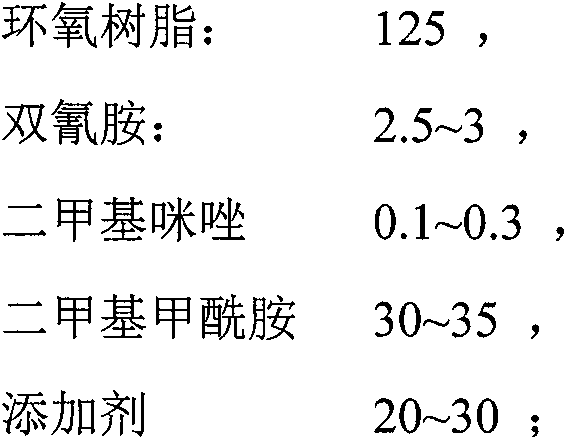

[0049] Resin Dicyandiamide Dimethylimidazole Dimethylformamide Additive

[0050] 125 2.5 0.2 30 25

[0051] 3) Gluing and drying:

[0052] Oven temperature setting: 150-210℃,

[0053] Gluing speed of prepreg: 12-15m / min.

[0054] 4) Control parameters of prepreg:

[0055] Gel time: 115sec Epoxy resin content: 42% (referring to the mass percentage of epoxy resin in the prepreg)

[0056] Resin fluidity: 20.5% volatile matter: 0.25%

[0057] 5) The number of layers of the sheet: 8 7628 prepregs (1.6mm)

[0058] 6) Pressure plate parameters:

[0059] Vacuum degree: -0.097MPa,

[0060] Pressure: 300-450psi,

[0061] Hot plate temperature: 135-220℃,

[0062] Curing time: 50min.

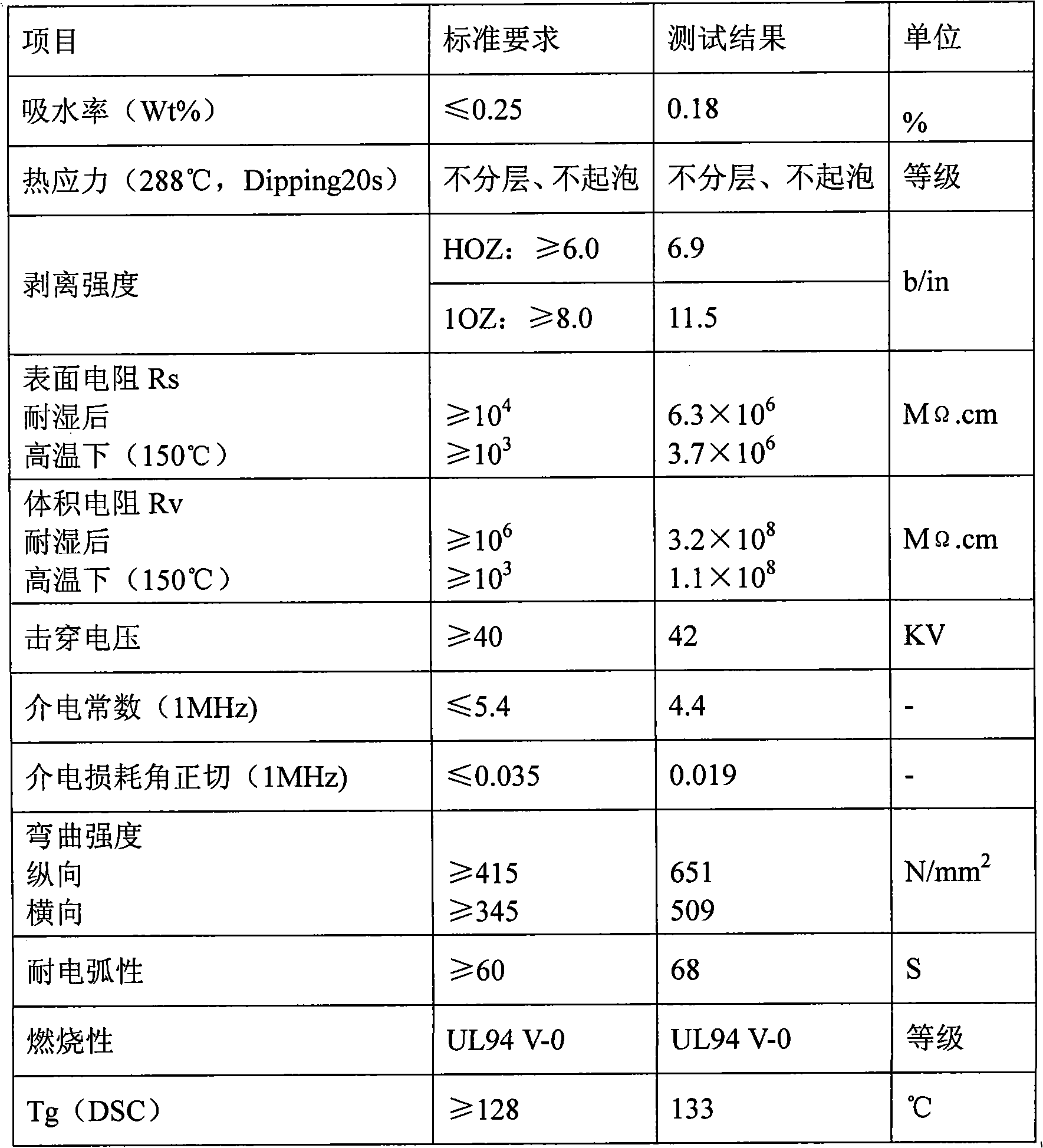

[0063] 7) Product substrate performance parameters

[0064]

Embodiment 2

[0066] 1) Additive formula (calculated by weight):

[0067] Nigrosine microsilica powder acetone

[0068] 12 45 45

[0069] 2) Glue adjustment formula (calculated by weight):

[0070] Resin Dicyandiamide Dimethylimidazole Dimethylformamide Additive

[0071] 125 2.5 0.2 35 20

[0072] 3) Gluing and drying:

[0073] Oven temperature setting: 150-210℃,

[0074] Gluing speed of prepreg: 12-15m / min.

[0075] 4) Control parameters of prepreg:

[0076] Gel time: 115sec Epoxy resin content: 45.0%

[0077] Resin fluidity: 20.5% volatile matter: 0.25%

[0078] 5) The number of layers of the sheet: 8 7628 prepregs (1.6mm)

[0079] 6) Pressure plate parameters:

[0080] Vacuum degree: -0.097Mpa,

[0081] Pressure: 300-450psi,

[0082] Hot plate temperature: 135-220℃,

[0083] Curing time: 50min.

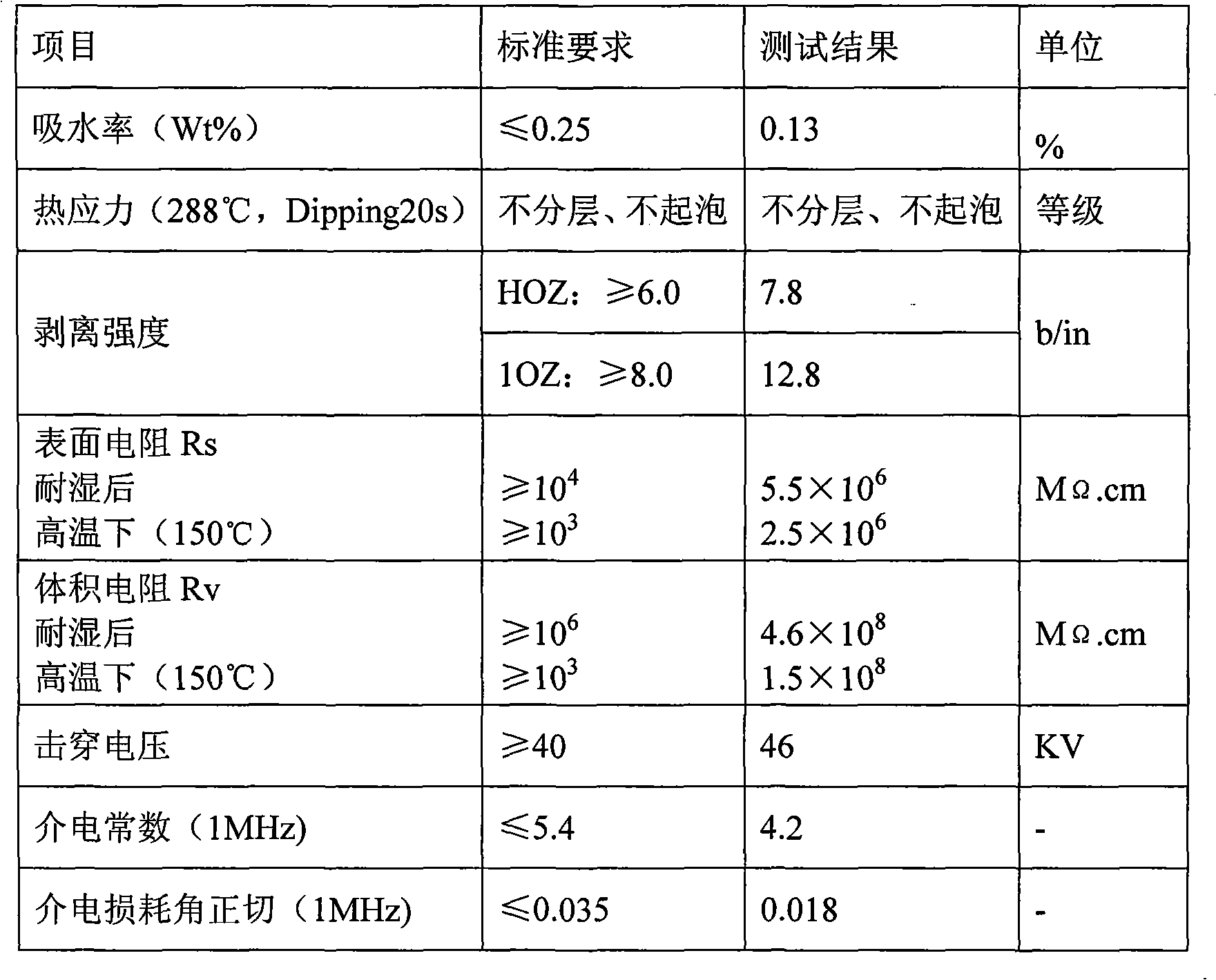

[0084] 7) Product substrate performance parameters

[0085]

[0086]

Embodiment 3

[0088] 1) Additive formula (calculated by weight):

[0089] Nigrosine microsilica powder acetone

[0090] 11 40 40

[0091] 2) Glue adjustment formula (calculated by weight):

[0092] Resin Dicyandiamide Dimethylimidazole Dimethylformamide Additive

[0093] 125 3 0.3 30 30

[0094] 3) Gluing and drying:

[0095] Oven temperature setting: 150-210℃,

[0096] Gluing speed of prepreg: 12-15m / min.

[0097] 4) Control parameters of prepreg:

[0098] Gel time: 115sec Epoxy resin content: 45.0%

[0099] Resin fluidity: 20.5% volatile matter: 0.25%

[0100] 5) The number of layers of the sheet: 8 7628 prepregs (1.6mm)

[0101] 6) Pressure plate parameters:

[0102] Vacuum degree: -0.097Mpa,

[0103] Pressure: 300-450psi,

[0104] Hot plate temperature: 135-220℃,

[0105] Curing time: 50min.

[0106] 7) Product substrate performance parameters

[0107]

[0108]

[0109] This epoxy glass cloth based copper clad laminate substrate has a light transmittance of <0.1% in the visible light region, and has excellent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com