Common Tg lead-free copper clad laminate and preparation method thereof

A copper clad laminate and common technology are applied in the field of common Tg lead-free epoxy glass cloth-based copper clad laminate and its preparation, which can solve the problems of inability to reduce the cost of raw materials, and achieve good machinability, low water absorption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

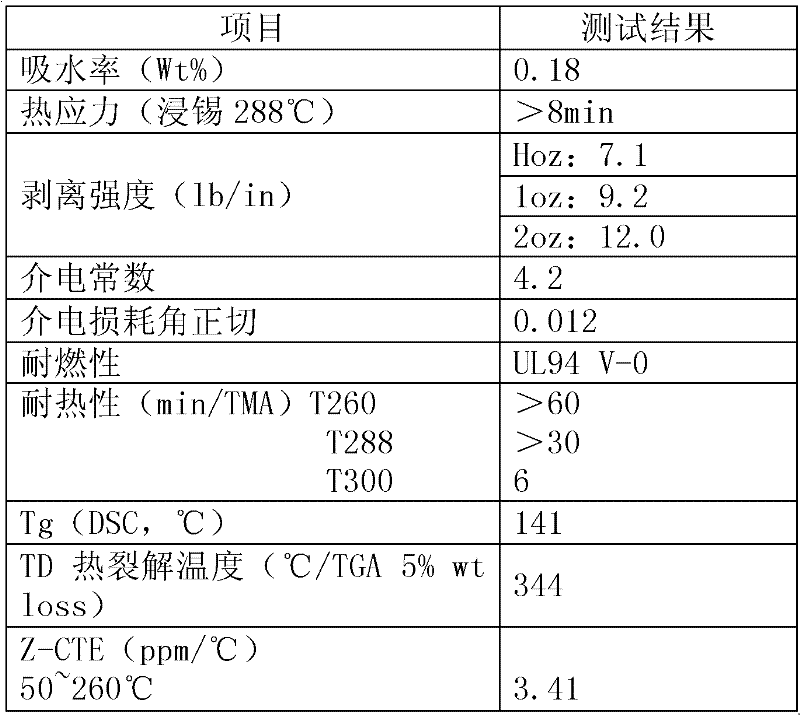

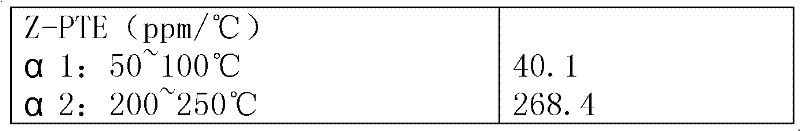

Examples

Embodiment 1

[0047] 1. Proportion of glue mixing formula (by weight):

[0048] Formula formula ratio (mass ratio)

[0049] Brominated modified epoxy resin 47.912%,

[0050] Phenolic curing agent 15%,

[0051] Dimethylimidazole 0.008%,

[0052] Microsilica 10%,

[0053] Aluminum hydroxide 4%,

[0054] Silane 0.08%,

[0055] Propylene Glycol Methyl Ether 23%.

[0056] 2. Preparation process:

[0057] 1> Glue adjustment:

[0058] A. Add propylene glycol methyl ether and silane sequentially into the mixing tank according to the formula amount, turn on the high-speed stirrer, control the speed at 1500 rpm, keep stirring continuously and control the tank temperature at 45°C, then add silicon micropowder and aluminum hydroxide, Continue stirring for 60 minutes after adding;

[0059]B. Add brominated modified epoxy resin and phenolic curing agent in sequence according to the formula in the stirring tank, stir for 40 minutes at a speed of 1500 rpm, and simultaneously start the cooling wate...

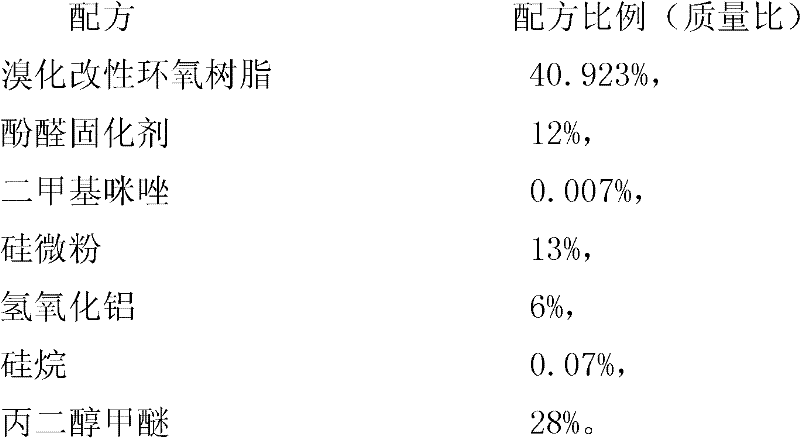

Embodiment 2

[0084] 1. Proportion of glue mixing formula (by weight):

[0085] Formula formula ratio (mass ratio)

[0086] Brominated modified epoxy resin 40.923%,

[0087] Phenolic curing agent 12%,

[0088] Dimethylimidazole 0.007%,

[0089] Microsilica 13%,

[0090] Aluminum hydroxide 6%,

[0091] Silane 0.07%,

[0092] Propylene Glycol Methyl Ether 28%.

[0093]

[0094] 2. Preparation process:

[0095] 1> Glue adjustment:

[0096] A. Add propylene glycol methyl ether and silane sequentially into the mixing tank according to the formula amount, turn on the high-speed stirrer, control the speed at 1500 rpm, keep stirring continuously and control the tank temperature at 45°C, then add silicon micropowder and aluminum hydroxide, Continue stirring for 60 minutes after adding;

[0097] B. Add brominated modified epoxy resin and phenolic curing agent in sequence according to the formula in the stirring tank, stir for 40 minutes at a speed of 1500 rpm, and simultaneously start the...

Embodiment 3

[0121] 1. Proportion of glue mixing formula (by weight):

[0122] Formula formula ratio (mass ratio)

[0123] Brominated modified epoxy resin 50.93%;

[0124] Phenolic curing agent 18%;

[0125] Dimethylimidazole 0.010%;

[0126] Silica powder 10%;

[0127] Aluminum hydroxide 3%;

[0128] Silane 0.06%;

[0129] Propylene Glycol Methyl Ether 18%.

[0130] 2. Preparation process:

[0131] 1> Glue adjustment:

[0132] A. Add propylene glycol methyl ether and silane sequentially into the mixing tank according to the formula amount, turn on the high-speed stirrer, control the speed at 1500 rpm, keep stirring continuously and control the tank temperature at 45°C, then add silicon micropowder and aluminum hydroxide, Continue stirring for 60 minutes after adding;

[0133] B. Add brominated modified epoxy resin and phenolic curing agent in sequence according to the formula amount in the stirring tank, stir at a speed of 1500 rpm for 40 minutes, and at the same time turn on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com