Iron and copper ferrous sulfide loading composite material, preparation method and application thereof

A composite material, ferrous sulfide technology, applied in the field of environmental remediation, can solve the problems of too fast formation of passivation layer, low utilization rate of zero-valent iron, low reaction selectivity of zero-valent iron, etc., so as to improve the reaction activity and improve the utilization rate efficiency, improving the reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

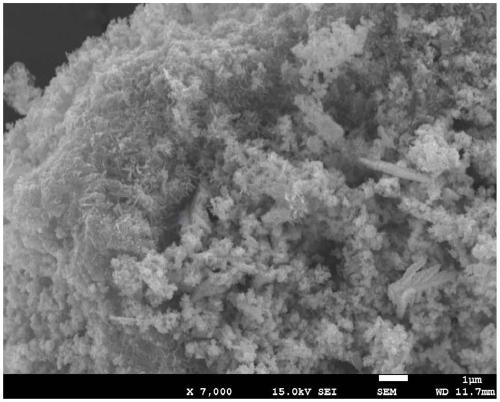

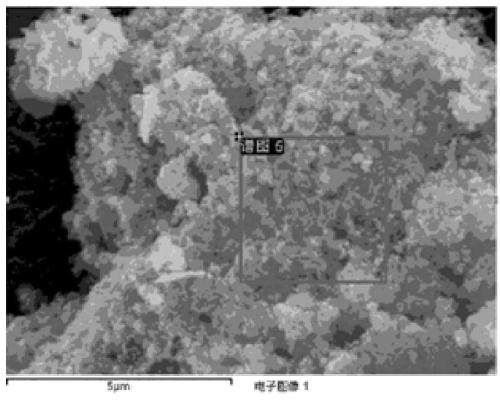

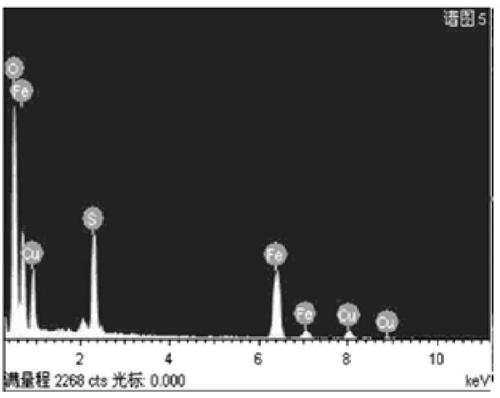

[0068] This embodiment provides a method for preparing an iron-copper bimetallic loaded ferrous sulfide composite material, the method comprising the following steps:

[0069](1) Prepare 200 mL of acetic acid-sodium acetate buffer solution with pH=6, and add 0.4 mmol of copper chloride, and mix well;

[0070] (2) Use nitrogen purging to remove the dissolved oxygen of the solution in step (1), and use a film seal;

[0071] (3) Add 1 g of micron-sized iron powder with a size of 400 mesh and a purity of 98% to the solution described in step (2), and fully undergo a displacement reaction in a water-bath shaker at a temperature of 25° C. and a rotation speed of 200 rpm for 30 minutes;

[0072] (4) Add the Na of 0.5mol / L of 2mL in the solution after the reaction described in step (3) 2 S solution, after fully reacting for 8 hours, vacuum filter with a 0.22 μm water filter membrane to obtain a filter residue, and finally vacuum freeze-dry to obtain an iron-copper bimetallic loaded f...

Embodiment 2

[0076] This embodiment provides a method for preparing an iron-copper bimetallic loaded ferrous sulfide composite material, the method comprising the following steps:

[0077] (1) Prepare 200 mL of acetic acid-sodium acetate buffer solution with pH=6, and add 0.8 mmol of copper chloride, and mix well;

[0078] (2) Use nitrogen purging to remove the dissolved oxygen of the solution in step (1), and use a film seal;

[0079] (3) Add 1 g of micron-sized iron powder with a size of 400 mesh and a purity of 98% to the solution described in step (2), and fully undergo a displacement reaction in a water-bath shaker at a temperature of 25° C. and a rotation speed of 200 rpm for 30 minutes;

[0080] (4) Add the Na of 0.5mol / L of 2mL in the solution after the reaction described in step (3) 2 S solution, after fully reacting for 6 hours, vacuum filter with a 0.22 μm water filter membrane to obtain a filter residue, and finally vacuum freeze-dry to obtain an iron-copper bimetallic loaded ...

Embodiment 3

[0085] This embodiment provides a method for preparing an iron-copper bimetallic loaded ferrous sulfide composite material, the method comprising the following steps:

[0086] (1) Prepare 200 mL of acetic acid-sodium acetate buffer solution with pH=6, and add 1.2 mmol of copper chloride, and mix well;

[0087] (2) Use nitrogen purging to remove the dissolved oxygen of the solution in step (1), and use a film seal;

[0088] (3) Add 1 g of micron-sized iron powder with a size of 400 mesh and a purity of 98% to the solution described in step (2), and fully undergo a displacement reaction in a water-bath shaker at a temperature of 25° C. and a rotation speed of 200 rpm for 30 minutes;

[0089] (4) Add the Na of 0.5mol / L of 2mL in the solution after the reaction described in step (3) 2 S solution, after fully reacting for 6 hours, vacuum filter with a 0.22 μm water filter membrane to obtain a filter residue, and finally vacuum freeze-dry to obtain an iron-copper bimetallic loaded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com