Sulfonated iron-copper bimetal composite material as well as preparation method and application thereof

A composite material, sulfonated iron-copper technology, applied in the field of environmental remediation, can solve the problems of reduced selectivity of zero-valent iron reaction, low processing efficiency, too fast formation of passivation layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

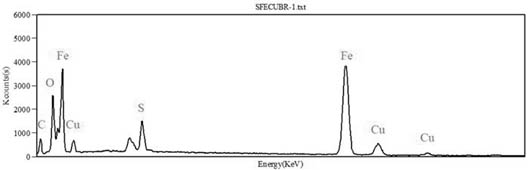

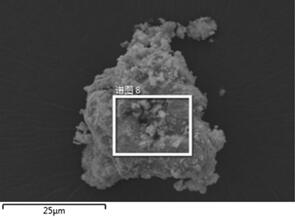

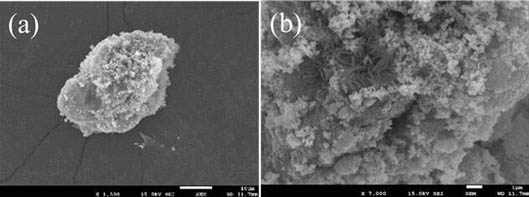

Image

Examples

Embodiment 1

[0063] This embodiment provides a preparation method of a sulfonated iron-copper bimetallic composite material, and its specific preparation method is:

[0064] (1) Prepare 200ml of 2mmol / L copper salt solution, use inert gas helium to purge to remove dissolved oxygen in the solution, and seal the solution system;

[0065] (2) Add 1 g of micron-sized iron powder to the system in step (1), and heat it in a water bath shaker for 30 minutes at a temperature of 25 ~ 30 °C and a stirring speed of 200 rpm;

[0066] (3) Vacuum filter the mixed solution after the reaction described in step (2) using a 0.22 μm water-based filter membrane to obtain a filter residue, which is vacuum freeze-dried to obtain an iron-copper bimetallic material;

[0067] (4) Configure pH = 6 acetic acid buffer solution, and pass inert gas argon to remove dissolved oxygen in the solution, and seal the solution system;

[0068] (5) Add 0.5g of the iron-copper bimetal produced in step (3) to the system in step ...

Embodiment 2

[0073] This embodiment provides a preparation method of a sulfonated iron-copper bimetallic composite material, and its specific preparation method is:

[0074] (1) Prepare 200ml of 6mmol / L copper salt solution, purge with inert gas argon to remove dissolved oxygen in the solution, and seal the solution system;

[0075] (2) Add 1 g of micron-sized iron powder to the system in step (1), and heat it in a water bath shaker for 30 minutes at a temperature of 25 ~ 30 °C and a stirring speed of 200 rpm;

[0076] (3) Vacuum filter the mixed solution after the reaction described in step (2) using a 0.22 μm water-based filter membrane to obtain a filter residue, which is then dried to obtain an iron-copper bimetallic material;

[0077] (4) Configure pH = 6 acetic acid buffer solution, and pass inert gas nitrogen to remove dissolved oxygen in the solution, and seal the solution system;

[0078] (5) Add 0.5g of the iron-copper bimetal produced in step (3) to the system in step (4), and ...

Embodiment 3

[0082] This embodiment provides a preparation method of a sulfonated iron-copper bimetallic composite material, and its specific preparation method is:

[0083] (1) Prepare 200ml of 8mmol / L copper salt solution, purge with inert gas nitrogen to remove dissolved oxygen in the solution, and seal the solution system;

[0084] (2) Add 1 g of micron-sized iron powder to the system in step (1), and heat it in a water bath shaker for 30 minutes at a temperature of 25 ~ 30 °C and a stirring speed of 200 rpm;

[0085] (3) Vacuum filter the mixed solution after the reaction described in step (2) using a 0.22 μm water-based filter membrane to obtain a filter residue, which is then dried to obtain an iron-copper bimetallic material;

[0086] (4) Configure pH = 6 acetic acid buffer solution, and pass inert gas helium to remove dissolved oxygen in the solution, and seal the solution system;

[0087] (5) Add 0.5g of the iron-copper bimetal produced in step (3) to the system in step (4), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com