A preparation method of a flexible composite material, an aqueous nickel-iron battery electrode comprising the flexible composite material, and a battery

A composite material and flexible technology, applied in battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of unsatisfactory electrochemical performance and uneven dispersion, so as to improve the rate performance, energy density and structure The effect of stability and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]After detailed description of the embodiments of the present invention by way of examples below in conjunction with the accompanying drawings, other features, characteristics and advantages of the present invention will be more apparent.

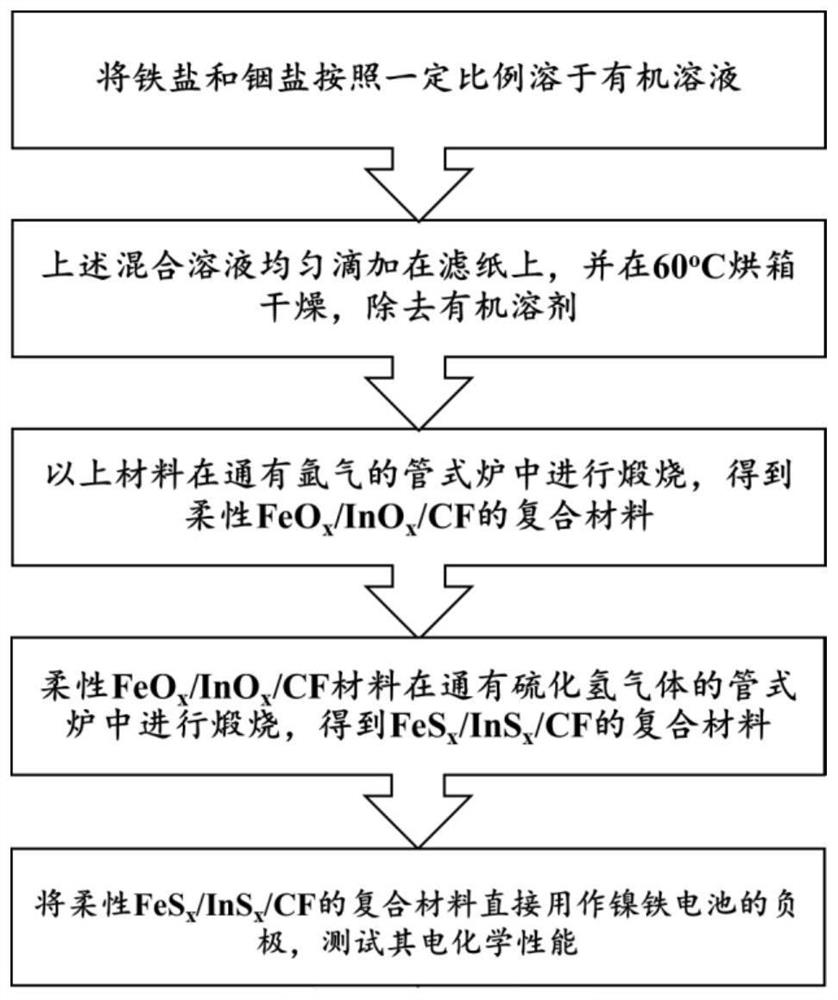

[0024]figure 1Preparation of flexible FeS provided by embodiments of the present inventionx / InSx / CF composite method flow diagram. Such asfigure 1As shown, the embodiment of the present invention provides the preparation of flexible FeSx / InSx / CF composite material method, where 0

[0025]Step 1: Dissolve iron acetylacetonate and indium acetylacetonate in an organic solvent;

[0026]In one embodiment, iron acetylacetonate and indium acetylacetonate are dissolved in an organic solvent in a molar ratio of 90:10, 85:15 or 80:20. Ethanol is used as the organic solvent.

[0027]Step 2: Drop the above mixed solution onto the carbon fiber and dry it in a 60 degree oven to remove the organic solvent;

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com