Oxide anode material and preparation process for cathodic protection and restoration of offshore platforms

A cathodic protection and anode material technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problem of insufficient stability of oxide anode and short service life, etc. problem, to achieve the effect of anti-polarization performance and stability improvement, improved service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

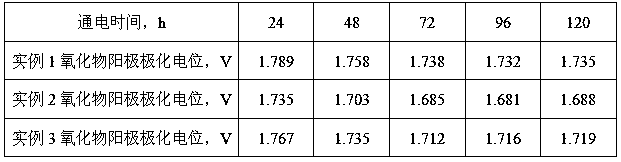

Examples

Embodiment

[0033] (1) Pretreatment of the substrate

[0034] Industrial pure titanium is selected as the base material of the oxide anode. The shape of the base material is plate-shaped and the size is 200×100mm. Sandblasting is performed on the base to increase the surface roughness; The alkali washing solution is kept warm for 1 hour to remove surface oil. Alkaline washing solution is 8% NaOH, Na 3 PO 4 and Na 2 CO 3 Mixture, where NaOH: Na 3 PO 4 : Na 2 CO 3 =4:45:65 (mass ratio); place the degreased titanium substrate in a boiling oxalic acid solution with a mass percentage of 20-25% for etching for 1-4 hours, wash it with deionized water after etching, and place it in ethanol stored in solution.

[0035] (2) Ir-Nb-Rh coating solution configuration

[0036] Dissolve a certain amount of chloroiridic acid, niobium pentachloride, and rhodium chloride in n-butanol. The atomic percentages of Ir, Nb, and Rh are shown in Table 1. Add 10ml of hydrochloric acid to every 100ml of coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com