A method for advanced treatment of printing and dyeing chemical comprehensive wastewater

An advanced treatment and comprehensive wastewater technology, applied in the field of environmental pollution treatment, can solve the problems of fast consumption rate, membrane fouling concentrate, high investment and operation costs, etc., and achieve efficient removal and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

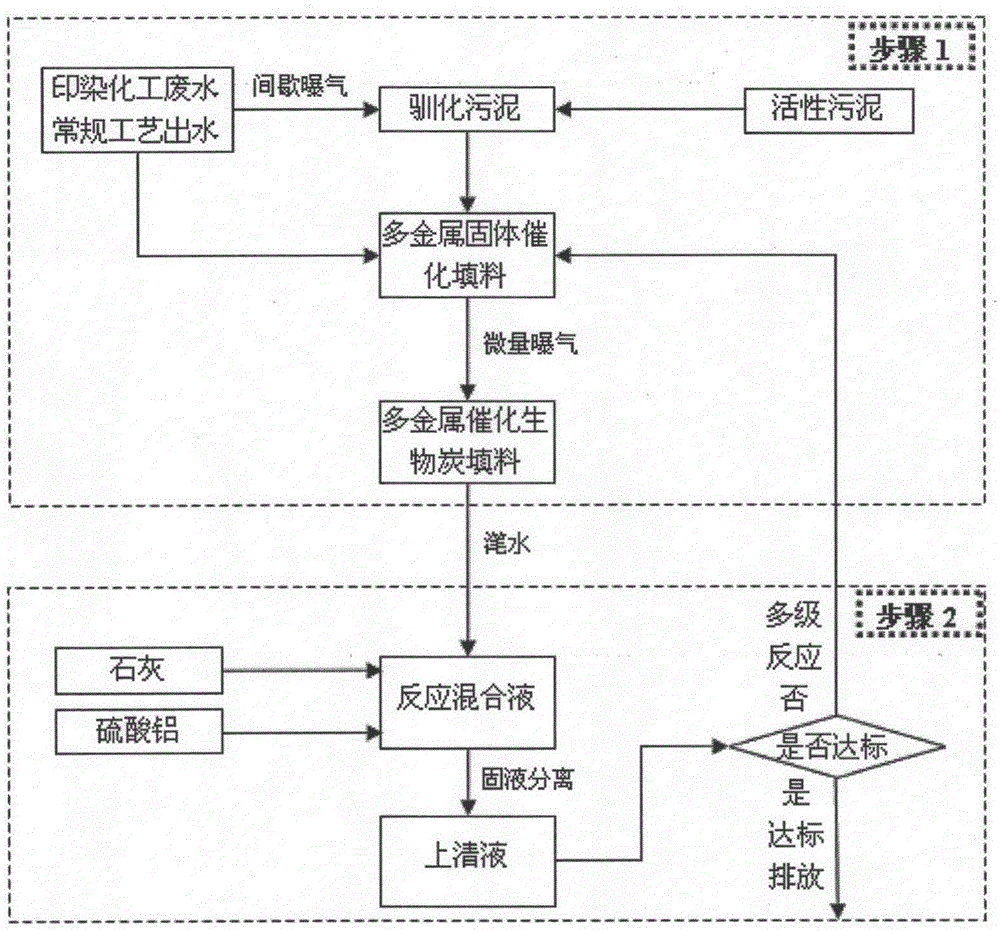

[0030] A method for advanced treatment of printing and dyeing chemical comprehensive wastewater, the process of which is as follows figure 1 Shown:

[0031] (1) Take 200mL of sludge from urban domestic sewage plants (TSS content is 8g / L, VSS / TSS is 0.68), and 400mL of conventional process effluent of printing and dyeing chemical wastewater (COD is 120mg / L, ammonia nitrogen is 20mg / L, SS is 40mg / L) mixed. Suspended, stirred and aerated for 4h. After the aeration, the facultative anaerobic stirring was continued for 16 hours, and then the aeration was continued for 8 hours, and this cycle was repeated for 3 days. After gravity concentration, the lower acclimatized sludge is obtained. Take 50mL of domesticated sludge and put it into the aeration reactor (effective volume 2L) containing the effluent (1L) of the conventional process of printing and dyeing chemical wastewater at 5%, and add polymetallic solid catalytic filler. Aerate for 6 hours, and control the dissolved oxyge...

Embodiment 2

[0035] A method for advanced treatment of printing and dyeing chemical comprehensive wastewater, the process of which is as follows figure 1 Shown:

[0036](1) Take 200mL of sludge from urban domestic sewage plants (TSS content is 12g / L, VSS / TSS is 0.68), and 200mL of conventional process effluent of printing and dyeing chemical wastewater (COD is 200mg / L, ammonia nitrogen is 60mg / L, SS is 60mg / L) mixed. Suspended, stirred and aerated for 8h. After the aeration, the facultative anaerobic stirring was continued for 8 hours, and then the aeration was continued for 8 hours, and this cycle was repeated for 5 days. After gravity concentration, the lower acclimatized sludge is obtained. Take 200mL of domesticated sludge and put it into the aeration reactor (effective volume 2L) containing the effluent (1L) of the conventional process of printing and dyeing chemical wastewater at 20%, and add polymetallic solid catalytic filler. Aerated for 10 hours, the dissolved oxygen was con...

Embodiment 3

[0040] A method for advanced treatment of printing and dyeing chemical comprehensive wastewater, the process of which is as follows figure 1 Shown:

[0041] (1) Take 200mL of sludge from urban domestic sewage plants (TSS content is 12g / L, VSS / TSS is 0.68), and 300mL of conventional process effluent of printing and dyeing chemical wastewater (COD is 160mg / L, ammonia nitrogen is 35mg / L, SS is 50mg / L) mixed. Suspended, stirred and aerated for 6h. After the aeration, the facultative anaerobic stirring was continued for 12 hours, and then the aeration was continued for 6 hours, and this cycle was repeated for 4 days. After gravity concentration, the lower acclimatized sludge was obtained. Take 50mL of concentrated sludge and insert it into an aeration reactor (effective volume 2L) containing effluent (1L) from the conventional process of printing and dyeing chemical wastewater at 5%, and add multi-metallic solid catalytic filler. Aerated for 8 hours, the dissolved oxygen was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com