Method for treating dye wastewater by using modified fly ash

A dye wastewater and fly ash technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve problems such as environmental pollution, high toxicity of dye components, and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

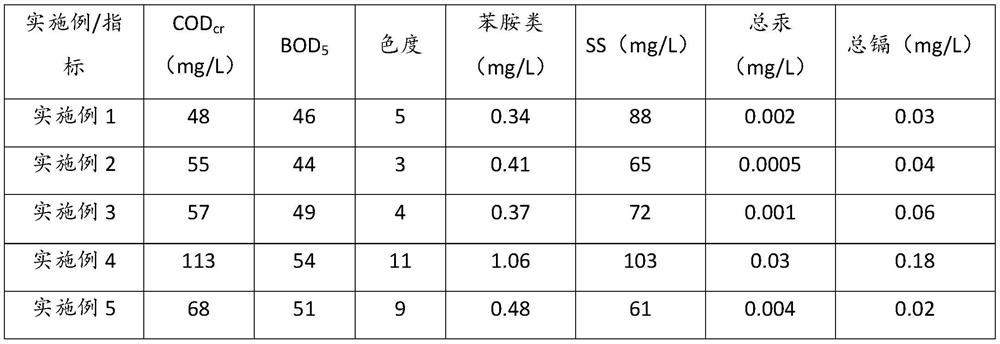

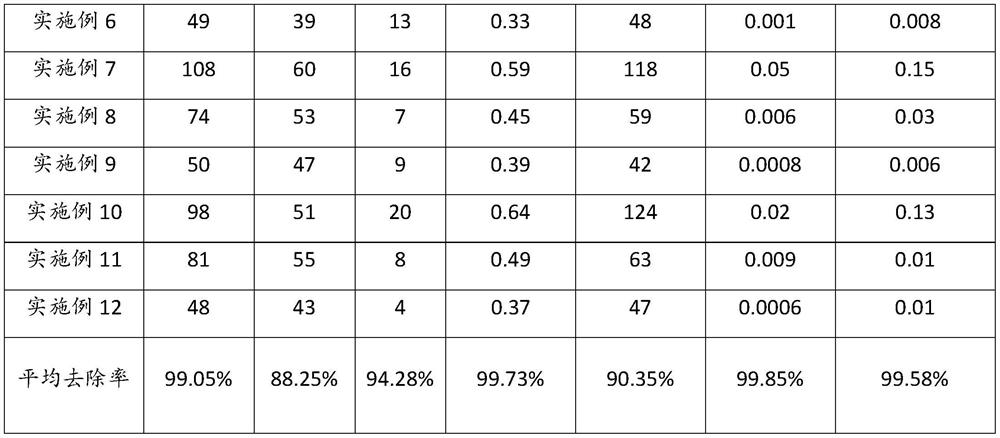

Examples

Embodiment 1

[0029] A method of utilizing modified fly ash to treat dye wastewater, comprising the following steps:

[0030] S1, fly ash modification: take 30g of fly ash, 10g of corn straw biochar, 10g of wheat straw biochar, 20g of sludge activated carbon, and 35g of calcium oxide, mix and roast at 600°C for 4h to obtain a fly ash mixture. Then add 210ml of hydrochloric acid with a mass fraction of 40% to wet the fly ash mixture and stir for 30 minutes to obtain modified fly ash;

[0031] The preparation process of the sludge activated carbon is as follows: take sludge from an urban sewage plant, add 4mol / L zinc chloride solution, stir for 3 hours, and then roast at 500°C for 2 hours to obtain sludge activated carbon;

[0032] The consumption ratio of described urban sewage plant sludge and described zinc chloride solution is 1g: 3ml;

[0033] S2. Preparation of white rot fungus mycelium dry powder: activate the white rot fungus strain, inoculate it in a white rot fungal culture medium ...

Embodiment 2

[0038] A method of utilizing modified fly ash to treat dye wastewater, comprising the following steps:

[0039] S1, Fly ash modification: take 30g of fly ash, 10g of corn straw biochar, 10g of wheat straw biochar, 20g of sludge activated carbon, and 30g of calcium oxide, mix and roast at 500°C for 2h to obtain a fly ash mixture. Then add 100ml of hydrochloric acid with a mass fraction of 30% to wet the fly ash mixture and stir for 20 minutes to obtain modified fly ash;

[0040] The preparation process of the sludge activated carbon is as follows: take sludge from an urban sewage plant, add 5mol / L zinc chloride solution, stir for 2.5 hours, and then roast at 550°C for 1 hour to obtain sludge activated carbon;

[0041] The consumption ratio of described urban sewage plant sludge and described zinc chloride solution is 1g:2ml;

[0042] S2. Preparation of white rot fungus mycelium dry powder: activate the white rot fungus strain, inoculate it in the white rot fungus culture mediu...

Embodiment 3

[0047] A method of utilizing modified fly ash to treat dye wastewater, comprising the following steps:

[0048]S1, Fly ash modification: Take 30g of fly ash, 10g of corn straw biochar, 10g of wheat straw biochar, 20g of sludge activated carbon, and 40g of calcium oxide, mix and roast at 750°C for 6h to obtain a fly ash mixture. Then add 330ml of hydrochloric acid with a mass fraction of 50% to wet the fly ash mixture and stir for 40min to obtain modified fly ash;

[0049] The preparation process of the sludge activated carbon is as follows: take sludge from an urban sewage plant, add 5mol / L zinc chloride solution, stir for 3.5 hours, and then roast at 600°C for 3 hours to obtain sludge activated carbon;

[0050] The consumption ratio of described urban sewage plant sludge and described zinc chloride solution is 1g: 4ml;

[0051] S2. Preparation of white rot fungus mycelium dry powder: activate the white rot fungus strain, inoculate it in a white rot fungus culture medium for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com