Method for extracting algae iodine by using calcium ion sedimentation and produced alginate using same

A technology of seaweed iodine salt and seaweed iodine, which is applied in chemical instruments and methods, food science, inorganic chemistry, etc., can solve the problems of high heavy metal content, complex seaweed iodine process, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1 Materials and methods

[0027] 1.1 Materials

[0028] Edible kelp, like dried kelp, was purchased from the Mawangdui Aquatic Products Market in Changsha. The place of origin is unknown.

[0029] Reagent: Na 2 CO 3 Glycerol (Glycerin) Ca(OH) 2 KCO 3 Commercially available bromine water 20% sodium formate KI 0.5% starch solution 0.002M / L Na 2 S 2 o 3

[0030] 1.2 Instruments

[0031] Constant temperature box rotary evaporator 1000ml measuring cylinder 250ml volumetric bottle scissors pipette 1000w electric furnace 500ml iodine measuring bottle muffle furnace

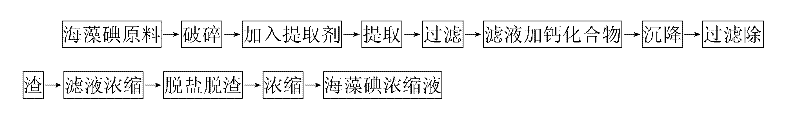

[0032] 1.3 Experimental process, see appendix figure 1 .

[0033] 2 Experimental results

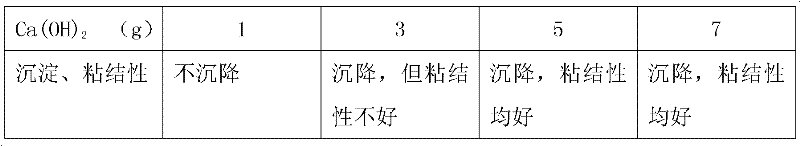

[0034] 2.1 Only add extractant without adding Ca(OH) 2 Settlement control experiment:

[0035] Experimental conditions: shredded kelp 50g

[0036] water 1000ml

[0037] Extraction temperature 50°C

[0038] time 12h

[0039] Glycerin 5g

[0040] Add 4g Na 2 C...

Embodiment 2

[0108] Get 50g of sea-tangle, break 1-2cm, add 5g glycerin, 4g sodium carbonate (Na 2 CO 3 ) mixed and extracted for 12h to obtain the filtrate, in which 5g of calcium hydroxide (Ca(OH) 2 ) to settle, to get the clear liquid, concentrate, then centrifuge to remove the residue and salt crystals of the concentrated solution, adjust the iodine content of the concentrated solution, neutralize, and promptly get the seaweed iodine solution that can be sprayed with iodine for 3% iodine content .

[0109] Utilize the spray equipment in the production line to spray the 3% seaweed iodine concentrate obtained by the above-mentioned enzymolysis method in the iodine-free salt evenly by the weight ratio of 1000: 1.5 iodine-free salt and seaweed iodine concentrate in the process, stir evenly, Then it is subpackaged into small packages of 200g, 400g, 500g, and 1000g.

Embodiment 3

[0111] Get 50g of sea-tangle, break 1-2cm, add 5g glycerin, 4g sodium carbonate (Na 2 CO 3 ) mixed and extracted for 12h to obtain the filtrate, in which 5g of calcium hydroxide (Ca(OH) 2 ) to settle, to obtain the clear liquid, concentrate, then centrifuge to remove the residue and salt crystals of the concentrated solution, adjust the iodine content of the concentrated solution, neutralize, and promptly get the seaweed iodine solution that can be sprayed with iodine and iodine with an iodine content of 2%. , adding seaweed polysaccharide to the seaweed iodine solution, stirring, drying and dehydrating, granulating to obtain the finished seaweed iodine crystal, and packing.

[0112] Fully mix 100kg of iodine-free salt with seaweed iodine crystals with an iodine content of 1%, so that the iodine content of the mixture reaches 0.012%-0.03% (weight ratio) to obtain iodine-containing mother salt, and then mix the mother salt with non-iodine salt in the machine cone Mix and mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com