Method for extracting algae iodine by using aluminum ion secondary sedimentation and produced algae iodine salt using same

A technology of seaweed iodized salt and seaweed iodine, applied in chemical instruments and methods, food science, inorganic chemistry, etc., can solve the problems of large loss of organic iodine, large residual amount, difficult removal of heavy metals, etc., and achieves high removal rate and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

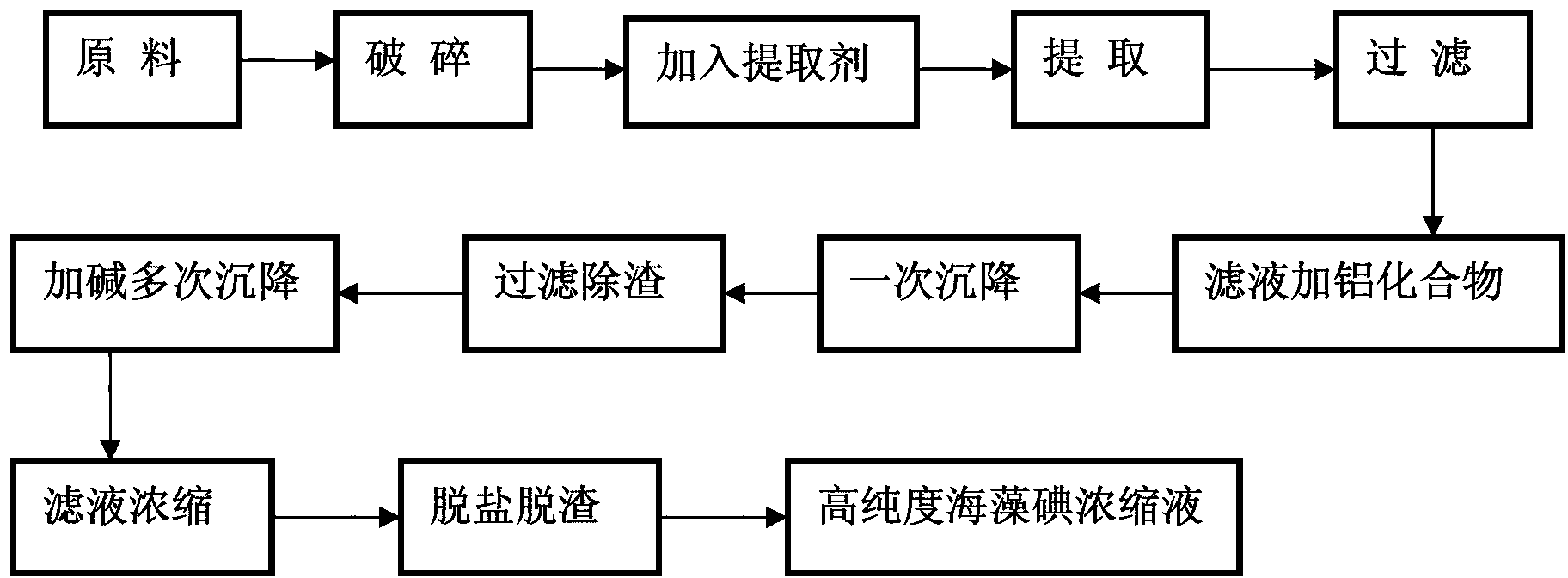

Method used

Image

Examples

Embodiment 1

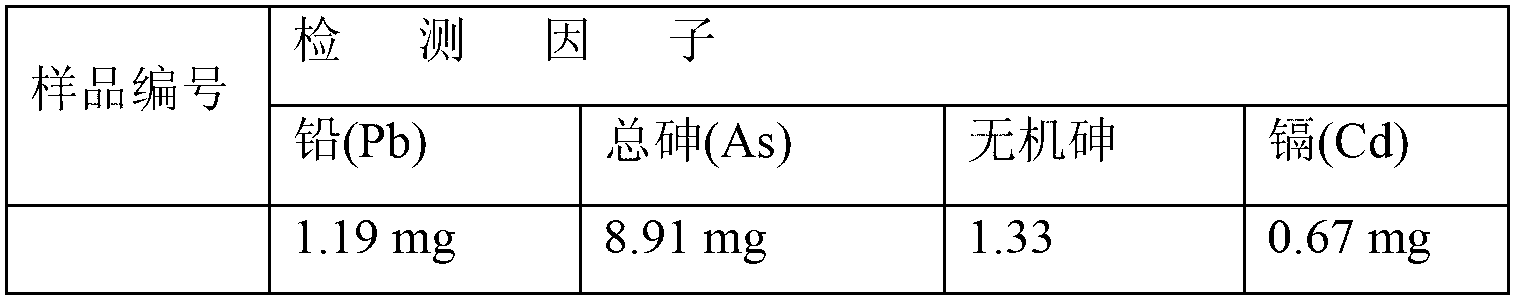

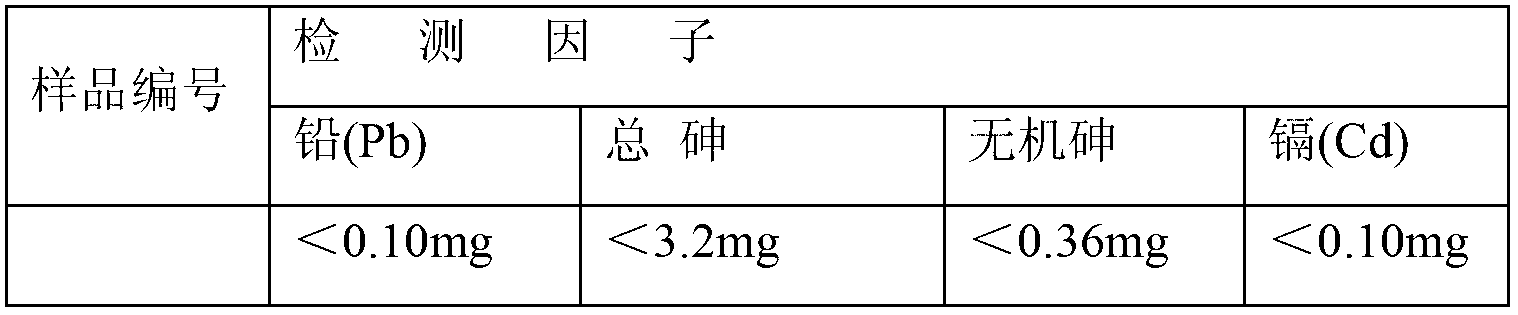

[0031] Take 1 kg of kelp, break it to about 20 cm, add 10 kg of water to soak, and add sodium carbonate to make it alkaline, extract at 50 ° C for 6 hours to obtain the filtrate, add 20% AlCl dropwise to the filtrate 3 The aqueous solution was settled, and then 20% Na was added 2 CO 3 The aqueous solution is settled for the second time to obtain a clear liquid, concentrated, and then centrifuged to remove the residue and salt crystals of the concentrated liquid, adjust the iodine content of the concentrated liquid, neutralize, and obtain a sprayable iodized seaweed iodine solution with an iodine content of 4%. agent.

[0032] Utilize the spray equipment in the production line to spray the seaweed iodine concentrate of 4% (mass percentage) prepared by the above method in the iodine-free salt evenly in the weight ratio of 1000: 0.75 in the processing process, stir, and then pack into 200g, Small packages of 400g, 500g, 1000g.

Embodiment 2

[0034] Take 1kg of wakame, break it to about 20cm, add 10kg of water to soak, and add sodium carbonate to make it alkaline, extract at 55°C for 12 hours, filter to obtain the filtrate, and add an appropriate amount of 15% AlCl dropwise to the filtrate 3 The aqueous solution settles, then add 10% Na 2 CO 3 The aqueous solution is settled for the second time, and the clear liquid is concentrated by centrifugation, then the sediment and salt crystals are removed, neutralized, the concentrated liquid is added to the seaweed polysaccharide, stirred, dried and dehydrated, granulated to obtain the finished seaweed iodine crystal, and packaged.

[0035] Fully mix 100kg of iodine-free salt with seaweed iodine crystals with an iodine content of 3%, so that the iodine content of the mixture reaches 0.0234% (weight ratio) to obtain iodine-containing mother salt, and then mix the mother salt with 500kg of iodine-free salt in a cone mixer Mix well, and then sub-package into 200g, 400g, 500...

Embodiment 3

[0037] Take 1 kg of leaf algae, break it to about 20 cm, add 10 kg of water to soak, and add sodium carbonate to make it alkaline, extract at 50 ° C for 12 hours, filter to obtain the filtrate, and add an appropriate amount of 3% AlCl to the filtrate dropwise 3 The aqueous solution settles, then add 5% Na 2 CO 3 The aqueous solution is settled for the second time, and the clear liquid is concentrated by centrifugation, then the sediment and salt crystals are removed, neutralized, the concentrated liquid is added to the seaweed polysaccharide, stirred, dried and dehydrated, granulated to obtain the finished seaweed iodine crystal, and packaged.

[0038] Fully mix 100kg of iodine-free salt with seaweed iodine crystals with an iodine content of 1%, so that the iodine content of the mixture reaches 0.0084% (weight ratio) to obtain iodine-containing mother salt, and then mix the mother salt with 500kg of iodine-free salt in a cone mixer Mix well, and then sub-package into 200g, 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com