Patents

Literature

124results about How to "High oxygen evolution potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

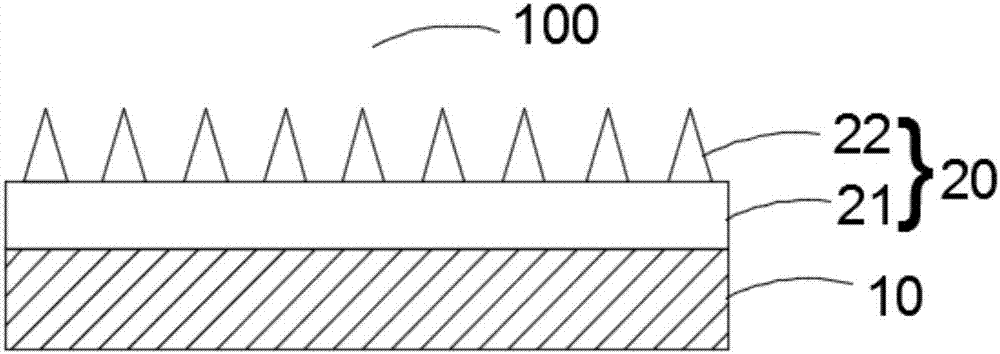

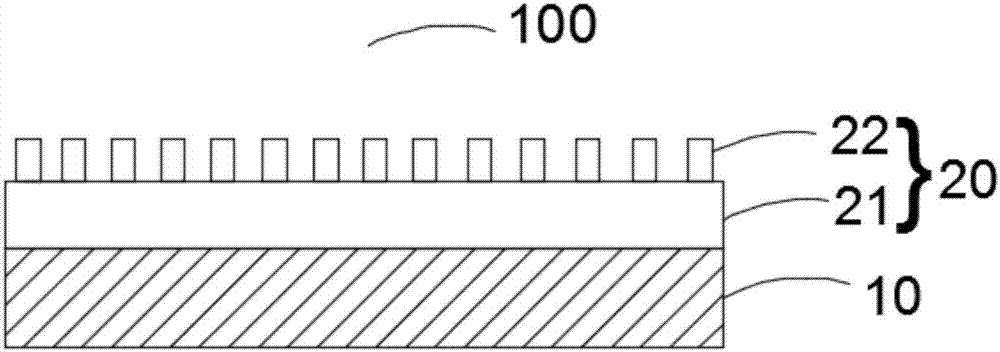

Electrode for electrolysis, preparation method of electrode and electrolytic bath

ActiveCN104562078AChlorine evolution potential is lowExtended service lifeElectrodesIridiumElectrolysis

The invention provides an electrode for electrolysis, a preparation method of the electrode and an electrolytic bath. The electrode for electrolysis comprises a conductive base material and an active coating, wherein the conductive base material is a base material containing titanium or titanium alloy; the active coating at least comprises a bottom coating layer and a surface coating layer; the bottom coating layer is prepared from titanic oxide, iridium oxide and ruthenium oxide; the surface coating layer is prepared from iridium oxide, ruthenium oxide, titanium oxide and a metal or an oxide of one of two of palladium and platinum. According to the electrode for electrolysis disclosed by the invention, the double coating layers are adopted; compared with the single coating layer only containing ruthenium, iridium and titanium, the electrode is better in activity, the chlorine evolution potential of the electrode is low, the oxygen evolution potential is high, the service life of the electrode is longer, and the electrolysis stability is better.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Nanocrystal metal oxide composite electrode and method for preparing same

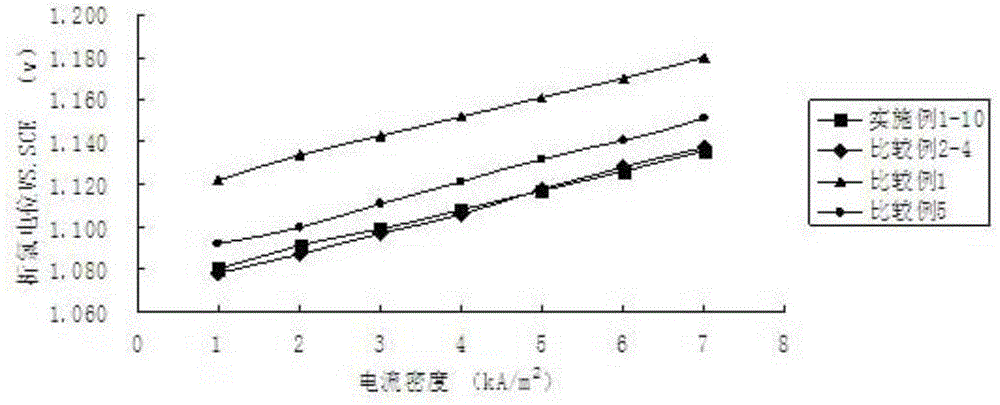

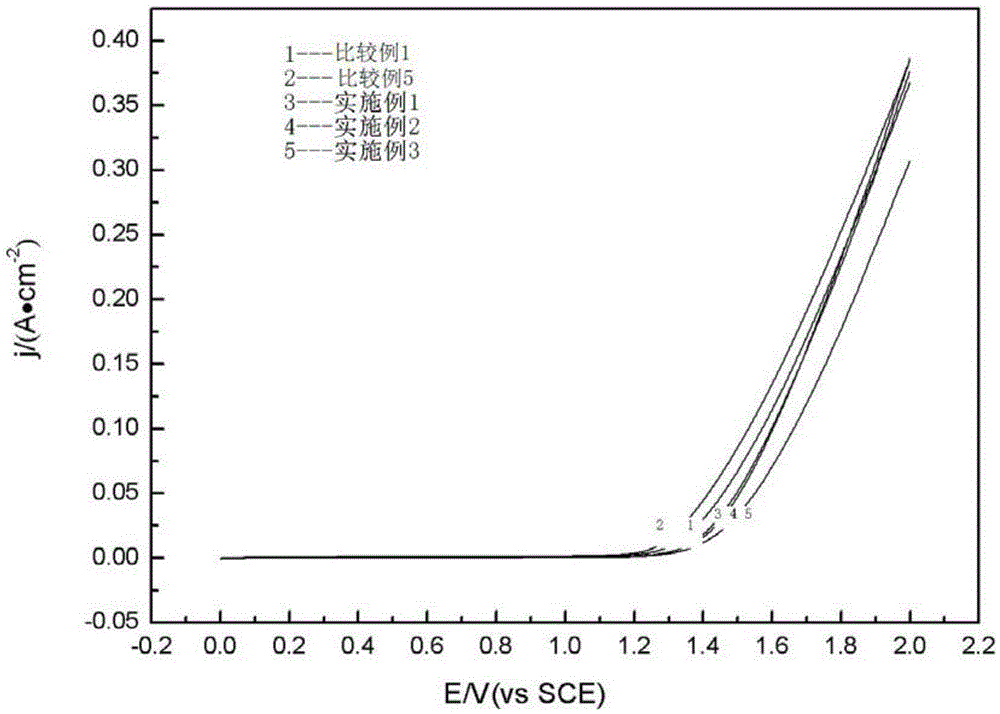

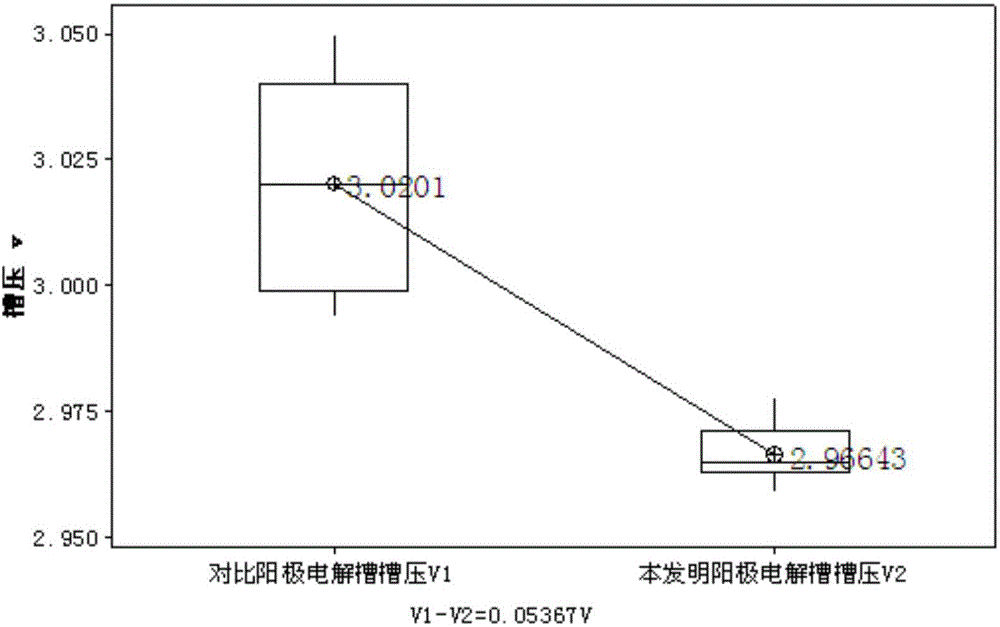

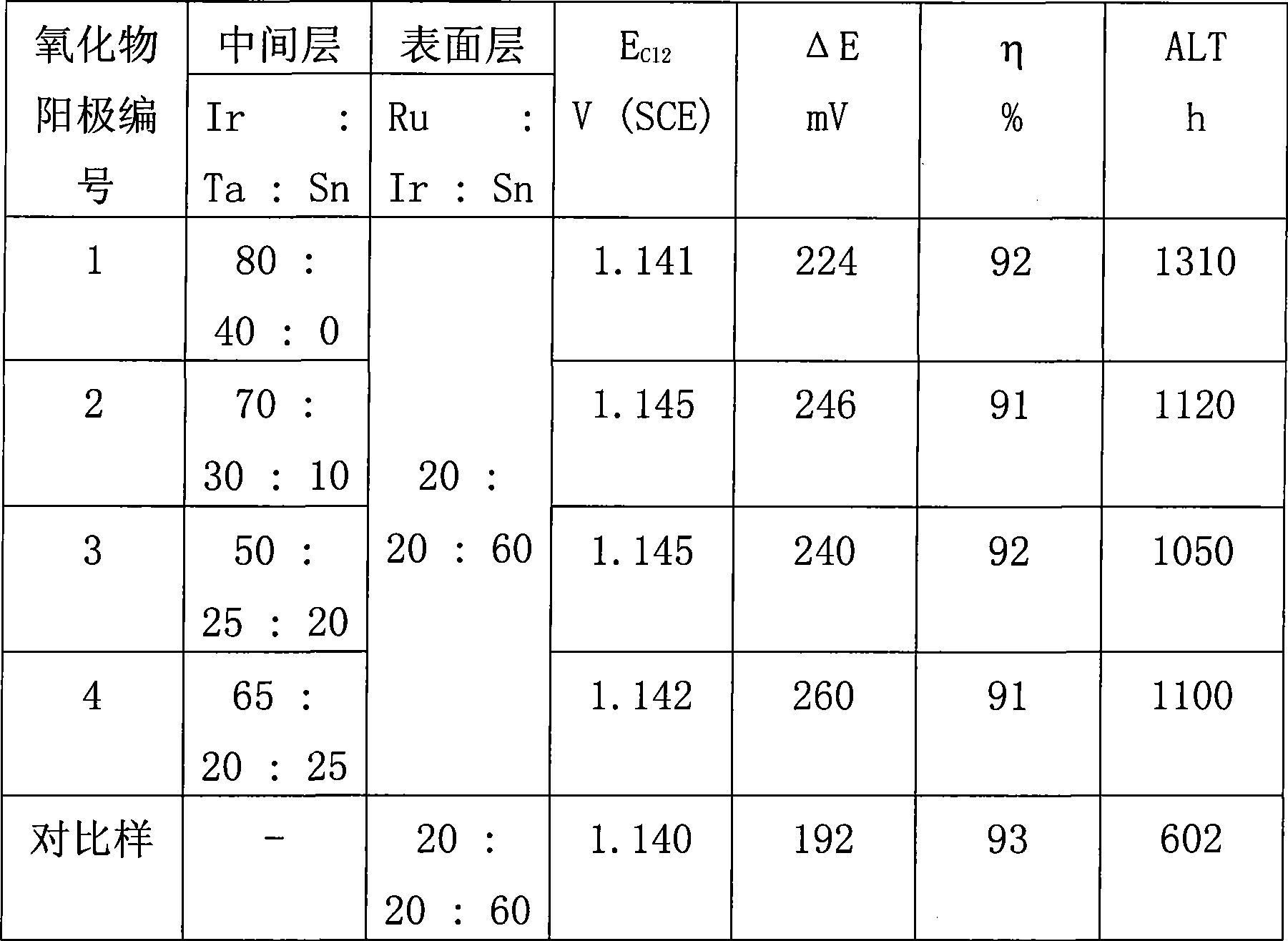

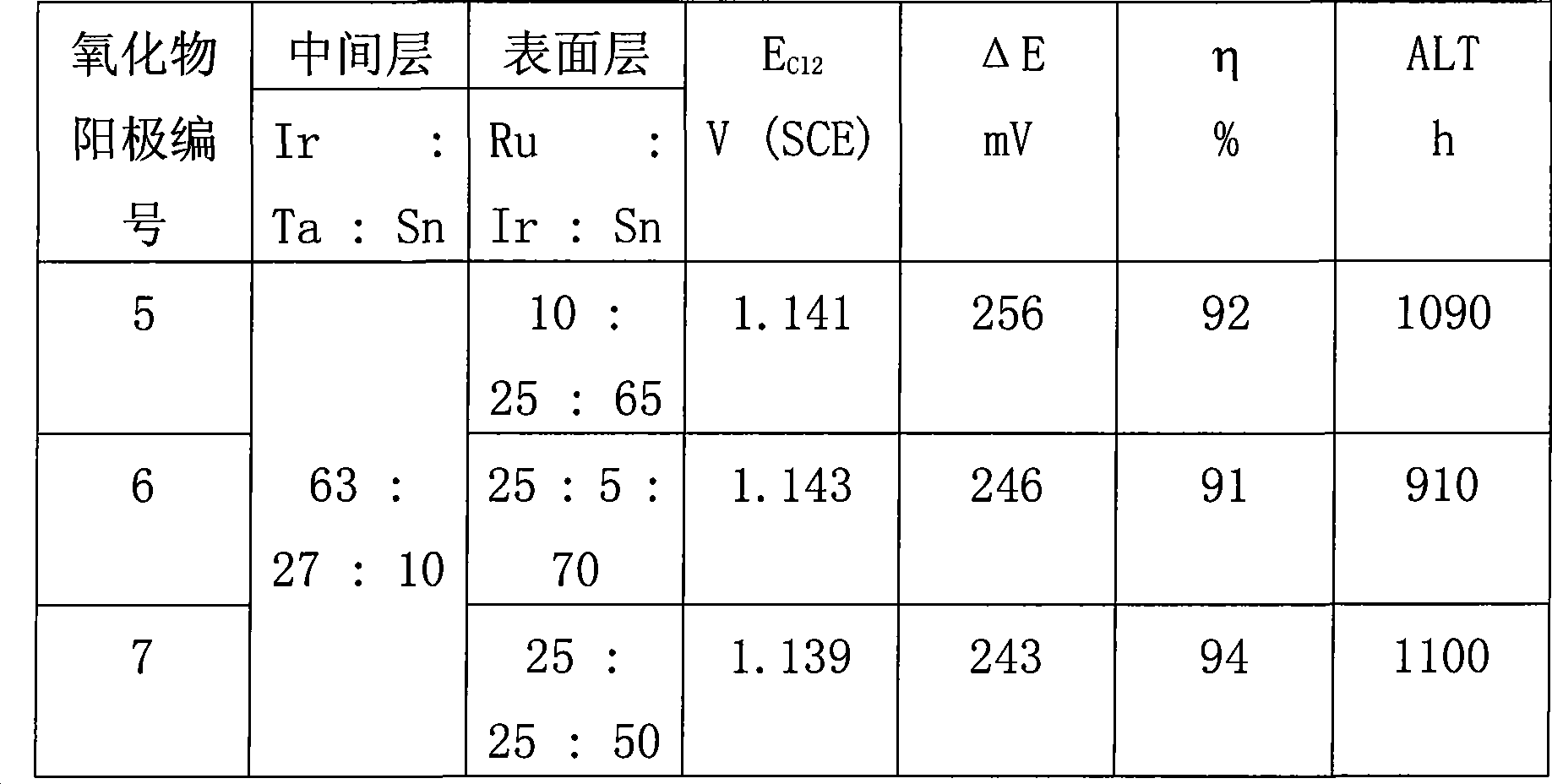

The invention relates to a nanocrystal metal oxide composite electrode and a method for preparing the same. The electrode is suitable for a seawater electrolysis device for preventing the contamination of sea creature and used for electrolytic production of sodium hypochlorite, cathode protection and other electrochemical engineering; a main structure of the electrode comprises a substrate, an anticorrosive antipassivated middle layer and a surface activity layer, wherein the substrate is metal titanium; the purity of the metal titanium is over 99 percent; the middle layer is iridium-tantalum or iridium-tantalum-tin oxide; the surface activity layer is ruthenium-iridium-tin metal oxide; a process for preparing the electrode adopts a sol-gel method and comprises three process steps of the pretreatment of the substrate, the preparation of the anticorrosive antipassivated middle layer and the preparation of the surface activity layer; and the electrode has the characteristics of even compositions, difficulty for burning loss, fine crystal grains, simple preparation process, controllable process and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

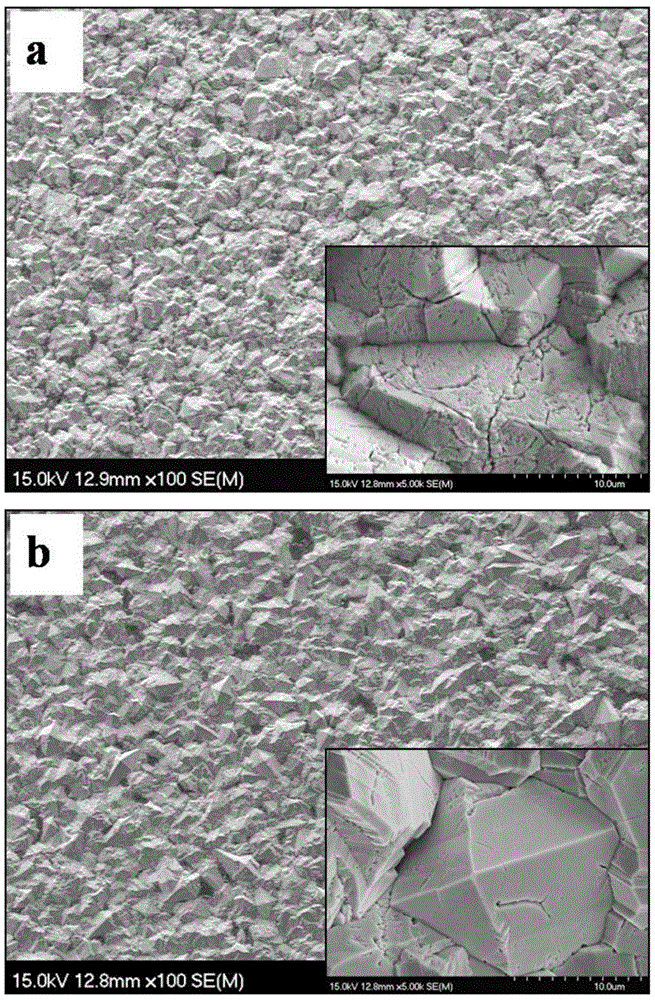

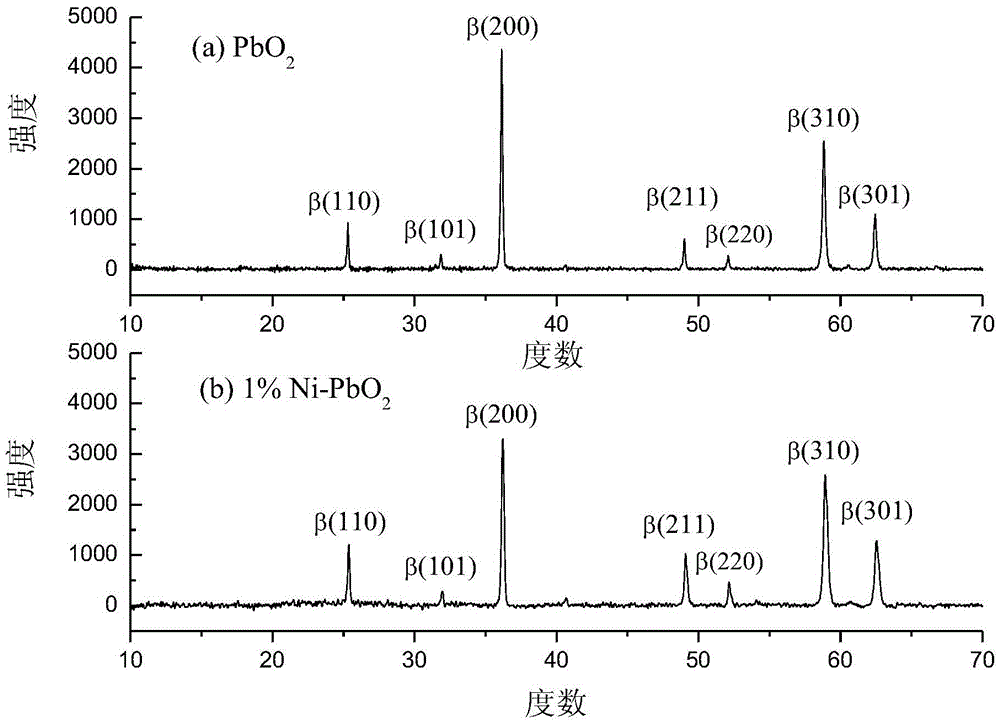

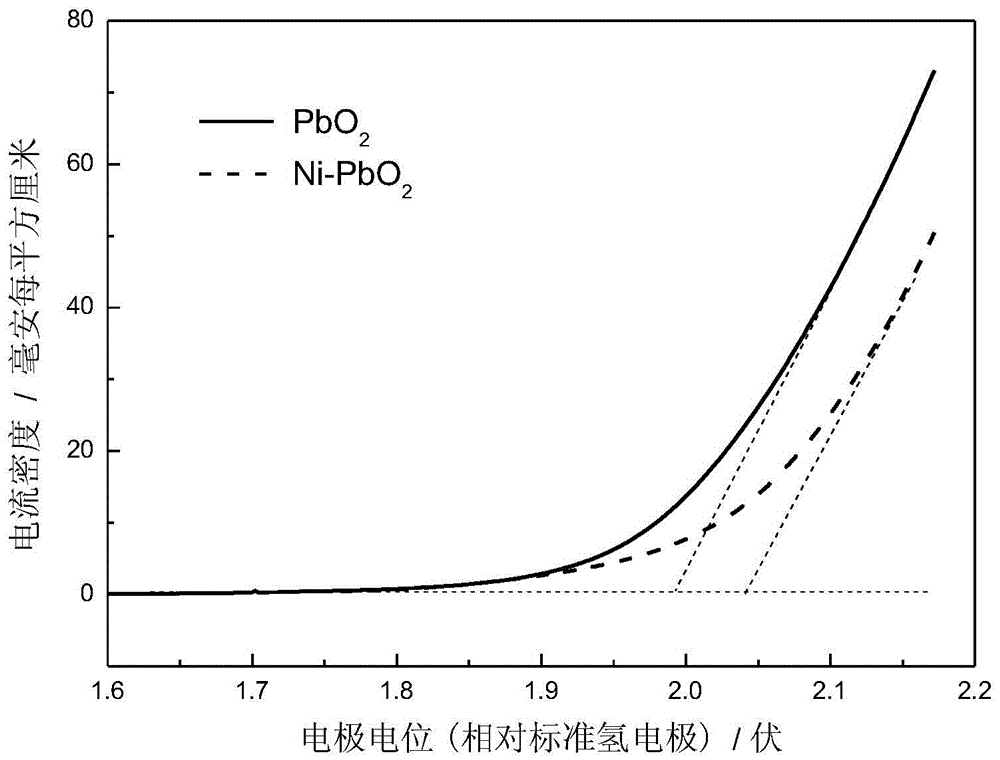

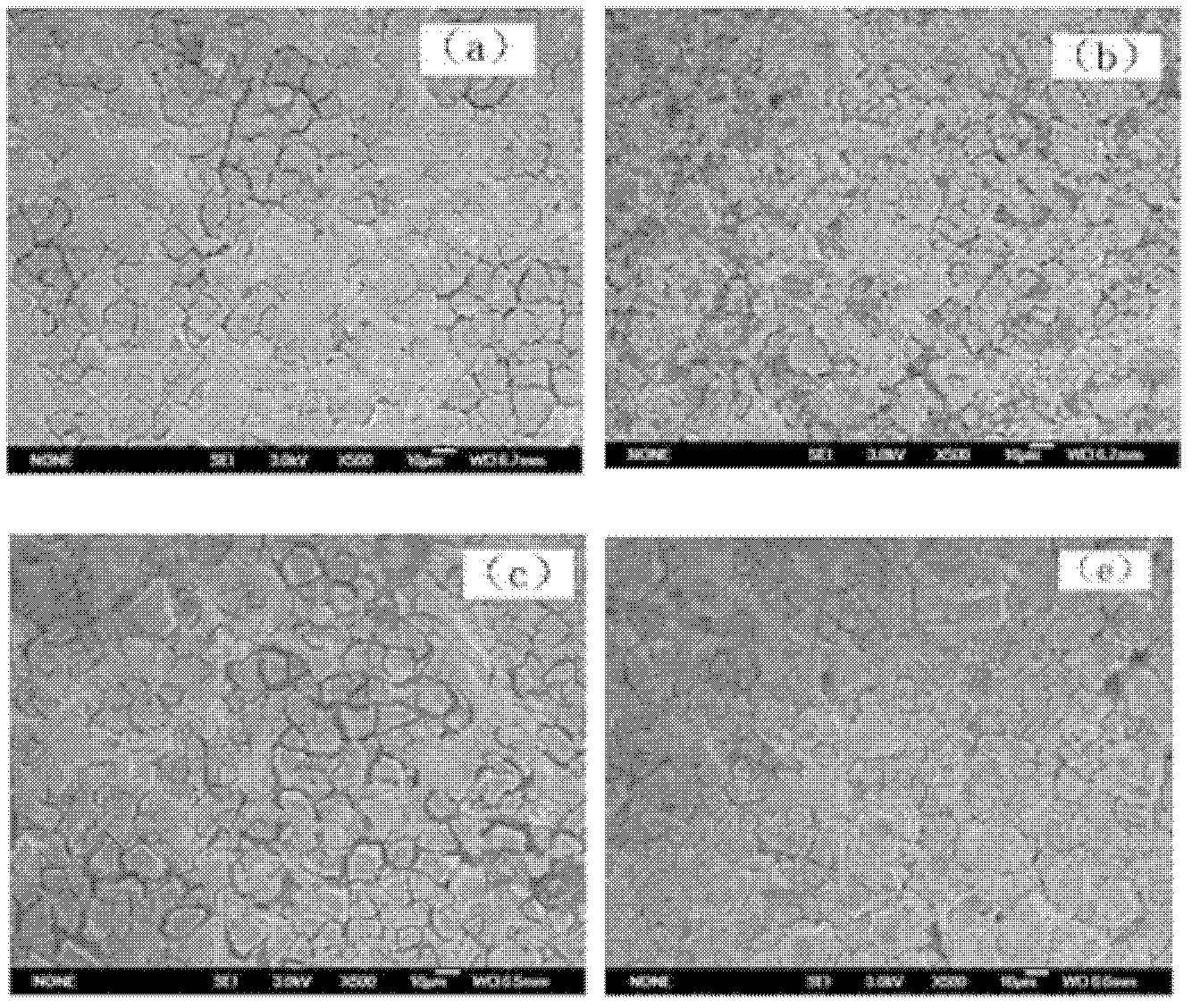

Transition-metal doped lead dioxide electrode for wastewater treatment as well as preparation method and application thereof

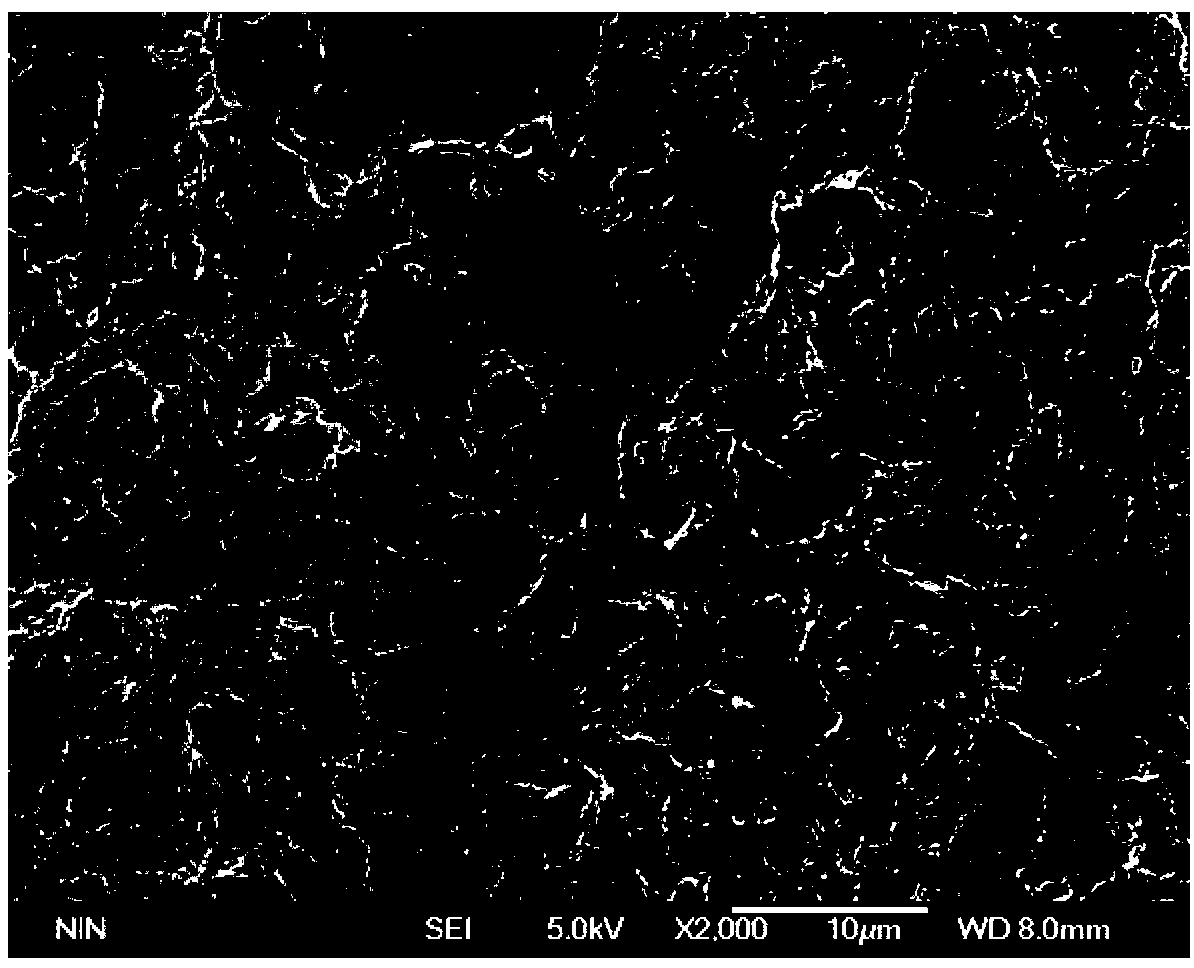

InactiveCN105621541AExtended service lifeDisperse tightly and evenlyElectrolytic inorganic material coatingWater/sewage treatmentLead dioxideAntimony

The invention discloses a transition-metal doped lead dioxide electrode for wastewater treatment and a preparation method thereof. The transition-metal doped lead dioxide electrode is prepared through the steps of performing thermal decomposition on a titanium material which serves as a substrate so as to prepare a tin-antimony oxide underlayer, then electroplating an alpha-PbO2 interlayer by use of an alkaline solution and finally preparing a transition-metal doped fluorine-containing beta-PbO2 surface active layer by use of acidic composite electroplating bath. The transition-metal doped lead dioxide electrode prepared by the method has the characteristics of low price, high oxygen evolution potential, high catalytic activity, long service life and the like; the electrode can be used for realizing effective removal of organic pollutants in wastewater through an electrochemical oxidation method, is simple to operate and convenient to manage and has wide social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

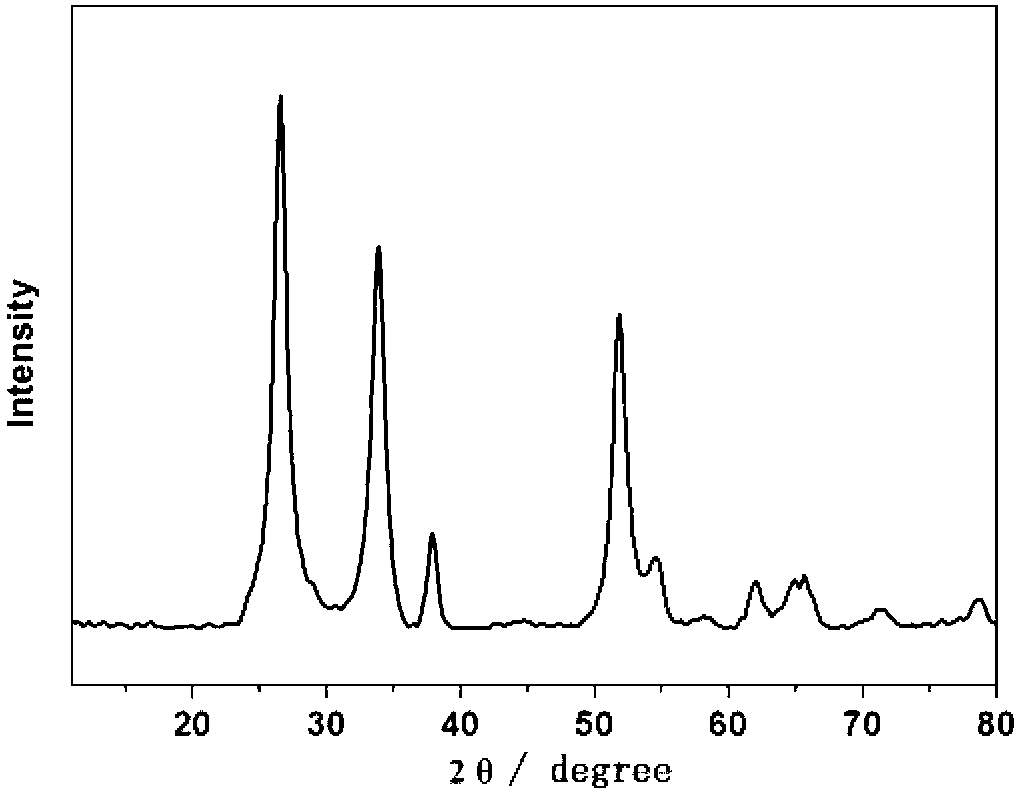

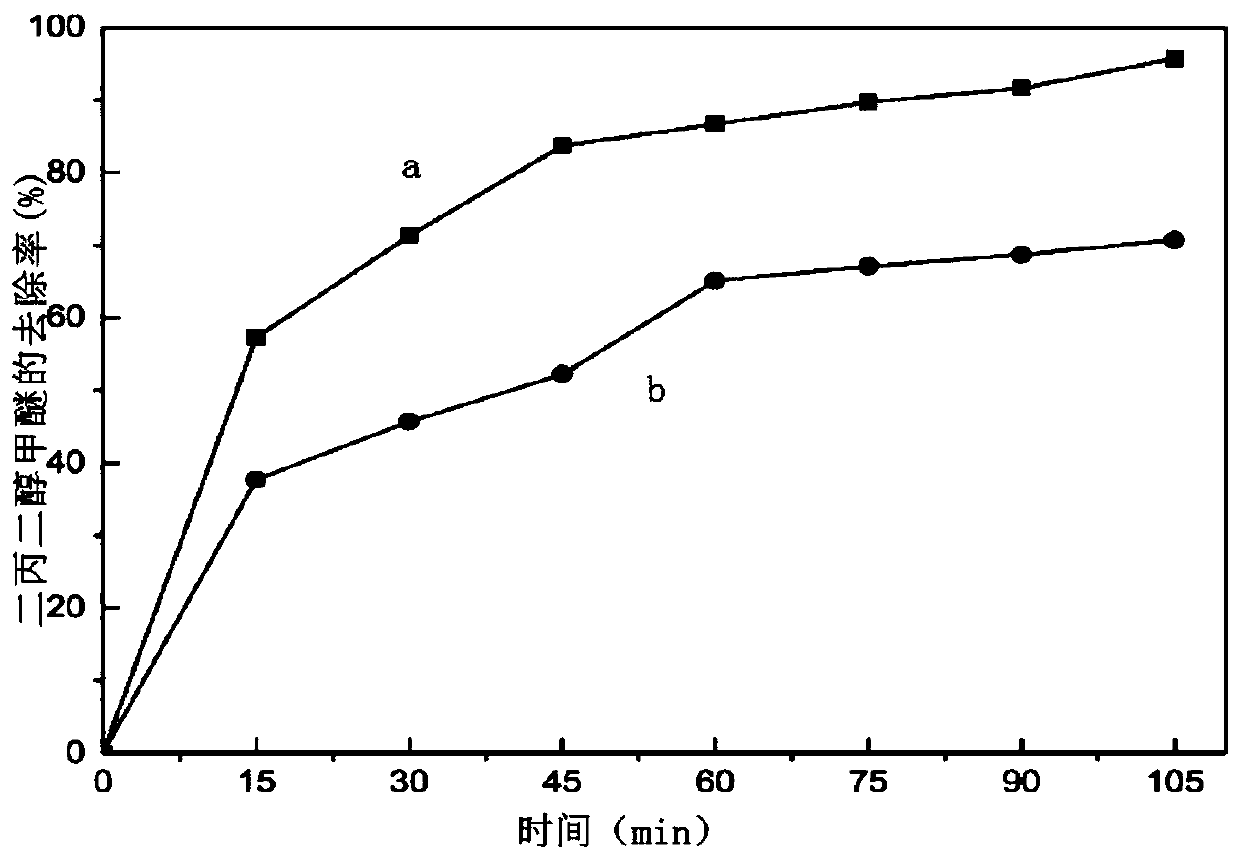

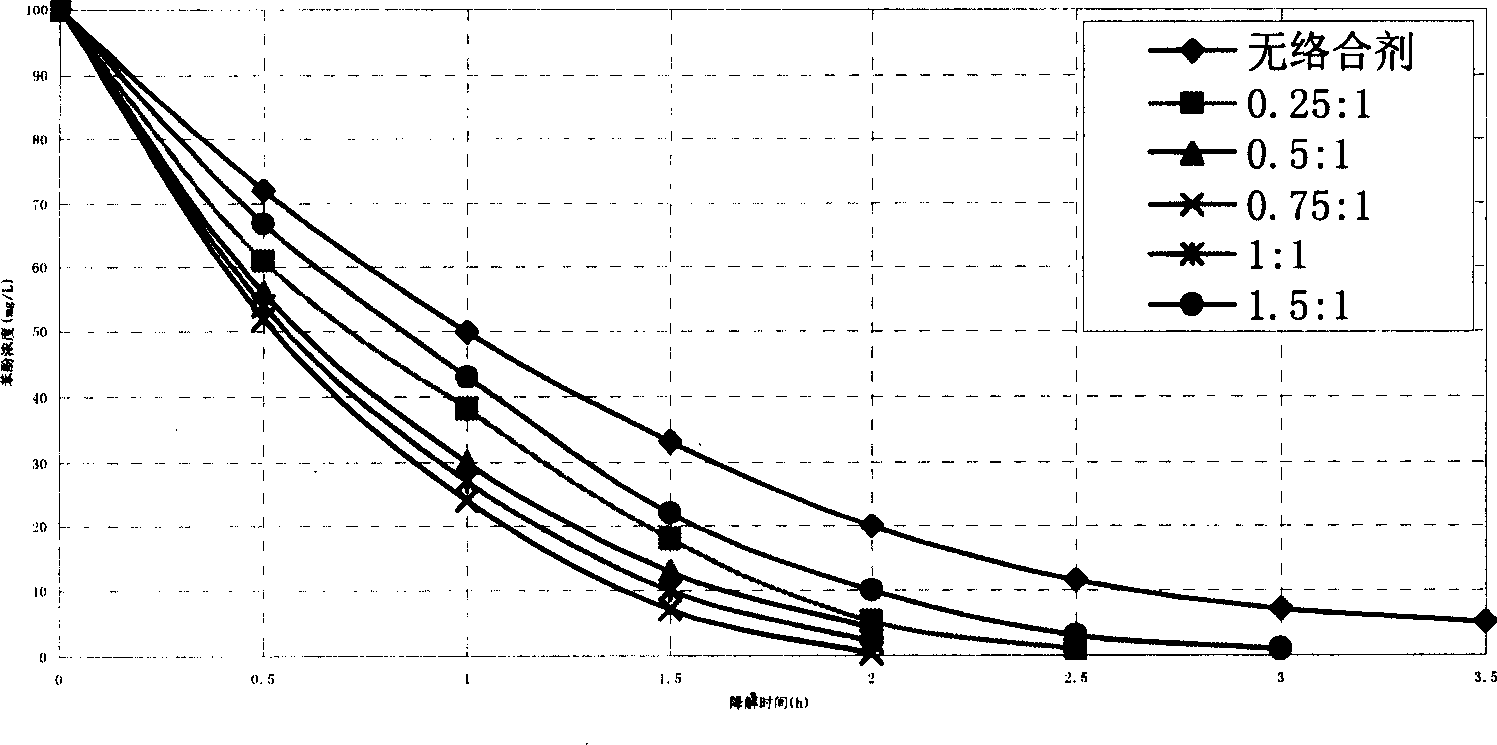

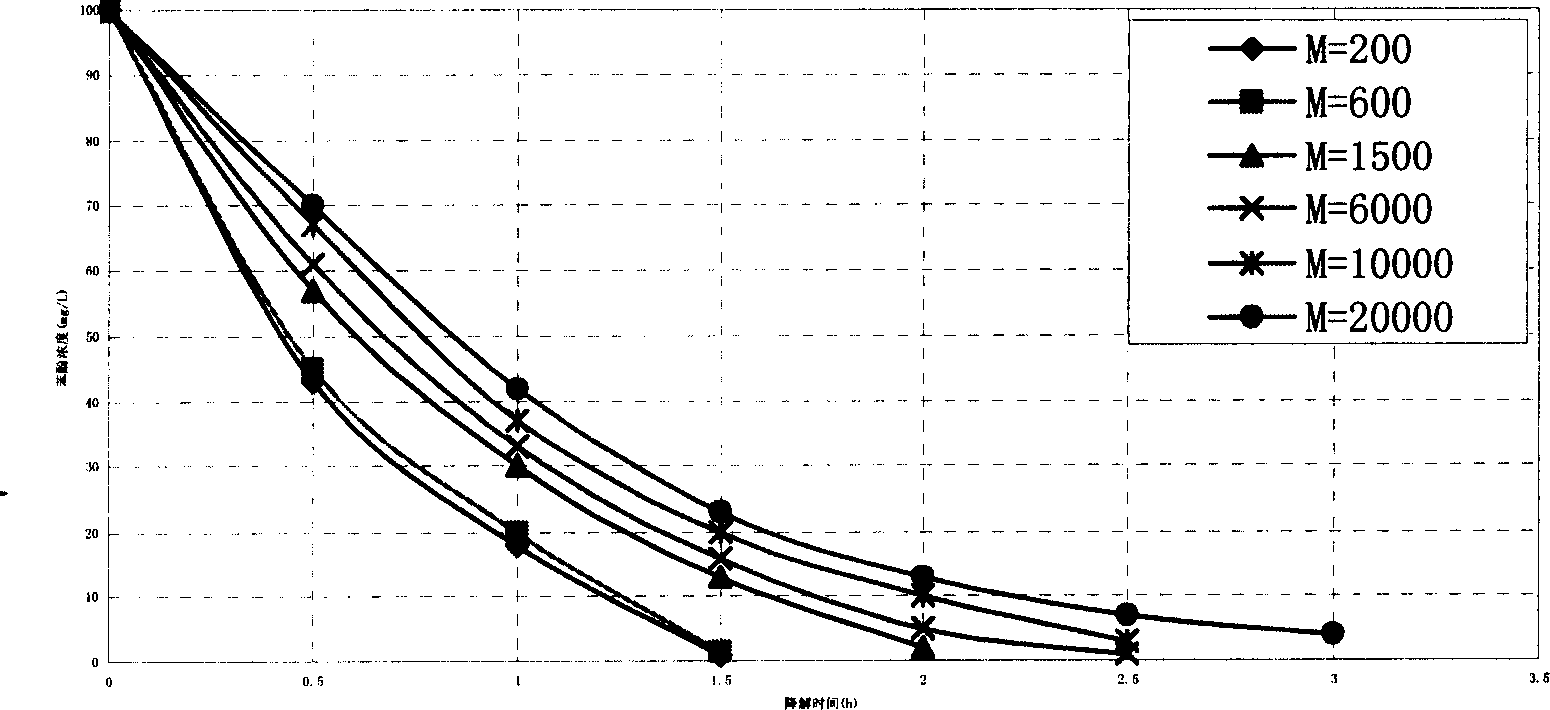

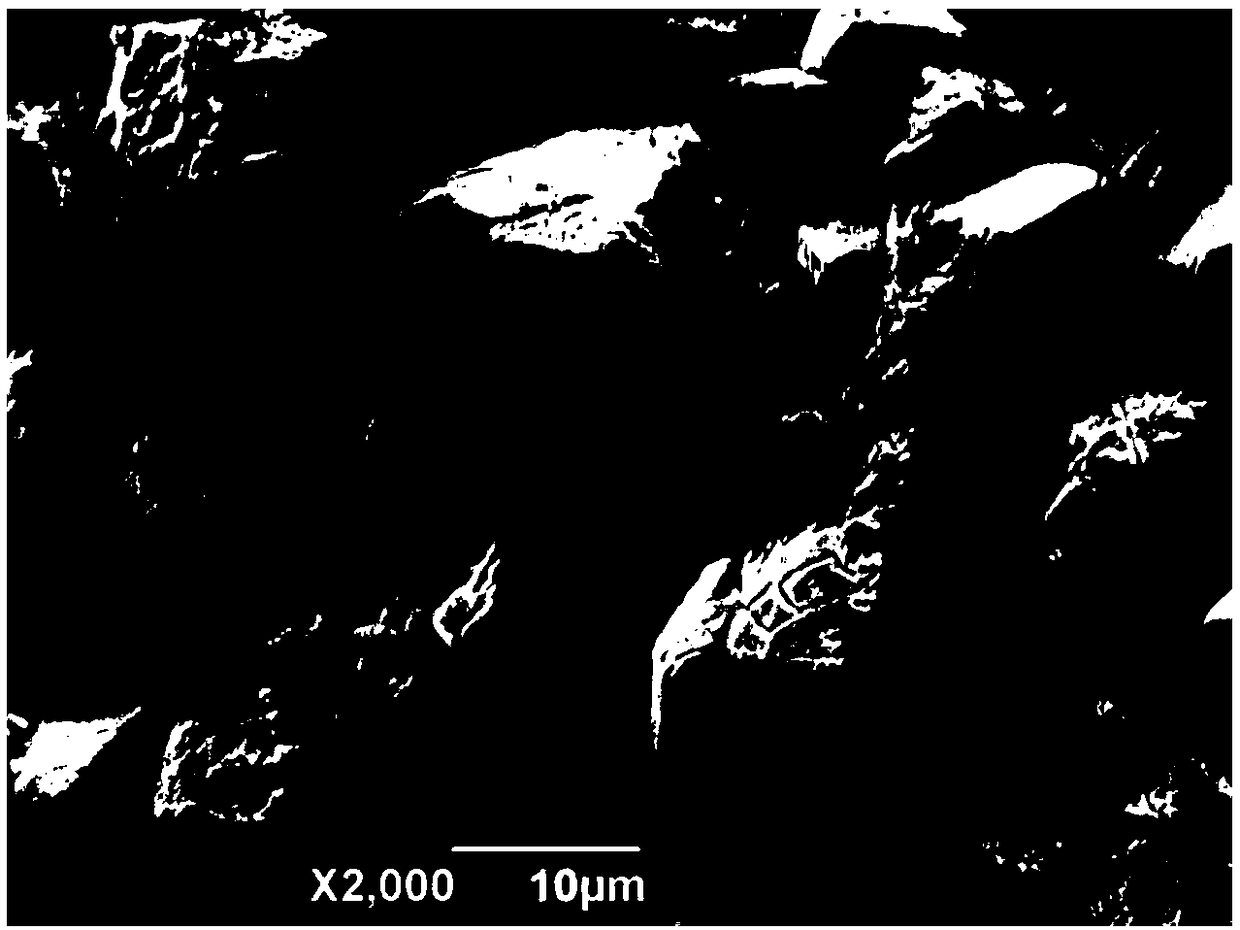

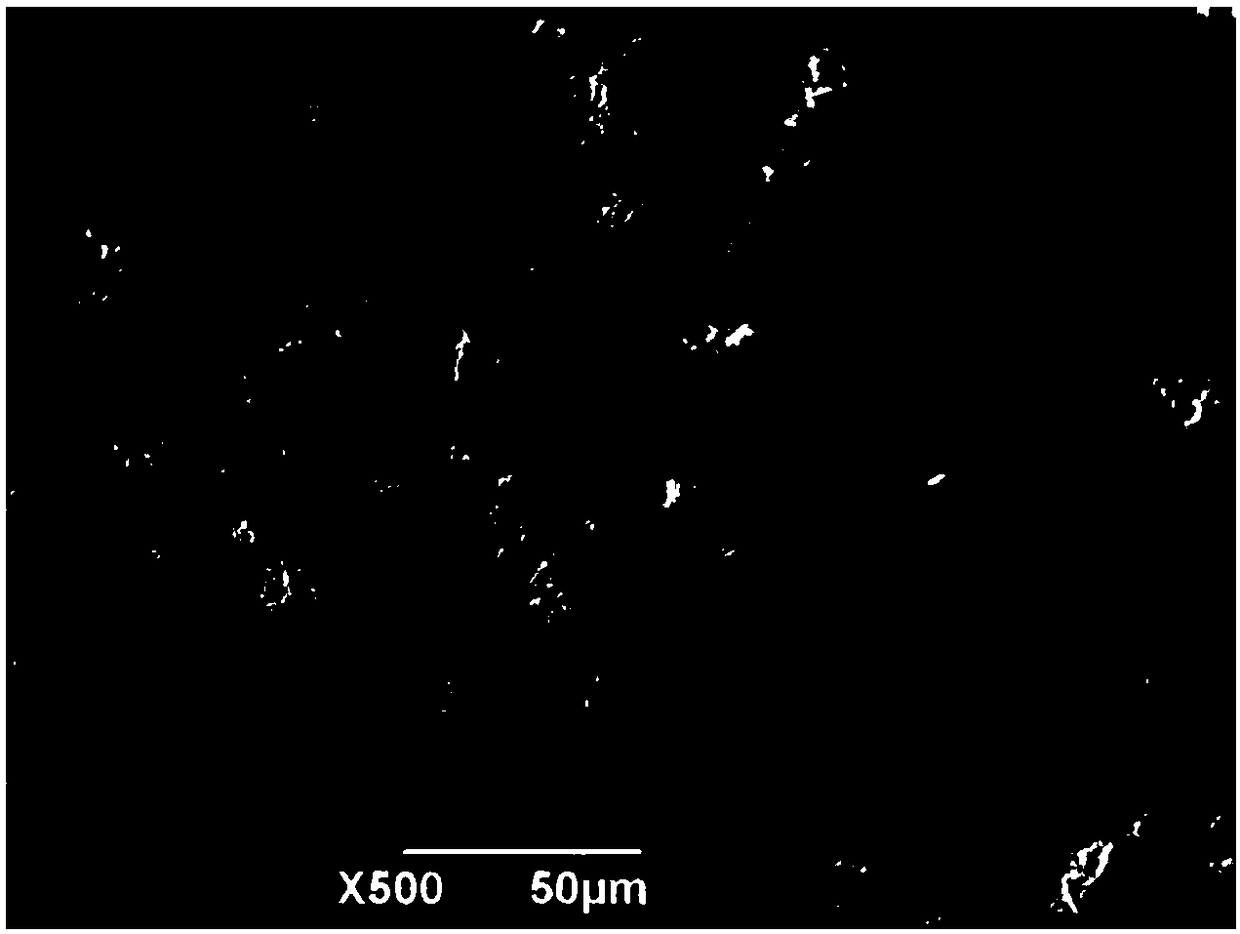

Rare-earth doped titanium-base SnO2 electrolytic electrode and its preparation

ActiveCN1896320AHigh oxygen evolution potentialPromote degradationElectrodesRare-earth elementTitanium electrode

A rare earth-doped Ti-base SnO2 electrocatalytic electrode relates to one type of DSA electrode and its preparing process. The rare earth-doped electrode in this invention is composed of the Titanium substrate and the rare earth-doped SnO2 coat in which the mol ratio of Sn, rare earth elements and Sb is 75-99.8:0.1-10:0.1-15. In this process the Titanium electrode is polished, washed with alkaline and acid, then undergoes delaminated impregnation and gradient temperature rise to realize the formation of the functionally gradient membrane that endows the electrode with relatively high potential of oxygen evolution, strong degrading ability of organic compounds and inert composition without dissolving out. The electrode has strong degrading ability especially of the materials persistent to biodegration or toxic to organisms.

Owner:HARBIN INST OF TECH

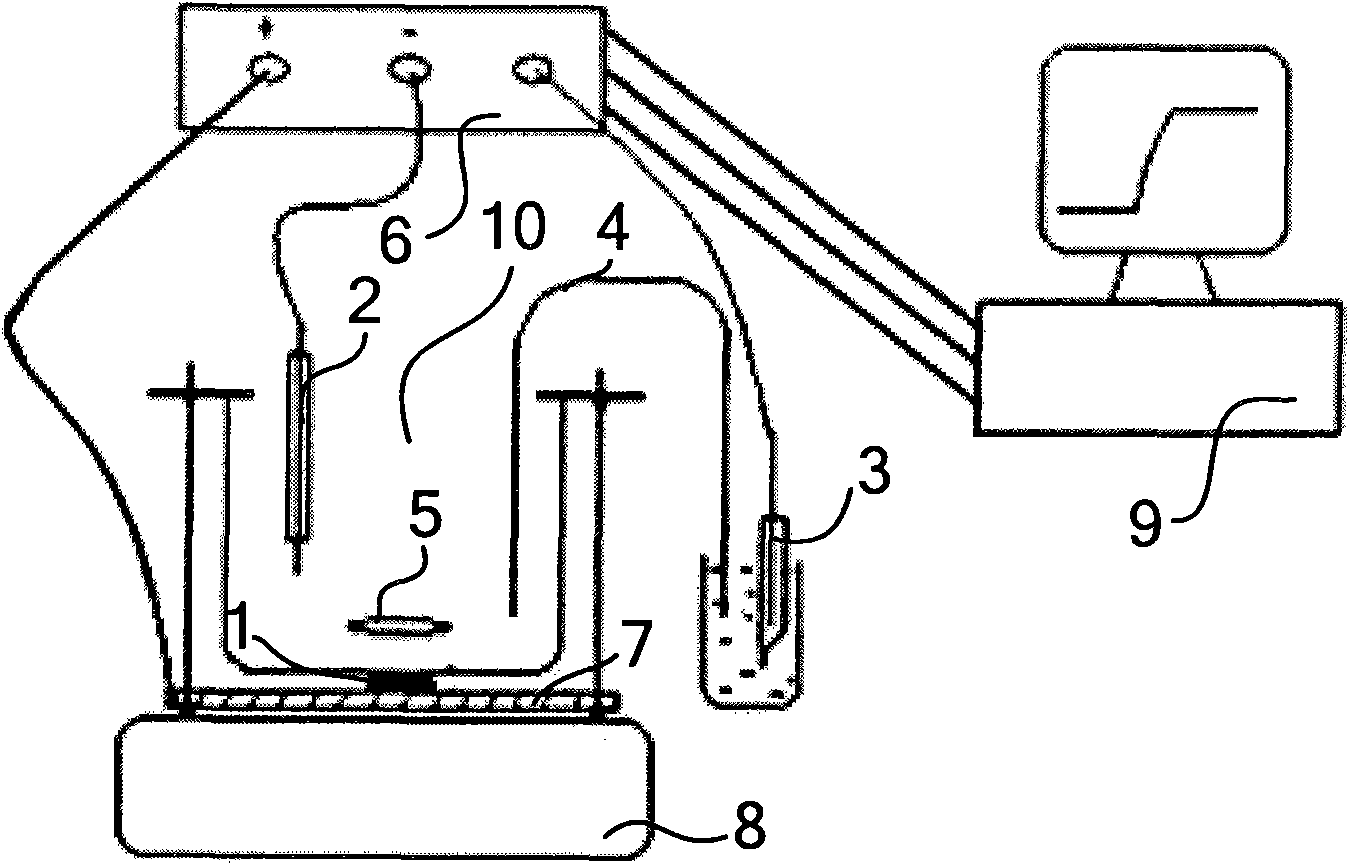

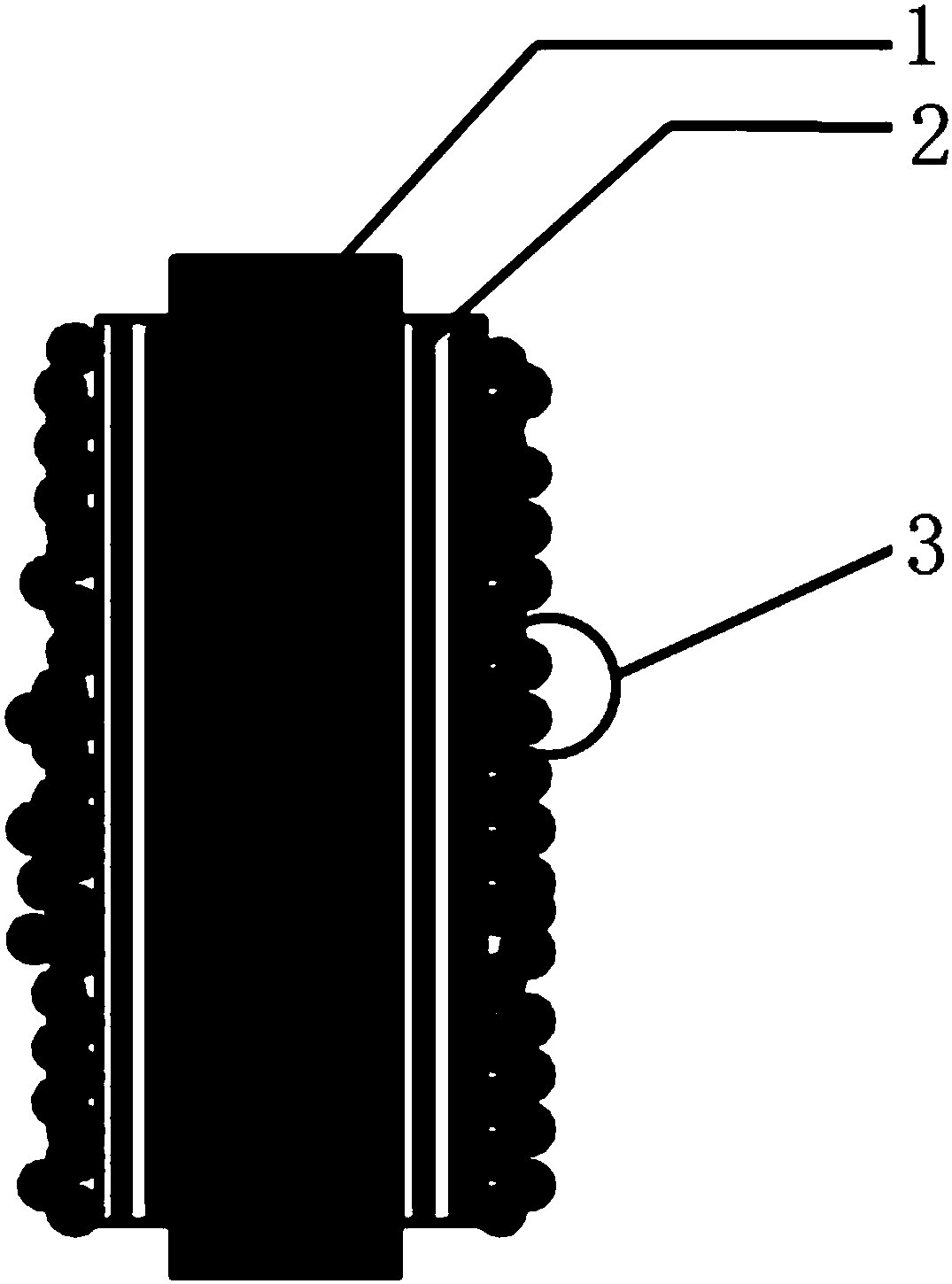

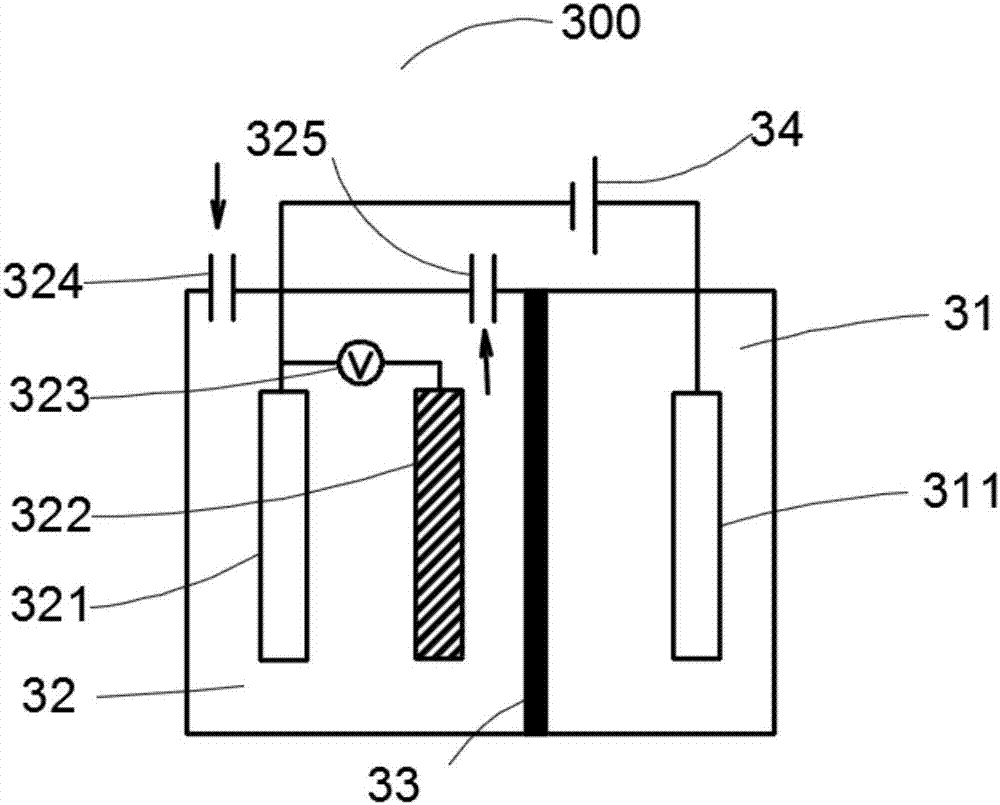

Subaqueous chemical oxygen demand measuring apparatus and method and method based on flow injection sampling

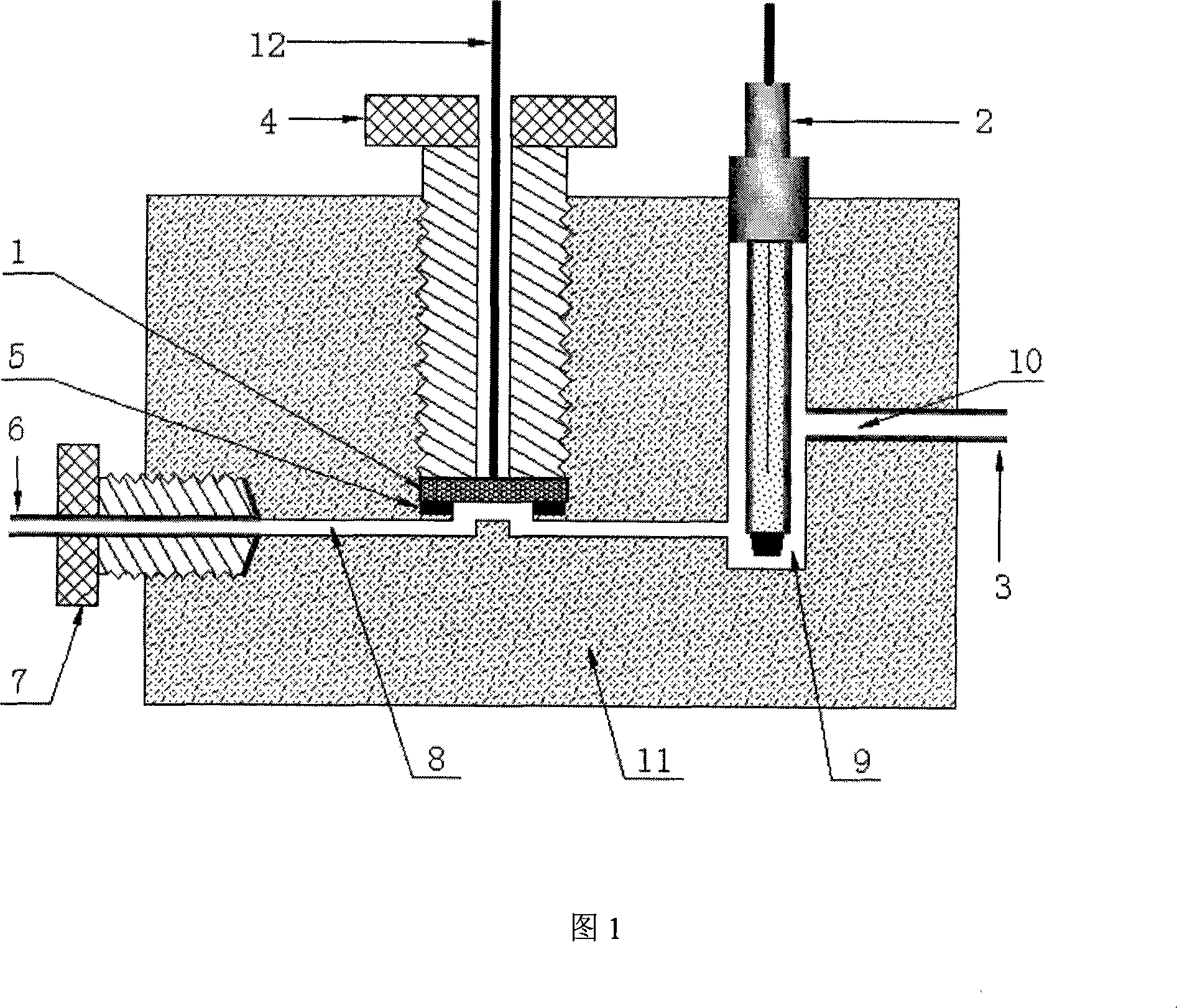

ActiveCN101221145ANo secondary pollutionHigh mechanical strengthMaterial analysis by electric/magnetic meansWater basedMeasurement device

The invention relates to a device and a method for measuring the chemical oxygen demand in water based on flowing injection sampling feeding, which belongs to the technical field of environment monitoring. The measuring device is composed of a flowing injection sampler feeder, a three-electrode system electrochemical circulation detecting pool and an electrochemical working station. The invention is characterized in that a working electrode of the electrochemical circulation detecting pool is a boron-doped diamond film electrode and is fixed on an inlet channel by a fastening bolt and is lined with a lock ring. The inlet channel, a reference electrode mounting channel and an outlet channel enlightened on an insulating, hard and corrosion-resistant pool body are mutually communicated. When in measurement, the pH value of a carrier liquid is 3 to 10 with a concentration of 0.05 to 0.5 mol / l. When the reference electrode adopts a saturated calomel electrode or an Ag / AgCl electrode, a positive voltage applied on the working electrode of the boron-doped diamond film electrode is 2.2 to 3.2V. The invention realizes the fast and accurate measurement of COD with no pollution.

Owner:DALIAN UNIV OF TECH

Electrode Ce doped PbO2 used for treating waste water and its preparation method

InactiveCN102190351AImprove stabilityImprove oxidation capacityWater/sewage treatment by electrochemical methodsElectricitySocial benefits

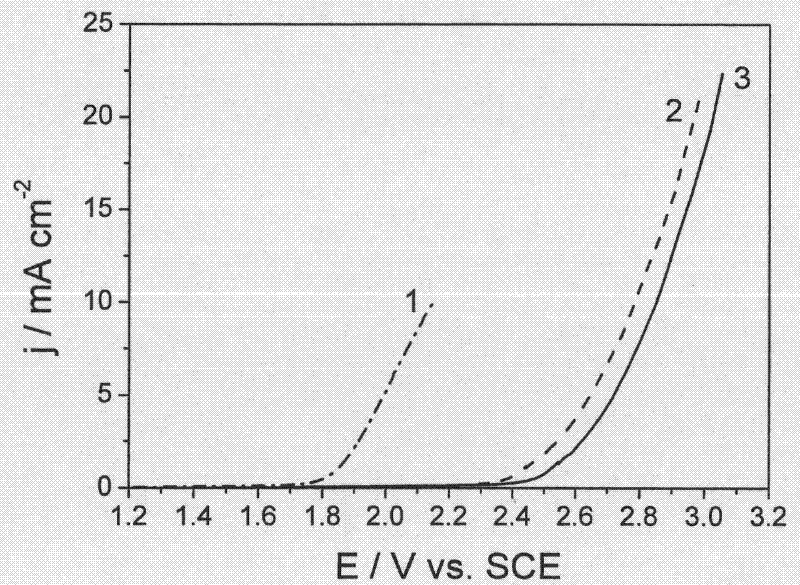

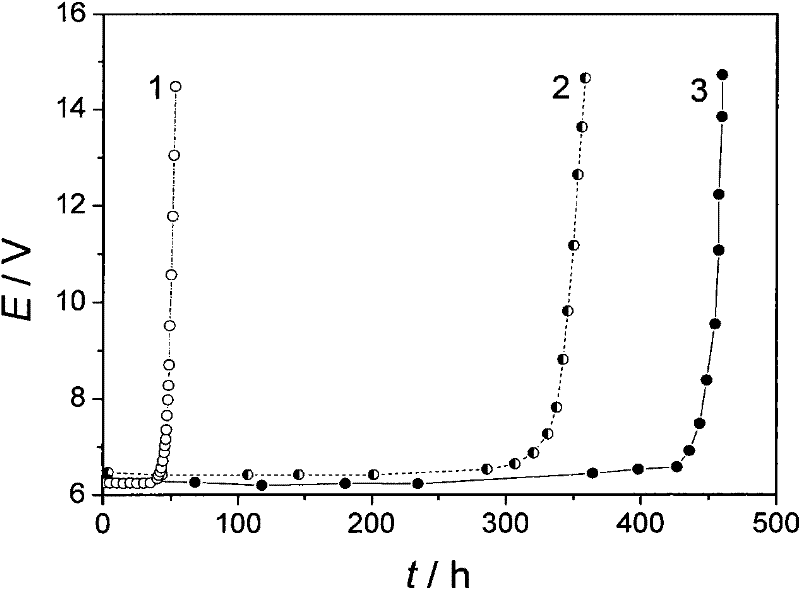

The invention relates to an electrode Ce doped PbO2 used for treating waste water and its preparation method. The electrode is a F-PbO2-CeO2 / TiO2-NTs / Ti electrode. The method for producing the electrode comprises that: obtaining a titania nano-tubes array (TiO2-NTs / Ti) matrix prepared by an anodization processing, doping rare earth Ce, preparing a doped-type F-PbO2-CeO2 / TiO2-NTs / Ti electrode by using an electrodeposition method. Compared with the prior art, the PbO2 electrode by the present invention has the advantages of high oxygen evolution potential, strong catalytic activity, stable electrode electrochemical performance and long service life. Compared with the traditional PbO2 electrode, the oxygen evolution potential of the electrode is higher than 2.4 V, and accelerated and strengthen life is more than 400 hours, the service life can reach about 40 years. The electrode has the advantages of simple preparation technology and low manufacturing cost, and can be effectively used for an electrochemical oxidation treatment of organic waste water which has high density and is difficult to degrade, the electrode also has a wide economic and social benefit.

Owner:TONGJI UNIV

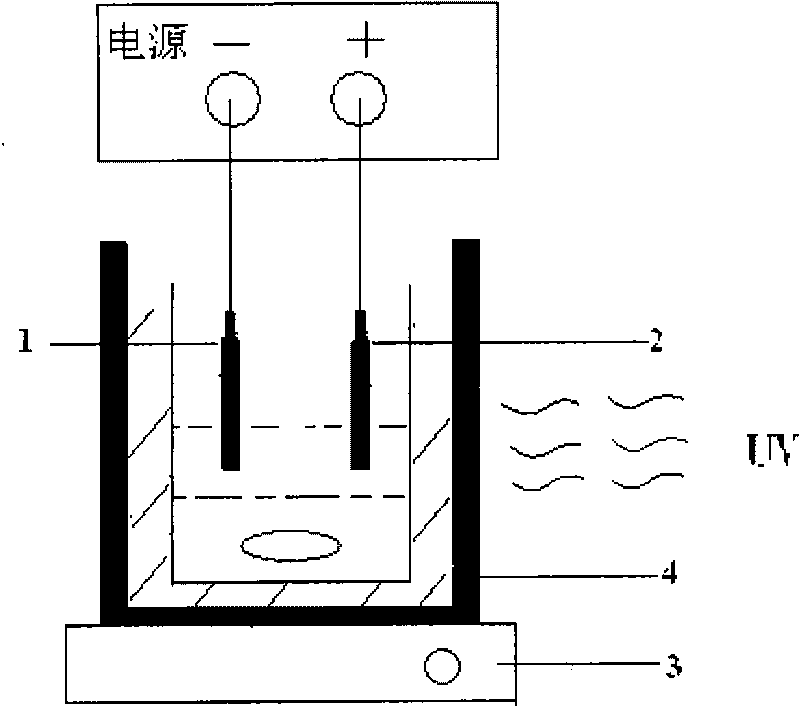

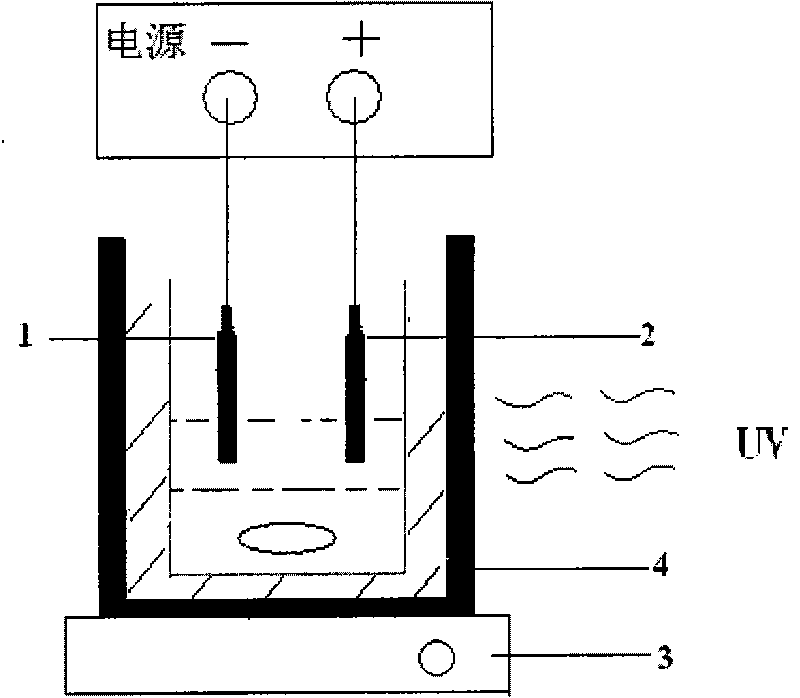

Segmented treatment method of high-concentration high-chromaticity dye wastewater

InactiveCN101704600AExcellent photocatalytic oxidation performanceExcellent electrochemical oxidation abilityWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsChemistryTreatment effect

The invention belongs to the technical field of high-concentration dye wastewater, and particularly relates to a segmented treatment method of high-concentration high-chromaticity dye wastewater. In the invention, electrochemical oxidation technology is optimally combined with photocatalytic oxidation technology to become a new electrochemical pre-oxidation-photoelectric collaborative oxidation-photocatalytic oxidation three-segment sewage treatment process, and an Sb*doped SnO2 / TiO2-NTs / Ti photoelectronic integrated electrode with excellent photoelectric catalytic properties concurrently is selected as anode material for degradation treatment. The process achieves prospective high-efficient treatment effect, saves energy consumption to the maximum extent, embodies the advantage of saving energy, and provides a brand-new method for the degradation of the high-concentration high-chromaticity dye wastewater, thus having broad application prospect and development potential.

Owner:TONGJI UNIV

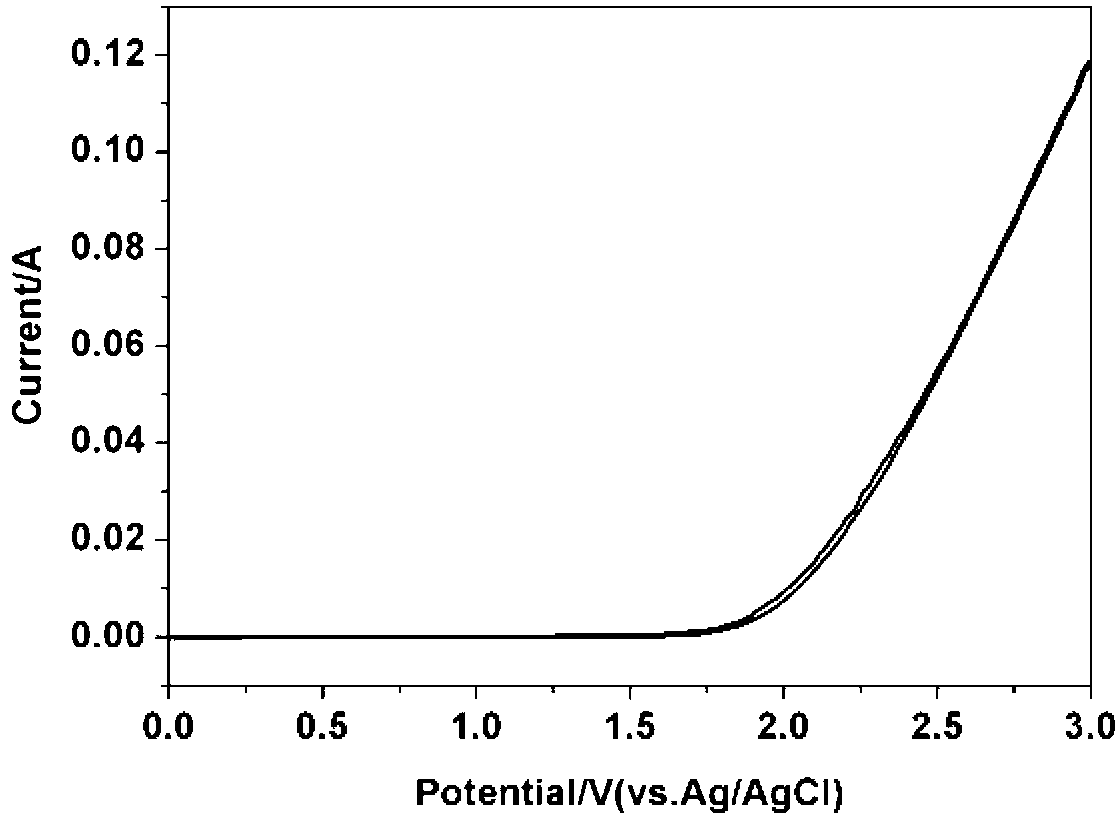

Electrochemical analysis device adopting nano boron-doped diamond film electrode and its uses

InactiveCN101149356AReduce usageIt has the characteristics of green environmental protectionMaterial electrochemical variablesElectrolysisTrace metal

The electrochemical analysis device and its application of the diamond membrane electrode of the nanometer mixed with the boron are used to detect the heavy metal ion with high sensitivity. It includes the electrolysis, the working station and data collecting and controlling system. The electrolysis system is made up of the electrolysis pool with the single room structure, the electrode frame and the working electrode fixed on the electrode frame, the assistant electrode, the reference electrode. The working electrode is the diamond membrane electrode of the nanometer mixed with the boron. The three electrodes are connected with the electrochemical analyzer by the electrode line. The data collecting and controlling system is the computer installed with the electrochemical analyzer. The device has avoided using the electrode containing the hydrargyrum and improved the detection sensitivity, the detection limit can reach 10-9mol / L and it has good repeatability. The detection process does not need to remove oxygen by giving nitrogen; also it can reach the renovation on the electrode surface. The invention can detect many trace metal ion in sample at the same time.

Owner:TONGJI UNIV

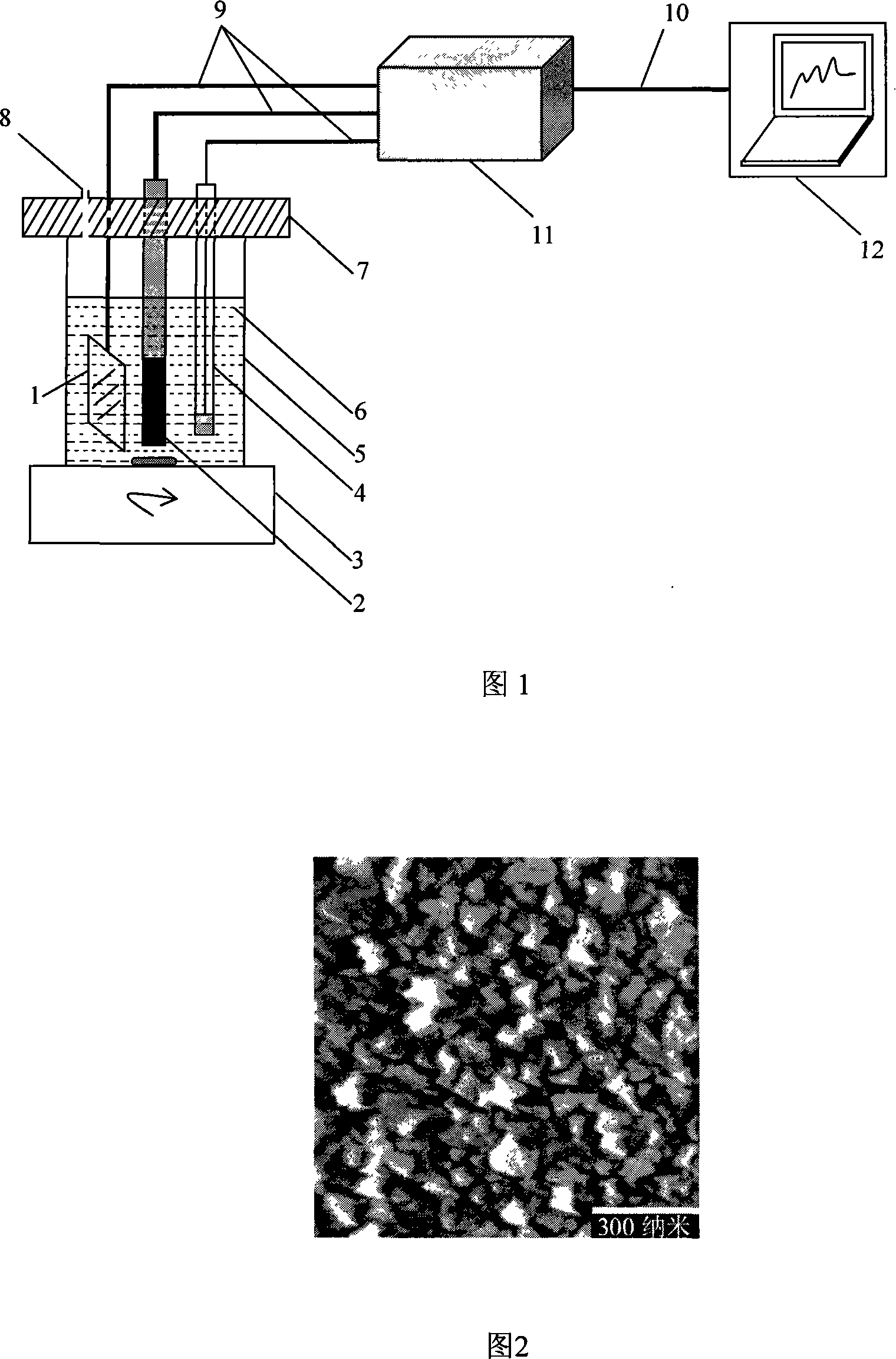

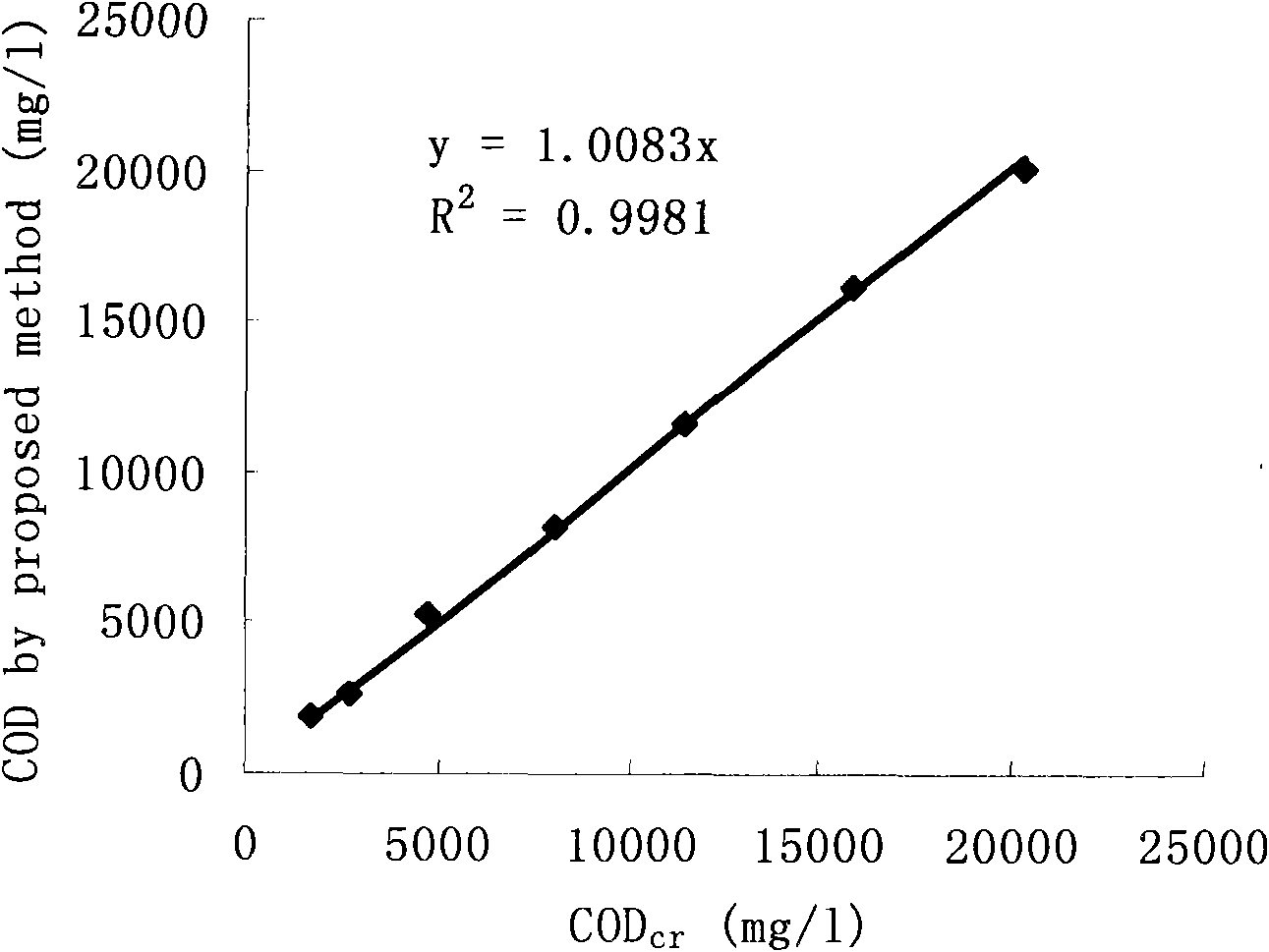

Water body chemical oxygen demand electrochemical measuring method

ActiveCN101105472AImprove corrosion resistanceHigh mechanical strengthMaterial analysis by electric/magnetic meansChemical oxygen demandOxygen

The invention relates to an electrochemistry measuring water chemical oxygen demand method; a working electrode, a counter electrode and a reference electrode are provided in a sodium sulfate electrolyte solution or a sodium nitrate electrolyte solution; constant potential is maintained; the chemistry oxygen demand value of a water sample is measured by measuring the response current generated by an oxidation organic substance. The invention is characterized in that the working electrode adopts microcrystal boron adulterated with diamond or nano-crystal boron adulterated with diamond; the PH value of the electrolyte solution is 1-7; the voltage exerted in the electrolyte solution is 2.24-2.28 V if the reference electrode is a standard hydrogen electrode. The invention has the advantages of environmental friendly, high accurate COD determination, wide measuring range, easy operation and small time consumption; the invention can be used to rapid test of COD in the samples of municipal sewage and industrial sewage.

Owner:DALIAN UNIV OF TECH

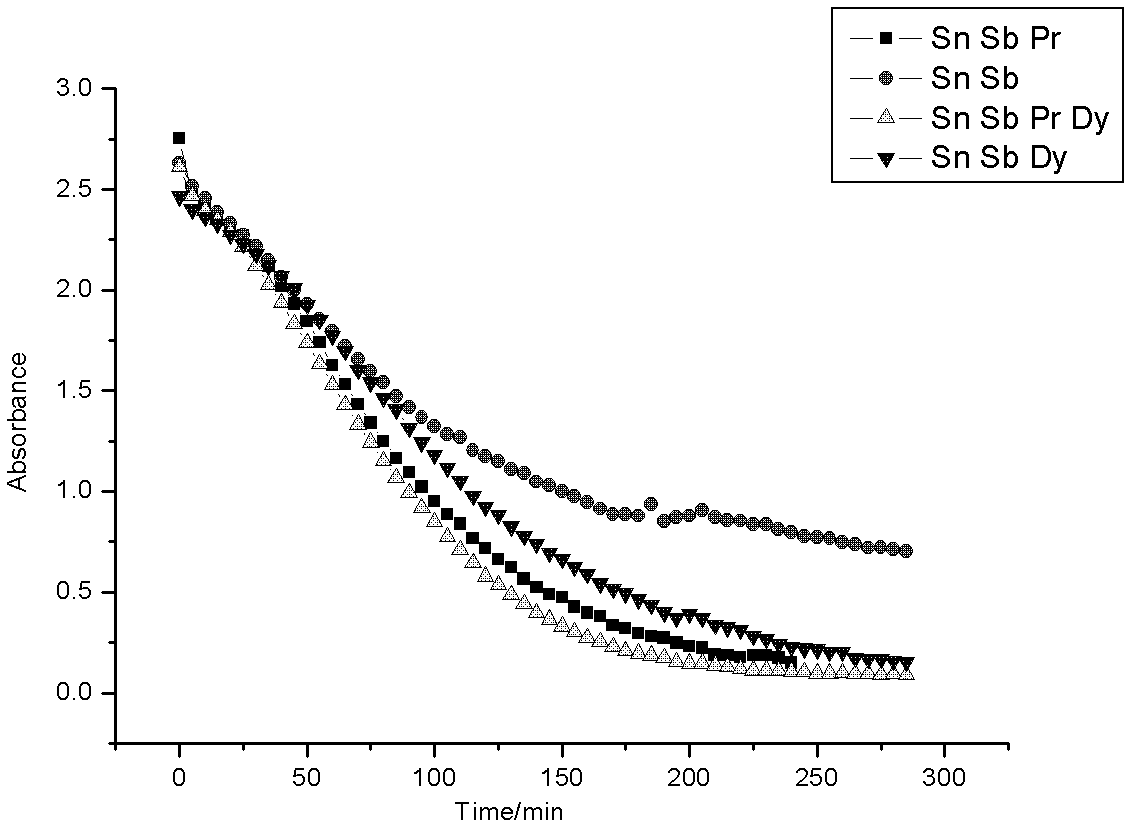

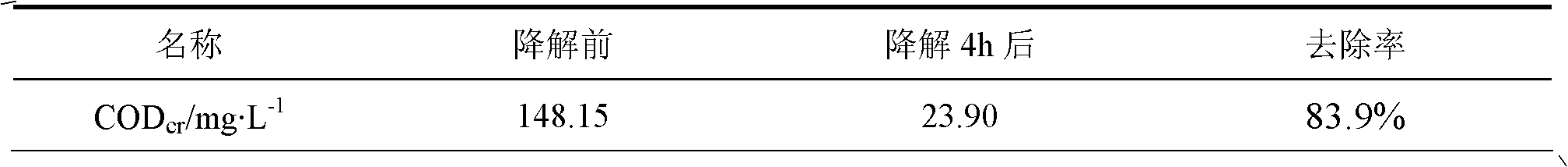

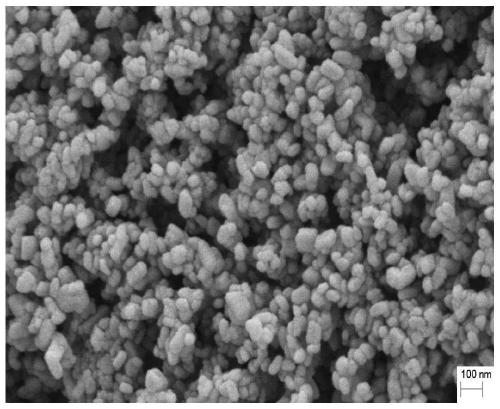

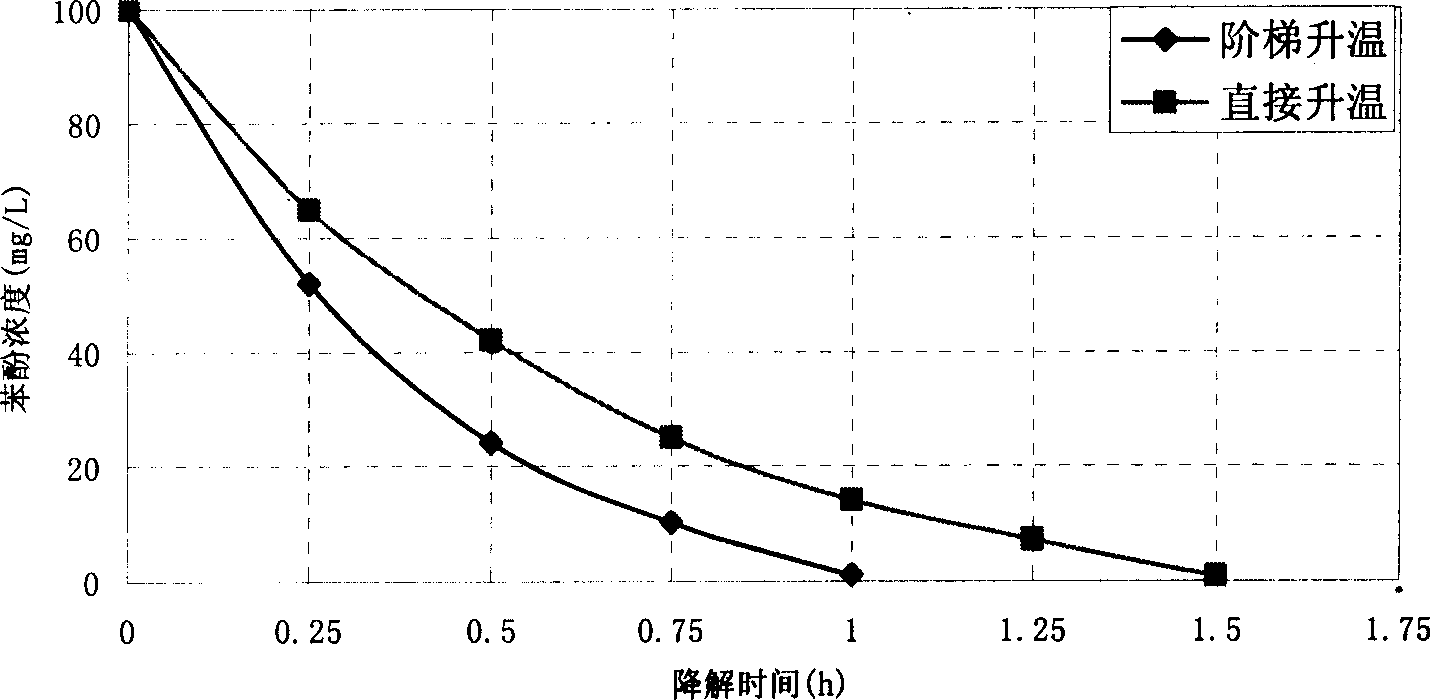

Preparation method of rare earth Pr (praseodymium)-Dy (dysprosium) doped nanometer titanium-based tin dioxide-antimony double coating electrode

InactiveCN102304724AImprove catalytic performanceReduce clumpingWater/sewage treatmentElectrodesTin dioxideDouble coating

The invention relates to a preparation method of a rare earth Pr (praseodymium)-Dy (dysprosium) Pr-Dy doped nanometer titanium-based tin dioxide-antimony (Ti / Sb-SnO2) double coating electrode, belonging to the technical field of electrochemical water treatment. The sol-gel technology is adopted to coat the Pr-Dy doped Sn-Sb sol on the surface of a pretreated electrode substrate; and the heat treatment technology combining soaking-bottom low temperature sintering and temperature programming is adopted to prepare the nanometer Ti / Sb-SnO2 double coating electrode with a Pr doped Sn-Sb intermediate layer and a Dy doped Sn-Sb catalyst layer. The electrode is characterized by high oxygen evolution potential, high catalytic performance, high conductivity, durability and the like.

Owner:SHANDONG UNIV

Method and device for detecting chemical oxygen demand of water body

ActiveCN101639459AImprove measurement accuracyHigh sensitivityMaterial analysis by electric/magnetic meansMagnetic tension forceChemical oxygen demand

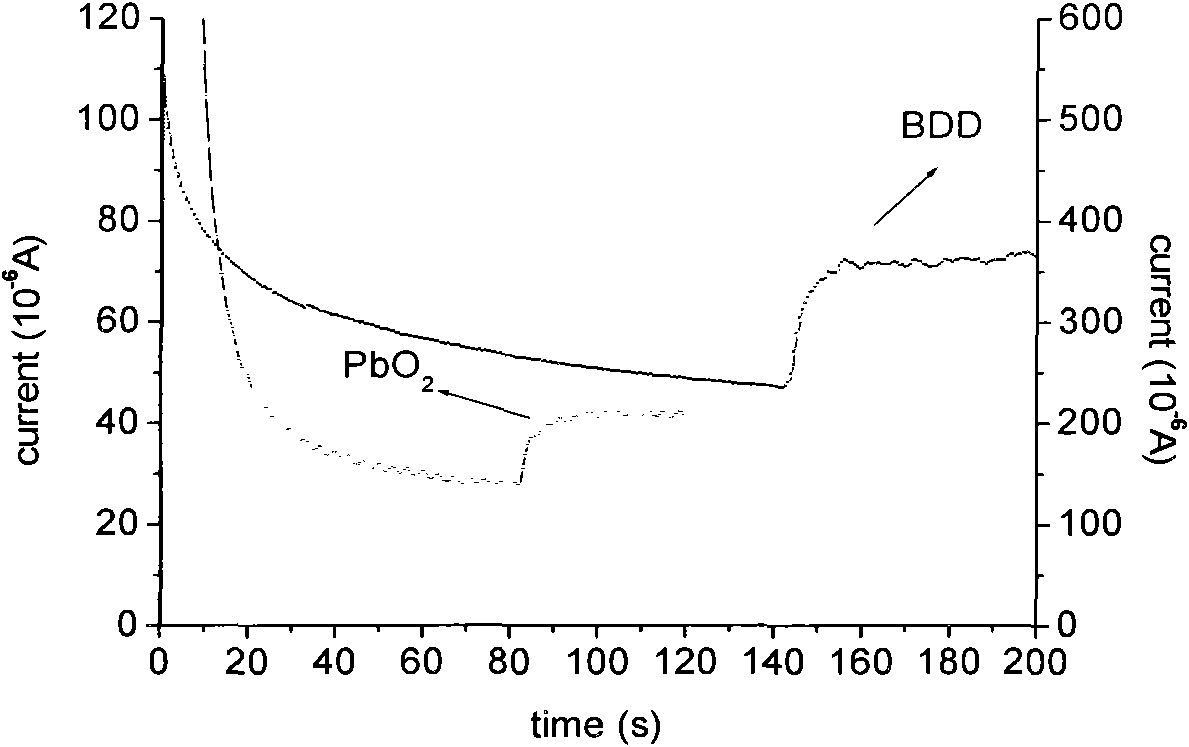

The invention discloses a method and a device for detecting chemical oxygen demand of a water body. The method comprises the following steps: applying 2.5V constant potential relative to a reference electrode to a boron-doped diamond film detection electrode as a working electrode by controlling an electrochemistry workstation; injecting certain volume of a sample to be detected into a backgroundsolution under a magnetic stirring condition; recording a current signal response of the working electrode acquired by the electrochemistry workstation in real-time; and calculating the chemical oxygen demand of the detected water body through current signals. The electrochemical detection method by the boron-doped diamond film detection electrode has the detection result in excellent comparable property compared with a national standard method, has high detection accuracy, wide the range without secondary pollution, and short electrode response time, ,and can meet the timely, quick and onlinerequirement in detecting the current environment. Compared with Pbo2 / Ti adopted in the current commercialized instrument, the detection signals have nearly one order of magnitude of predominance under the respective optimal use condition.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Fabrication method of long-life titanium base electrode

The invention discloses a fabrication method of a long-life titanium base electrode, which comprises the steps of fabricating a titanium oxide layer on a titanium substrate by a dipping-thermal decomposition method, reducing the titanium oxide layer in a reducing atmosphere, synchronously depositing a tin metal simple substance and an antimony metal simple substance in proportion on the surface of the titanium oxide layer by an electrodeposition method, and conducting thermal oxidation to allow an antimony doped tin oxide layer to be tightly combined with the titanium oxide layer connected with the titanium substrate to form a solid solution structure. The prepared titanium base tin dioxide electrode has the advantages of long service life, high oxygen evolution potential, high electrocatalytic activity, high generation efficiency of ozone from electrolyzed water, and the like. In addition, the cost of the fabrication process is low, the requirement of equipment is low, the operation is easy to control, and industrial mass production is facilitated.

Owner:XI AN JIAOTONG UNIV

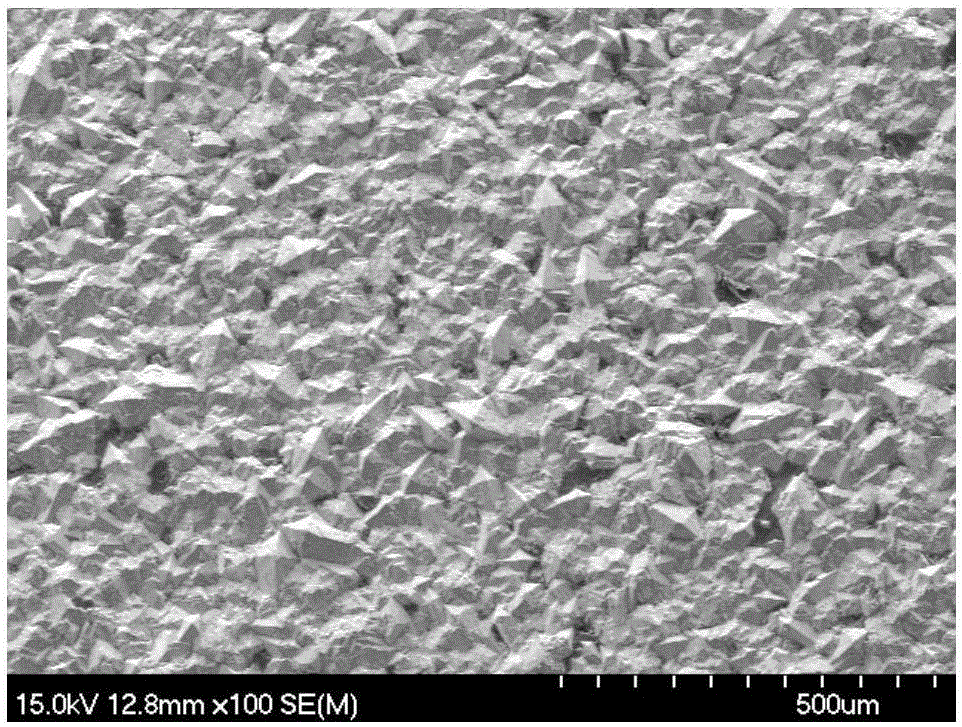

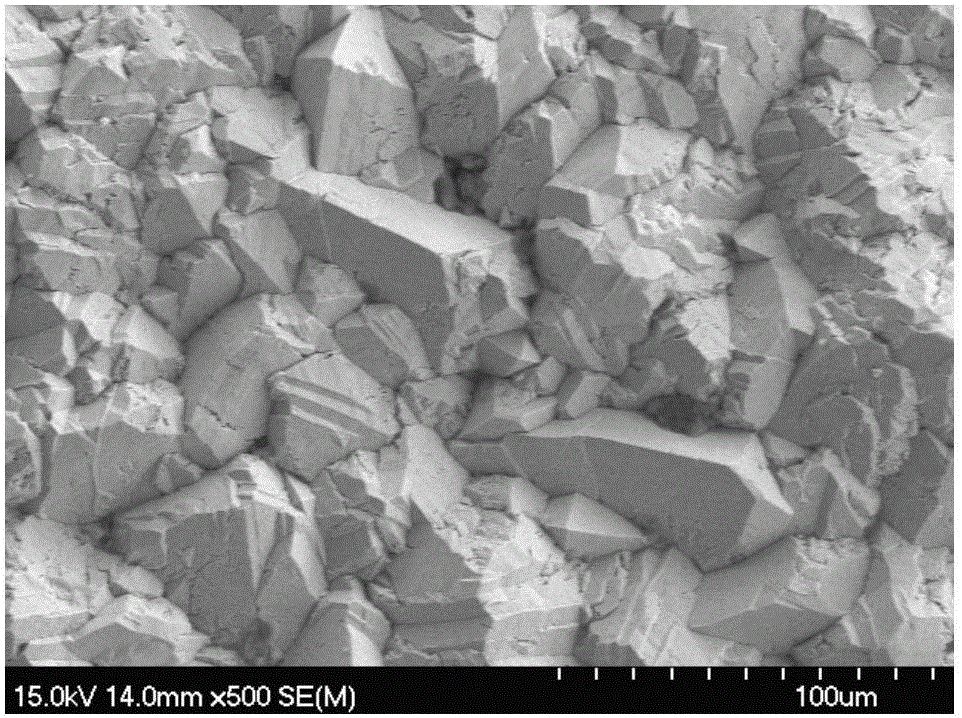

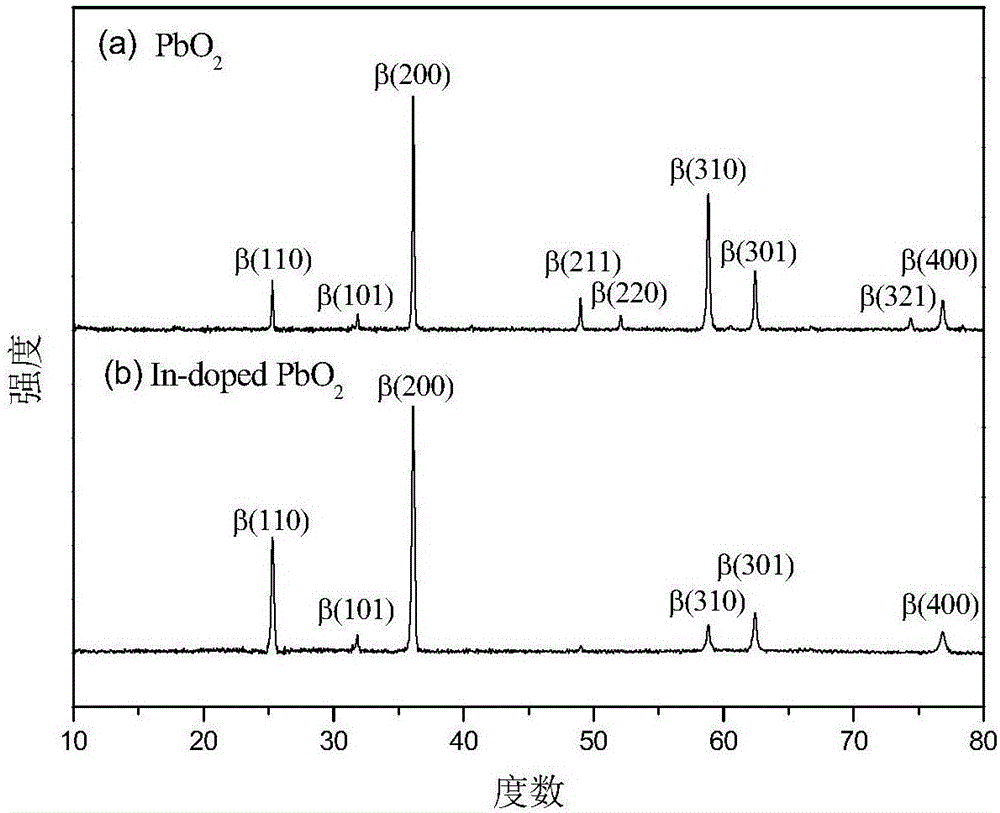

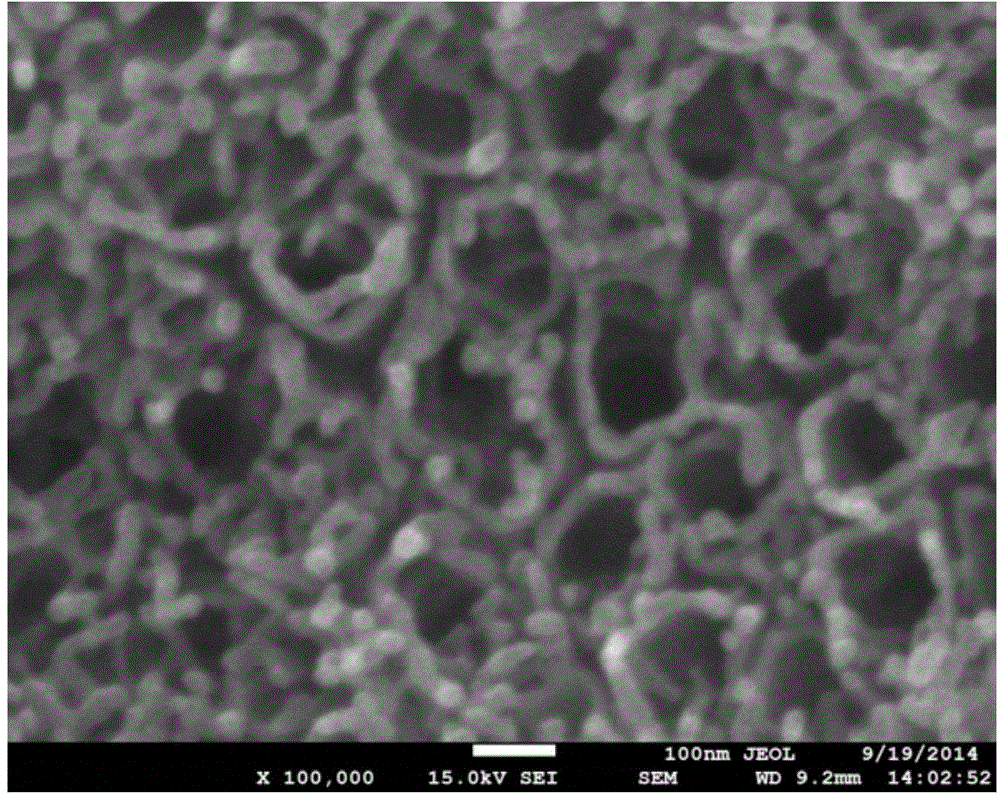

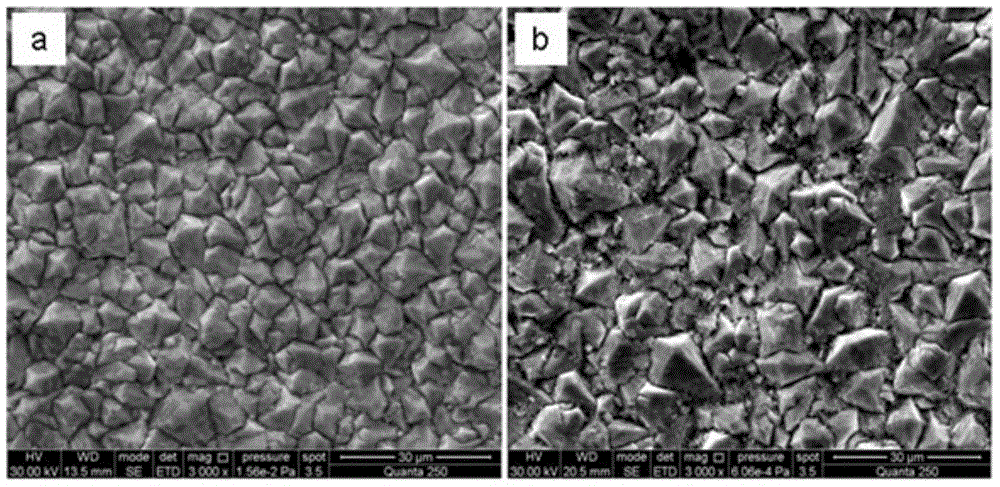

Indium-doped titanium-based lead dioxide electrode as well as preparation method and application thereof

InactiveCN106277216AHigh oxygen evolution potentialImprove electrochemical stabilityElectrolytic inorganic material coatingWater contaminantsHigh concentrationIndium

The invention provides an indium-doped titanium-based lead dioxide electrode as well as a preparation method thereof and application to degradation treatment of high-concentration pharmaceutical wastewater which is difficult to biologically degrade. The electrode takes titanium as a base body; a tin-antimony oxide bottom layer, an alpha-PbO2 middle layer and an In-doped fluorine-containing beta-PbO2 active layer are plated on the titanium base body from inside to outside in sequence; the lead dioxide electrode is modified through an electrode structural design and surface doping, and PbO2 micro-particles on the surface of the electrode can be more tightly and uniformly dispersed through adding main group metal In and a high polymer fluorine resin, so that the structure and properties of the surface of the electrode are greatly improved; inner stress between the PbO2 active layer and the titanium base body is reduced, so that the prepared electrode has higher oxygen evolution potential and electrochemical stability and the service life of the electrode is effectively prolonged; the electrode has a good catalytic performance, a long service life and high practicability, is easy to prepare and has a wide market prospect.

Owner:ZHEJIANG UNIV OF TECH

Lead acid storage battery positive electrode lead paste

The invention discloses lead acid storage battery positive electrode lead paste, and belongs to the technical field of lead acid storage battery manufacturing. The lead acid storage battery positive electrode lead paste is prepared from lead powder, sulfuric acid, water, short fiber, sodium perborate, sodium pyroantimonate, red lead and titanium black. Besides the ingredients of the lead powder, the sulfuric acid, the water and the short fiber, the lead acid storage battery positive electrode lead paste also comprises the effective ingredients of the sodium perborate, the red lead, the titanium black conducting ceramic materials and the like. The hole shape and the porosity are maintained by a lead acid storage battery assembled in such a way in the charging and discharging process; the positive electrode active ingredients have high forming performance and active ingredient utilization rate; high capacity is realized during high-rate discharging; the network structure of the positive electrode active substances is stable; the early stage capacity of the battery can be increased; the early capacity attenuation of the battery can be prevented; meanwhile, the hydrogen separation potential of the battery is obviously reduced.

Owner:CHAOWEI POWER CO LTD

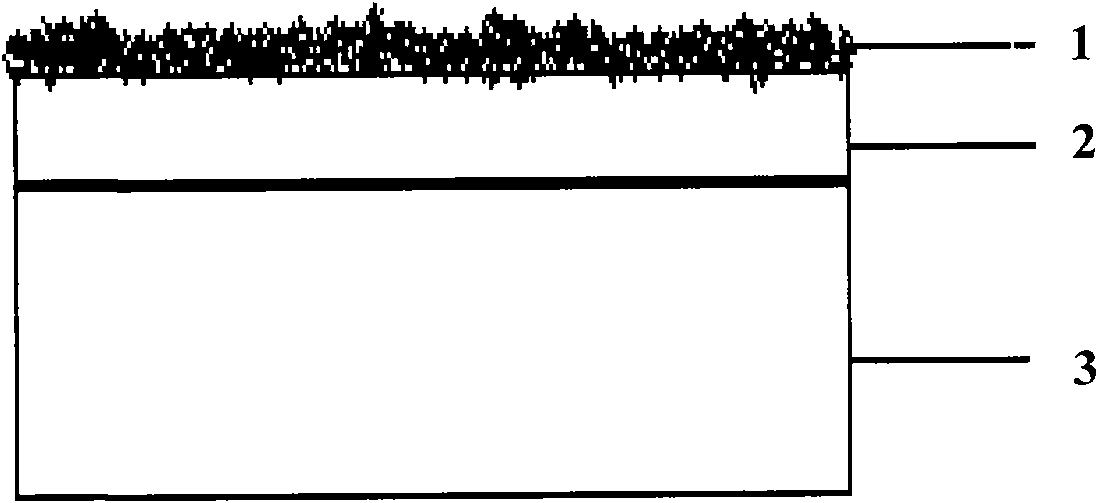

Titanium-based lead dioxide anode with intermediate layer made of modified TiO2 nanotube arrays, preparation method and applications thereof

ActiveCN104404566AHigh degree of bindingExtend your lifeMaterial nanotechnologyWater/sewage treatmentLead dioxideTio2 nanotube

The invention belongs to the technical field of electrode materials, and specifically relates to a titanium-based lead dioxide anode with an intermediate layer made of modified TiO2 nanotube arrays, a preparation method and applications thereof. The anode preparation method comprises the following steps: pre-treating a titanium plate, performing anode oxidation and calcination to obtain a Ti / TiO2 nanotube array electrode, carrying out electric deposition in an AgNO3 solution to obtain a Ti / TiO2-NTs / Ag electrode, carrying out anode oxidation to obtain a Ti / TiO2-NTs / Ag2O electrode, and finally performing electrochemical deposition in an electrolyte solution containing Pb(NO3)2, HNO3, and NaF to obtain a Ti / TiO2-NTs / Ag2O / PbO2 anode. Through preparing an Ag2O layer between titanium dioxide nanotubes and PbO2, the oxygen evolution potential, service life, and electrochemical oxidizing performance of the electrode are all improved.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

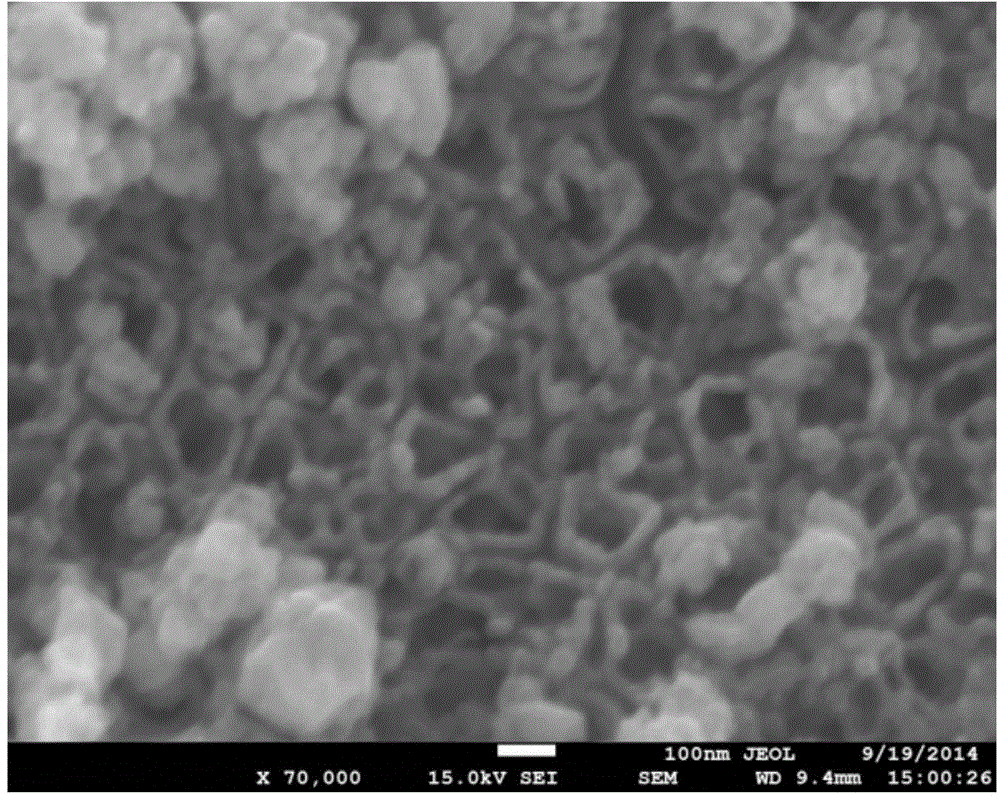

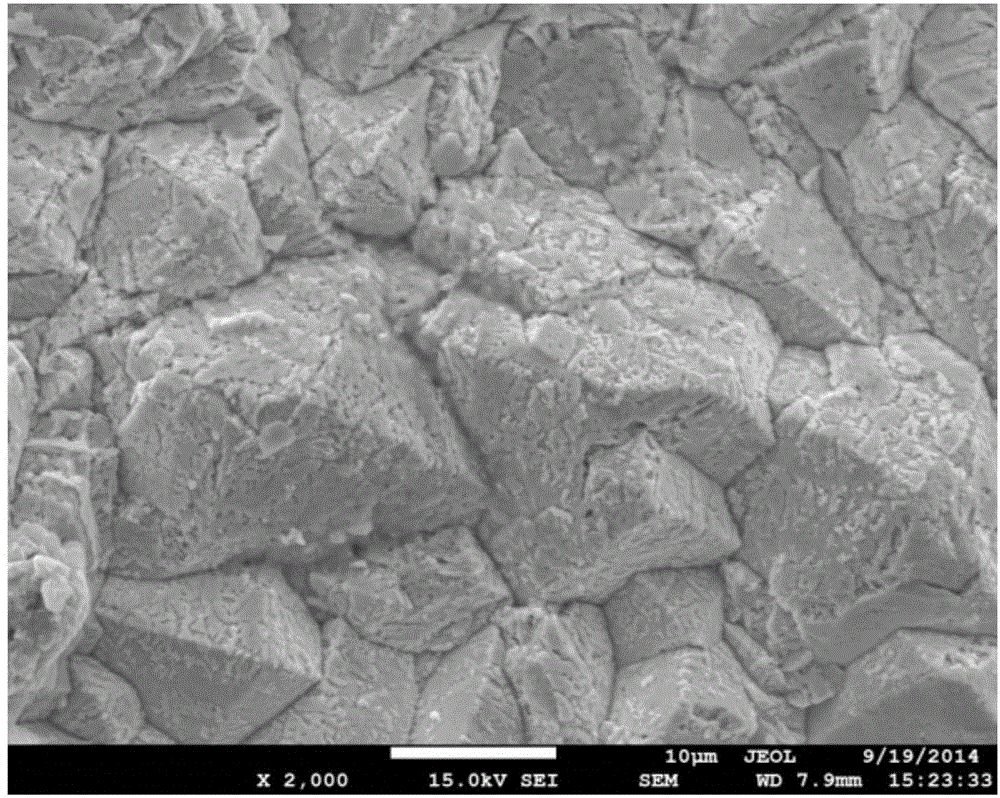

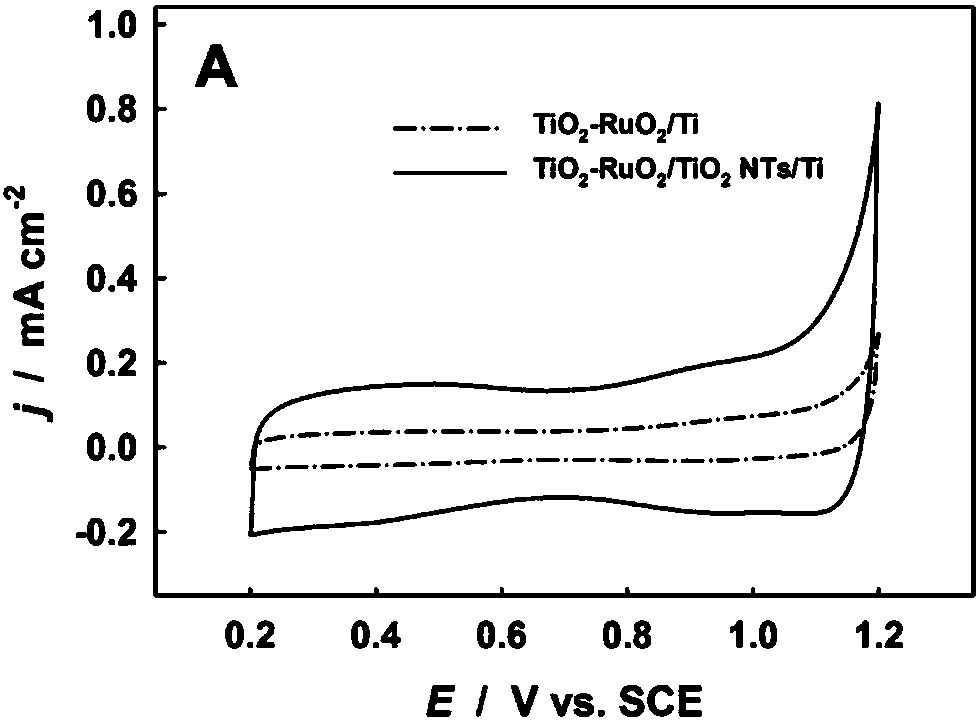

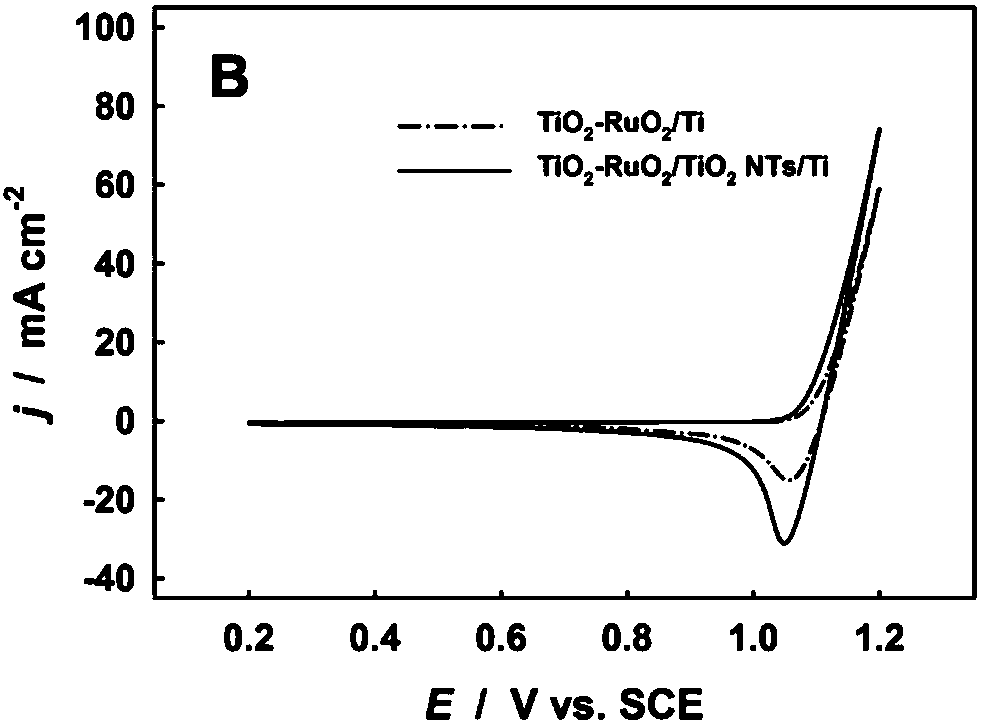

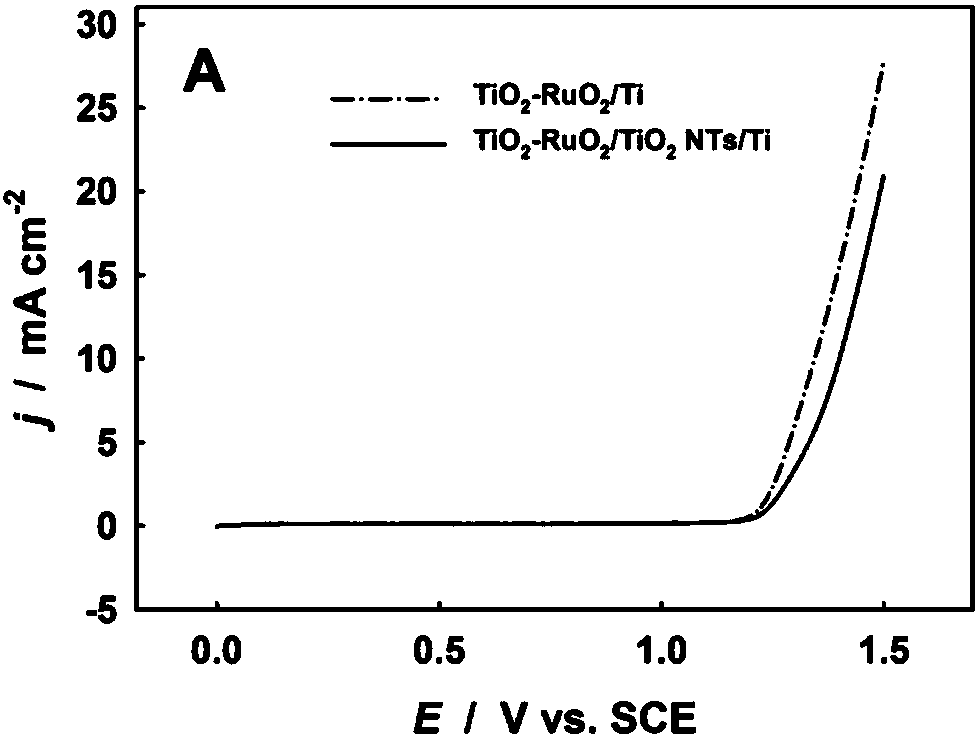

Preparation method of titanium dioxide nanotube-ruthenium-titanium oxide coating titanium electrode

InactiveCN107740138ALow degree of reunionMild preparation conditionsSurface reaction electrolytic coatingSuperimposed coating processTio2 nanotubeTitanium electrode

The invention discloses a preparation method of a titanium dioxide nanotube-ruthenium-titanium oxide coating titanium electrode. The preparation method comprises the following steps: carrying out pre-treatment on a titanium substrate, namely putting a pre-treated titanium sheet as a positive electrode and a large-area platinum mesh as a negative electrode into an electrolyte solution; then applying a direct current constant voltage to the two electrodes to anodize; in the anodizing process, keeping the temperature of the electrolyte solution constant and stirring the electrolyte solution; after anodizing, taking out the oxidized titanium sheet, namely a TiO2 nanotube / Ti electrode; ultrasonically cleaning with ethanol and water and annealing, and cooling to room temperature for later use; and coating the surface of the TiO2 nanotube / Ti electrode with coating liquid by means of a brush coating method, and drying, thermally oxidizing and cooling the TiO2 nanotube / Ti electrode to obtain the titanium dioxide nanotube-ruthenium-titanium oxide coating titanium electrode. According to the preparation method disclosed by the invention, the TiO2 nanotube can directly grow on a Ti substrate and has a very good bonding force with the titanium substrate, so that the TiO2.RuO2 / TiO2 naotube / Ti electrode is longer in fortified life, and the electrochemical active area is large.

Owner:西安博岳环保科技有限公司

Positive pole coating for ion membrane electrolysis bath

ActiveCN110318068AHigh oxygen evolution potentialStrong catalytic abilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesIonIridium

The invention relates to a positive pole coating for an ion membrane electrolysis bath. The positive pole coating is characterized by comprising, in weight percent, 35-45mol% of ruthenium, 5-15mol% ofiridium, 5-10mol% of platinum, 35-45mol% of titanium and smaller than 4%mol% of other additives. The additives comprise zirconium chloride or palladium chloride. The positive pole coating for the ionmembrane electrolysis bath is used for an active anode, an oxygen evolution potential is high, catalytic ability is high, conductivity is high, oxygen evolution side reaction cannot be easily generated, the coat is stable in performance, resistant to corrosion, long in service life, coating can continue to be used after recoating after an electrode is faulted, electrodes is effectively controlled, product quality is improved, and required chlorine purity is high, and oxygen content is low.

Owner:宏泽(江苏)科技股份有限公司

Titanium-based tin-antimony-platinum oxide electrode material and preparation method thereof

InactiveCN102320683AImprove bindingImprove compactnessWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationSulfate radicalsPlatinum oxide

The invention relates to a titanium-based tin-antimony-platinum oxide electrode material and a preparation method thereof. The preparation method comprises the steps of pretreating a titanium matrix, plating tin, coating an active layer and sintering, wherein the active layer is antimony-platinum coating liquid; and the constitution of the antimony-platinum coating liquid is characterized in thatSbCl3:H2PtCl6.6H2O:36wt% HCl:n-butyl alcohol=0.1g:(0.01-0.03g):1ml:5ml. A titanium-based tin-antimony-platinum oxide electrode provided by the invention has high oxygen evolution potential and is suitable for the treatment of organic waste water which is difficult to degrade; meanwhile, the electrode can be used for better catalyzing the reaction for generating apersulfate radical (S2O8<2->) froma sulfate radical (SO4<2->); and under the condition of same power consumption and same electrolyte, the output of S2O8<2-> is 30-35% higher than that of the titanium-based tin-antimony (Ti / Sn-Sb) oxide electrode.

Owner:DALIAN MARITIME UNIVERSITY

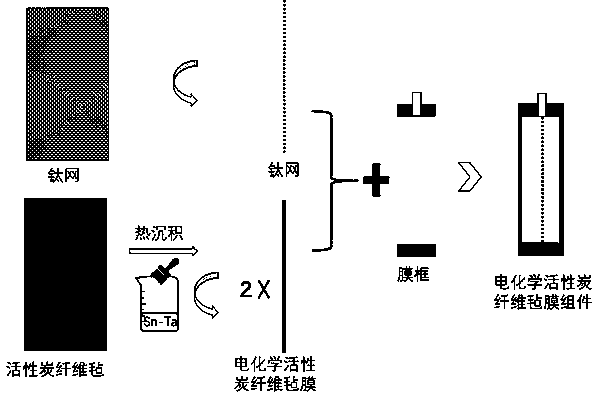

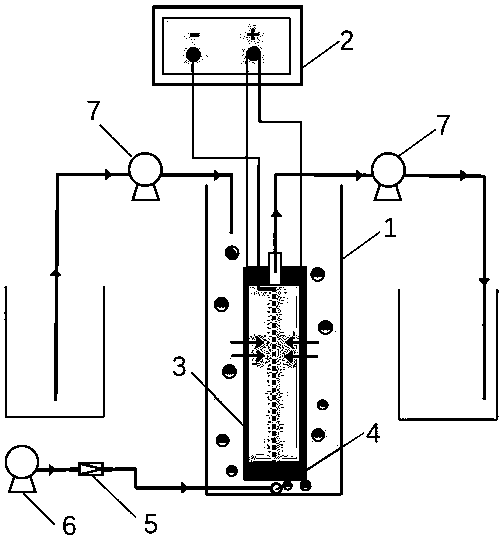

Electrochemical activated carbon fiber felt reactor applicable to removal of refractory organic matters in water

ActiveCN108658177AReduce pollutionHigh oxygen evolution potentialSemi-permeable membranesTreatment by combined electrochemical biological processesFiberElectron transfer reactions

The invention relates to an electrochemical activated carbon fiber felt reactor applicable to removal of refractory organic matters in water. A titanium mesh cathode is embedded into a PVC membrane bracket, ACFF / SnO2-Ta serves as an anode and a filter membrane at the same time, and an electrochemical microfiltration membrane assembly is placed in a reactor. The reactor is applied with an externalelectric field by a regulated DC power supply, and an oxidant variety with a relatively strong oxidizing property is produced in situ; in a continuous flow mode, convective mass transfer of a bulk solution and an anode interface is promoted by pumping of a peristaltic water outlet pump, so that an electron transfer reaction at the anode interface is accelerated, the yield of the oxidant is increased, and the probability of contact between organic pollutants in water and the produced oxidant is increased; particles, colloids and macromolecular pollutants in water can be filtered out through a dimensional exclusion effect of membrane pores, and because of relatively high specific surface area thereof, the electrochemical activated carbon fiber felt reactor can provide a large number of adsorption sites for small molecular organic pollutants in water; through doping of a Ta element, the electrocatalytic performance of SnO2 is significantly improved; H2O can form a large number of adsorbedand dissociated -OH through discharge at an anode, so that an important role is played in degradation of the small molecular organic pollutants.

Owner:TONGJI UNIV

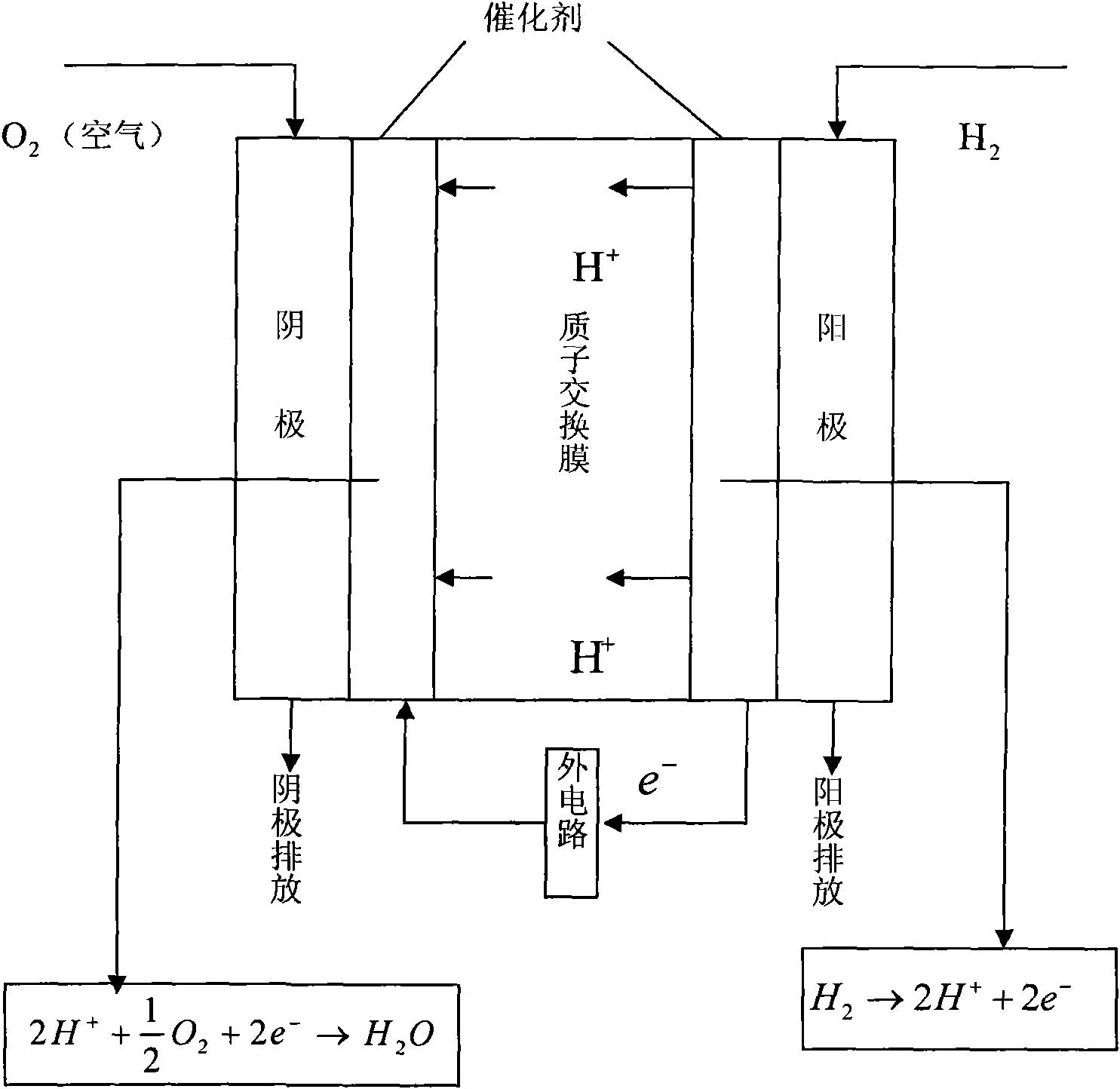

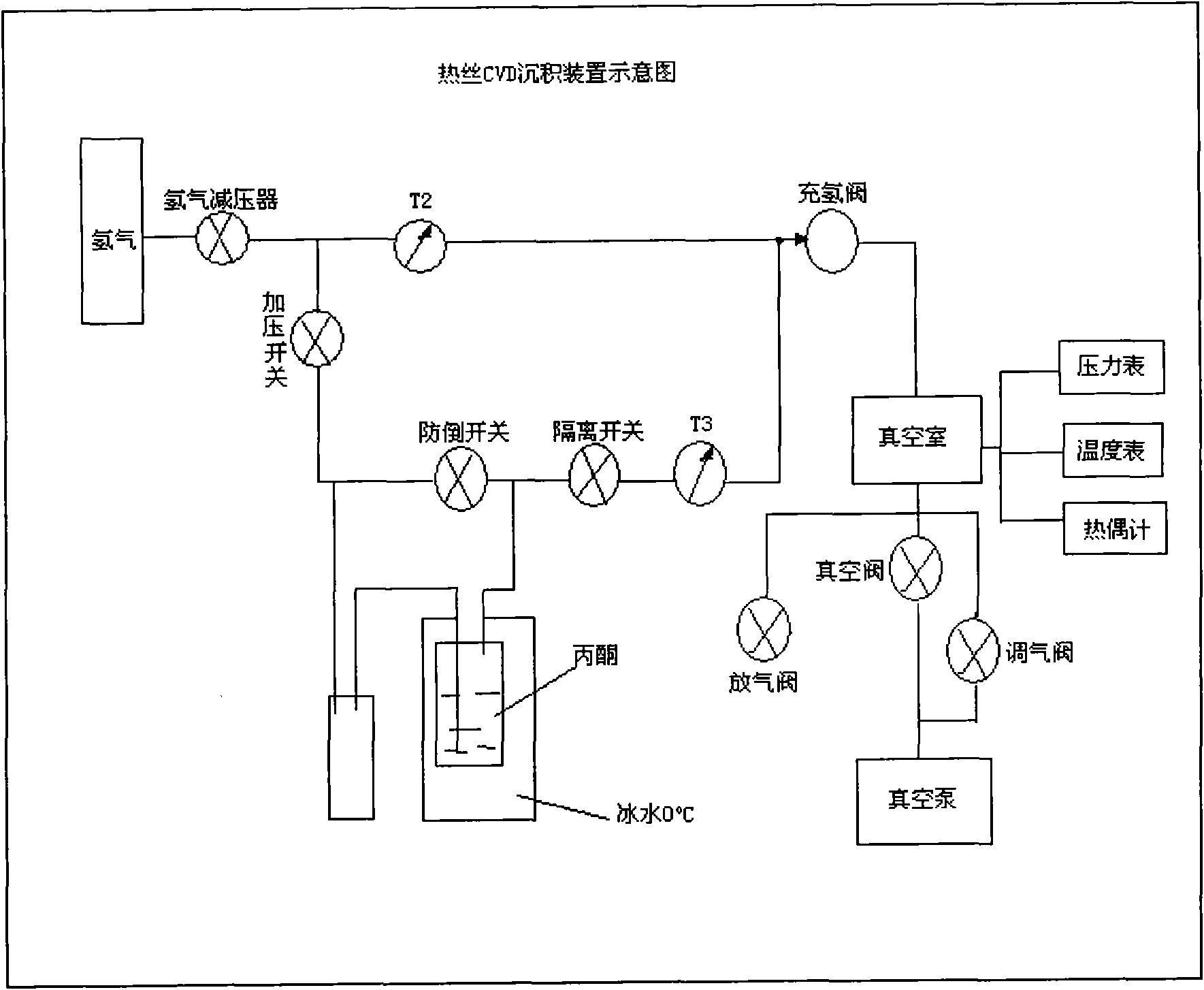

Boron-doping diamond film modification-based PEMFC (Proton Exchange Membrane Fuel Cell) bipolar plate and preparation method thereof

InactiveCN102074708AAccelerated corrosionImprove conductivityCell electrodesSputteringHeat conducting

The invention discloses a boron-doping diamond film modification-based PEMFC (Proton Exchange Membrane Fuel Cell) bipolar plate and a preparation method thereof, belonging to the field of batteries. In the boron-doping diamond film modification-based PEMFC bipolar plate, after a stainless steel plate is subjected to surface pretreatment, a layer of TI film is sputtered on the stainless steel plate by using magnetron sputtering; a boron-doping diamond film is deposited on the TI film by using heat wire CVD (Chemical Vapor Deposition) equipment; and a diamond film and TI film compounded modification layer is formed on the surface of stainless steel. The stainless steel plate treated by the method has high corrosion resistance and a favorable conductive and heat-conducting property; and according to the stainless steel plate, the battery ratio power can be greatly improved and the PEMFC can achieve the aims of prolonging the service life and reducing the weight, the volume and the cost.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

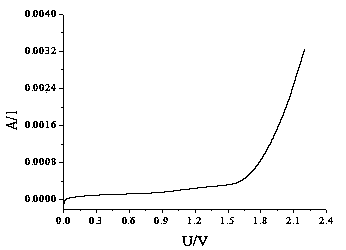

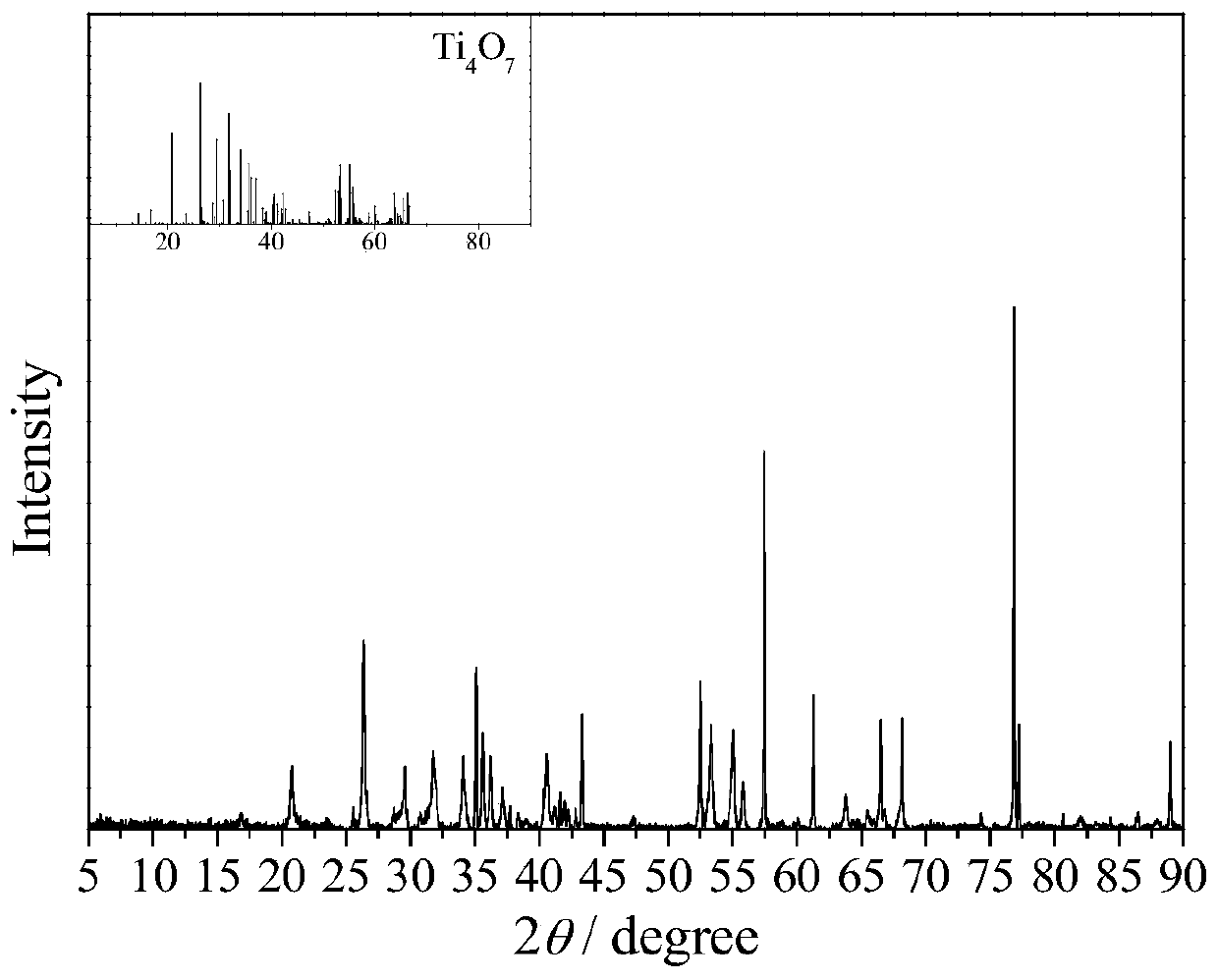

Preparation method of TinO2n-1 porous electrode and application thereof

ActiveCN110217863AEasy to prepareSimple ingredientsWater contaminantsWater/sewage treatment using germicide/oligodynamic-processEpoxyElectrolysis

The invention provides a preparation method of a TinO2n-1 porous electrode. The method comprises the following steps: mixing TiH2 and TiO2, carrying out ball milling, drying and screening, carrying out sintering, dropping polyvinyl alcohol so as to obtain a precursor mixture, adding the precursor mixture into foam nickel, carrying out pressurization so as to obtain a pressing blank, carrying out sintering, welding a lead on the surface of the foam nickel, sleeving the outer side of the lead by a polyvinyl alcohol tube, packaging a TinO2n-1 pre-finished product by using an epoxy resin, and after the epoxy resin is cured, carrying out flat polishing, so as to obtain the TinO2n-1 porous electrode. The invention further provides application, namely electrochemical degradation on organic matters in organic wastewater. By adopting the preparation method, TiH2 is adopted as a reducing agent of TiO2, TiH2 is capable of reducing temperatures required by reactions, Ti atoms and H atoms are decomposed by TiH2 to directly join in TiO2 reduction, and reaction processes can be simplified; and the TinO2n-1 pre-finished product is of a porous structure, is large in specific surface area, high in electrolysis rate and high in content of Ti4O7, and the TinO2n-1 porous electrode is high in oxygen evolution potential, good in electrochemical stability and high in organic matter removal rate in electrochemical degradation of organic matters in organic wastewater, can be repeatedly used, and is long in service life.

Owner:NAVAL UNIV OF ENG PLA

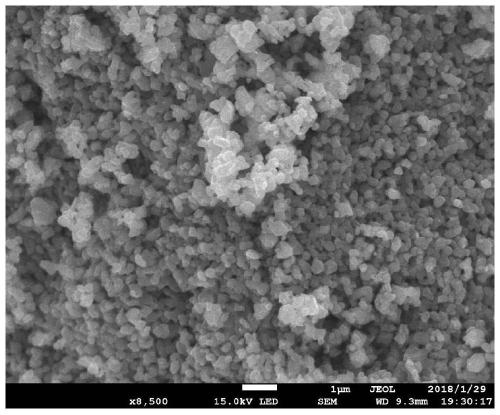

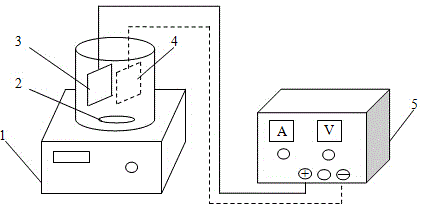

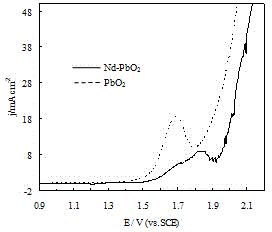

Preparation method of neodymium-doped lead dioxide electrode

InactiveCN104451678ALow running costStrong catalysis · OH abilityElectrolytic inorganic material coatingSurface reaction electrolytic coatingLead dioxideInter layer

The invention discloses a preparation method of a neodymium-doped lead dioxide electrode. The preparation method comprises the following steps: performing polishing and etching pretreatment on a titanium substrate and then coating the surface of the titanium substrate with a tin-antimony middle layer by use of a pyrolytic process, and furthermore, and electroplating a neodymium oxide-containing beta-PbO2 crystal active layer by use of an electrodeposition method, thereby forming the neodymium-doped lead dioxide electrode. According to the preparation method of the neodymium-doped lead dioxide electrode, the surface structure of the electrode is improved by virtue of the doping of neodymium, the catalytic oxidizing activity and the stability of the electrode are improved, and the prepared electrode is capable of effectively degrading organic matters, good in treatment effect, high in current efficiency and low in cost, and has an excellent application value.

Owner:NANTONG AGRI COLLEGE

Method for preparing lead dioxide electrode with porous matrix

InactiveCN105887131AImprove performanceUnique three-dimensional internal structureElectrolytic inorganic material coatingWater/sewage treatmentElectricityElectrical resistance and conductance

The invention relates to a method for preparing a lead dioxide electrode with a porous matrix. The method includes the following steps that a porous material serves as the matrix, the matrix is subjected to surface treatment, and a mud-crack-free middle coating and a lead dioxide surface layer are prepared on the treated surface of the matrix sequentially. The method has the beneficial effects that the lead dioxide electrode with the porous matrix is of a unique three-dimensional internal structure, and the middle layer can be closely combined with the porous matrix as a solid solution or in other forms, and forms a compact mud-crack-free covering layer, so that the matrix is effectively protected, and the service life of the electrode is greatly prolonged; an active layer and the matrix can be firmly combined, and high bonding force and high anti-stripping capacity are achieved; the special internal meshed communication mechanism of the porous matrix material improves the overall performance of the electrode and plays a significant role in assisting in electrocatalytic oxidation; and the prepared lead dioxide electrode with the porous matrix has the advantages of high oxygen evolution potential, good catalytic activity, large electrode specific surface area, and small interface resistance and internal stress.

Owner:CHANGZHOU UNIV

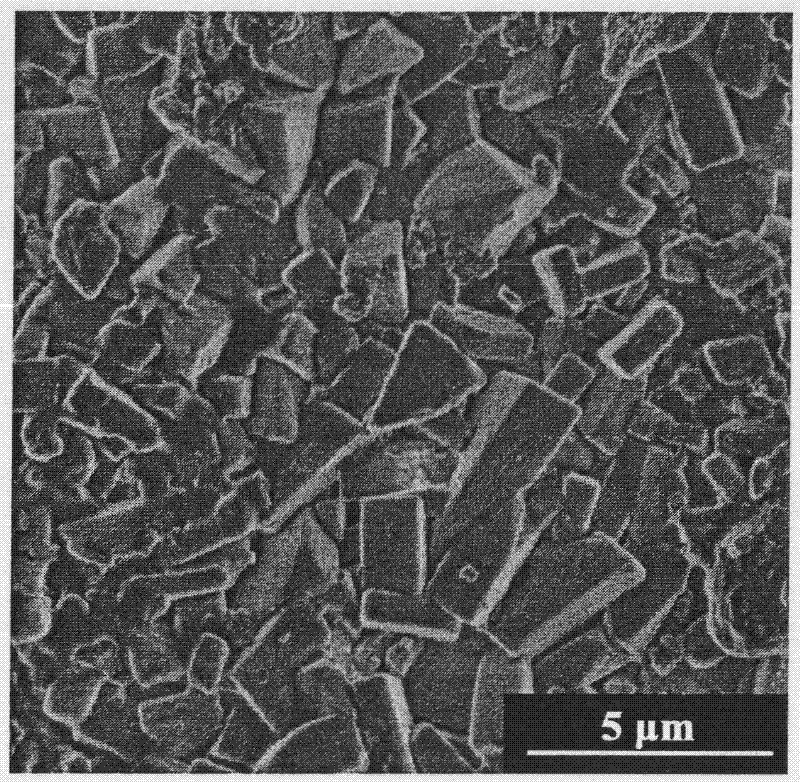

Preparation of nano-structured DSA electrolytic electrode

A preparing process of a nanostructured DSA eletrocatalytic electrode aims at the problems of low potential of oxygen evolution, incompact and loose coating on the electrode surface and low specific sueface area at present. The preparing process of nanostructured DSA electrode provided by this invention includes the pretreatment of the Titanium substrate, the preparation of sol and the heat treatment of the surface nano-coating. By this process the electrode has a higher potential of oxygen evolution and a compact and fast coating. Compared with the electrodes in published papers, this preparing process improves the electrocatalytic ability significantly, reduces the degration time of equal amount of organic compounds by 33%, increases the oxygen evolution potential by 0.1V to above 1.9V(vs.SHE), elongates the lifespan of the electrode by two times and is convenient for spreading.

Owner:HARBIN INST OF TECH

Preparation method of high catalytic activity magnetic particle loading 2.5-dimensional anode

InactiveCN108130582AIncrease the real catalytic areaExtended service lifeElectrolytic inorganic material coatingWater/sewage treatmentTin dioxideElectrolysis

The invention discloses a preparation method of a high catalytic activity magnetic particle loading 2.5-dimensional anode. The preparation method comprises the following steps of preparing a titaniumoxide layer on ferroferric oxide magnetic particles by utilizing a dipping-heat oxidation method firstly, and then further coating the particles, covered with titanium oxide, with a antimony-doped tindioxide layer through the dipping-heat oxidation method to enable the antimony-doped tin dioxide layer to be tightly combined with the titanium oxide layer which is adhered to a magnetic particle substrate to form a solid solution; and attracting the magnetic particles by adopting the magnetic force to enable the magnetic particles to be adhered to the surface of a cylindrical electrode to form the 2.5-dimensional magnetic particle loading anode. According to the preparation method, due to the flexibility of the magnetic force, the magnetic particles on a novel electrode can be recovered in situ, so that operation is simple; and the experiment condition requirements are relatively low, the technological process is liable to control, and the prepared composite anode has high electro-catalytic activity, is high in oxygen evolution potential and long in service life and is suitable for being applied to industrially electrolyzing waste water in a large scale.

Owner:SHAANXI UNIV OF SCI & TECH

Nickel-boron-nitrogen co-doped diamond electrode as well as preparation thereof and application thereof

PendingCN107988616AHigh hydrogen evolutionHigh oxygen evolution potentialElectrolytic organic productionSolid state diffusion coatingDiamond electrodesChemical stability

The invention provides a nickel-boron-nitrogen co-doped diamond electrode. The nickel-boron-nitrogen co-doped diamond electrode comprises a base body and a nickel-boron-nitrogen co-doped diamond filmlayer arranged on the surface of the base body, wherein the nickel-boron-nitrogen co-doped diamond film layer comprises a flat structural layer arranged on the surface of the base body and an array bump structure arranged on the surface of the flat structural layer. The array bump structure is arranged on the nickel-boron-nitrogen co-doped diamond film layer of the nickel-boron-nitrogen co-doped diamond electrode, so that a catalysis specific surface area can be provided; the nickel-boron-nitrogen co-doped diamond electrode has a very high hydrogen-evolution electric potential, very strong electrocatalytic activity and physical and chemical stability, has a very low resistance value, and can perform electrocatalytic reduction on carbon dioxide with high selectivity. The invention further provides preparation and application of the nickel-boron-nitrogen co-doped diamond electrode.

Owner:SHENZHEN INST OF ADVANCED TECH

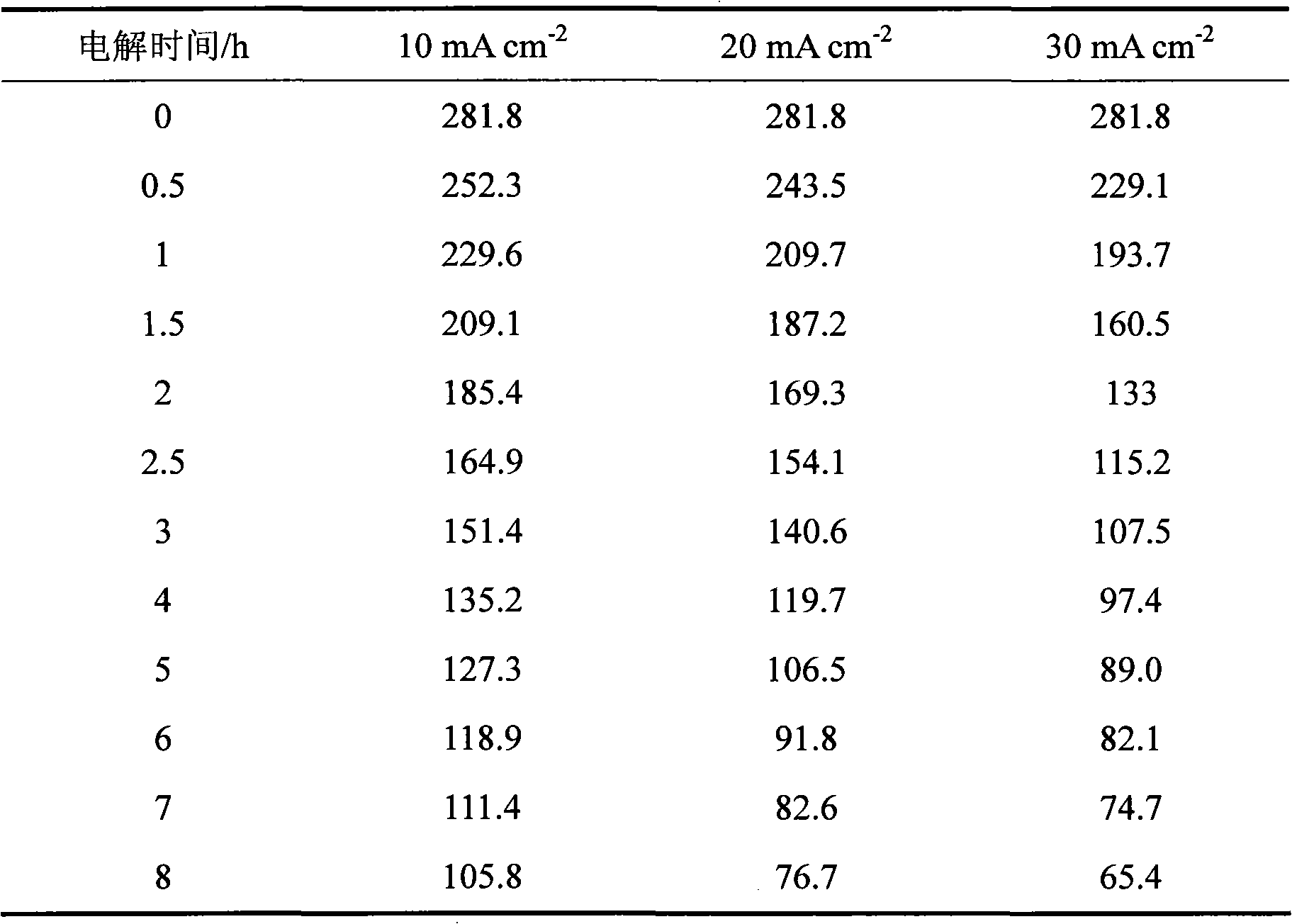

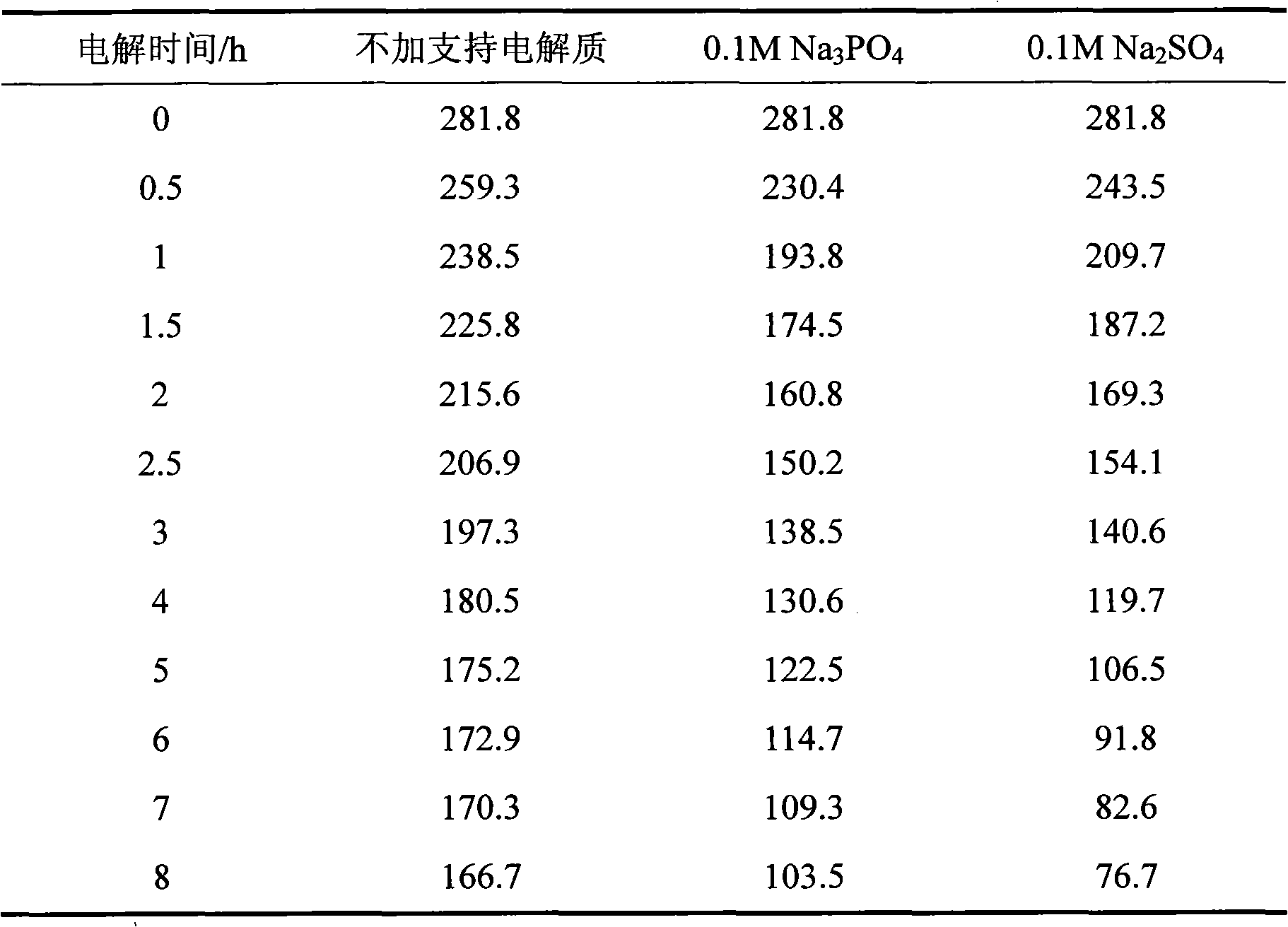

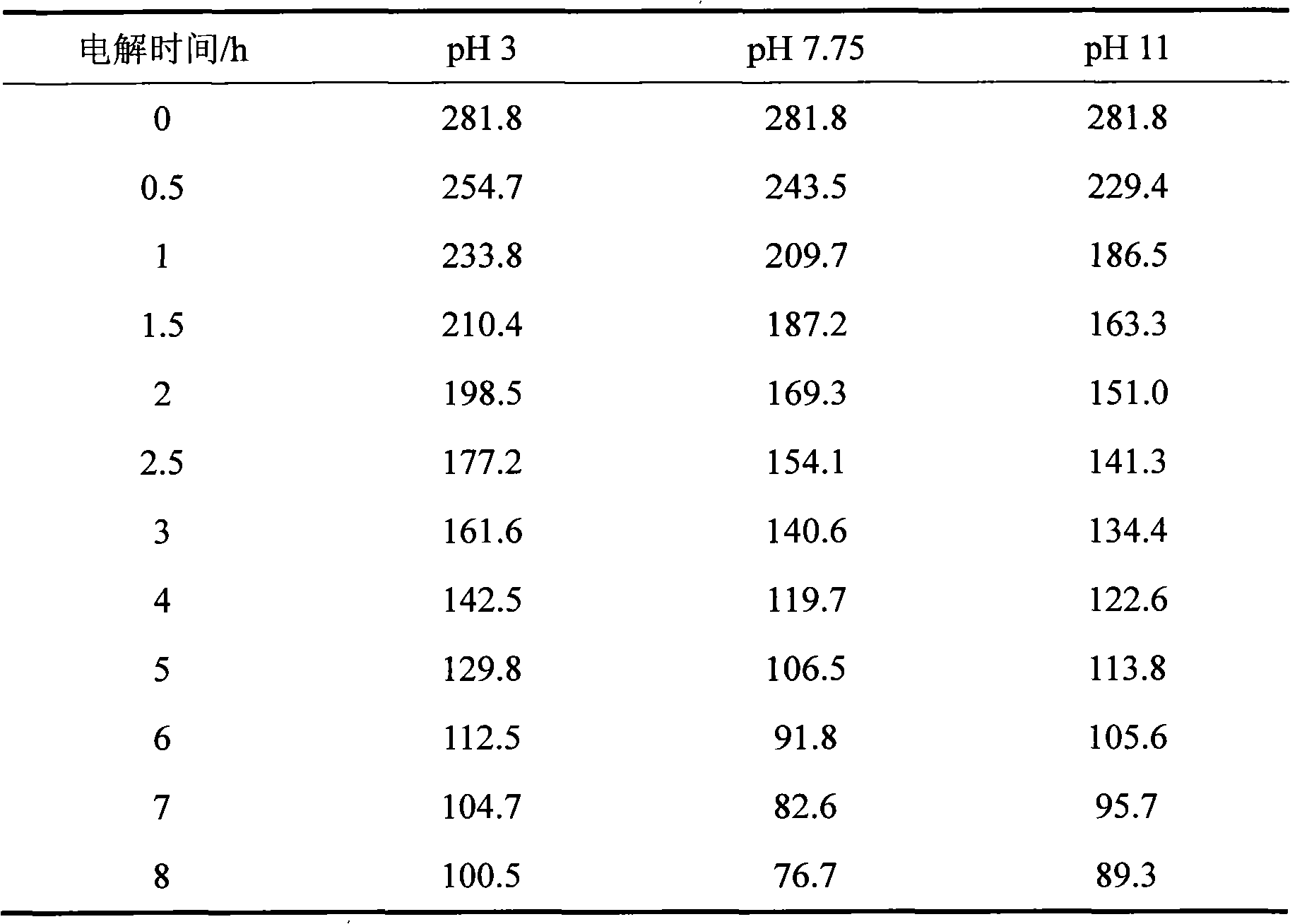

Advanced treatment method for Dioscoreazingiberensis C.H.Wright wastewater

InactiveCN101863534AHigh oxygen evolution potentialImprove current efficiencyWater/sewage treatmentSupporting electrolyteTherapeutic effect

The invention discloses an advanced treatment method for DIoscoreazingiberensis C.H.Wright wastewater, which takes a boron-doped diamond film BDD electrode as an anode and stainless steel as a cathode to perform an advanced treatment on biologically-treated dioscoreazingiberensis C.H.Wright wastewater via an electrochemical oxidation method, the biologically-treated dioscoreazingiberensis C.H.Wright wastewater is obtained from the process (disclosed in the patent with a patent publication number of CN1789171A) combining neutralization, hydrolysis acidification, desulfuration, methane fermentation, I-BAF-1 and I-BAF-2. The persistent organic pollutants in the biologically-treated dioscoreazingiberensis C.H.Wright wastewater can be effectively removed under the operation conditions of a current density of 30mA cm<-2>, a pH value of 7.75 and the addition of 0.1M supporting electrolyte Na2SO4. The COD content in the biologically-treated dioscoreazingiberensis C.H.Wright wastewater is reduced to 97.4mg / L from 281.8mg / L, meeting the national discharge standard of class I, and the energy consumption is 13.44kWhm <-3>. The method has the advantages of high oxidation capacity, excellent treatment effect, low energy consumption, low controllability and high potential in industrial application.

Owner:PEKING UNIV

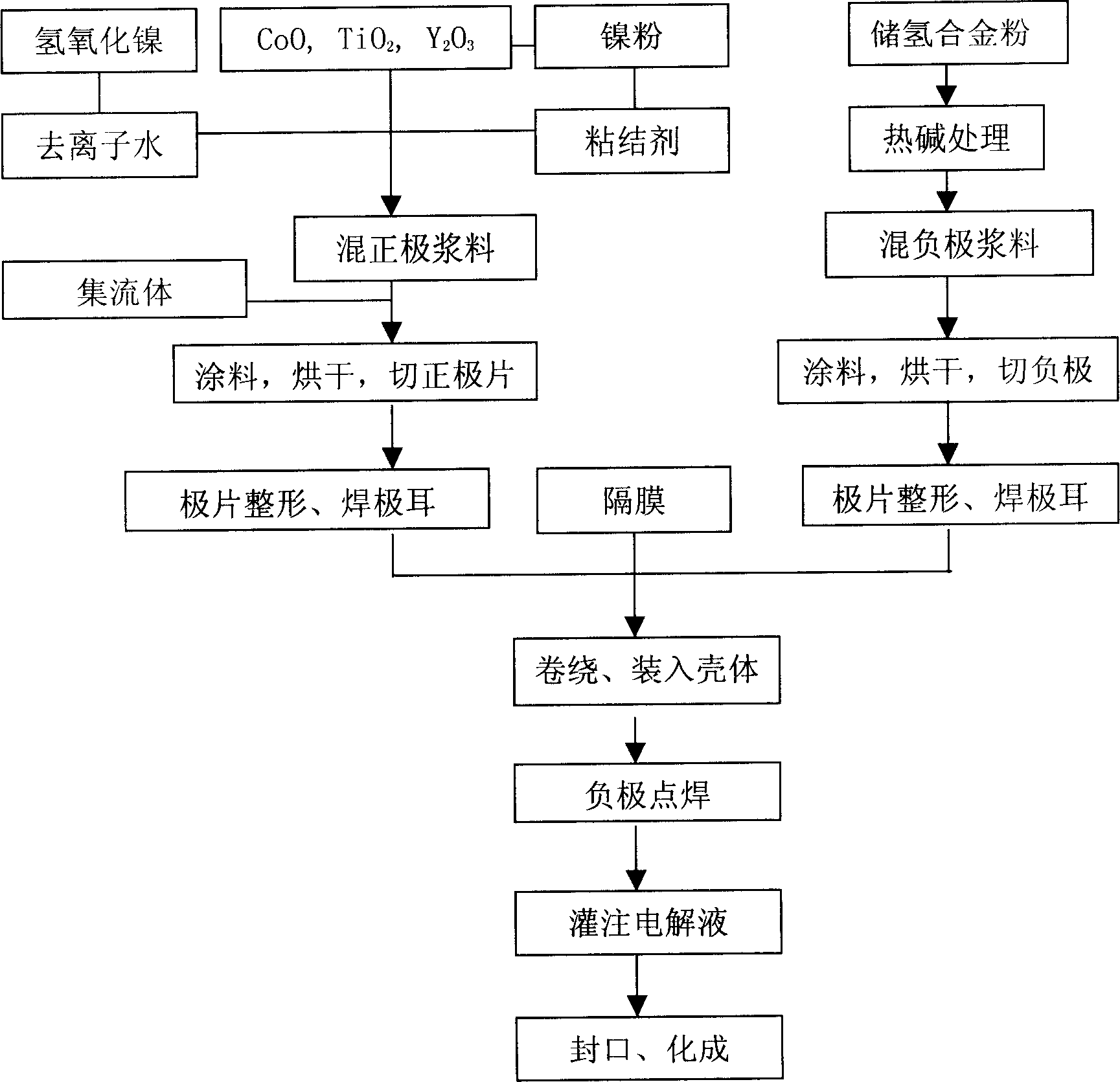

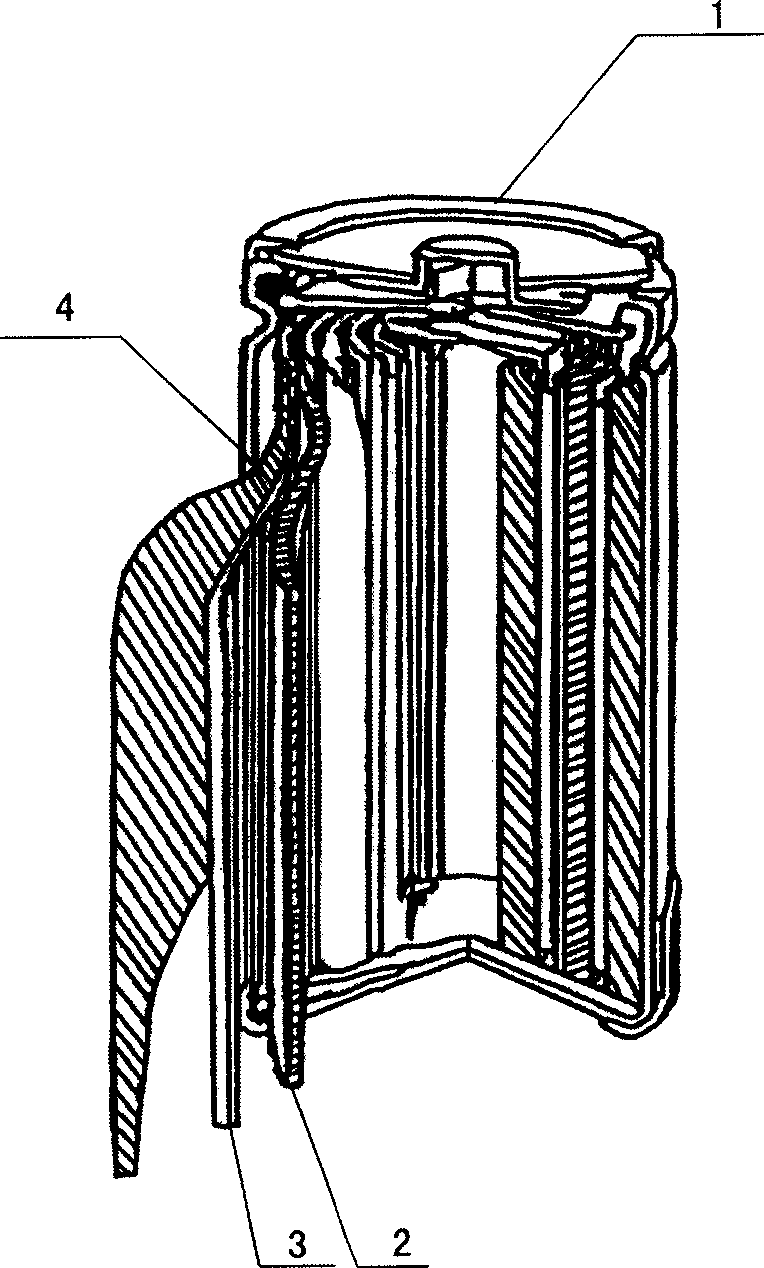

Columnar nickel hydrogen secondary battery and production thereof

InactiveCN1819320AComposite speedFast phase changeFinal product manufactureAlkaline accumulator electrodesNickel oxide hydroxideCurrent collector

In the battery shell there are pole pieces of anode and cathode. The anode paste is mainly composed of nickel hydroxide. In the supplementary materials there are CoO, TiO2, and Y2O2 as additive. The cathode paste is mainly composed of hydrogen storage alloy powder. The pastes are coated on current collector to form pole pieces of anode and cathode. The anode piece, diaphragm, and cathode piece are rolled to form cell core. The electrolyte is filled into the battery shell. The said cathode piece is longer than the one of anode in rolling direction, and is 1-4mm wider than the one of anode, so that the cathode piece in outmost layer contacts the inner wall of battery shell, and the bottom of cathode is bonded with the bottom of battery shell by welding.

Owner:赵兵 +1

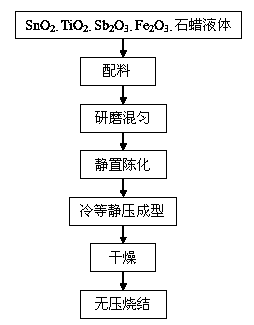

Tin dioxide modified ceramic electrode making method

The invention discloses a tin dioxide modified ceramic electrode making method. The method comprises the steps of burdening, granulating, cold isostatic pressing, pressureless sintering and the like. The method has the advantages of simplicity, low cost and low apparatus requirement. A tubular tin dioxide electrode made through the method has a good stability and a high conductivity, has a higher oxygen evolution potential than general anodes, and has a greatly improved electrocatalysis performance.

Owner:NANJING UNIV OF SCI & TECH

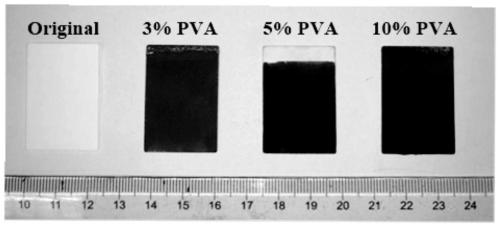

Production method of ceramic microfiltration membrane electrode with Ti4O7 coating

ActiveCN110272100AEasy to prepareLow costWater contaminantsWater/sewage treatment using germicide/oligodynamic-processHydrogen atmospherePolyvinyl alcohol

The invention relates to a production method of a ceramic microfiltration membrane electrode with a Ti4O7 coating. The production method of the ceramic microfiltration membrane electrode with the Ti4O7 coating comprises the steps of (1) producing a polyvinyl alcohol solution, adding titanium dioxide, polyacrylic acid, glycerin and polyvinylpyrrolidone, and conducting mechanical stirring to form Ti4O7 precursor sol; (2) immersing a flat ceramic microfiltration membrane into the Ti4O7 precursor sol obtained in the step (1), coating the surface of the flat ceramic microfiltration membrane with a Ti4O7 precursor sol membrane through dip-coating, and placing the flat ceramic microfiltration membrane coated with the Ti4O7 precursor sol membrane in air for drying to form a ceramic microfiltration membrane electrode coated with Ti4O7 precursor gel; (3) placing the ceramic microfiltration membrane electrode, which is obtained in the step (2), coated with the Ti4O7 precursor gel in a muffle furnace for annealing, and conducting cooling to form a ceramic microfiltration membrane electrode with a Ti4O7 precursor coating; and (4) conducting annealing reduction on the ceramic microfiltration membrane electrode, which is synthesized in the step (3), with the Ti4O7 precursor coating in a hydrogen atmosphere to finally form the ceramic microfiltration membrane electrode with the Ti4O7 coating.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com