Transition-metal doped lead dioxide electrode for wastewater treatment as well as preparation method and application thereof

A transition metal, lead dioxide technology, applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of limited rare earth reserves, low catalytic oxidation efficiency, short electrode life, etc., and achieve the removal effect. Good, low price, the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

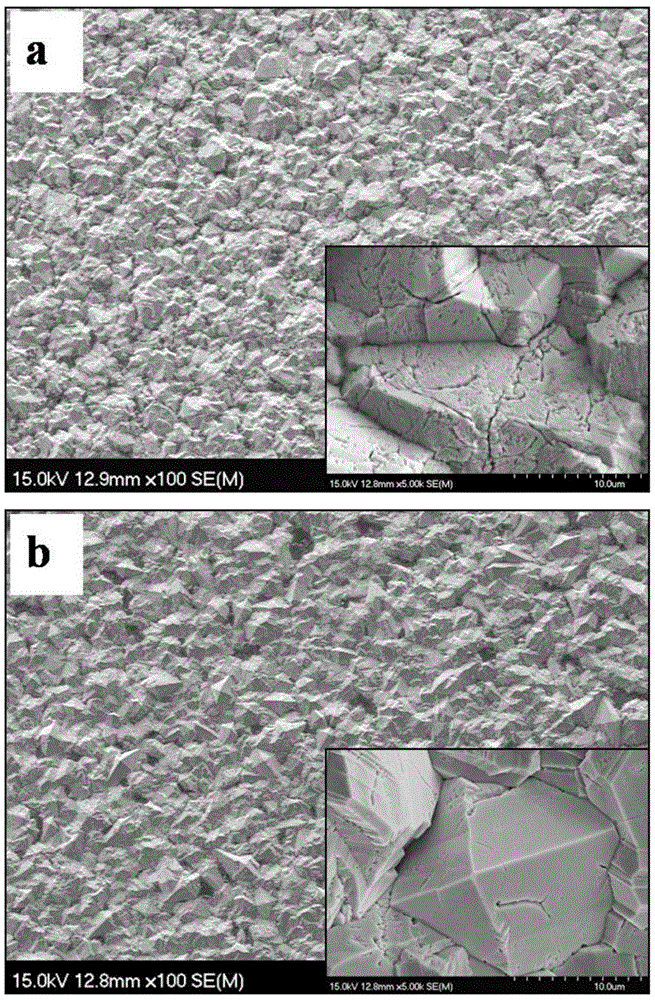

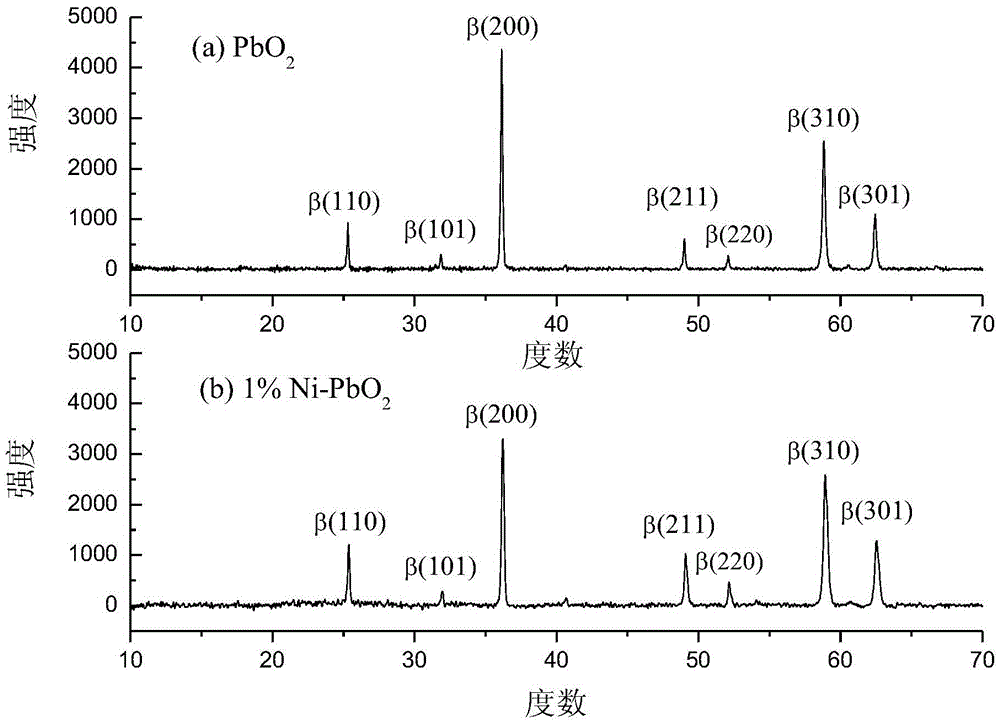

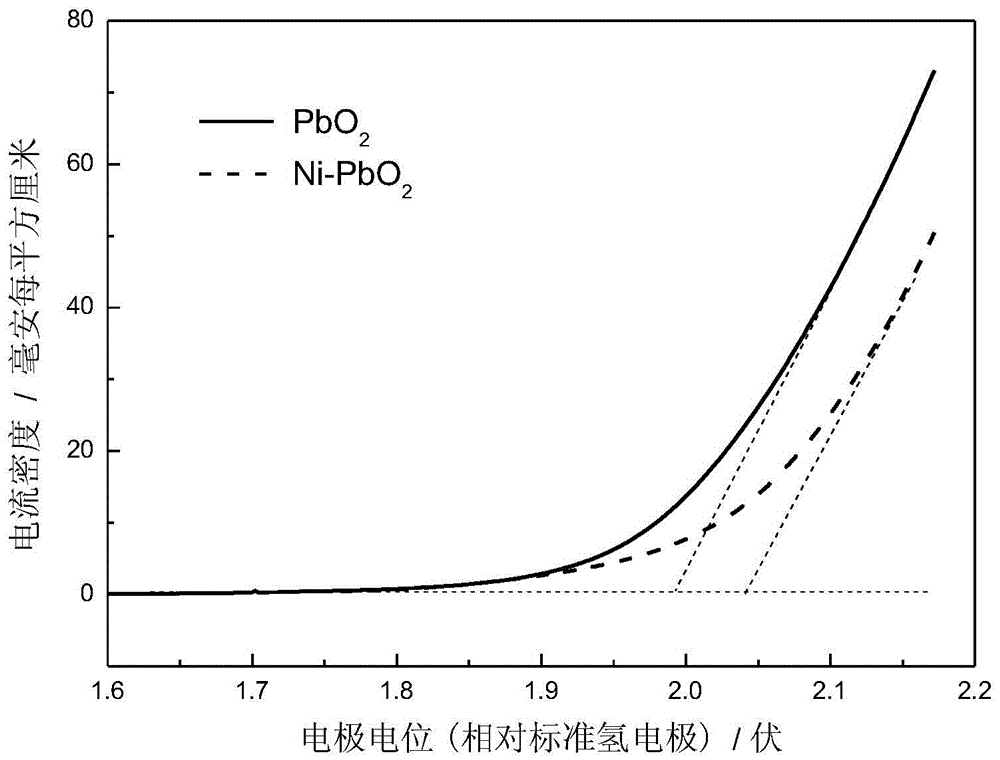

Embodiment 1

[0041] A preparation method of a transition metal nickel-doped lead dioxide electrode. The nickel-doped lead dioxide electrode uses a titanium sheet as a substrate. The treated titanium substrate was prepared by brushing and pyrolysis to prepare the bottom layer of tin antimony oxide, and then in the prepared electroplating solution, α-PbO was sequentially plated by electrodeposition method. 2 Intermediate layer and fluorine-containing β-PbO doped with a certain amount of nickel 2 active layer.

[0042] The concrete steps of described method are as follows:

[0043] (1) Titanium substrate pretreatment: the thickness is 0.1mm, the size is 14cm 2 (2cm×7cm) of pure titanium sheet with 120 # 、600 # and 1200 # Grind with sandpaper to make the surface appear silver-white metallic luster, then rinse with deionized water; soak in 40% NaOH solution for 30min, take it out and rinse with deionized water; then rinse with 20% H 2 SO 4 Soak the solution at 60°C for 20min, take it out...

Embodiment 2

[0055] The preparation method of the electrode is the same as in Example 1, except that in step (4), the acidic electroplating solution is 500mL mixed with 0.003molL -1 Zn(NO 3 ) 2 ·6H 2 O, 0.3molL -1 Pb(NO 3 ) 2 , 0.01molL -1 KF·2H 2 O, 2mL mass fraction is 60% fluororesin emulsion (PTFE), the pH value is adjusted to 1.8 with nitric acid (65wt%), and solvent is water. A zinc-doped lead dioxide electrode was prepared.

[0056] Using the prepared zinc-doped lead dioxide electrode as the anode, process 500mgL -1 Aspirin solution, method is as embodiment 1, after reaction carries out 2.5h, the removal rate of the aspirin of zinc-doped lead dioxide electrode reaches 78.23%, is 1.22 times of undoped lead dioxide electrode; The removal rate of COD is 50.23% , 1.15 times that of the undoped lead dioxide electrode.

Embodiment 3

[0058] The preparation method of the electrode is the same as in Example 1, except that in step (4), the acidic electroplating solution is 500mL mixed with 0.012molL -1 Mn(NO 3 ) 2 , 0.3molL -1 Pb(NO 3 ) 2 , 0.01molL -1 KF·2H 2 O, 2mL mass fraction is 60% fluororesin emulsion (PTFE), the pH value is adjusted to 1.8 with nitric acid (65wt%), and solvent is water. A manganese-doped lead dioxide electrode was prepared.

[0059] The prepared manganese-doped lead dioxide electrode or undoped lead dioxide electrode is used as the anode, and the titanium sheet is used as the cathode, and the electrode area is 14cm 2 , electrochemical degradation using constant current electrolysis. The constant current density is 30mAcm -2 , the electrode spacing is 4cm, to contain 0.1molL -1 Electrolyte Na 2 SO 4 1000mgL -1 Diclofenac sodium is a simulated wastewater with a reaction volume of 250mL. Under the action of magnetic stirring, the wastewater is treated, and the degradation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com