Preparation method of TinO2n-1 porous electrode and application thereof

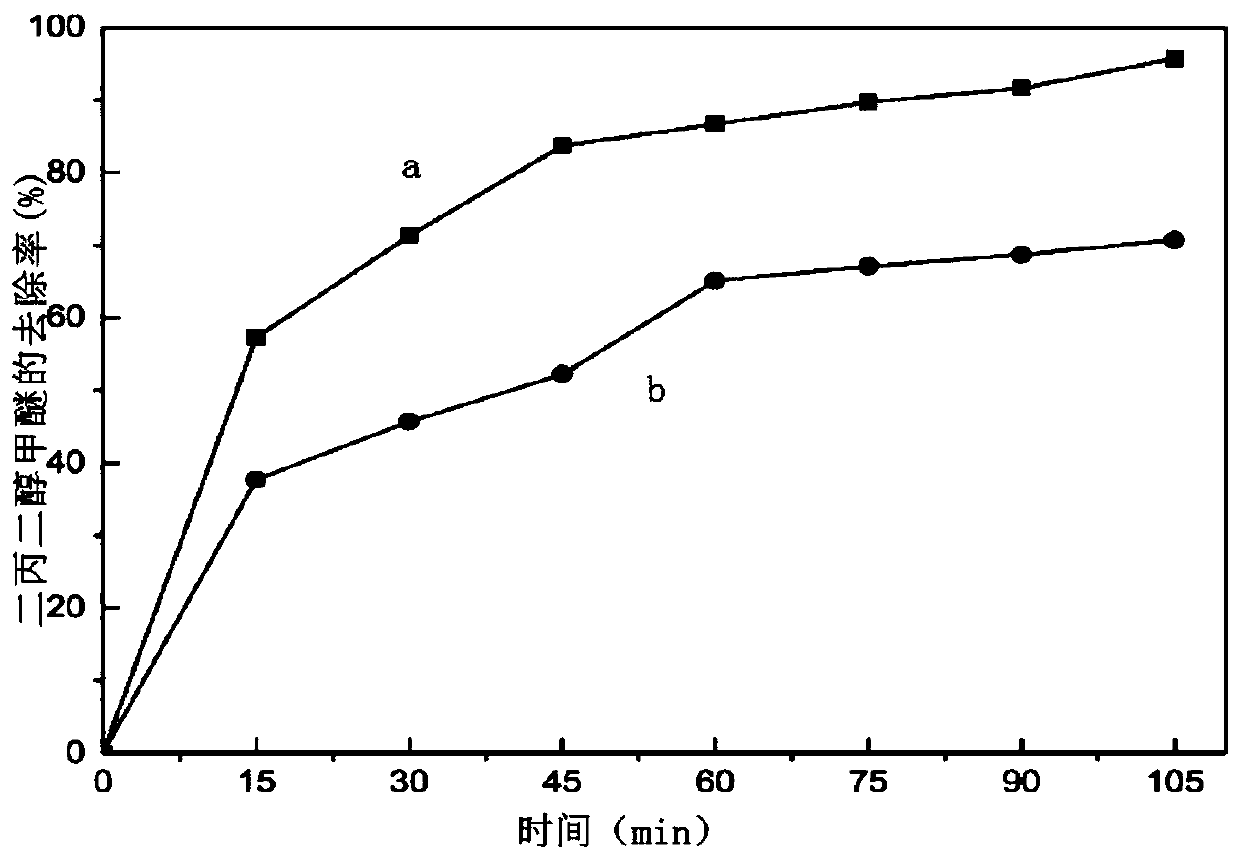

A tino2n-1, porous electrode technology, applied in the field of electrochemistry, can solve the problems of low electrolysis efficiency of metal oxide electrodes, long cycle life of electrodes, high requirements for reaction temperature, etc., and achieves simple preparation method and strong electrochemical stability , The effect of simplifying the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

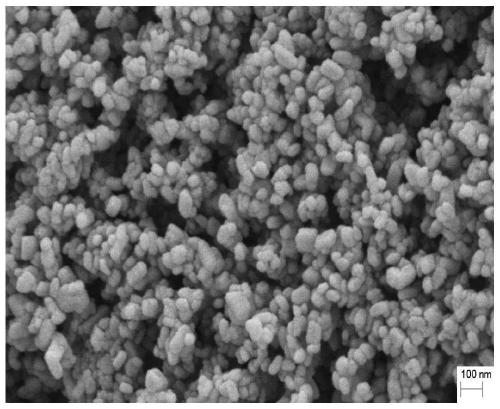

Embodiment 1

[0031] A kind of Ti n o 2n-1 The preparation method of porous electrode, the method is:

[0032] S1, TiH with a mass ratio of 1:5 2 and TiO 2The raw material mixture of composition is put into the ball mill jar, adds the agate ball mixture that is that the big agate ball that is 1cm in diameter and the small agate ball that diameter is 0.5cm by the mass ratio of 2:1 is formed, then adds ethanol, in rotating speed is Ball milling under the condition of 240r / min for 24h to obtain a paste; the mass ratio of the agate ball mixture, raw material mixture and ethanol is 6:1:2;

[0033] S2. Treat the paste obtained in S1 at a temperature of 50°C for 24 hours, and then pass through a 100-mesh sieve to obtain a powder;

[0034] S3. Put the powder obtained in S2 into a tube furnace for sintering to obtain Ti n o 2n-1 powder; the sintering system is as follows: first use the high vacuum system to control the vacuum degree to 1×10 -3 hPa, then the temperature was raised from room te...

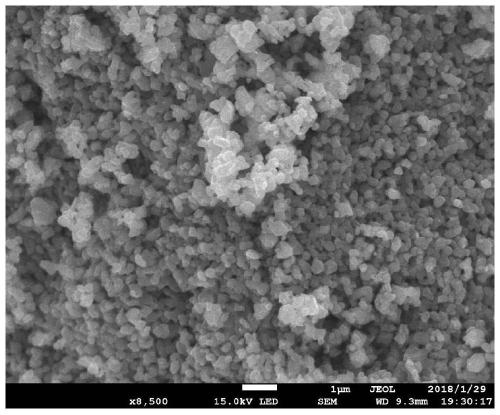

Embodiment 2

[0045] A kind of Ti n o 2n-1 The preparation method of porous electrode, the method is:

[0046] S1, TiH with a mass ratio of 1:5 2 and TiO 2 The raw material mixture of composition is put into the ball mill jar, adds the agate ball mixture that is that the big agate ball that is 1cm in diameter and the small agate ball that diameter is 0.5cm by the mass ratio of 2:1 is formed, then adds ethanol, in rotating speed is Ball milling under the condition of 240r / min for 24h to obtain a paste; the mass ratio of the agate ball mixture, raw material mixture and ethanol is 6:1:2.5;

[0047] S2. Treat the paste obtained in S1 at a temperature of 50°C for 24 hours, and then pass through a 100-mesh sieve to obtain a powder;

[0048] S3. Put the powder obtained in S2 into a tube furnace for sintering to obtain Ti n o 2n-1 powder; the sintering system is as follows: first use the high vacuum system to control the vacuum degree to 1×10 -3 hPa, then the temperature was raised from room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com