Production method of ceramic microfiltration membrane electrode with Ti4O7 coating

A ceramic microfiltration and membrane electrode technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of high electrode cost and poor effect, and achieve The effect of long service life, simple production method and wide potential window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further detailed below in conjunction with the embodiments:

[0032] Ti 4 O 7 The preparation method of the coated ceramic microfiltration membrane electrode includes the following steps:

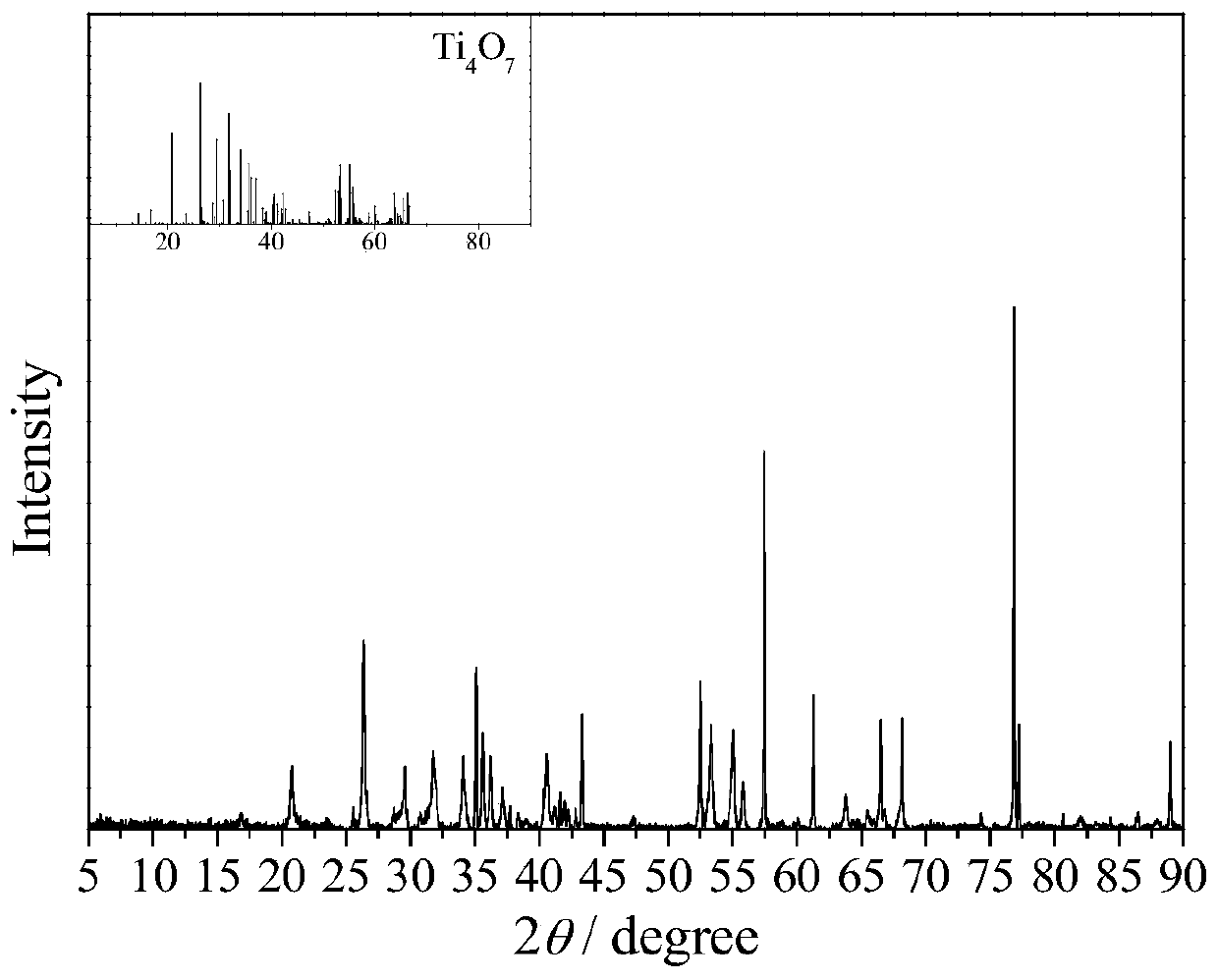

[0033] ⑴Ti 4 O 7 Preparation of precursor sol:

[0034] Put 10g PVA in a beaker, pour deionized water to 100ml, then place the beaker on a 105℃ hot plate (IKA, RT-10) to dissolve the PVA, add deionized water to supplement the deionization during the dissolution process Evaporation loss of water; add 20gTiO after cooling 2 , 2gPAA, 1.5g glycerol and 1.2g PVP and stir, finally dilute the volume to 100ml with deionized water; use a stirrer (IKA, RW-20) to mechanically stir the sol at 900rpm to strengthen the TiO 2 Dispersibility in the sol, Ti can be obtained after stirring 4 O 7 Precursor sol

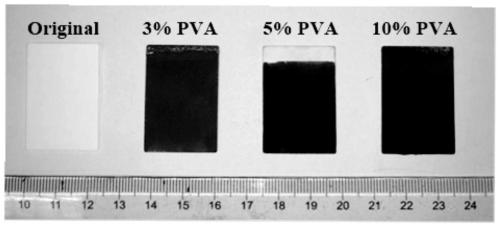

[0035] ⑵Ti 4 O 7 Preparation of ceramic microfiltration membrane coated with precursor gel:

[0036] Use PTL-OV5P to pull the coating machine for Ti 4 O 7 Precursor gel-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com