Tin dioxide modified ceramic electrode making method

A technology of tin dioxide and ceramic electrodes, which is applied in the field of preparation of tin dioxide modified ceramic electrodes, can solve problems such as large resistance at room temperature, and achieve the effects of low equipment requirements, high conductivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

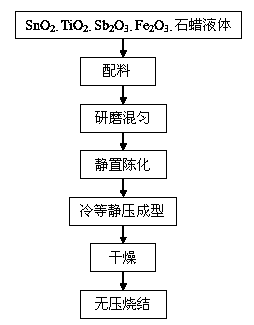

[0019] A kind of preparation method of tin dioxide modified ceramic electrode of the present invention is characterized in that: comprise the following steps:

[0020] Step 1: Ingredients: Select SnO with a particle size of 0.1-20μm 2 Powder, sintering aid choose TiO with a particle size of 0.1-0.5μm 2 Powder, paraffin liquid as plasticizer, 0.1-0.5μm Sb as additive 2 o 3 Powder and 0.1-0.5μm Fe 2 o 3 Powder, among them, TiO 2 The quality of the powder is SnO 2 0.5-2.5% of the mass of the powder, the mass of the paraffin liquid is SnO 2 3-5% of powder mass, Sb 2 o 3 The quality of the powder is SnO 2 15-25% of powder mass, Fe 2 o 3 The quality of the powder is SnO 2 10-20% of the powder mass, spare;

[0021] Step 2: Granulation: SnO 2 Powder raw material, TiO 2 Powder, Sb 2 o 3 Powder, Fe 2 o 3 The powder and the paraffin liquid are fully ground and mixed in a mortar, and the uniformly mixed slurry is poured into a container, and left to age at room temperat...

Embodiment 1

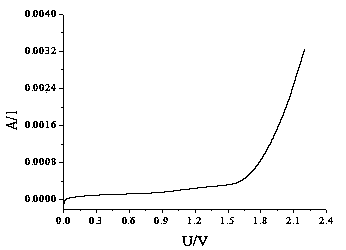

[0039] 1) Ingredients: 0.1μm SnO with a purity of 99% in an electronic balance 2 Powder, 0.2μm TiO with a purity of 99% 2 Powder, 0.2μm Sb with a purity of 98% 2 o 3 Powder, 0.2μm Fe with a purity of 98% 2 o 3 Powder, and paraffin liquid, according to the mass ratio of 100:1.5:20:20:4 (wherein SnO 2 The mass is 60g) to weigh and set aside. 2) Granulation: the above SnO 2 Powder, TiO 2 Powder, Sb 2 o 3 Powder, Fe 2 o 3 The powder and paraffin are fully ground and mixed in a mortar, and the evenly mixed slurry is poured into a container, and aged at room temperature for 24 hours to obtain a mixed powder; 3) cold isostatic pressing: put the mixed powder into a mold 4) drying: put the prepared embryo body in an oven to dry; 5) pressureless sintering: put the embryo body into a muffle Sintering in the furnace, the sintering atmosphere is air, the sintering temperature is 1500°C, the holding time is 150min, and the tin dioxide electrode ceramic material is obtained by na...

Embodiment 2

[0044] 1) Ingredients: 10μm SnO with a purity of 99% in an electronic balance 2 Powder, 0.2μm TiO with a purity of 99% 2 Powder, 0.2μm Sb with a purity of 98% 2 o 3 Powder, 0.2μm Fe with a purity of 98% 2 o 3 Powder, and paraffin liquid, according to the mass ratio of 100:1.5:20:20:4 (wherein SnO 2 The mass is 60g) to weigh and set aside. 2) Granulation: the above SnO 2 Powder, TiO 2 Powder, Sb 2 o 3 Powder, Fe 2 o 3 The powder and paraffin are fully ground and mixed in a mortar, and the evenly mixed slurry is poured into a container, and aged at room temperature for 24 hours to obtain a mixed powder; 3) cold isostatic pressing: put the mixed powder into a mold 4) drying: put the prepared embryo body in an oven to dry; 5) pressureless sintering: put the embryo body into a muffle Sintering in the furnace, the sintering atmosphere is air, the sintering temperature is 1500°C, the holding time is 150min, and the tin dioxide electrode ceramic material is obtained by nat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com