Segmented treatment method of high-concentration high-chromaticity dye wastewater

A dye wastewater and treatment method technology, which is applied in the field of segmented treatment of high-concentration and high-chroma dye wastewater, can solve problems such as reduced current efficiency, increased electrochemical energy consumption, and refractory degradation effects, achieving high-efficiency energy-saving treatment, The effect of excellent electrochemical oxidation ability and good electrocatalytic oxidation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 is an example with high-concentration methyl orange wastewater.

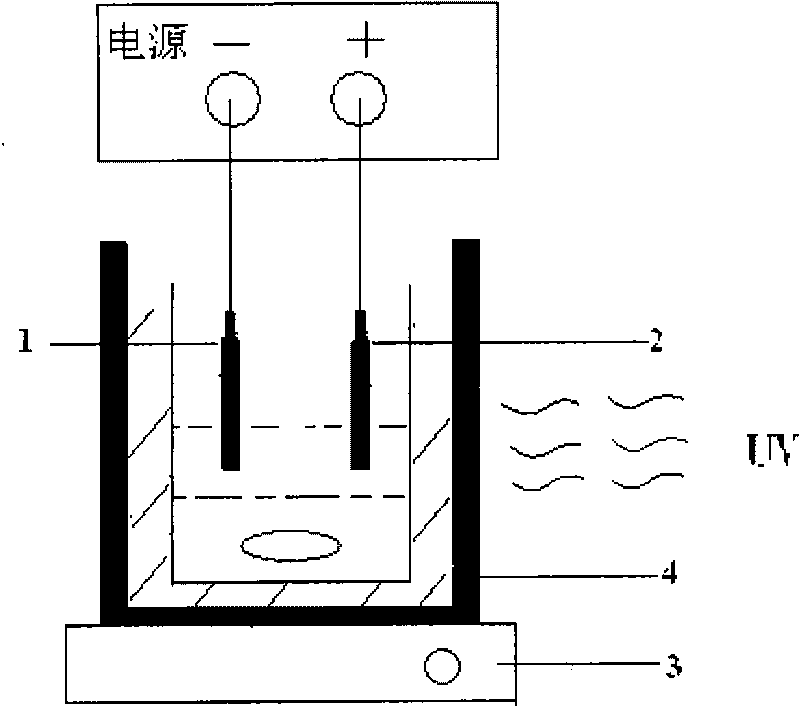

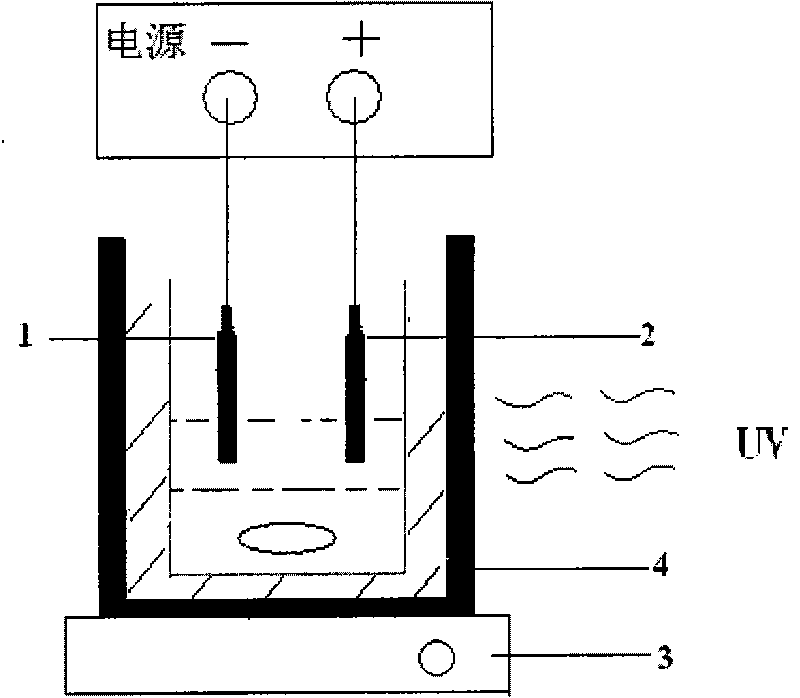

[0018] Sb doped SnO 2 / Ti electrode is used as the anode electrode 2, the titanium electrode is used as the cathode electrode 1, and the area of the cathode electrode 1 and the anode electrode 2 is 4.5cm 2 , the electrode spacing is 1cm, the current density is 30mA / cm 2 ; 300W UV lamp is used as the UV light source (center wavelength 365nm), and the light intensity is 3mW·cm -2 , the distance between the anode electrode 2 and the light source (placed in the solution after being covered with a quartz tube) is 15.0 cm. The concentration of methyl orange in the simulated wastewater is 500mg / L, the TOC is 237.35mg / L, and the chromaticity is as high as 10 5 times, the light transmittance is almost 0, the concentration of the supporting electrolyte sodium sulfate is 0.1mol / L, and the volume is 100ml. First, put the waste water to be treated in the reaction pool 4, the reaction pool 4 adopts a...

Embodiment 2

[0019] Embodiment 2 is an example with high chroma methylene blue wastewater.

[0020] Sb doped SnO as anode and cathode electrodes, respectively 2 The area of / Ti electrode and titanium electrode is 4.5cm 2 , the electrode spacing is 1cm, the current density is 30mA / cm 2 ; 300W UV lamp is used as the UV light source (center wavelength 365nm), and the light intensity is 3mW·cm -2 , the distance between the anode electrode and the light source (placed in the solution after putting on a quartz tube) is 15.0cm. The concentration of methylene blue in the simulated wastewater is 100mg / L, the TOC is 53.46mg / L, the light transmittance is almost 0, and the concentration of the supporting electrolyte sodium sulfate It is 0.1mol / L, and the volume is 100ml. First, carry out constant current degradation for 1.5h, then introduce ultraviolet light for photoelectric synergistic oxidation for 2.5h, and finally carry out subsequent degradation with separate photocatalytic oxidation. Separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com