Patents

Literature

33results about How to "Hypoxic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

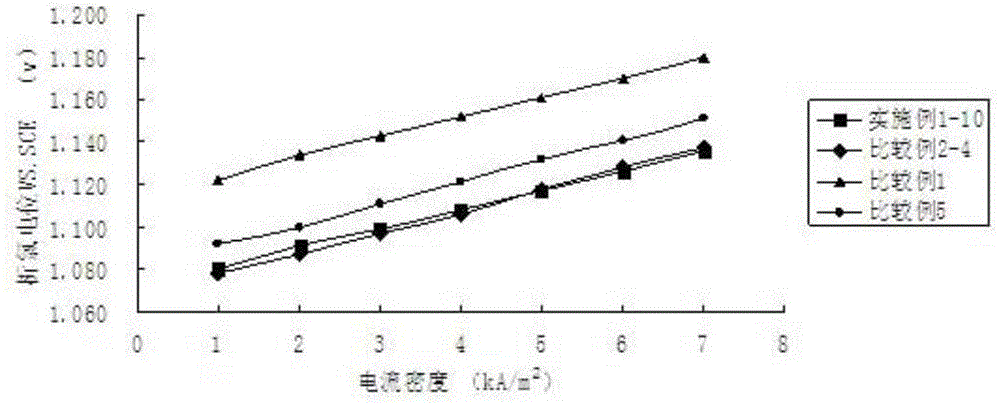

Electrode for electrolysis, preparation method of electrode and electrolytic bath

ActiveCN104562078AChlorine evolution potential is lowExtended service lifeElectrodesIridiumElectrolysis

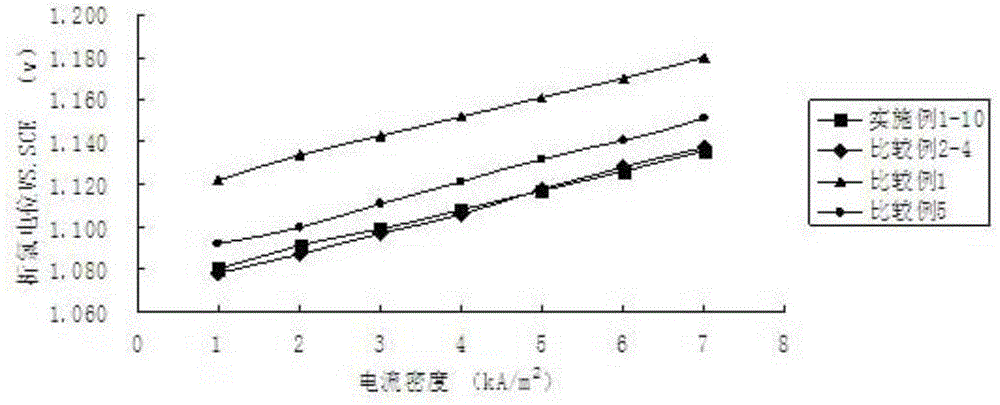

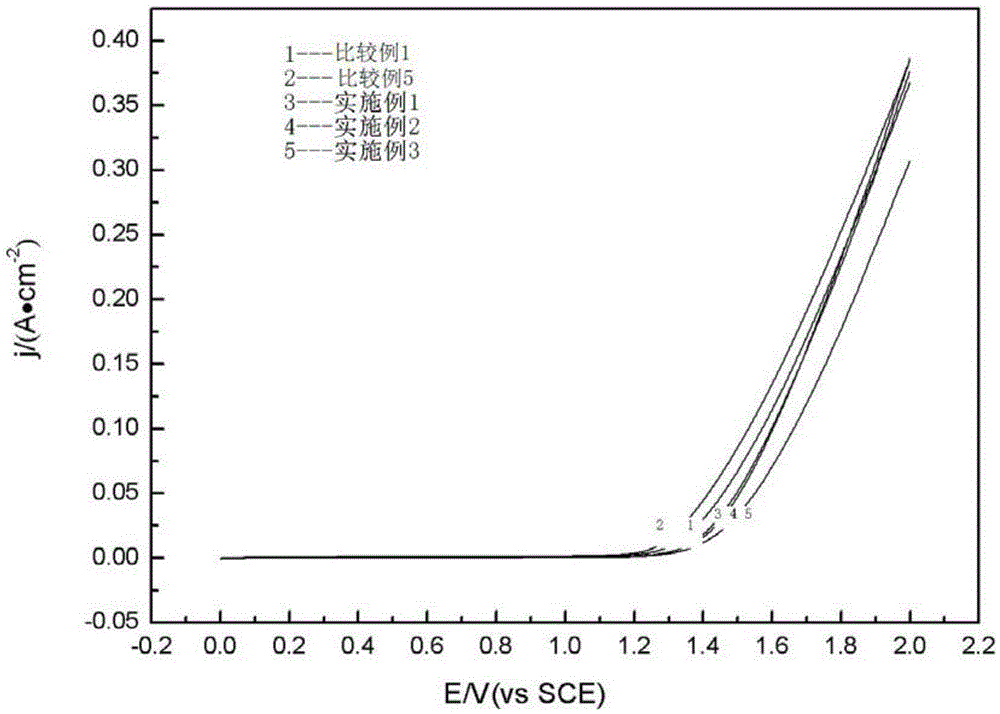

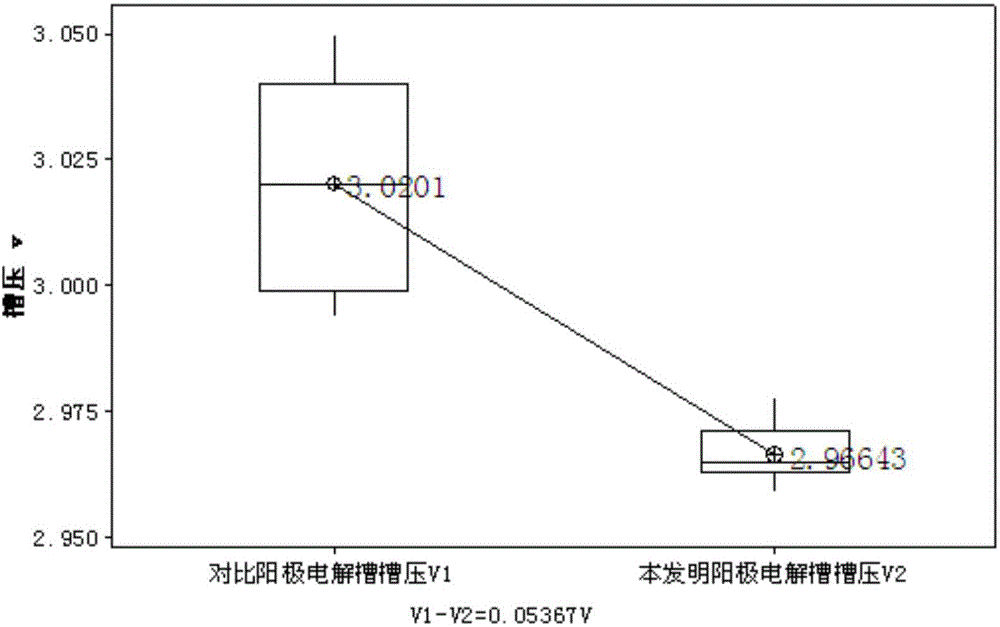

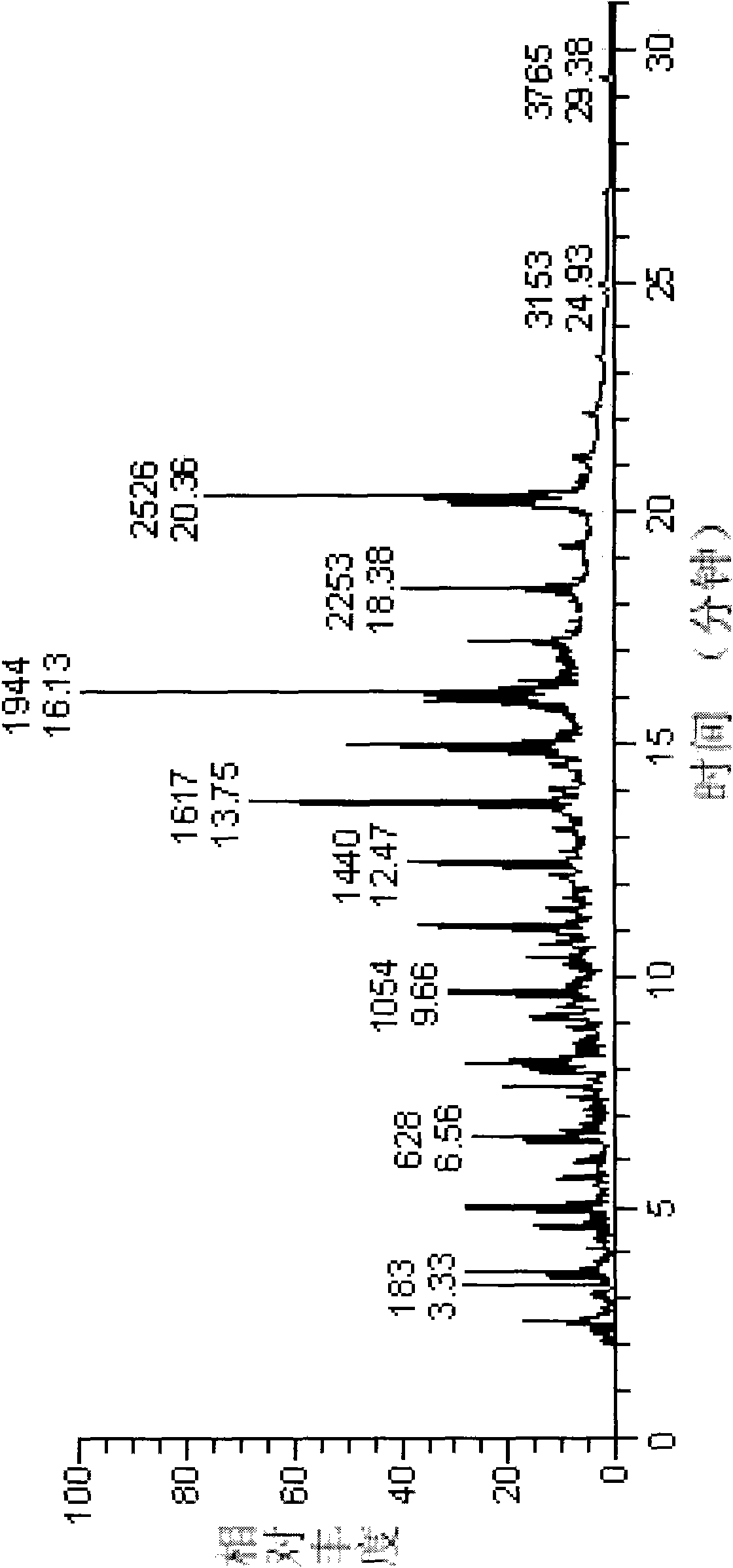

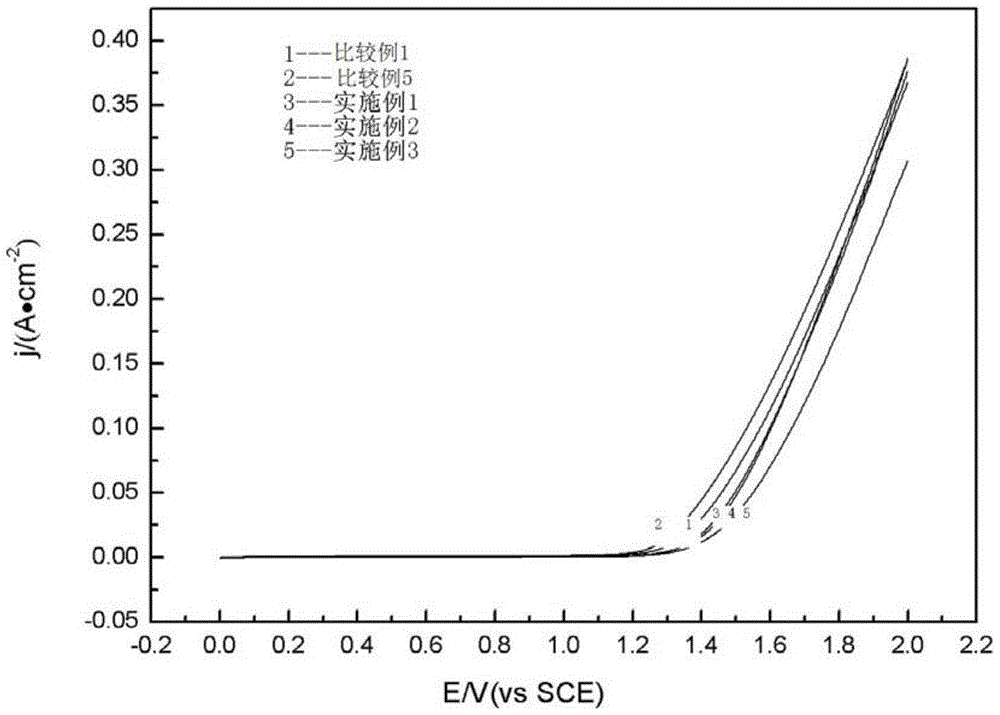

The invention provides an electrode for electrolysis, a preparation method of the electrode and an electrolytic bath. The electrode for electrolysis comprises a conductive base material and an active coating, wherein the conductive base material is a base material containing titanium or titanium alloy; the active coating at least comprises a bottom coating layer and a surface coating layer; the bottom coating layer is prepared from titanic oxide, iridium oxide and ruthenium oxide; the surface coating layer is prepared from iridium oxide, ruthenium oxide, titanium oxide and a metal or an oxide of one of two of palladium and platinum. According to the electrode for electrolysis disclosed by the invention, the double coating layers are adopted; compared with the single coating layer only containing ruthenium, iridium and titanium, the electrode is better in activity, the chlorine evolution potential of the electrode is low, the oxygen evolution potential is high, the service life of the electrode is longer, and the electrolysis stability is better.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Method for preparing hydrocarbon fuel oil by mixing biomass oil and animal and vegetable oil

InactiveCN101906312AHigh calorific valueHypoxicMolecular sieve catalystsBiofuelsHydrogen compoundsBiomass

The invention relates to the technical field of comprehensive utilization of biomass oil and animal and vegetable oil, in particular to a method for preparing hydrocarbon fuel oil by mixing the biomass oil and the animal and vegetable oil. Simple process flow is adopted in the method; and a mixture of the biomass oil and the animal and vegetable oil is converted into the hydrocarbon fuel oil withthe properties and the components (taking fractions such as gasoline, diesel oil, kerosene and the like as the main components) similar to those of petroleum at a certain temperature by adopting a small amount of water as a medium and adopting transition metals, a molecular sieve and the like as catalysts. Different kinds of biomass oil and animal and vegetable oil are mixed according to different proportions, so that the alkane content can be obviously increased and the properties of the fuel oil can be improved. The calorific value of the obtained fuel oil is 36 to 45 MJ / kg and the oxygen content is less than 7 percent.

Owner:北京瑞增兰宇新能源科技有限公司

Rare earth magnesium-alloy material for 3D printing and preparation method of same

ActiveCN104762541AImprove flame retardant performanceMicrostructureAdditive manufacturing apparatusRare-earth elementSlag

The invention belongs to the technical field of 3D printing materials and discloses a rare earth magnesium-alloy material for 3D printing and a preparation method of the same. The preparation method particularly comprises following steps: (1) weighing raw materials according to element mass ratio of Mg:Mn:Re being 85-97:2-10:1-5; (2) adding pure magnesium, pure manganese and magnesium alloy into a pre-heated crucible, adding a cover agent and smelting the mixture under atmospheric conditions; (3) after the mixture smelted completely, adding an Mg-Re intermediate alloy and pure rare earth elements, melting the components with stirring uniformly and increasing the temperature to 700-750 DEG C; (4) adding a refining agent for refining the alloy for 2-25 min, allowing the refined alloy to stand, removing floated slag, adding the refined alloy into a sand mould trough to obtain a rare earth magnesium alloy base metal; and (5) smelting and atomizing the base metal to obtain the rare earth magnesium-alloy material. The rare earth magnesium-alloy material is excellent in flame retarding performance, is easy to control in powder shape and particle size, can be smelted without protective gas so that a problem of flammability during preparation of the magnesium alloy powder through an atomization method is solved, and can be used for laser 3D printing.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

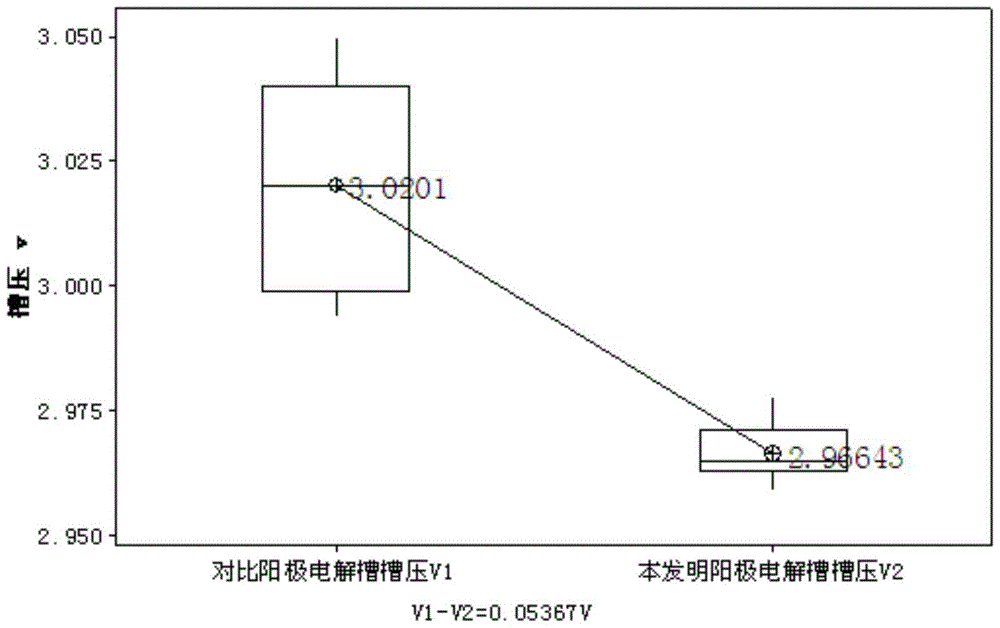

Positive pole coating for ion membrane electrolysis bath

ActiveCN110318068AHigh oxygen evolution potentialStrong catalytic abilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesIonIridium

The invention relates to a positive pole coating for an ion membrane electrolysis bath. The positive pole coating is characterized by comprising, in weight percent, 35-45mol% of ruthenium, 5-15mol% ofiridium, 5-10mol% of platinum, 35-45mol% of titanium and smaller than 4%mol% of other additives. The additives comprise zirconium chloride or palladium chloride. The positive pole coating for the ionmembrane electrolysis bath is used for an active anode, an oxygen evolution potential is high, catalytic ability is high, conductivity is high, oxygen evolution side reaction cannot be easily generated, the coat is stable in performance, resistant to corrosion, long in service life, coating can continue to be used after recoating after an electrode is faulted, electrodes is effectively controlled, product quality is improved, and required chlorine purity is high, and oxygen content is low.

Owner:宏泽(江苏)科技股份有限公司

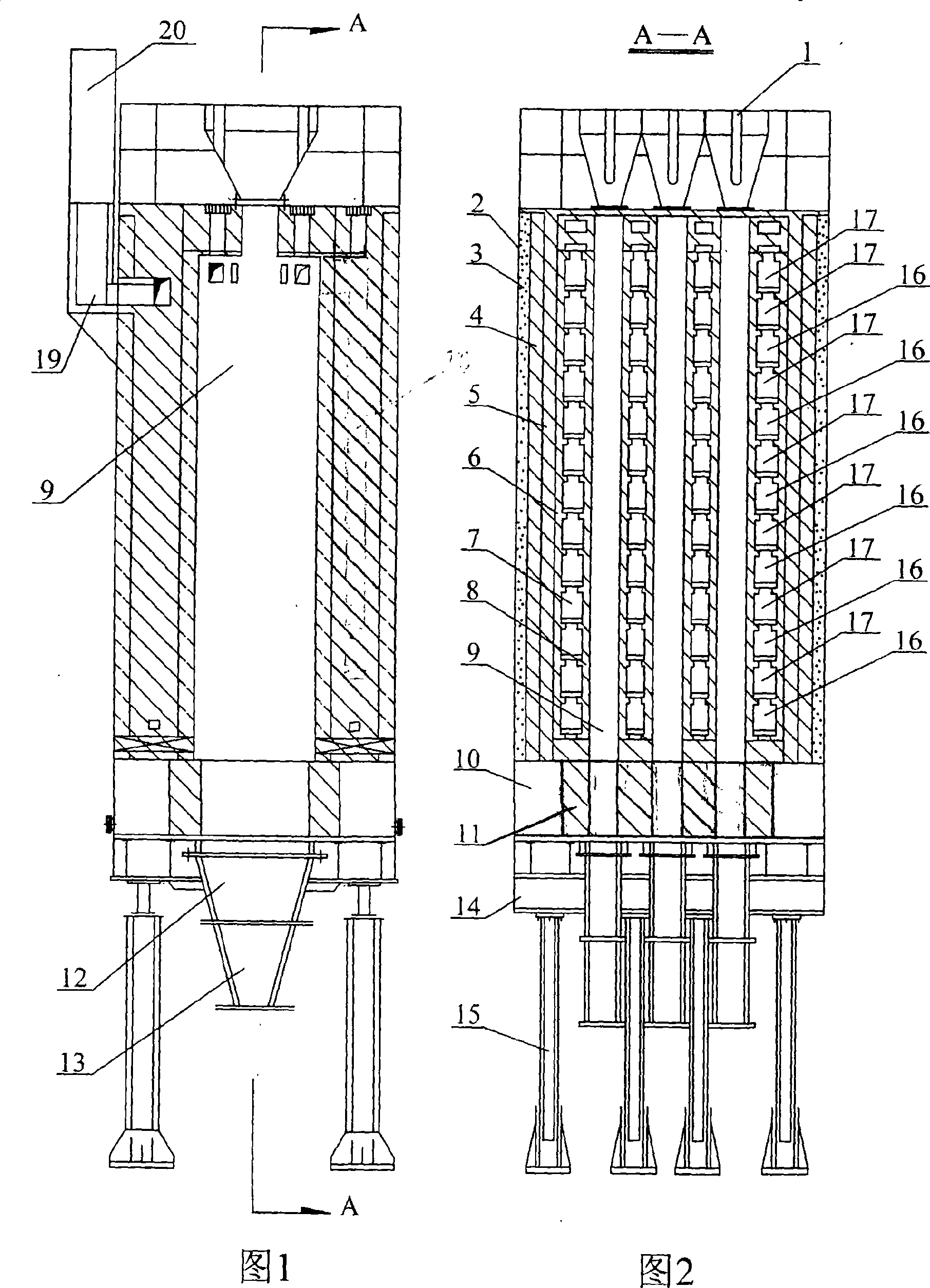

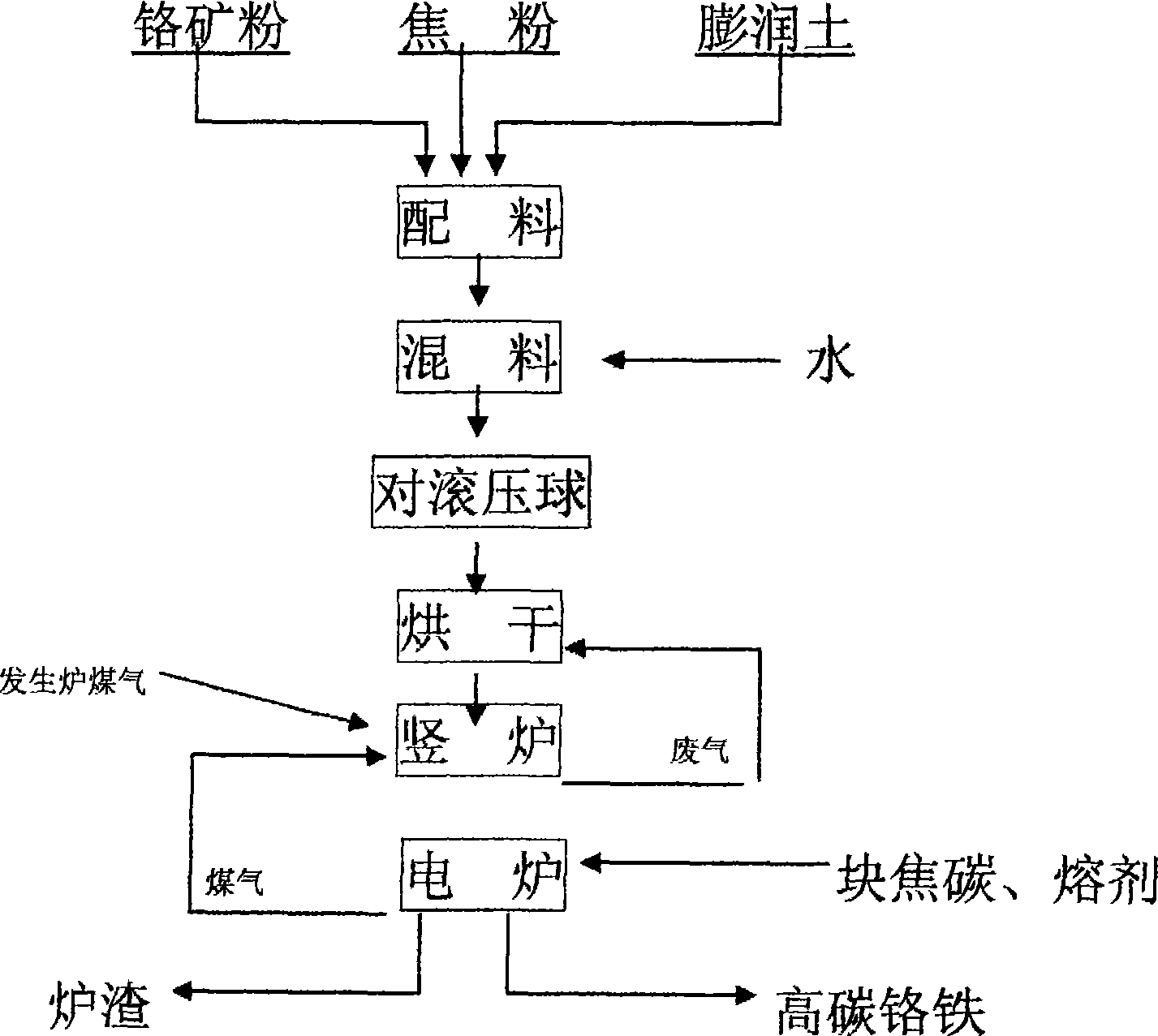

Production of pre-reduced chrome ore pellet by external heated shaft furnace

InactiveCN101418372AOvercome the difficulty of controlling the reducing atmosphereOvercome Kiln DifficultiesVertical furnacesCombustion chamberHigh carbon

The invention discloses a chrome ore prereduction external heating type shaft furnace, which is characterized in that multilayer gas burner flame paths arranged on both sides of reduction reaction chambers with a rectangular cross section indirectly supply heat under the condition of air separation. The shaft furnace consists of a plurality of independently working reaction reduction chambers; the reduction reaction chambers and the gas burner flame paths are built by tailored high aluminium special-form refractory bricks; and the shaft furnace body is vertically arranged on a bearing girder. Dried carbon-contained chrome ore pellets are added into a bin on the top end of the shaft furnace and are discharged out of the furnace through the preheating section, the reduction section and the cooling section of the shaft furnace. The temperature of the reduction reaction is 1,300 to 1,400 DEG C; the material stays at the reduction section for 3 to 4 hours; and the comprehensive reduction degree is 60 to 70 percent. The prereduced pellet ore is used for producing high carbon ferrochrome in a closed electric furnace. The cold pellet ore which is charged into the closed electric furnace can reduce the power consumption for ferrochrome by above 25 percent, improve the yield by above 40 percent, reduce the emission by above 20 percent, and improve the chrome recovery rate by above 3 percent. The chrome ore prereduction external heating type shaft furnace can be used for continuous production, and has the advantages of circulation, high economical efficiency, environmental protection, energy conservation, emission reduction, and the like.

Owner:李志忠

Preparation method of high-heat-conduction aluminum nitride thick film

InactiveCN103173727AImprove thermal conductivityFast depositionVacuum evaporation coatingSputtering coatingAluminum IonEpoxy

The invention relates to a preparation method of a high-heat-conduction aluminum nitride thick film, belongs to the technical field of surface coating preparation and application and mainly solves the technical problems that an aluminum nitride thick film can not be prepared, the deposition speed is low, commercialization is difficult to realize and the like in the prior art. According to the method, the aluminum nitride thick film is deposited through arc ion plating, the nitrogen / aluminum ratio in the film is uniform, the thickness of the prepared AlN high-heat-conduction film can be up to 3-10mu m, and a large bonding force can be generated between the film and a substrate, wherein the involved substrate material can be metal such as stainless steel, iron, copper, aluminum and the like, or can be an inorganic non-metal material such as ceramic, glass and the like, or can be a high-molecular organic polymer such as epoxy resin, polyimide and the like. The preparation method comprises the following steps: performing surface treatment on the substrate material; and by selecting pure aluminum as a cathode target material and using pure nitrogen gas as reacting gas, forming the AlN high-heat-conduction film through reaction between aluminum ions obtained by ionization and the nitrogen gas, wherein the purity of the aluminum target material is 99.99%, and the purity of the nitrogen gas is 99.999%. Thus, the method is applicable to multiple fields such as electronic measuring instruments, computer equipment, measurement and control systems, airplanes, precision weapons and the like.

Owner:辽宁法库陶瓷工程技术研究中心

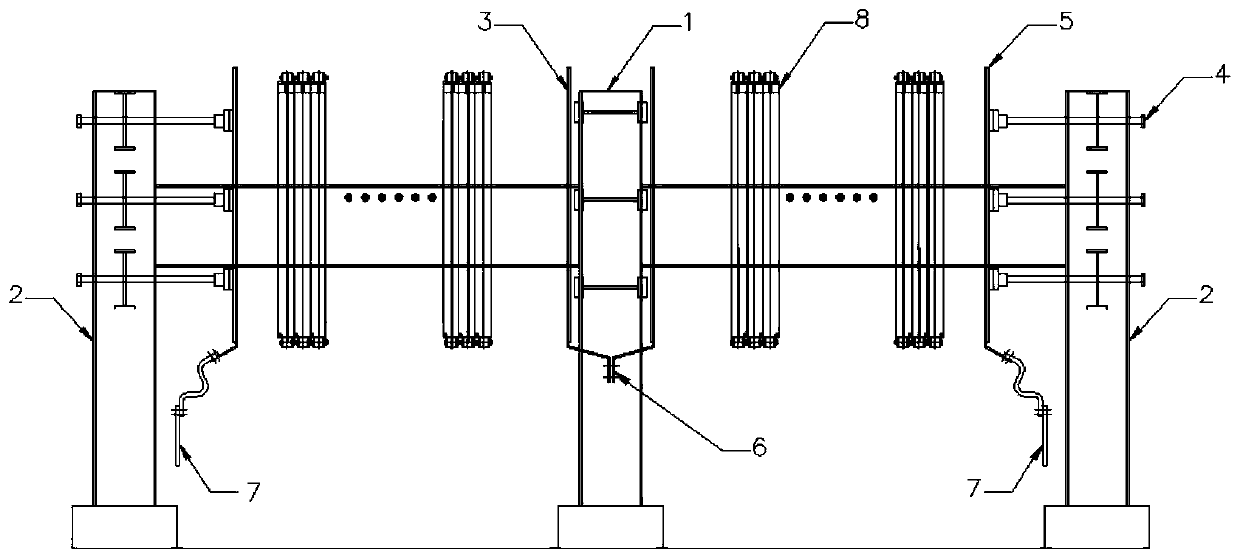

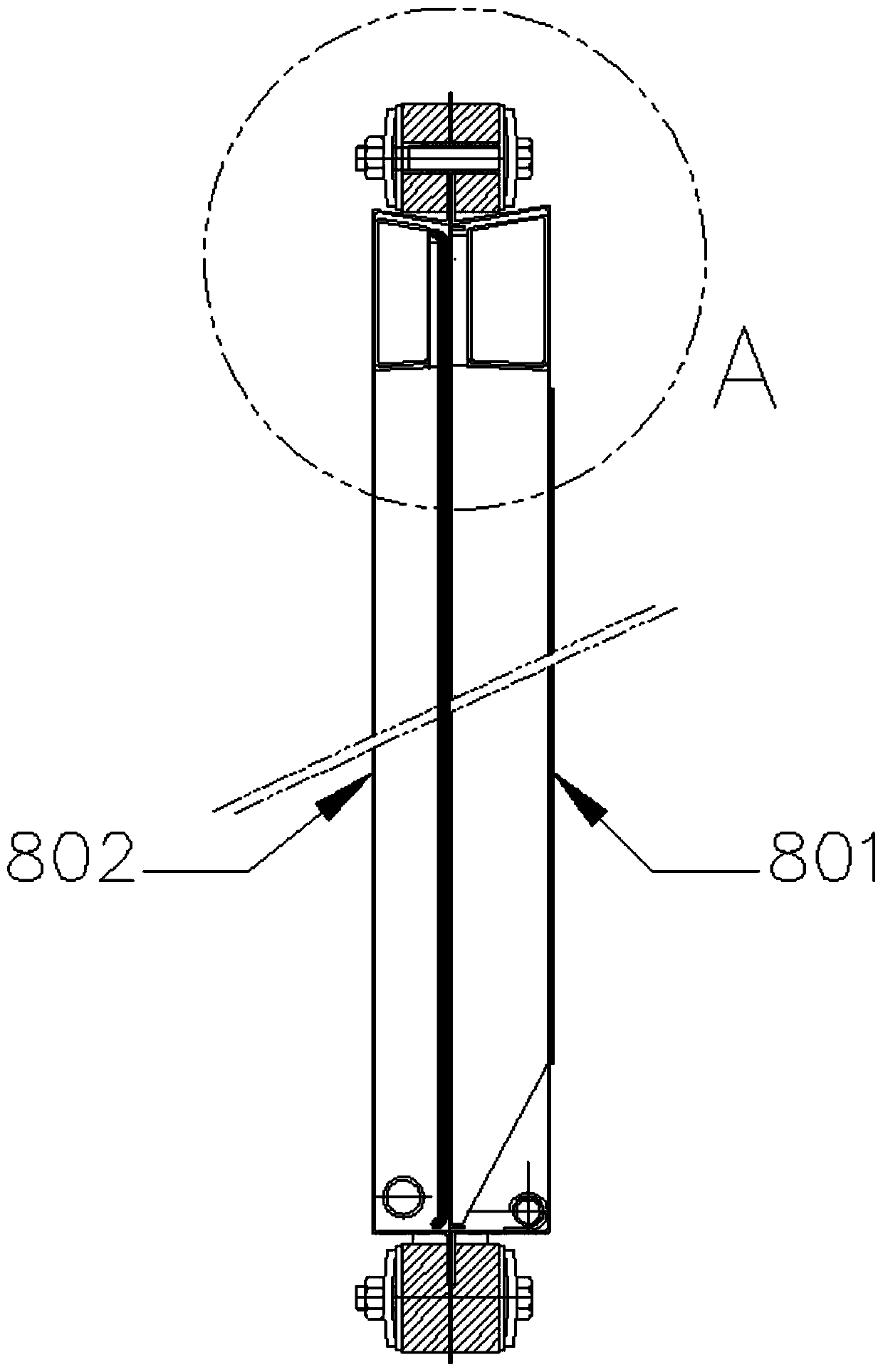

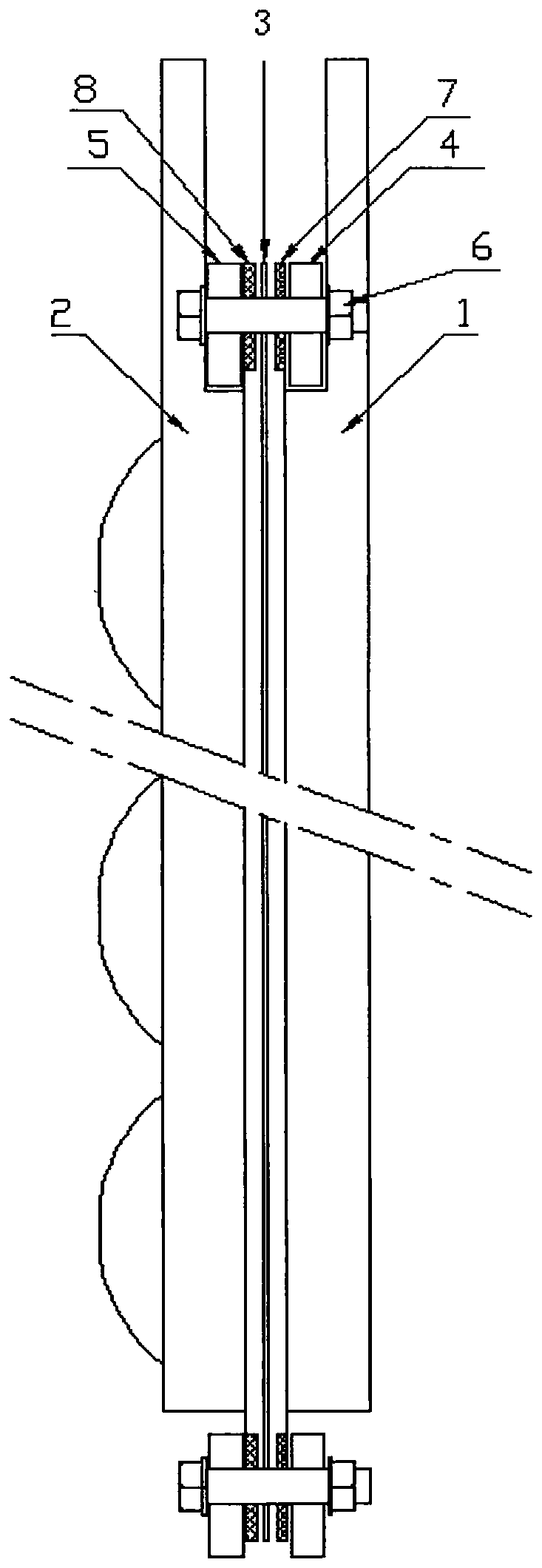

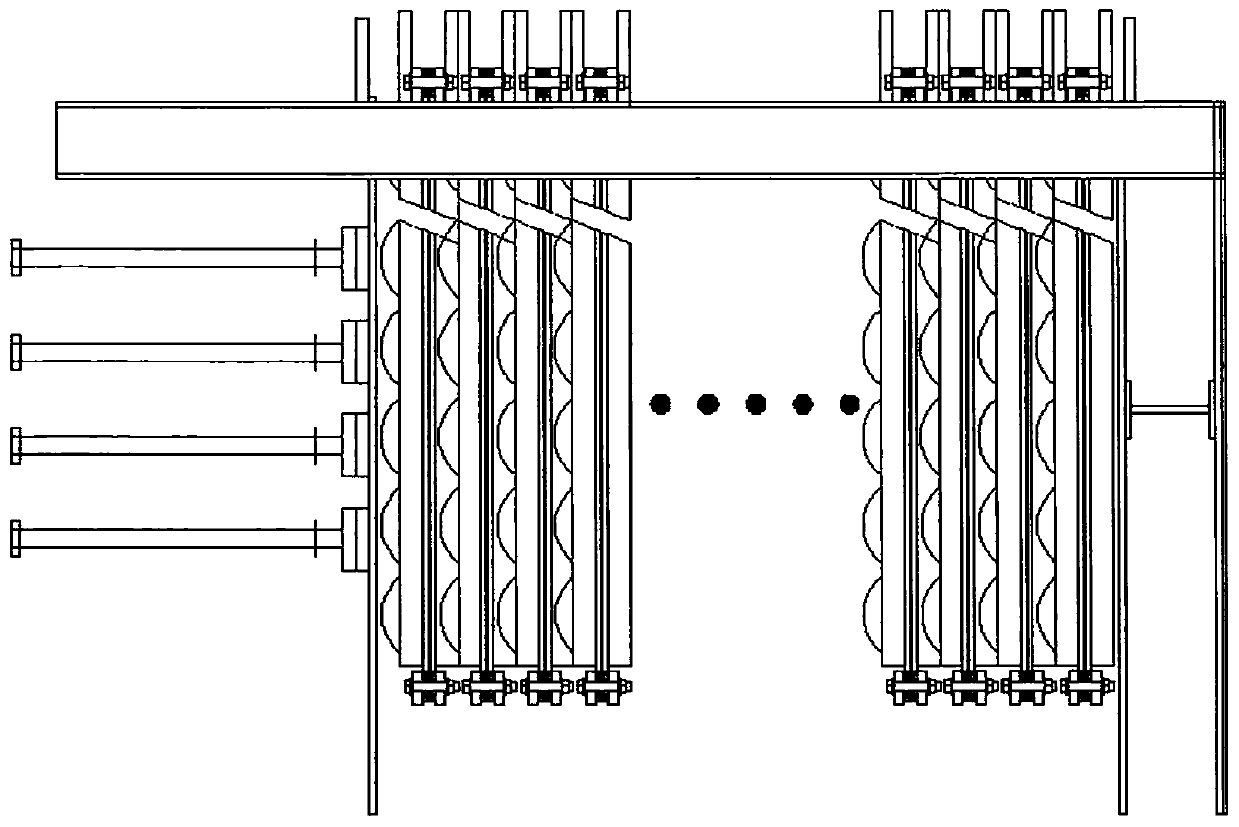

Ion membrane electrolytic cell

PendingCN110219012ANo leaksHigh temperature resistantCellsElectrode shape/formsCopperHigh productivity

The invention relates to an ion membrane electrolytic cell. The ion membrane electrolytic cell comprises a cell rack, wherein a plurality of electrolysis unit cell groups (8) are arranged on the cellrack, and the electrolysis unit cell groups (8) have the characteristics that two ends of each electrolysis unit cell group (8) are locked separately through copper row end plates; the copper row endplates are copper row end plates which are fixed on a fixing base or mobile copper row end plates which are fixed on a push rod base, different number of electrolysis unit cell groups (8) and copper row end plates for locking a plurality of electrolysis unit cell groups (8) are selected according to the capacity requirement, and the copper row end plates are connected with a power source. The ionmembrane electrolytic cell has the advantages of good running stability, free assembly and allocation according to the capacity requirement, low electric loss, high production efficiency and high productivity.

Owner:宏泽(江苏)科技股份有限公司

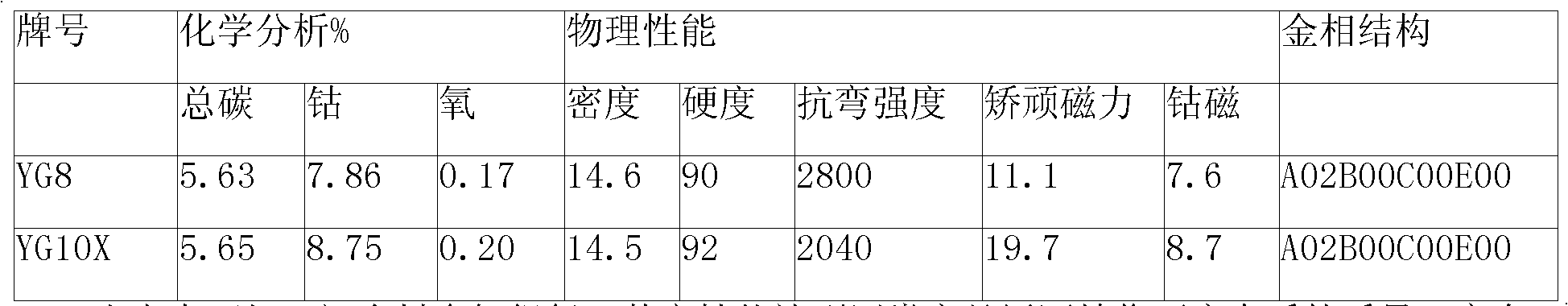

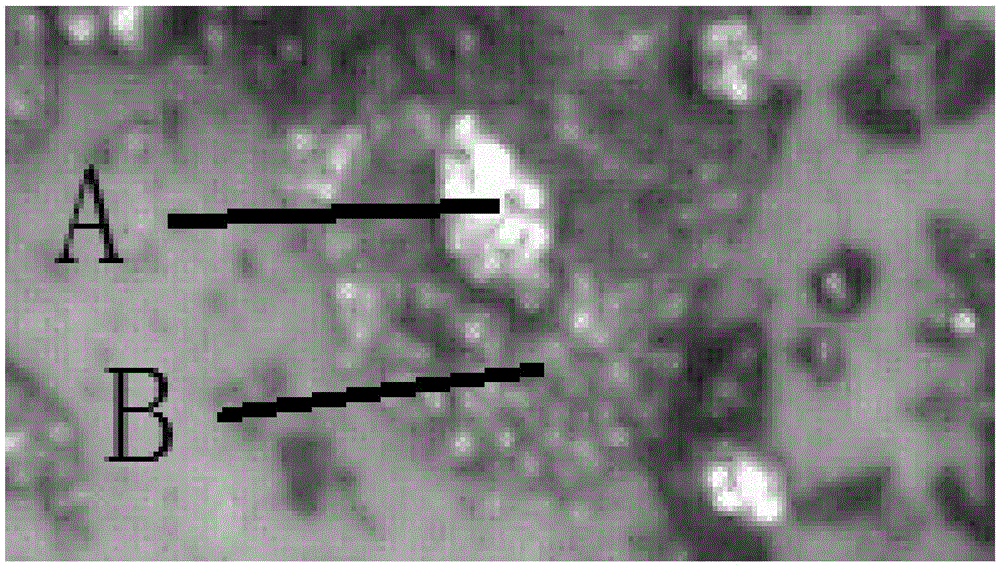

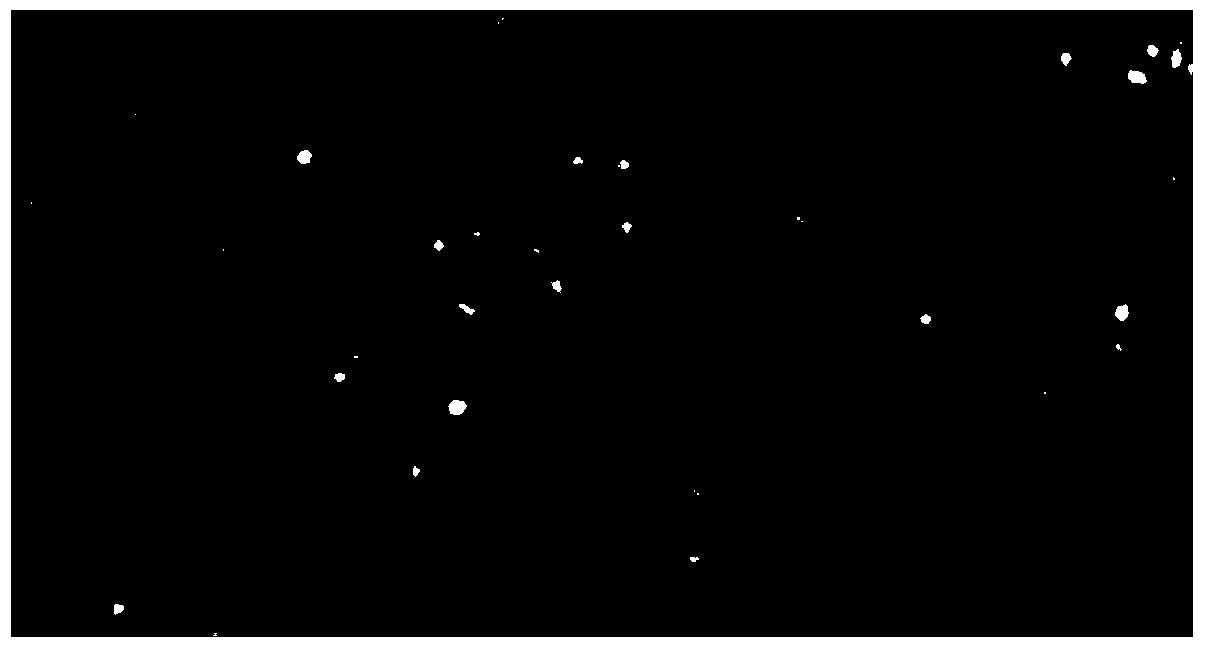

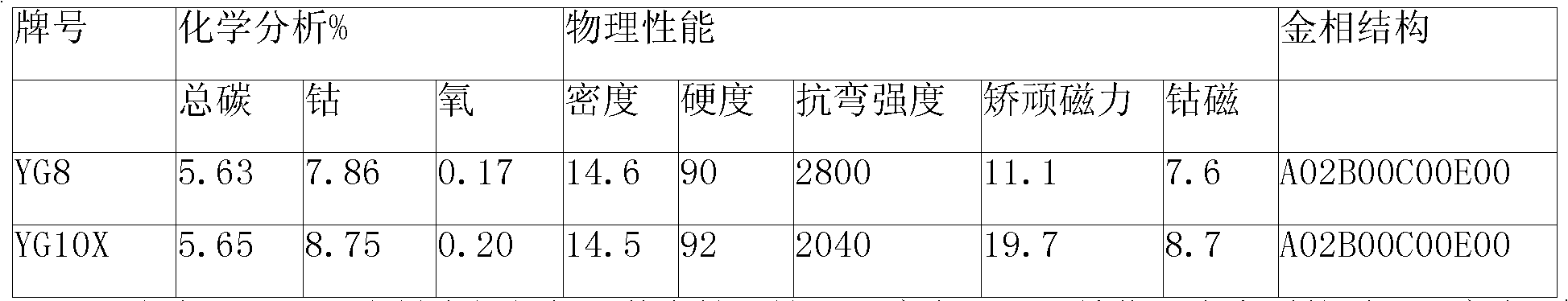

Novel preparation technology for mixture taking water as grinding medium

The invention relates to novel preparation technology for a mixture taking water as a grinding medium. The novel preparation technology contains working procedures such as batching, wet grinding, unloading, slurry drying and the like, wherein in the working procedure of the wet grinding, distilled water is adopted as the grinding medium, and 2 to 3 percent of antioxidant substance is added into the distilled water; in the working procedure of unloading, the mixture is unloaded from a wet grinder and passes through a 320-mesh sieve, and the wet grinder is washed for 6 times by water; and in the working procedure of slurry drying, an open type spray drying tower is adopted for drying, slurry is output to a nozzle for atomization by a pump, fog drops move from the bottom up, encounter the hot air which moves from the top down, and then are dried and a material flows out of the tower and is loaded into a material barrel after the automatic cooling. The preparation technology can effectively eliminate potential safety hazard, and save a large amount of energy sources; and the preparation technology does not need fire prevention and explosion prevention, adopts open type spray drying equipment, saves one half of equipment investment, does not need chilled water and nitrogen, and greatly reduces the cost for production operation.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

Preparation method for tungsten copper nickel alloy powder

The invention discloses a preparation method for tungsten copper nickel alloy powder. Atomized copper powder and crystalline tungsten powder are selected and used as raw materials; carbonyl nickel powder is added to the atomized copper powder and the crystalline tungsten powder; mixed materials are put into a steel belt reduction furnace; high-temperature diffusion treatment is carried out at shielding gas or reducible atmosphere; alloy connection of the atomized copper powder and the crystalline tungsten powder is achieved through the diffusion of the carbonyl nickel powder in the atomized copper powder and the crystalline tungsten powder; the tungsten copper nickel alloy powder is obtained through crushing and screening of a crusher after the alloy connection. According to the preparation method for the tungsten copper nickel alloy powder, the prepared tungsten copper nickel alloy powder is even in composition, high in density, good in flowing property and easy to form; the problem of liable segregation in a traditional preparation method is solved; in addition, the preparation technology is simple and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

A kind of preparation method of tungsten-copper-cobalt alloy powder

The invention discloses a preparation method of tungsten-copper-cobalt alloy powder. The invention selects atomized copper powder and crystalline tungsten powder as raw materials, adds carbonyl cobalt powder into the atomized copper powder and crystalline tungsten powder, and places them in a steel strip reduction furnace. In the process, high-temperature diffusion treatment is carried out under protective gas or reducing atmosphere, through the diffusion of cobalt carbonyl powder in atomized copper powder and crystalline tungsten powder, the atomized copper powder and crystalline tungsten powder are connected by alloy, and then crushed by a crusher Sieve to obtain tungsten-copper-cobalt alloy powder. The tungsten-copper-cobalt alloy powder prepared by the preparation method of the present invention has uniform composition, high density, excellent fluidity and is easy to form, solves the problem of easy segregation in the traditional preparation method, and has a simple preparation process and is easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Preparation method of lithium titanate material

The invention belongs to a lithium battery material, and concretely relates to a preparation method of a lithium titanate material. The method comprises the following steps: 1, adding tetrabutyl titanate into anhydrous ethanol, and uniformly stirring to form a titanium alcohol solution; 2, adding lithium acetate into the titanium alcohol solution, and uniformly stirring to form a mixed solution; 3, adding titanium monoxide powder into the mixed solution, and carrying out low-temperature ultrasonic treatment for 1-2 h to obtain a suspension; 4, spraying the suspension into a constant-temperature reaction kettle, sealing, depositing, decompressing and cooling to obtain coated titanium monoxide particles; and 5, putting the coated titanium monoxide particles into the sealed reaction kettle, carrying out constant-pressure standing for 1-3 h, then introducing water vapor, carrying out a sealed pressurization reaction for 2-3 h, relieving the pressure, and carrying out sealed sintering so asto obtain lithium titanate particles. The problem that an existing lithium titanate material is poor in electrical conductivity is solved; and titanium monoxide is used as an inner core, and lithiumtitanate is used as a surface coating layer, so it is guaranteed that the prepared material has oxygen deficiency, the mobility of electrons is improved, and the electrical conductivity is improved.

Owner:江苏众钠能源科技有限公司

Preparation method for tungsten-copper-cobalt alloy powder

The invention discloses a preparation method for tungsten-copper-cobalt alloy powder. The preparation method comprises the following steps: selecting atomized copper powder and crystalline tungsten powder as raw materials; adding cobalt carbonyl powder into the atomized copper powder and the crystalline tungsten powder to obtain a mixture; putting the mixture into a steel belt reducing furnace to carry out high-temperature diffusion treatment under protective gas or a reducing atmosphere; diffusing the cobalt carbonyl powder in the atomized copper powder and the crystalline tungsten powder, thereby realizing alloy connection between the atomized copper powder and the crystalline tungsten powder; and crushing and screening the mixture by a crusher to obtain the tungsten-copper-cobalt alloy powder. The tungsten-copper-cobalt alloy powder prepared by the preparation method disclosed by the invention is uniform in component, high in compactness, excellent in flowing property and easy to form; the liable segregation problem in a conventional preparation method is solved; and the preparation method is simple and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Preparation method of tungsten-copper-tin alloy powder

The invention discloses a preparation method of tungsten-copper-tin alloy powder. The preparation method comprises the steps that atomized copper powder and crystalline tungsten powder are taken as the raw materials; tin power is added to the atomized copper powder and the crystalline tungsten powder; the mixed powder is placed in a steel band reduction furnace, and is subjected to high temperature diffusion treatment in a shielding gas or reducing gas atmosphere; and through the diffusion of the tin power in the atomized copper powder and the crystalline tungsten powder, alloy connection between the atomized copper powder and the crystalline tungsten powder is realized; and through breaking and screening of a crusher, the tungsten-copper-tin alloy powder is obtained. The tungsten-copper-tin alloy powder prepared by preparation method is uniform in component, high in density, excellent in flowing property and easy to form; the problem that the possibility of segregation in the traditional preparation method is high is solved; and the preparation method is simple in preparation technology and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

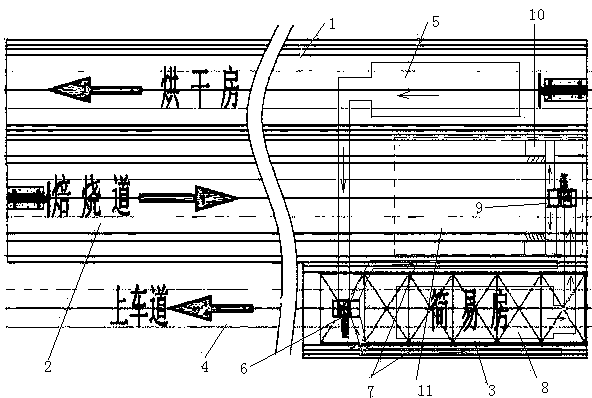

Flue gas secondary re-burning tunnel kiln and flue gas secondary re-burning method

PendingCN110631360AExtended drying timeHeating fastFurnace typesHeating arrangementComing outTunnel kiln

The invention discloses a structure of a flue gas secondary re-burning tunnel kiln and a flue gas secondary re-burning method. The structure is characterized in that a first air cabinet for air inletis installed in a drying room of the tunnel kiln, the first air cabinet is connected to a first centrifugal fan, the first centrifugal fan is connected with first air ducts used for air outlet, the first air ducts are distributed on channels arranged on the two sides of a simplified house, and air outlets of the first air ducts are aligned with a brick pile in the simplified house; and a second air cabinet for air inlet is installed at the upper part of the simplified house, the second air cabinet is connected to a second centrifugal fan, the second centrifugal fan is connected with second airducts used for air outlet, and the second air ducts are arranged on the two sides in a roasting channel low-temperature section of a roasting channel. According to the flue gas secondary re-burning tunnel kiln, the waste heat of finished bricks is fully utilized, the waste heat is used for baking the flue gas coming out of the drying room, the roasting channel is injected with the dry flue gas ofhot air, so that the roasting channel is not cooled, the roasting channel is fast to roast, the finished brick is fast to produce, and the problems of high coal consumption, poor product quality, lowyield and high oxygen content are effectively prevented.

Owner:江西振大机械制造科技有限公司

A rare earth magnesium alloy material for 3D printing and its preparation method

ActiveCN104762541BImprove flame retardant performanceMicrostructureAdditive manufacturing apparatusSlagCrucible

The invention belongs to the technical field of 3D printing materials and discloses a rare earth magnesium-alloy material for 3D printing and a preparation method of the same. The preparation method particularly comprises following steps: (1) weighing raw materials according to element mass ratio of Mg:Mn:Re being 85-97:2-10:1-5; (2) adding pure magnesium, pure manganese and magnesium alloy into a pre-heated crucible, adding a cover agent and smelting the mixture under atmospheric conditions; (3) after the mixture smelted completely, adding an Mg-Re intermediate alloy and pure rare earth elements, melting the components with stirring uniformly and increasing the temperature to 700-750 DEG C; (4) adding a refining agent for refining the alloy for 2-25 min, allowing the refined alloy to stand, removing floated slag, adding the refined alloy into a sand mould trough to obtain a rare earth magnesium alloy base metal; and (5) smelting and atomizing the base metal to obtain the rare earth magnesium-alloy material. The rare earth magnesium-alloy material is excellent in flame retarding performance, is easy to control in powder shape and particle size, can be smelted without protective gas so that a problem of flammability during preparation of the magnesium alloy powder through an atomization method is solved, and can be used for laser 3D printing.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

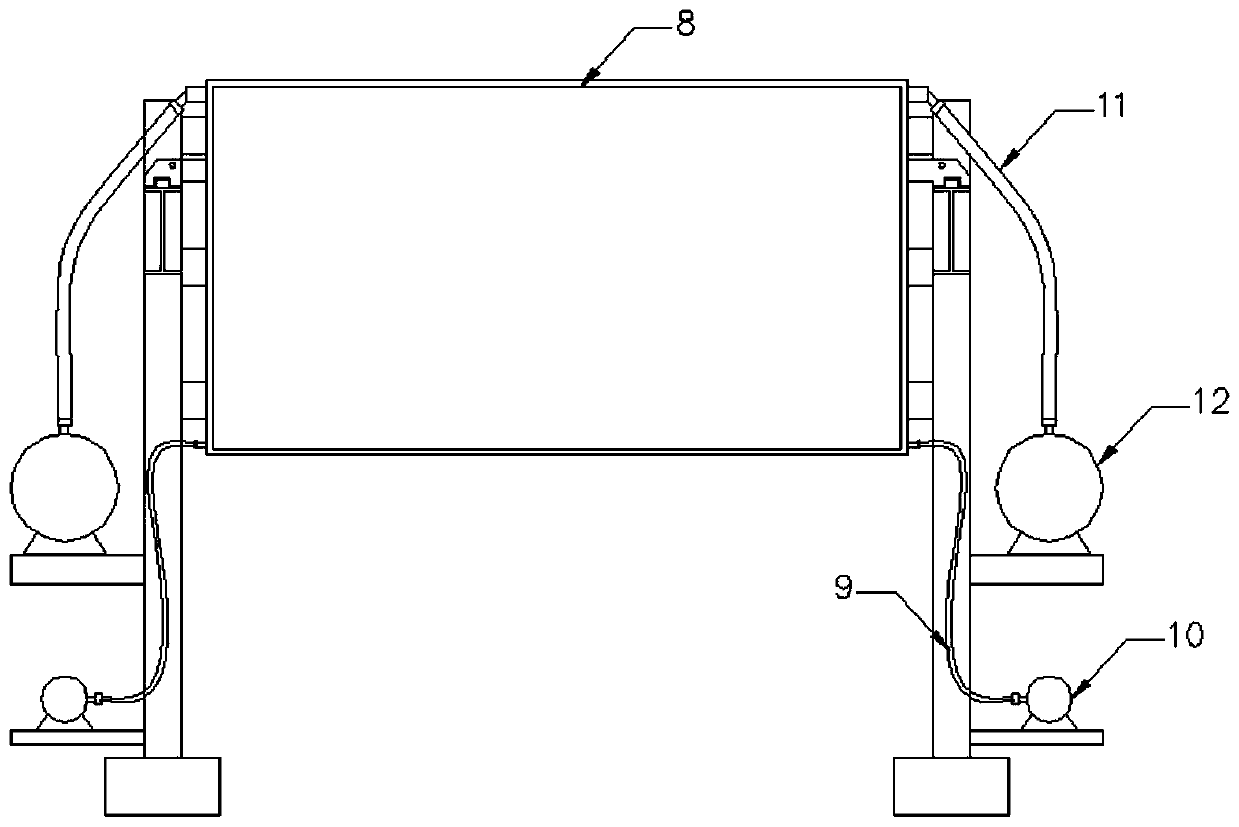

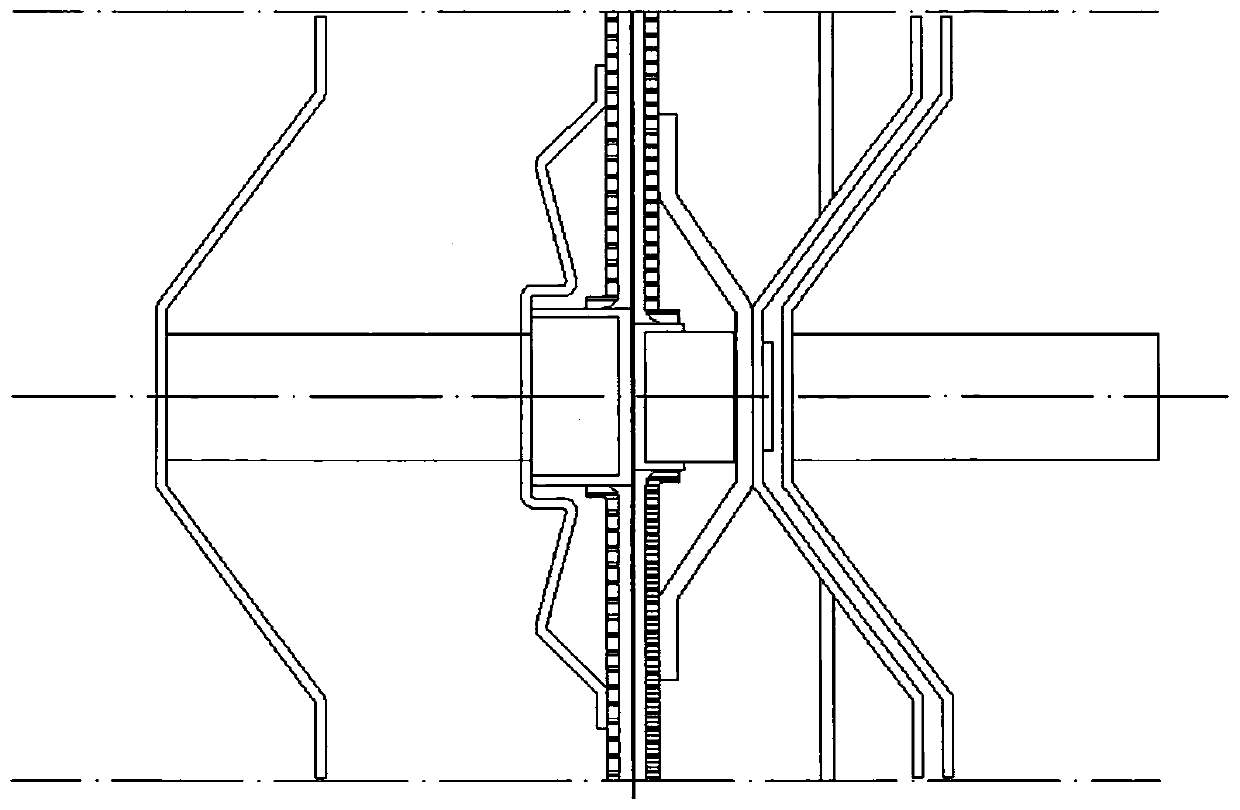

Novel INEOS membrane polar distance electrolytic cell

The invention relates to a novel INEOS membrane polar distance electrolytic cell. The electrolytic cell comprises an anode unit, a cathode unit and ion membranes positioned between the anode unit andthe cathode unit. The electrolytic cell is characterized in that the anode unit comprises anode unit cell bodies, and a new anode net is arranged on the left side face of each anode elastic claw, wherein each new anode net is a complete net; the cathode unit comprises cathode unit cell bodies, each cathode column is provided with a cathode elastic claw on the right, the right side face of each cathode elastic claw is provided with an original cathode net, and the right side face of each original cathode net is provided with an elastomer; a new cathode net is arranged on the right side face ofeach elastomer, and each ion membrane is arranged between the corresponding new cathode net and corresponding new anode net of the same unit cell group. The novel INEOS membrane polar distance electrolytic cell has the advantages of being capable of reducing overvoltage, reducing damage of the ion membranes, providing convenience for replacing cathode and anode nets in the later period and increasing the effective electrolytic area, and reliable and safe during running.

Owner:宏泽(江苏)科技股份有限公司

High-strength heat-resistant light alloy for three-dimensional printing and preparation method thereof

ActiveCN111218598ABreak through limitationsHigh strengthAdditive manufacturing apparatusTransportation and packagingHeat resistanceManufactured material

The invention discloses a high-strength heat-resistant light alloy for three-dimensional printing and a preparation method thereof. The high-strength heat-resistant light alloy comprises the followingcomponents according to the percentage by mass: 4-12wt.% of Gd, 0.5-5wt.% of Er, 0.2-3wt.% of Sm, 0.2-2wt.% of Zn, 0-1wt.% of Zr, and the balance being Mg and inevitable impurities. The preparation method comprises the following steps of: making raw materials into spherical powder after component design, fully mixing the metal powder, sintering the mixed raw material powder, performing solution heat treatment, and obtaining the light alloy spherical powder through mechanical grinding alloying. A finished product obtained through the three-dimensional printing of the obtained materials has theadvantages of high strength, light weight, good heat resistance and wear resistance.

Owner:苏州轻金三维科技有限公司

Preparation method of aluminum nitride thick film with high heat conductivity and high heat dissipation properties

InactiveCN108220878AConsistent proportionHypoxicVacuum evaporation coatingSputtering coatingAluminum IonNitrogen gas

The invention discloses a preparation method of an aluminum nitride thick film with high heat conductivity and high heat dissipation properties. In the method, pure aluminum is selected as a cathode target, the purity of the aluminum target is 99.99%, pure nitrogen is adopted as reaction gas, the purity of nitrogen is 99.999%, and aluminum ions obtained through ionization react with nitrogen to form an A1N high-heat-conductivity film. The method comprises the implementation steps that 1, a workpiece substrate is cleaned, dried and placed into a sample chamber, vacuum pumping is carried out, and the vacuum degree needs to be controlled below 9*10<-3>Pa in order to obtain a high-quality aluminum nitride coating; 2, high-purity Ar gas is led in for carrying out sputtering cleaning; 3, argon leading, arc starting, negative bias adding and nitrogen leading are carried out, nitrogen pressure is 1-3*10<-1>Pa, and pre-bombardment cleaning is carried out under the negative bias of 250 V-650 V for 10-180 min. The aluminum nitride thick film can be deposited on the surface of a complex sample, and the film layer preparation method is most widely applied to the engineering technical field. Themethod is simple, operation is easy, the technology is practical, and the method is suitable for industrial production. The prepared aluminum nitride thick film is uniform in ratio, low in nitrogen content and high in heat conductivity.

Owner:辽宁法库陶瓷工程技术研究中心

A kind of preparation method of tungsten-copper-tin alloy powder

The invention discloses a preparation method of tungsten-copper-tin alloy powder. The invention selects atomized copper powder and crystalline tungsten powder as raw materials, adds tin powder into the atomized copper powder and crystalline tungsten powder, and places them in a steel strip reduction furnace. , high-temperature diffusion treatment is carried out under protective gas or reducing atmosphere, through the diffusion of tin powder in atomized copper powder and crystalline tungsten powder, the atomized copper powder and crystalline tungsten powder are connected by alloy, and then crushed and screened by the crusher Obtain tungsten-copper-tin alloy powder. The tungsten-copper-tin alloy powder prepared by the preparation method of the present invention has uniform composition, high density, excellent fluidity and is easy to form, solves the problem of easy segregation in the traditional preparation method, and has simple preparation process and easy operation.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

A kind of preparation method of lithium titanate material

Owner:江苏众钠能源科技有限公司

Anode Coatings for Ion Membrane Electrolyzers

ActiveCN110318068BHigh oxygen evolution potentialImprove conductivityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisSide reaction

The invention relates to an anode coating for an ion membrane electrolyzer, which is characterized in that its formula is a combined formula of ruthenium, iridium, platinum and titanium, in which the ruthenium content is 35-45 mol%, the iridium content is 5-15 mol%, and the platinum content is 5-10 mol%, titanium content 35-45 mol%, the formula can also contain other additives less than 4% mol%, other additives are zirconium chloride or palladium chloride. The anode coating for ion membrane electrolyzers of the present invention is used for active anodes to meet the following requirements: high oxygen evolution potential, strong catalytic ability, high conductivity, and difficulty in oxygen evolution side reactions; stable performance, corrosion resistance, long life, and electrode After failure, it can be recoated and continued to be used; the cost of the electrode is effectively controlled; improving product quality requires high purity of chlorine and low oxygen content.

Owner:宏泽(江苏)科技股份有限公司

Anti-deterioration storage method of frozen food

PendingCN111280370AAchieve FreshnessGuaranteed shelf lifeFood freezingFood preservationEngineeringProcess engineering

The invention discloses an anti-deterioration storage method of frozen food. The anti-deterioration storage method comprises the following steps: spraying a trehalose solution to the surface of the to-be-frozen food; wherein the spraying amount is 0.2-0.4% of the weight of the to-be-frozen food, then putting the frozen food sprayed with the trehalose solution into a closed pressure bin, applying pressure for 1-2 h at the pressure of 80-120 Mpa, and then performing ventilation and airing under the room temperature condition to enable the moisture content of the frozen food to be not higher than4% for standby application; performing vacuumizing; performing bag opening packaging on the frozen food obtained after degassing treatment is completed; and freezing and storing, namely storing the packaged frozen food in a refrigeration house; according to the anti-deterioration storage method of the frozen food, surface treatment, vacuumizing, packaging and freezing storage are conducted on theto-be-frozen food, the fresh-keeping rate of the food can be achieved to the maximum extent, the expiration date of the food is guaranteed to the maximum extent, and therefore the expiration time ofthe food is shortened, the practical time of the food is prolonged, and practicability is achieved.

Owner:江苏丰诺供应链管理集团有限公司

A kind of medical three-dimensional printing alloy material and preparation method thereof

The invention discloses a medical three-dimensional printing alloy material and a preparation method thereof. The medical alloy components and their mass percentages for three-dimensional printing are: 6~12wt.%Fe, 1~11wt.%Zn, 0.5~4wt. %Y, 0.01~0.07wt.%Cu, 0.5~3 wt.%Ca, 0.1~2.5wt.%Mn, 0.1~1wt.%Zr, and the balance is Mg. The preparation method is as follows: after designing the composition, the raw materials are made into spherical powder, and the metal powder is fully mixed, the mixed raw material powder is sintered and solid solution heat treated, and then the light alloy spherical powder is obtained through mechanical grinding and alloying. The invention is a multi-component degradable alloy material composed of human nutritional elements with complete biological safety, and has excellent flame retardancy, powder shape and particle size are easy to control, and can be used in the field of medical degradable implant materials and three-dimensional printing All have important application potential and good application prospects.

Owner:苏州轻金三维科技有限公司

A kind of high plasticity light alloy for three-dimensional printing and preparation method thereof

ActiveCN111155015BHigh strengthImprove plasticityAdditive manufacturing apparatusHeat resistanceManufactured material

The invention discloses a high-plastic light alloy for three-dimensional printing and a preparation method thereof. The mass percentages of the components of the alloy are: 1-8wt.%Zn, 1-7wt.%Er, 0.2-5wt.%Nd, 0.2~2wt.%Mn, 0.1~1wt.%Zr, the balance is Mg and unavoidable impurities. The preparation method is as follows: after designing the composition, the raw materials are made into spherical powder, and the metal powder is fully mixed, the mixed raw material powder is sintered and solid solution heat treated, and then the light alloy spherical powder is obtained through mechanical grinding and alloying. The finished product obtained by three-dimensional printing has the advantages of high plasticity, light weight, good heat resistance and wear resistance under the premise of maintaining high strength.

Owner:苏州轻金三维科技有限公司

A high-strength alloy for three-dimensional printing and its preparation method

ActiveCN111155014BBreak through limitationsHigh strengthAdditive manufacturing apparatusTransportation and packagingManufactured materialAlloy

The invention discloses a high-strength alloy for three-dimensional printing and a preparation method thereof. The mass percentages of the components of the alloy are: 6~18wt.%Gd, 0.5~4wt.%Er, 0.5~4wt.%Y, 0.2 ~1wt.%Ca, 0~1wt.%Zr, the balance is Mg and unavoidable impurities. The preparation method is as follows: after designing the composition, the raw materials are made into spherical powder, and the metal powder is fully mixed, the mixed raw material powder is sintered and solid solution heat treated, and then the alloy spherical powder is obtained through mechanical grinding and alloying. The finished product obtained by three-dimensional printing has the advantages of high flame retardancy, light weight, high strength and wear resistance.

Owner:苏州轻金三维科技有限公司

Electrode for electrolysis, preparation method thereof, and electrolytic cell

ActiveCN104562078BChlorine evolution potential is lowExtended service lifeElectrodesTitanium alloyOxygen evolution

The invention provides an electrode for electrolysis, a preparation method of the electrode and an electrolytic bath. The electrode for electrolysis comprises a conductive base material and an active coating, wherein the conductive base material is a base material containing titanium or titanium alloy; the active coating at least comprises a bottom coating layer and a surface coating layer; the bottom coating layer is prepared from titanic oxide, iridium oxide and ruthenium oxide; the surface coating layer is prepared from iridium oxide, ruthenium oxide, titanium oxide and a metal or an oxide of one of two of palladium and platinum. According to the electrode for electrolysis disclosed by the invention, the double coating layers are adopted; compared with the single coating layer only containing ruthenium, iridium and titanium, the electrode is better in activity, the chlorine evolution potential of the electrode is low, the oxygen evolution potential is high, the service life of the electrode is longer, and the electrolysis stability is better.

Owner:BLUESTAR BEIJING CHEM MACHINERY

A kind of preparation method of tungsten-copper-nickel alloy powder

The invention discloses a preparation method of tungsten-copper-nickel alloy powder. The invention selects atomized copper powder and crystalline tungsten powder as raw materials, adds carbonyl nickel powder into the atomized copper powder and crystalline tungsten powder, and places it in a steel strip reduction furnace. In the process, high-temperature diffusion treatment is carried out under protective gas or reducing atmosphere, and the atomized copper powder and crystalline tungsten powder are connected by alloy through the diffusion of carbonyl nickel powder in atomized copper powder and crystalline tungsten powder, and then crushed by a crusher Sieve to obtain tungsten-copper-nickel alloy powder. The tungsten-copper-nickel alloy powder prepared by the preparation method of the invention has uniform composition, high density, excellent fluidity and is easy to form, solves the problem of easy segregation in the traditional preparation method, and has simple preparation process and easy operation.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Novel preparation technology for mixture taking water as grinding medium

Owner:OKE PRECISION CUTTING TOOLS CO LTD

Method for preparing hydrocarbon fuel oil by mixing biomass oil and animal and vegetable oil

The invention relates to the technical field of comprehensive utilization of biomass oil and animal and vegetable oil, in particular to a method for preparing hydrocarbon fuel oil by mixing the biomass oil and the animal and vegetable oil. Simple process flow is adopted in the method; and a mixture of the biomass oil and the animal and vegetable oil is converted into the hydrocarbon fuel oil withthe properties and the components (taking fractions such as gasoline, diesel oil, kerosene and the like as the main components) similar to those of petroleum at a certain temperature by adopting a small amount of water as a medium and adopting transition metals, a molecular sieve and the like as catalysts. Different kinds of biomass oil and animal and vegetable oil are mixed according to different proportions, so that the alkane content can be obviously increased and the properties of the fuel oil can be improved. The calorific value of the obtained fuel oil is 36 to 45 MJ / kg and the oxygen content is less than 7 percent.

Owner:北京瑞增兰宇新能源科技有限公司

A preparation method, material and application of 3D printing medical magnesium alloy material

ActiveCN107245618BAvoid painAvoid troubleAdditive manufacturing apparatusSurgeryElemental compositionMixed materials

The invention discloses a preparing method, material and application of a medical magnesium alloy material used for 3D printing. The magnesium alloy material comprises, by mass, 10-16wt% of Fe, 1-3wt% of Mn, 0.2-2wt% of Zn, 0.5-3wt% of Ca and the balance Mg. According to the preparing steps, the material is prepared according to the compositions and the mass; pure magnesium, pure manganese, pure zinc and pure calcium are put into a preheated crucible, a covering agent is added, and the mixed material is smelted on the atmosphere condition; after the mixed material is smelted, a magnesium iron intermediate alloy is added, after the mixed material is smelted, the mixed material is stirred uniformly, and the temperature is stabilized to range from 700 DEG C to 740 DEG C; a refining agent is added, refining is carried out for 5-30 min, the material stands for 10-30 min at the temperature of 700 DEG C-740 DEG C, surface dross is skimmed, the material is poured into a metal mould, and medical magnesium alloy base metal is obtained; and the base metal is smelted and atomized, and the medical magnesium alloy material is obtained. The medical magnesium alloy material is a multi-element degradable alloy material completely composed of biosecurity human body nutrient elements, has an excellent flame retardant property, can degrade an inner implanted material medically, has an important application potential in the 3D printing field, and has a good application prospect, and the powder shape and the particle diameter are easy to control.

Owner:苏州轻金三维科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com