Novel preparation technology for mixture taking water as grinding medium

A technology of grinding media and mixtures, which is applied in the field of new technology for preparation of water as grinding media mixtures, can solve the problems of large energy consumption, potential safety hazards, and insecurity, and achieve reduced production and operation costs, saving equipment investment, and eliminating safety hazards. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention are described in detail below.

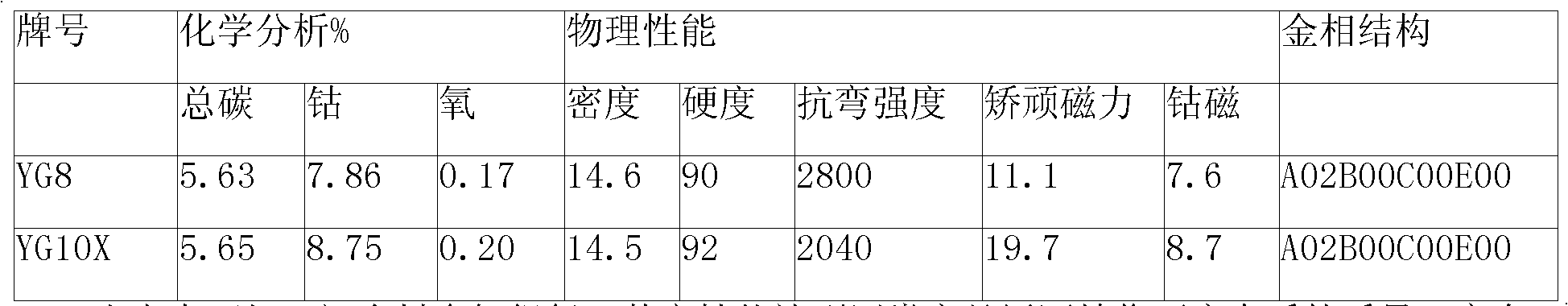

[0014] The present invention carries out batching according to the ingredients of each brand of hard alloy, which includes batching, wet grinding, unloading, slurry drying and other processes. In the wet grinding process, distilled water is used as the grinding medium, and 2-3 % antioxidant substances; in the unloading process, the mixture is discharged from the wet mill, passed through a 320 mesh sieve, and the wet mill is washed with water for 6 times; in the slurry drying process, it is dried in an open spray drying tower, And the slurry is pumped to the nozzle for atomization. The spray pressure is controlled at 0.9-1.0MPa. The droplets move from bottom to top and meet the hot air from top to bottom to dry. The outlet temperature is 105-110°C. The tower flows out, and the material is automatically cooled and then loaded into the barrel.

[0015] The present invention adopts PEG (polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com