Flue gas secondary re-burning tunnel kiln and flue gas secondary re-burning method

A tunnel kiln and flue gas technology, applied in the field of tunnel kiln, can solve the problems of poor product quality, high oxygen content, low output, etc., and achieve the effect of low production cost, high output, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

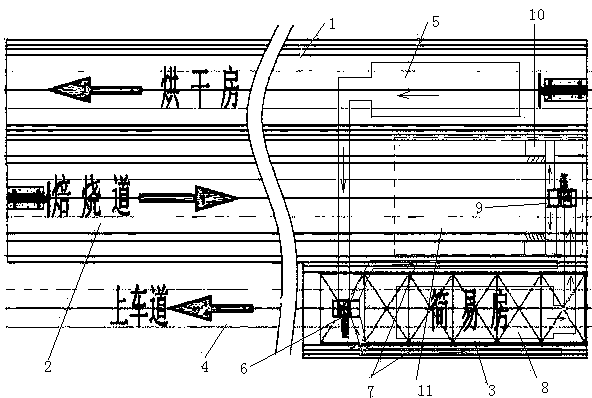

[0012] Such as figure 1 As shown, a tunnel kiln kiln for secondary reburning of flue gas is mainly composed of a drying room 1, a roasting road 2 and a simple room 3. The finished bricks after cooling are transported from the simple room 3 and the upper lane 4, and the simple Passages are set on both sides of the room 3, and the simple room stores the finished bricks fired and transported by the roasting channel 2. In the drying room 1, the first wind cabinet 5 for air intake is installed, the first wind cabinet 5 is connected to the first centrifugal fan 6, and the first centrifugal fan 6 is connected to the first air duct for the air outlet 7. The first air duct 7 is distributed on the passages set on both sides of the simple house 3 and its air outlet is aimed at the brick pile of the simple house 3 (the direction of the air path is as follows: figure 1 indicated by the arrow). The second wind cabinet 8 for air intake is installed on the top of the simple room 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com