Electrode for electrolysis, preparation method of electrode and electrolytic bath

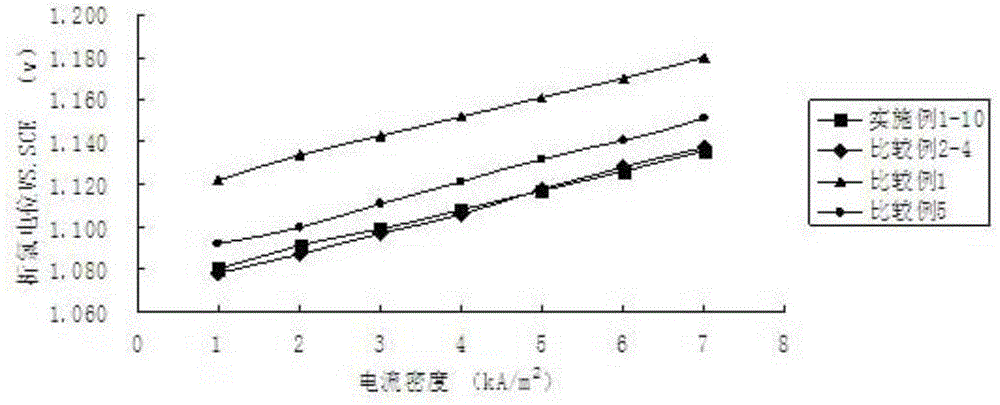

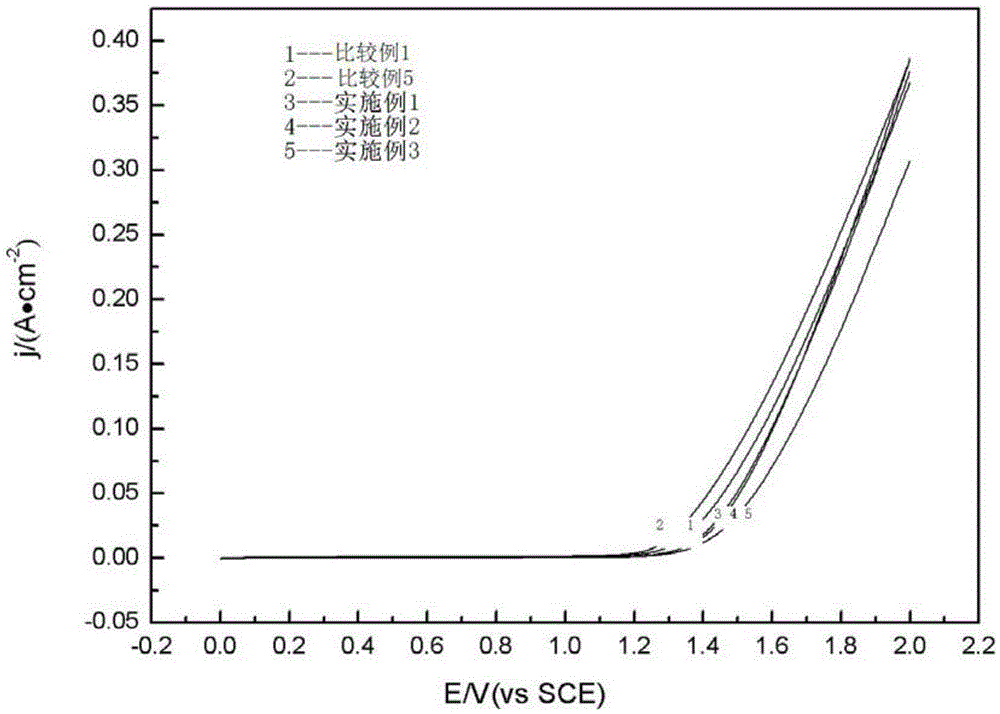

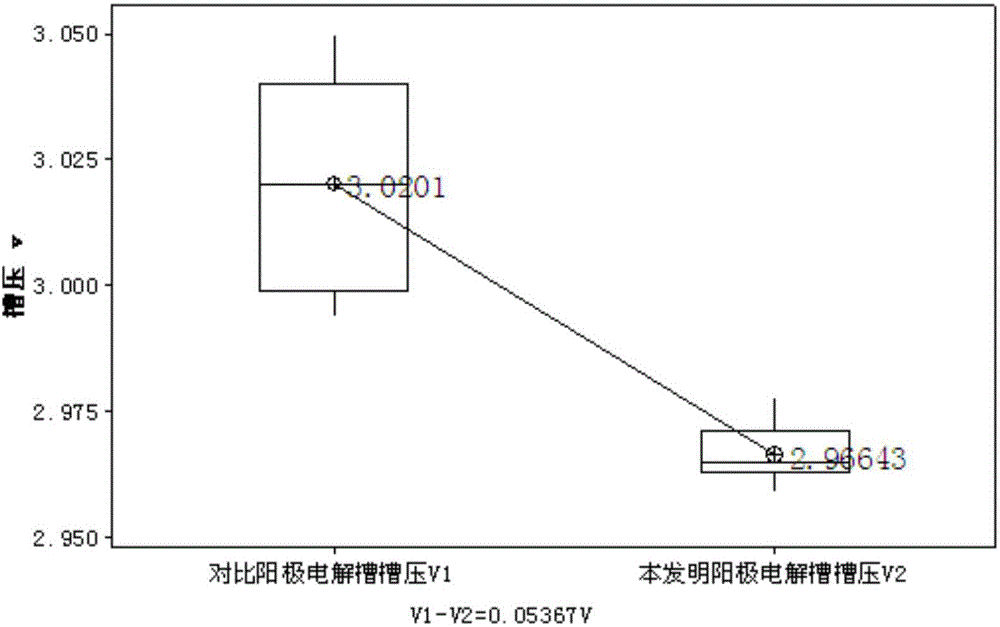

A technology of electrode and conductivity, which is applied in the field of electrolytic cell, electrode for electrolysis and its preparation, can solve the problems such as the drop of chlorine evolution current efficiency, the second layer is easy to fall off, and the electrode oxygen evolution potential is low, so as to achieve good electrocatalytic performance, Good electrolytic stability and high oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of electrode for electrolysis of the present invention comprises the steps:

[0055] S100: Pretreat the conductive substrate; pretreatment includes decontamination and sandblasting; first remove the surface oil, which can make the conductive substrate and the underlying coating stronger; then conduct the substrate Sand blasting treatment, sand blasting treatment can increase the roughness of the surface of the conductive substrate, increase the contact area between the bottom coating and the conductive substrate, and improve the adhesion of the bottom coating on the conductive substrate;

[0056] S200: Anneal the conductive substrate that has been sandblasted; the operation steps of the annealing treatment are to clamp the conductive substrate with an annealing extrusion frame, keep it warm for 30 to 120 minutes at 450°C to 600°C, and then anneal It reduces the hardness of the surface of the conductive substrate, eliminates the internal residual s...

Embodiment 1

[0062] Electrode preparation for present embodiment electrolysis is as follows:

[0063] Step (1): Conductive base material pretreatment: Conductive base material is drawn into the net (mesh size is: long pitch * short pitch * silk stem width: 6.0 * 3.0 * 1.0 ), first degreasing the conductive substrate, and then putting the titanium mesh into the annealing furnace for annealing and leveling. After annealing, an oxide layer is formed on the surface of the conductive substrate, and then it is etched in a sulfuric acid solution. In this embodiment, the acid concentration is 23-27%, the temperature is 85-95°C, and the etching time is 2-6 hours. After pickling, the titanium mesh is cleaned with water and dried.

[0064] Step (2): Primer coating preparation:

[0065] Contain ruthenium, iridium, titanium three kinds of elements in the primer coating in the present embodiment, and wherein in the primer coating solution, metal salt mol percentage is as follows: Ruthenium: iridium: t...

Embodiment 2

[0071] The preparation of the electrode for electrolysis in this embodiment is as follows:

[0072] Step (1): Conductive substrate pretreatment:

[0073] The base material is a net made of δ=1.2mm TA1 plate (mesh size: long pitch×short pitch×stem width: 8.0×4.0×1.2), degreasing, annealing, leveling, etching and pickling Finally, the titanium mesh is cleaned with water and dried.

[0074] Step (2): Primer coating preparation:

[0075] The molar percentage content of the metal salt in the primer coating solution is as follows: ruthenium: iridium: titanium=41%:20%:39%, and the preparation of the primer coating solution is the same as in Example 1.

[0076] Use a coating machine to evenly coat the prepared bottom layer coating solution on the anode grid. Send the anode mesh that has completed the coating and drying process into a firing furnace for firing in an air atmosphere. The burning temperature is 488°C, and the time is 15-40 minutes. Repeat this 8 times to obtain the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com