Titan anode of addition surface active agent coating and preparation method thereof

A technology of surfactant and titanium anode, applied in the direction of electrode, electrolysis process, electrolysis components, etc., to achieve the effect of easy control, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

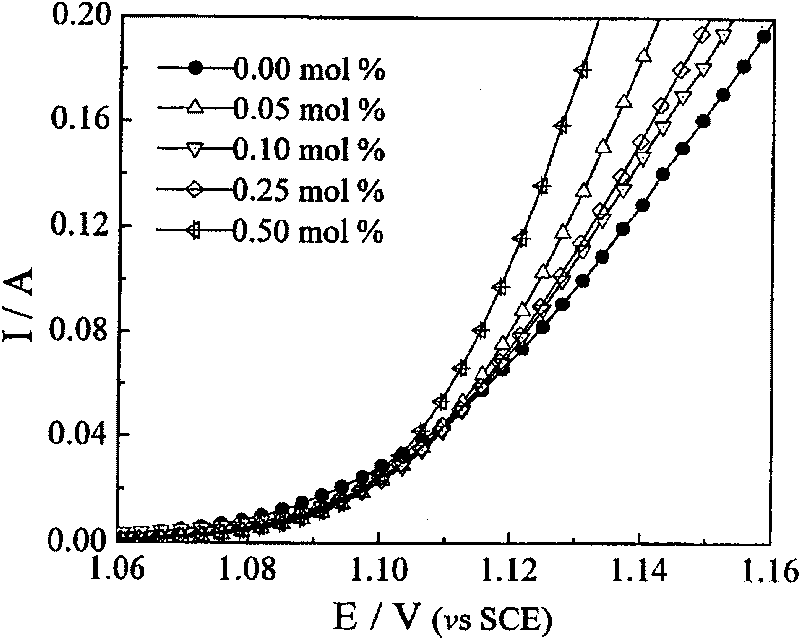

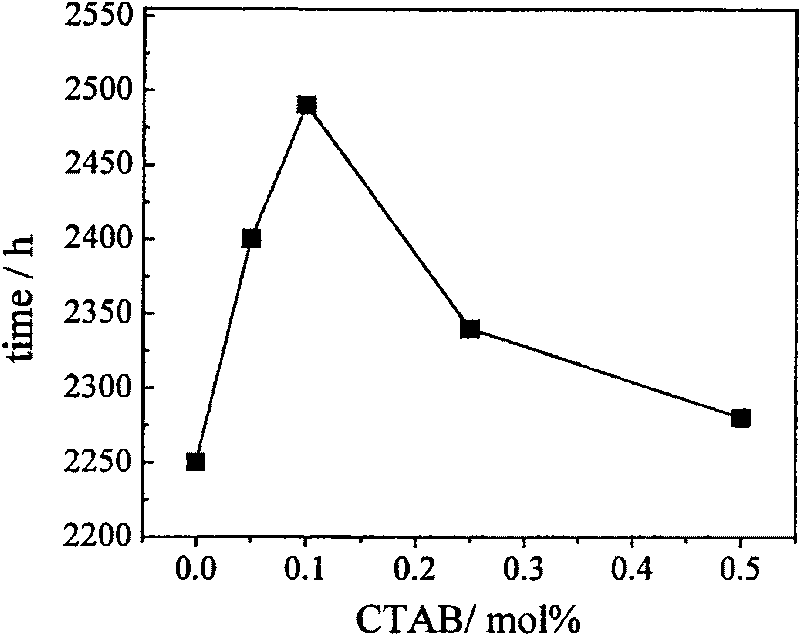

Image

Examples

Embodiment 1

[0029] Preparation Add 0.01% CTAB to prepare Ru-Ti coating. The specific steps are: 1) The area with a thickness of 1.0mm is 20cm 2 The TA1 was washed with 5% washing powder solution, soaked in 15% hydrochloric acid solution for 2 hours, washed with water, and dried. 2) According to the calculation of the required Ru:Ti molar ratio of 30:70 coating, weigh RuCl 3 , Butyl titanate. Dissolve the two in ethanol to form a solution, in which the volume ratio of butyl titanate to ethanol is 28:72. 3) Take industrially pure CTAB as the surfactant, and use the designed RuCl 3 and 0.1% of the total molar content of butyl titanate weighed CTAB, and mixed the weighed into the above solution to prepare a coating. 4) Coating the paint on the titanium substrate, drying it and then oxidizing it in a muffle furnace at 450°C. 5) Repeat coating, drying and oxidation until the coating liquid is used up. Finally, anneal at 450°C for 1 h. A Ru-Ti coated titanium anode was obtained.

[0030] ...

Embodiment 2

[0034] Preparation Add 0.01% CTAB to prepare Ru-Ti-Sn coating. The specific steps are: 1) The area with a thickness of 1.0mm is 20cm 2 The TA1 was washed with 5% washing powder solution, soaked in 15% hydrochloric acid solution for 2 hours, washed with water, and dried. 2) According to the calculation of the required Ru:Ti:Sn molar ratio of 30:60:10 coating, weigh RuCl 3 , butyl titanate and SnCl 2, they were sequentially dissolved in ethanol to form a solution, in which the volume ratio of butyl titanate to ethanol was 25:75. 3) Take industrially pure CTAB as the surfactant, according to the designed RuCl 3 , butyl titanate and SnCl 2 0.25% of the total molar content of CTAB was weighed, and the weighed was mixed into the above solution to make a coating. 4) Coating the paint on the titanium substrate, drying it and then oxidizing it in a muffle furnace at 450°C. 5) Repeat coating, drying and oxidation until the coating liquid is used up. Finally, anneal at 450°C for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com