A high-efficiency electrode for treating industrial circulating cooling water and its preparation method

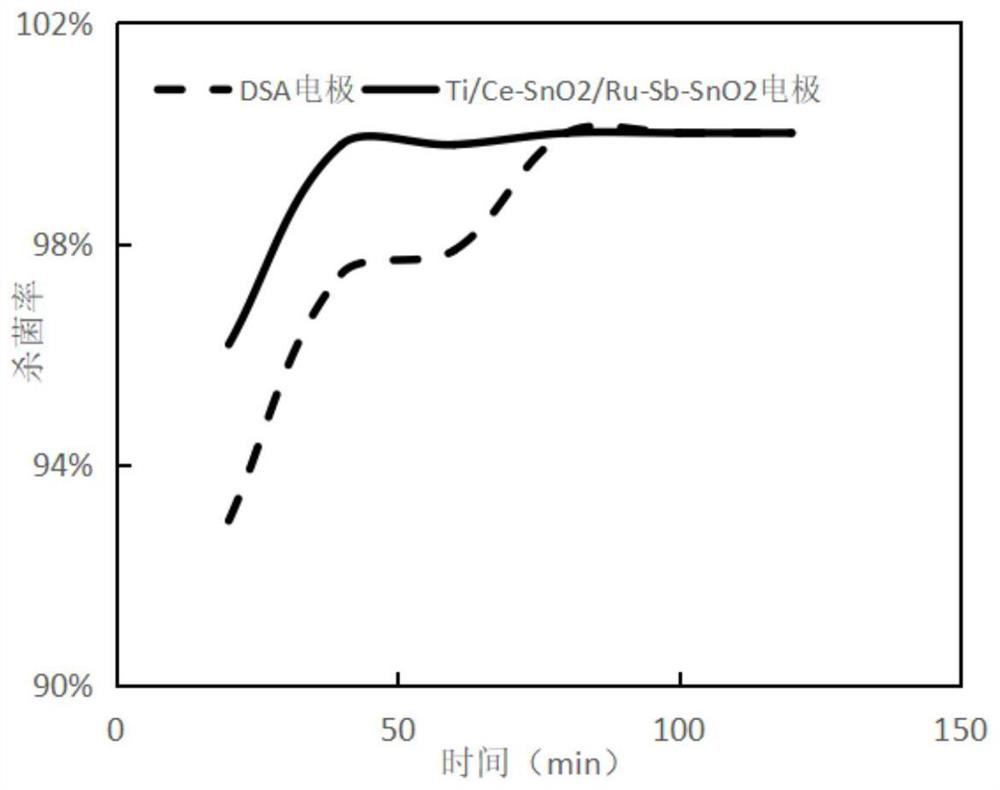

A technology of circulating cooling water and electrodes, which is applied in the direction of active material electrodes, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high price, electrochemical activity, weak sterilization ability, high energy consumption, etc., and achieve sterilization ability Strong, increased reactive sites, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

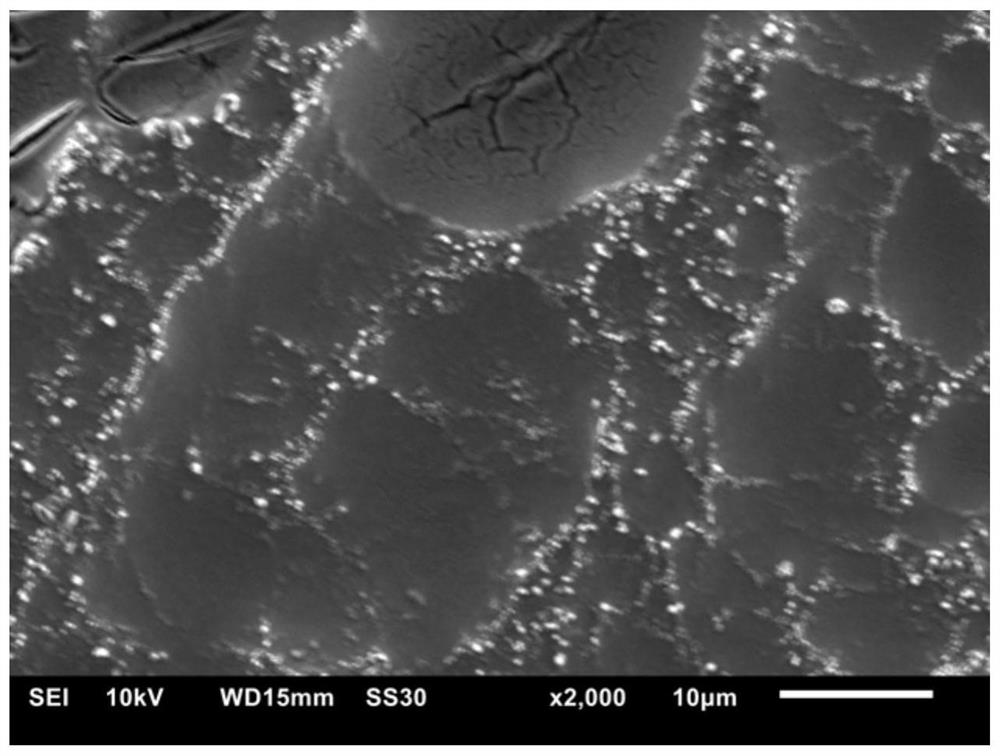

Image

Examples

preparation example Construction

[0031] The preparation method of the high-efficiency electrode for treating industrial circulating cooling water according to the present invention comprises the following steps:

[0032] 1) Select a titanium plate and pretreat the titanium plate;

[0033] 2) the first SnCl 4 ·5H 2 O and the soluble metal salt containing Ce are dissolved in the first organic solvent, and then aged to obtain the precursor solution A;

[0034] 3) the second part of SnCl 4 ·5H 2 O, SbCl 3 and RuCl 3 Dissolved in the second part of organic solvent, and then aged to obtain precursor solution B;

[0035] 4) Apply the precursor solution A to the titanium plate obtained by step 1) in stages, wherein, after each application of the precursor solution A, it is grilled and roasted to obtain Ti / Ce-SnO 2 electrode;

[0036] 5) Brush the precursor solution B onto the Ti / Ce-SnO obtained in step 4) 2 Electrodes, wherein, after each brushing is completed, it is baked and roasted to be used for processi...

Embodiment 1

[0050] The preparation method of the high-efficiency electrode for treating industrial circulating cooling water according to the present invention comprises the following steps:

[0051] 1) Select a titanium plate and pretreat the titanium plate;

[0052] 2) the first SnCl 4 ·5H 2 O and the soluble metal salt containing Ce are dissolved in the first organic solvent, and then aged to obtain the precursor solution A;

[0053] 3) the second part of SnCl 4 ·5H 2 O, SbCl 3 and RuCl 3 Dissolved in the second part of organic solvent, and then aged to obtain precursor solution B;

[0054] 4) Apply the precursor solution A to the titanium plate obtained by step 1) in stages, wherein, after each application of the precursor solution A, it is grilled and roasted to obtain Ti / Ce-SnO 2 electrode;

[0055] 5) Brush the precursor solution B onto the Ti / Ce-SnO obtained in step 4) 2 Electrodes, wherein, after each brushing is completed, it is baked and roasted to be used for processi...

Embodiment 2

[0067] The preparation method of the high-efficiency electrode for treating industrial circulating cooling water according to the present invention comprises the following steps:

[0068] 1) Select a titanium plate and pretreat the titanium plate;

[0069] 2) the first SnCl 4 ·5H 2 O and the soluble metal salt containing Ce are dissolved in the first organic solvent, and then aged to obtain the precursor solution A;

[0070] 3) the second part of SnCl 4 ·5H 2 O, SbCl 3 and RuCl 3 Dissolved in the second part of organic solvent, and then aged to obtain precursor solution B;

[0071] 4) Apply the precursor solution A to the titanium plate obtained by step 1) in stages, wherein, after each application of the precursor solution A, it is grilled and roasted to obtain Ti / Ce-SnO 2 electrode;

[0072] 5) Brush the precursor solution B onto the Ti / Ce-SnO obtained in step 4) 2 Electrodes, wherein, after each brushing is completed, it is baked and roasted to be used for processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com