Production of pre-reduced chrome ore pellet by external heated shaft furnace

An externally heated shaft furnace technology, applied in the field of shaft furnaces, can solve problems such as complex process technology, huge equipment, and difficult operation, and achieve the effects of easy operation, high labor productivity, and reduced CO gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

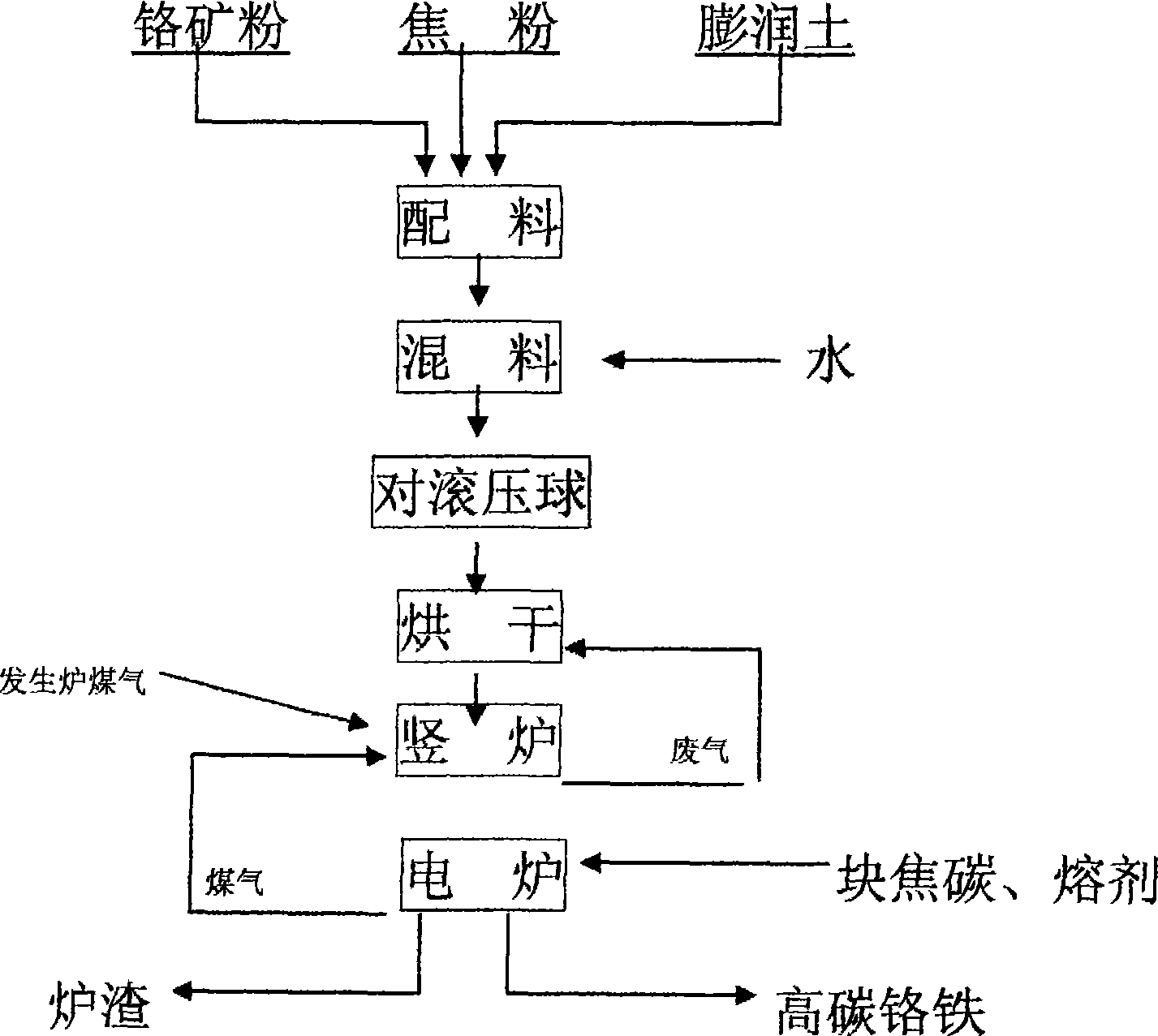

[0028] The chromium ore pre-reduction shaft furnace and electric furnace smelting production process are as follows:

[0029]

[0030] 1. Ball pressing process: chrome ore powder (<5mm), metallurgical coke powder (<3mm), bentonite (<80 mesh), added to the mixer according to the ratio of 100:15-20:4-5, and then dry mixed and wet After mixing, it is added to the counter-rolling ball machine, and the particle size of the cold-pressed ball is <30mm. It can be dried at 200-300℃ and then loaded into the shaft furnace by the elevator, or directly into the shaft furnace without drying.

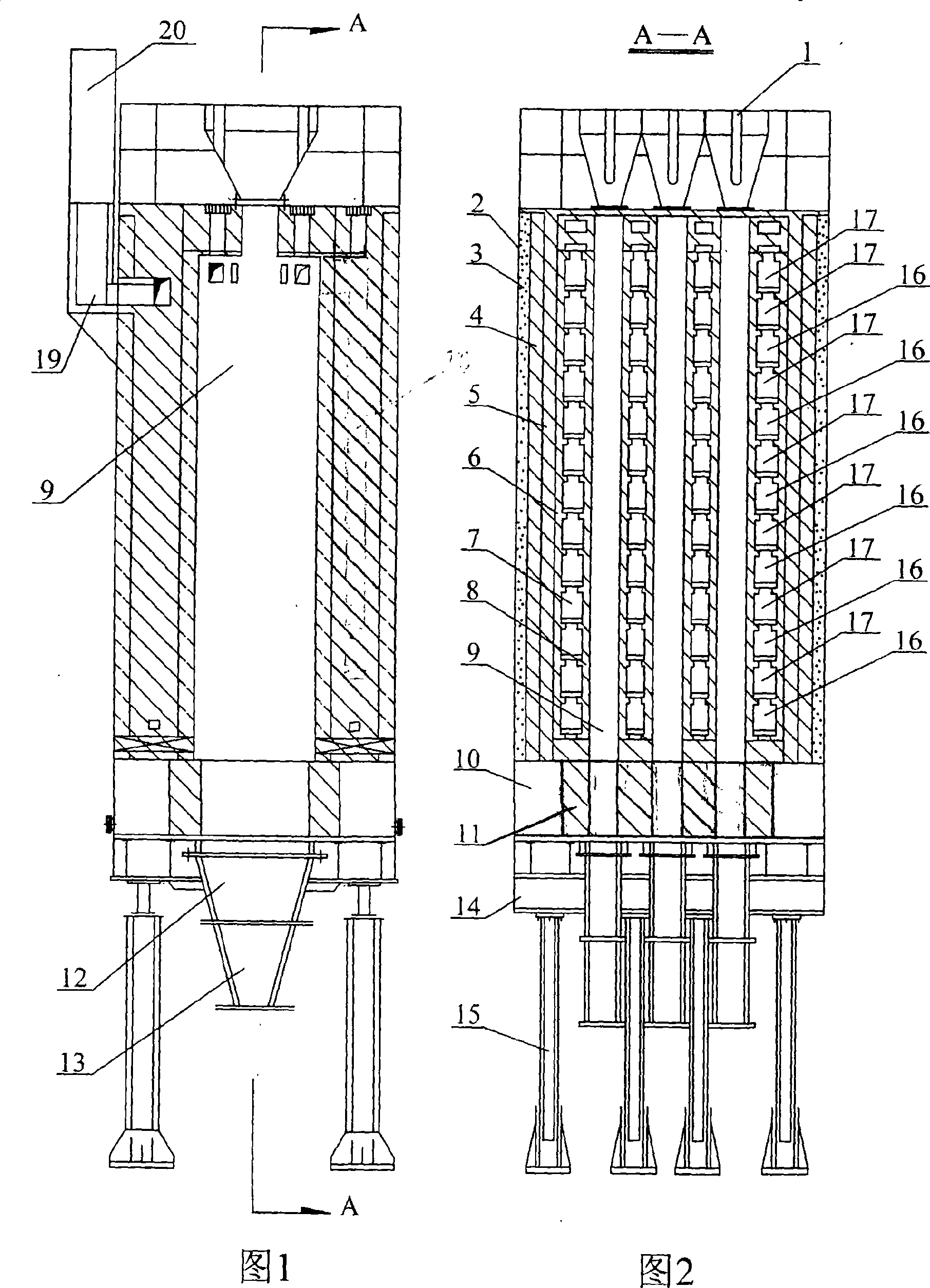

[0031] 2. Shaft furnace pre-reduction process: Shaft furnace is divided into preheating section, reduction section and cooling section. The shaft furnace consists of several reduction reaction chambers with independent systems. The dried chromium ore pellets are loaded into the silo on the top of the shaft furnace. The charge first enters the preheating section, the upper part of the preheating section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com