Method for preparing hydrocarbon fuel oil by mixing biomass oil and animal and vegetable oil

A hydrocarbon, animal and vegetable oil technology, applied in the field of comprehensive utilization of biomass and animal and vegetable oil, can solve the problems of high viscosity, cloud point and high acid value of biodiesel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 4.0g soybean stalks (particle size less than 20 mesh) with 0.60g sunflower oil, add 0.12g iron, and add 0.40ml water, stir and mix evenly, compact it into a 10ml miniature airtight reaction kettle, and heat up at 80°C / min The temperature was raised to 400° C. and kept for 20 minutes to end the reaction. After the reaction is cooled, the reaction product is distilled at atmospheric pressure, the fraction at 60-500°C is collected, and the water in the collected liquid is separated to obtain hydrocarbon fuel oil mainly composed of alkanes and aromatic hydrocarbons. The calorific value of fuel oil is 42.71MJ / kg, and the oxygen content is less than 6%.

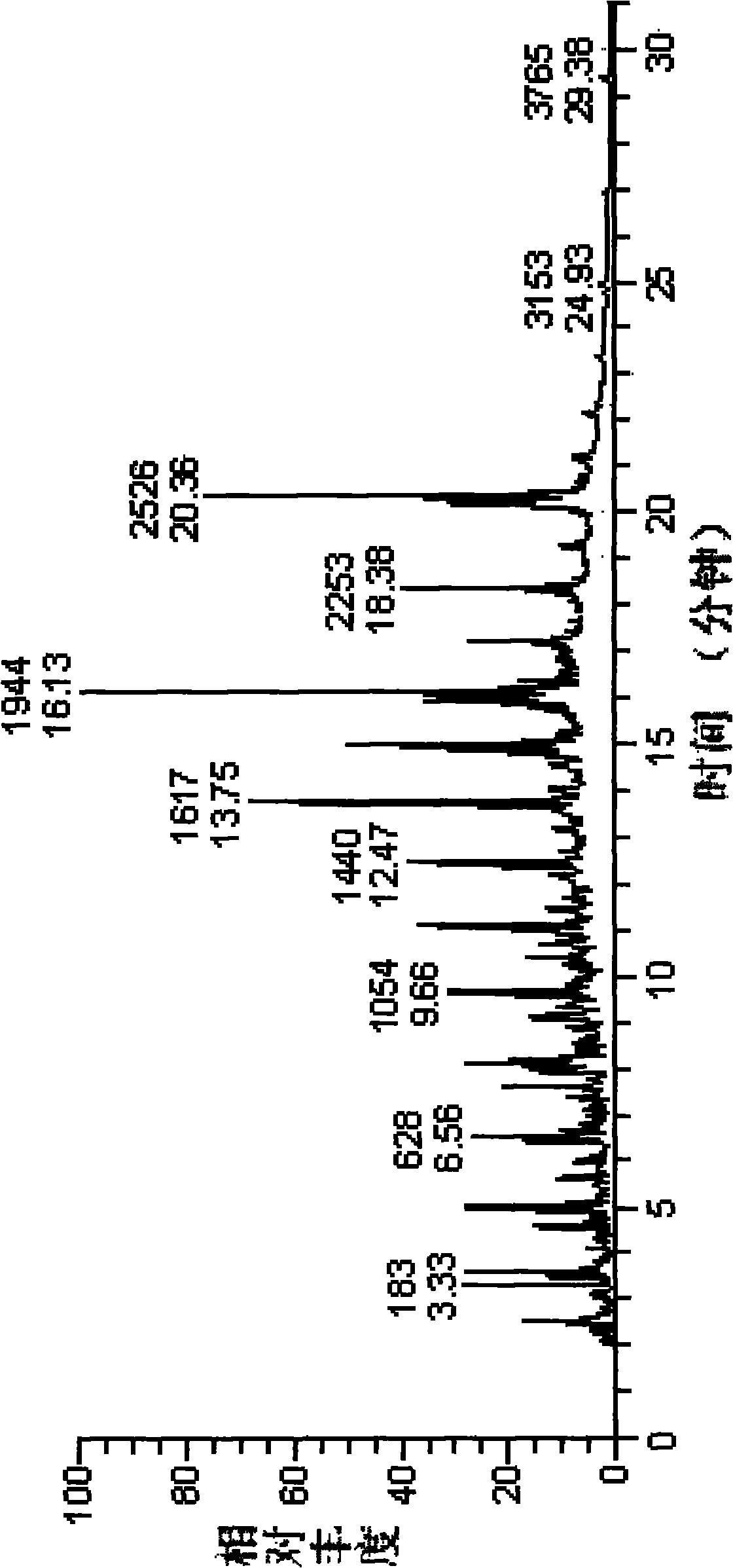

[0025] figure 1 It is the GC-MS total ion chromatogram of the obtained hydrocarbon fuel oil with alkanes and aromatics as main components. Analysis of the mass spectrogram shows that the main components of hydrocarbon fuel are:

[0026] (1) Hydrocarbons mainly include: decane, octane, nonane, decane, undecane, dodecan...

Embodiment 2

[0030] Mix 4.0g of peanut shells (particle size less than 20 mesh) with 1.00g of sunflower oil, add 0.15g of aluminum oxide, and add 0.40ml of water, stir and mix evenly, then compact it into a 10ml airtight reaction kettle, at 10℃ / Raise the temperature to 450°C at a heating rate of min, keep it for 25 minutes, and end the reaction. After the reaction is cooled, the reaction product is distilled at atmospheric pressure, the fraction at 60-500°C is collected, and the water in the collected liquid is separated to obtain hydrocarbon fuel oil mainly composed of alkanes and aromatics. The calorific value of fuel oil is 43.21MJ / kg, and the oxygen content is less than 5.5%.

Embodiment 3

[0032] Mix 4.0g of lawn grass clippings (particle size less than 20 mesh) with 1.5g of peanut oil, add 0.25g of manganese, and add 0.30ml of water, stir and mix evenly, compact it into a 10ml closed reaction kettle, and heat up at a rate of 40°C / min. The temperature was raised to 350° C. and kept for 10 minutes to end the reaction. After the reaction is cooled down, the reaction product is distilled at atmospheric pressure, the fraction at 60-500°C is collected, and the water in the collected liquid is separated to obtain hydrocarbon fuel oil mainly composed of alkanes and olefins. The calorific value of fuel oil is 40.87MJ / kg, and the oxygen content is less than 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com