Patents

Literature

50results about How to "Composite speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

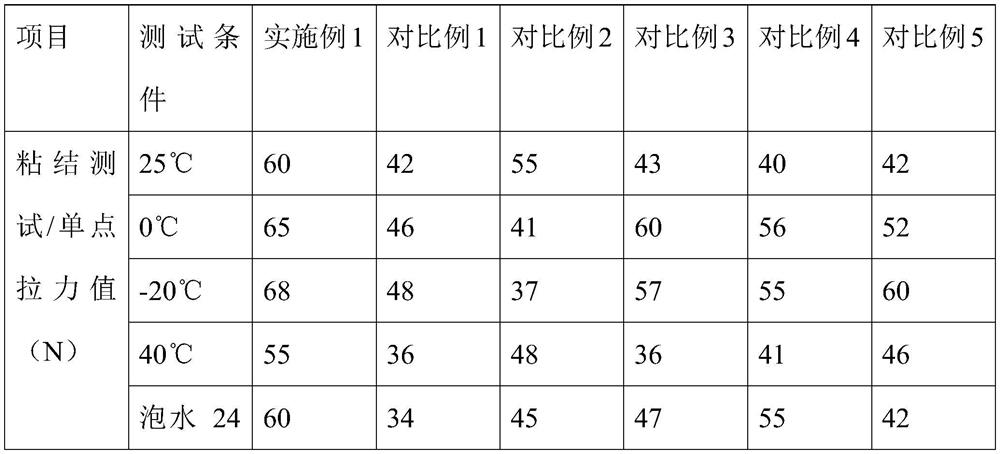

Steam-resistant solvent-free laminating adhesive and preparation method thereof

ActiveCN102604583ALow viscosityImprove heat resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides steam-resistant solvent-free laminating adhesive applicable to compound soft package, which comprises a component A and a component B. The component A is isocyanate terminated polyurethane polymer formed by reacting polyhydroxy compound and polyisocyanate terminated compound. The component B is formed by mixing more than one type of plant oil polyalcohol, curing accelerator and synthetic modifier. The polyhydroxy compound in component A is formed of polyester polyol and / or polyether polyol with more than two degrees of functionality and a molecular weight range of from 600-2000, and more than one type of plant oil polyalcohol. The curing accelerator in the component B is formed of small molecular polyalcohol with more than two degrees of functionality. The synthetic modifier is formed by reacting more than one type of silane coupling agent and polyalcohol. The steam-resistant solvent-free laminating adhesive is low in viscosity and fast in curing speed, has high peel strength after boiled in water at 100 DEG C, and is especially suitable for soft packages requiring long-term high temperature sterilization (such as soft packages for foods, drugs and baby products). The invention further provides a preparation method of the steam-resistant solvent-free laminating adhesive.

Owner:SOUTH CHINA UNIV OF TECH +1

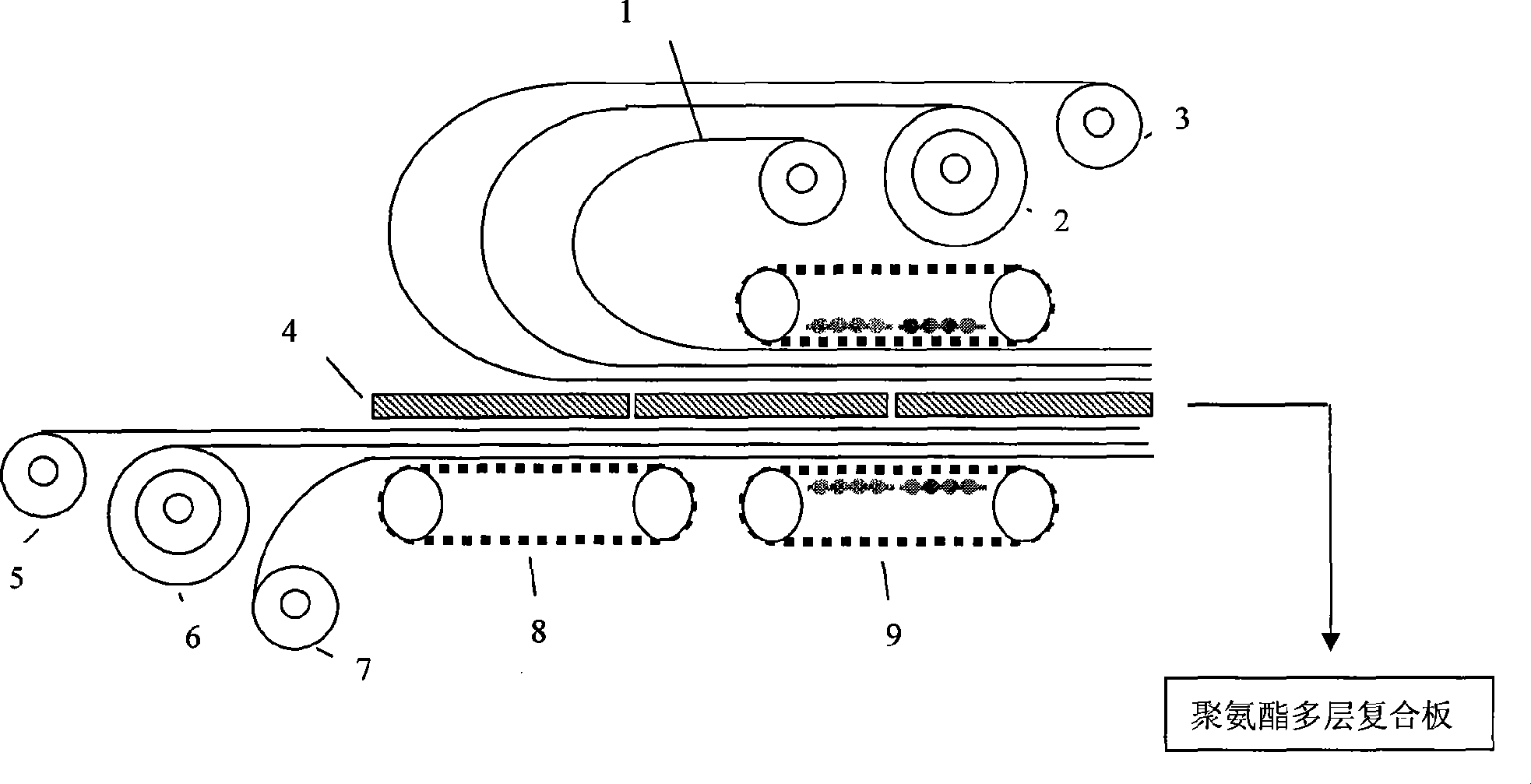

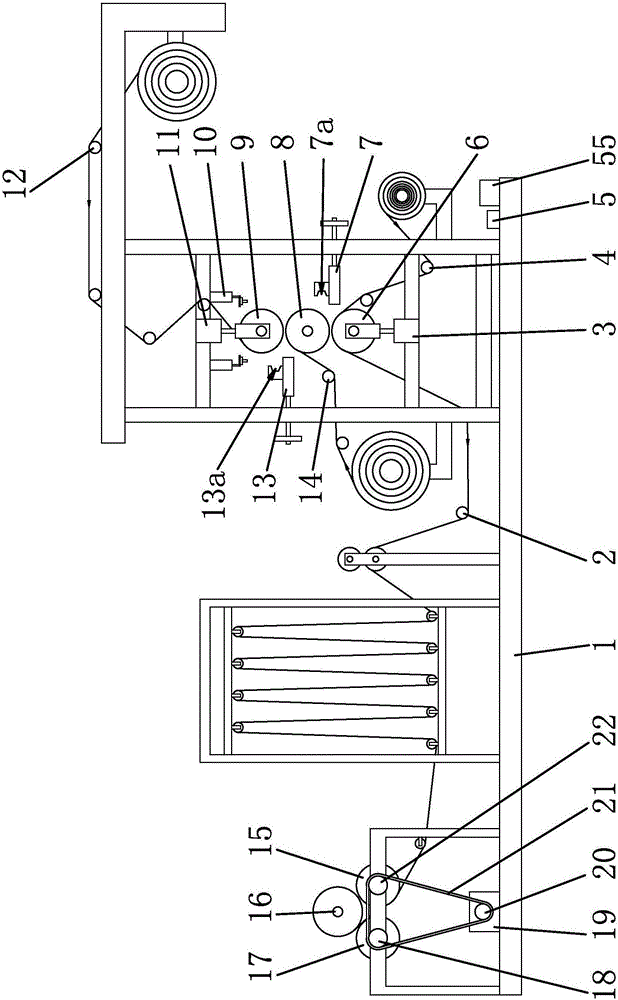

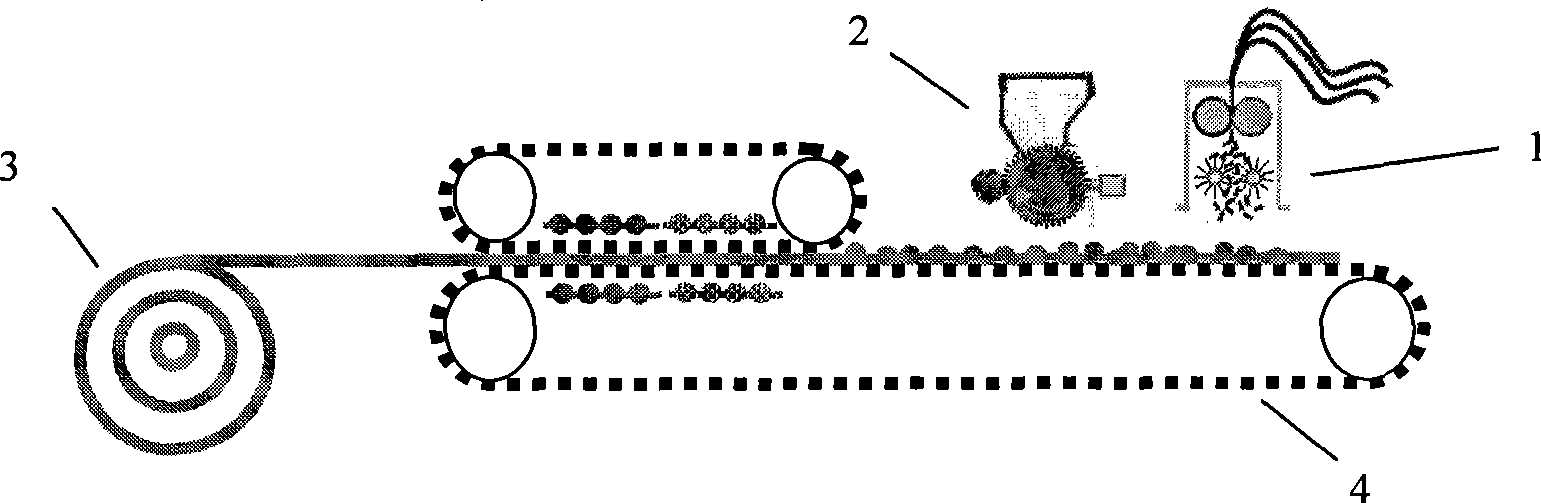

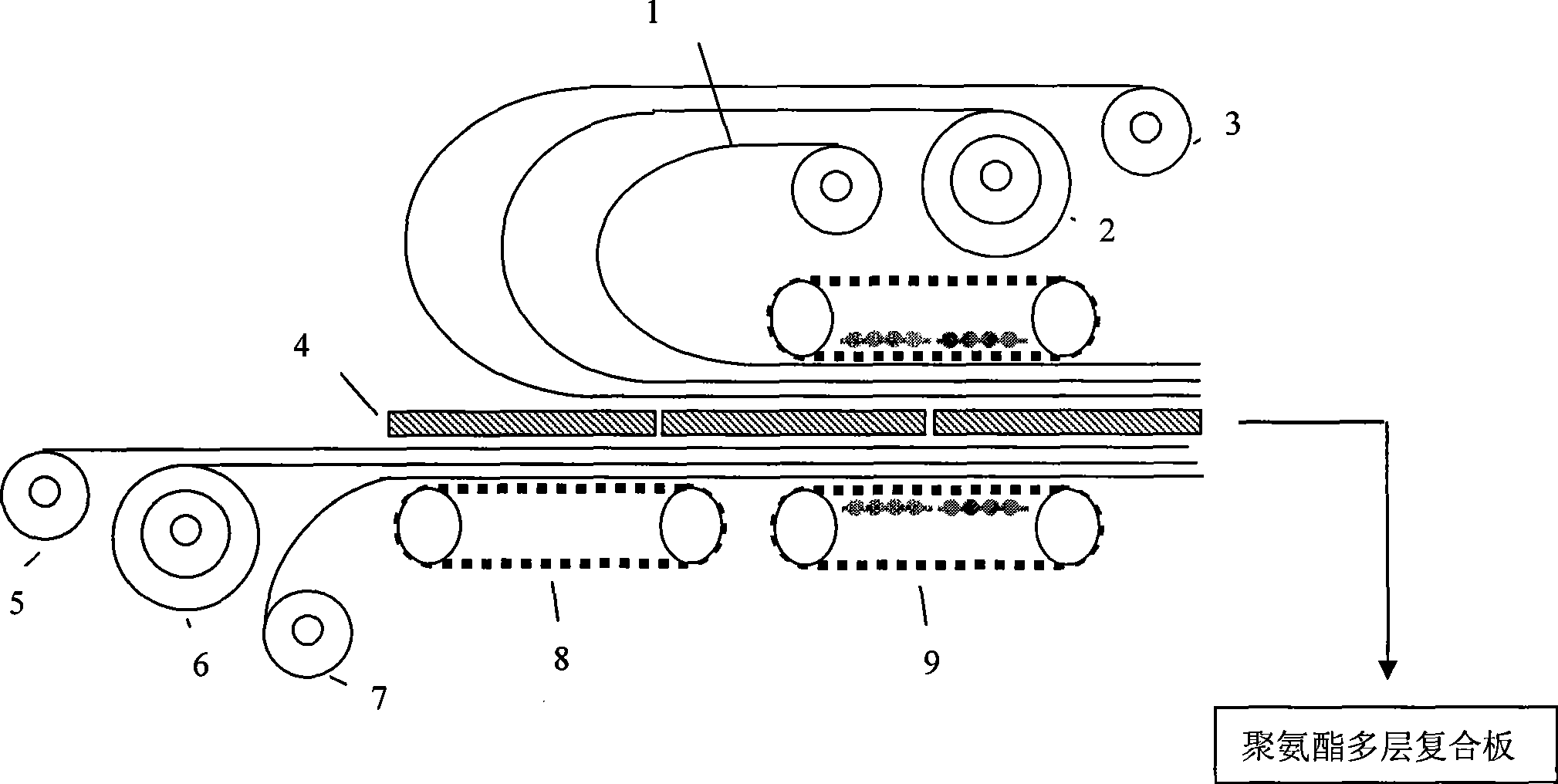

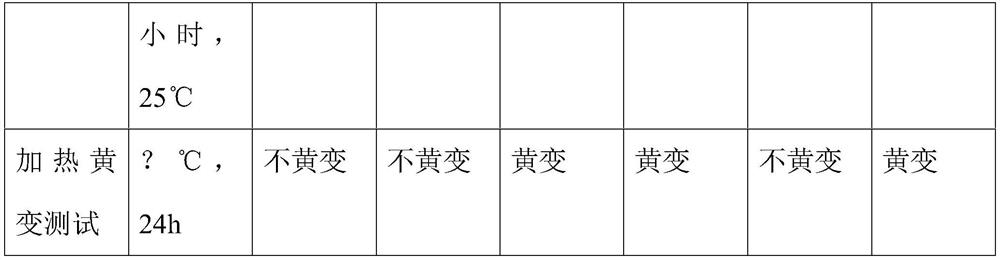

Manufacturing method of multilayer composite board of polyurethane

InactiveCN101367287AEvenly distributedReduce energy consumptionSynthetic resin layered productsLaminationGlass fiberProduction line

The invention discloses a method for producing a polyurethane multilayered composite plate. The method comprises the following steps: (1)chopped glass fiber and hot melt rubber powder are scattered on a transmission caterpillar of a compounding machine and are subjected to heat pressing and compounding to form a film; and the film is cooled and coiled to obtain a rubber glass film; and (2) firstly, nonwoven fabric, the rubber glass film and an adhesive film in turn are unreeled, stacked and paved on a worktable of a composite production line from top to bottom; and secondly, a polyurethane rigid foam plate is placed; the adhesive film, the rubber glass film and a hot melt rubber film in turn are unreeled, stacked and paved on the polyurethane rigid foam plate from bottom to top and are subjected to heat pressing, compounding and cooling to obtain the polyurethane multilayered composite plate. The method can realize one-step compounding and molding of the polyurethane composite plate and has low consumption of the production line and high production efficiency; a production process using the rubber glass film as a strengthening material and the adhesive film as a cementing agent improves the bonding force between the strengthening material and a PU plate; and a prepared product has the advantages of strong rigidity, flat surface and stable quality and suitability for molding the roof of an automobile by a cold mould method or a dry method.

Owner:LIYANG SHANHU IND CO LTD

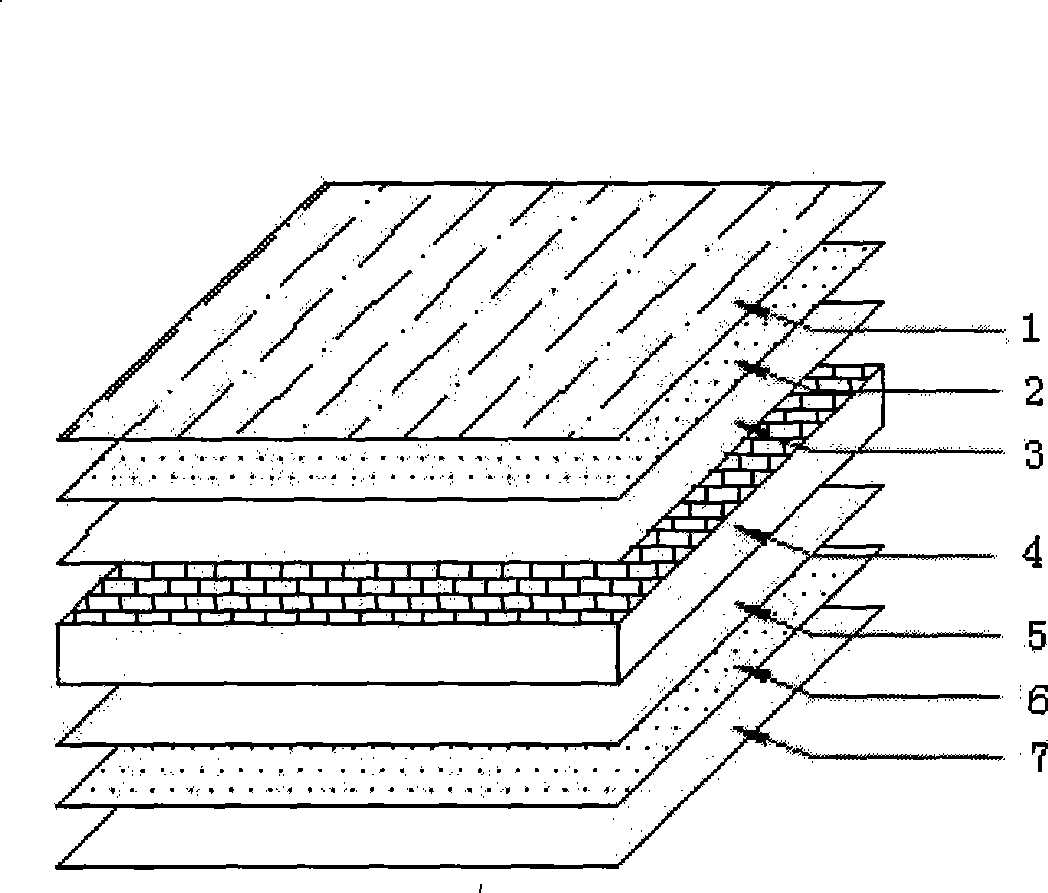

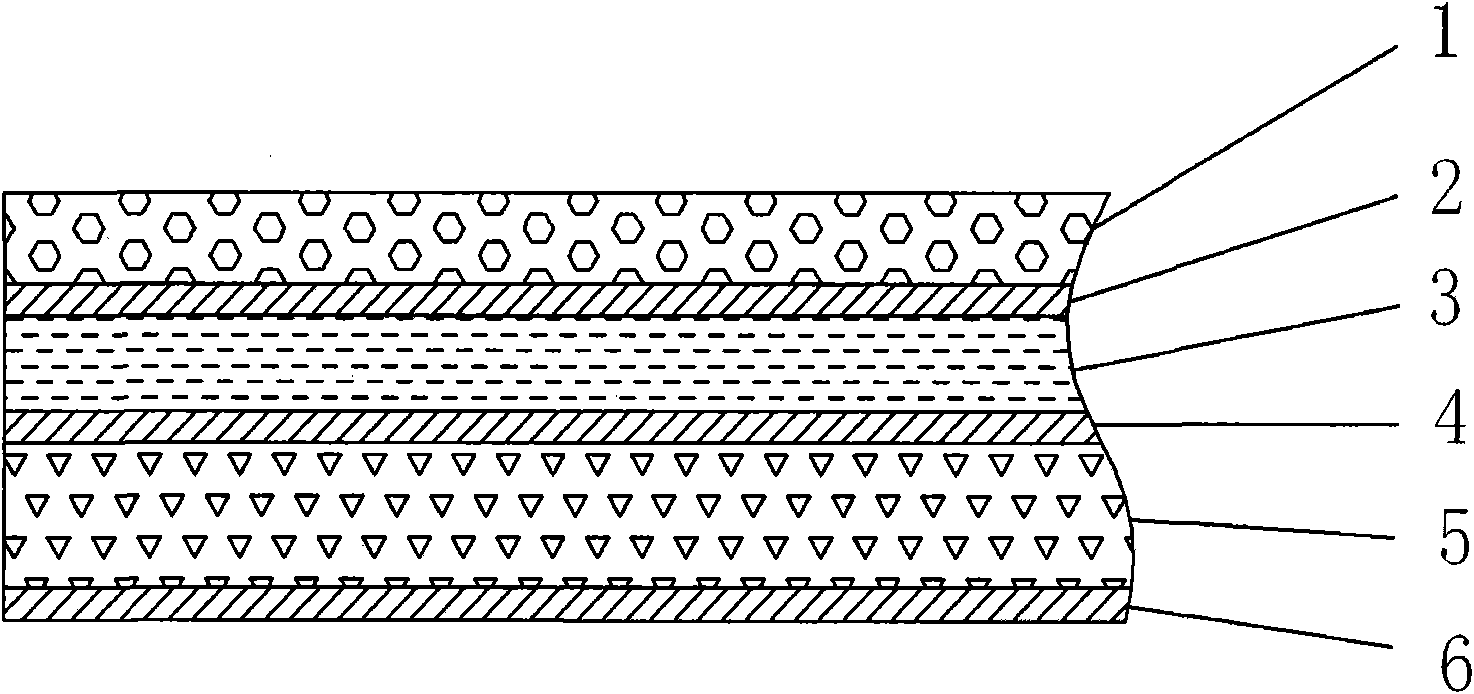

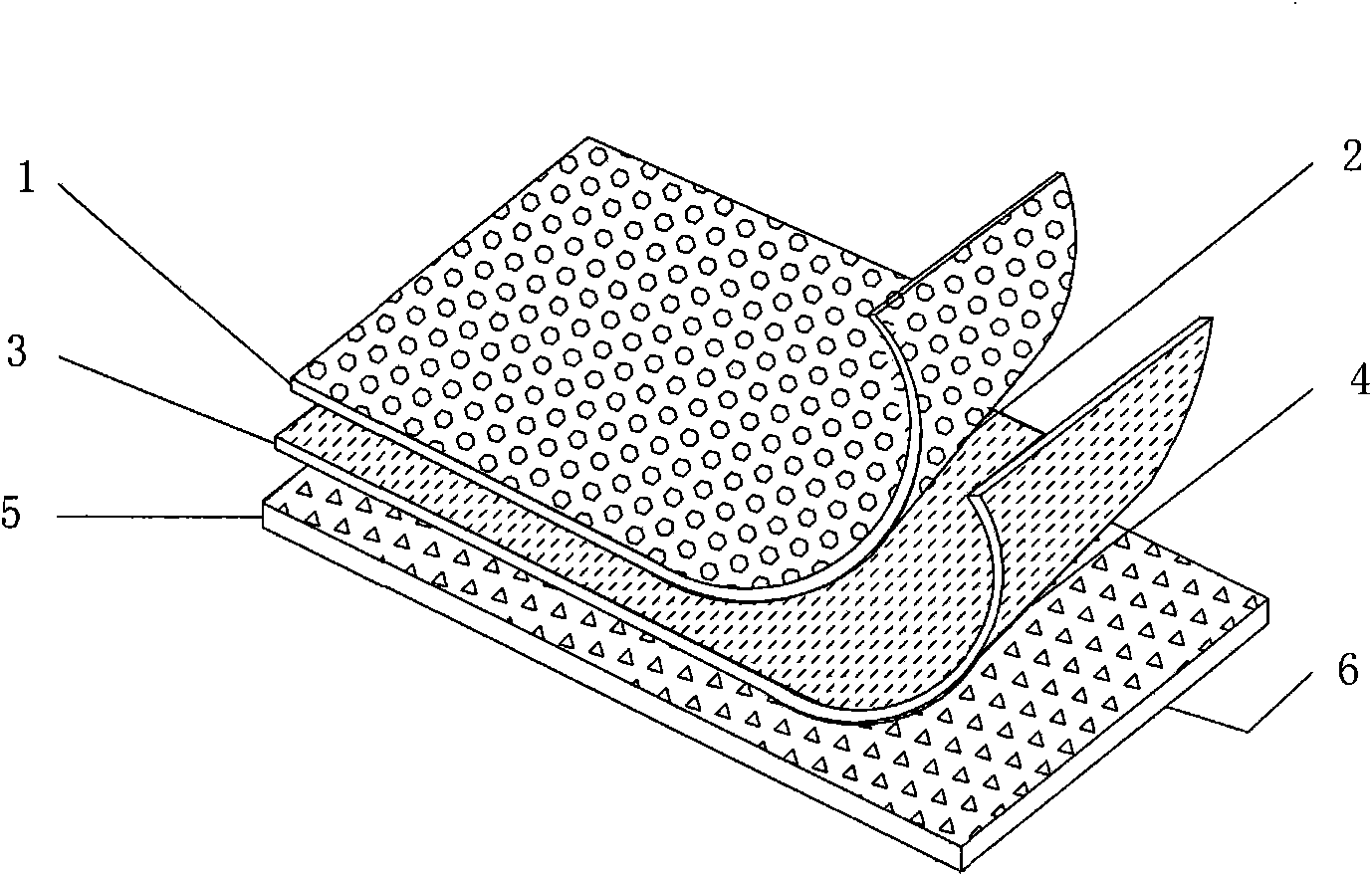

Composite material with high obstruction and high performance and preparation method thereof

InactiveCN101554789AGood weather resistanceImproves resistance to gas permeationLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveSolvent free

The invention relates to a composite material with high obstruction and high performance and a preparation method thereof. The composite material with high obstruction and high performance is a laminated body sequentially compounded by a polyfluoroethylene thin film layer, a polyurethane adhesive layer, an AL / PET film layer, a polyurethane adhesive layer, a Kevlar fabric layer and a polyurethane coating. The composite material can ensure lower gas permeability and good mechanical properties and fatigue resistivity under the condition of lighter quality and can be really adapted to the application requirement on the material with high obstruction in the aerospace field. The preparation method is a dry method solvent-free composite technology, the solid content of adhesive used for the method is 100 percent, and no solvent is contained. The method has the great characteristics of environment protection, high product hygiene index and product quality guarantee.

Owner:CHINESE TEXTILE ACAD +1

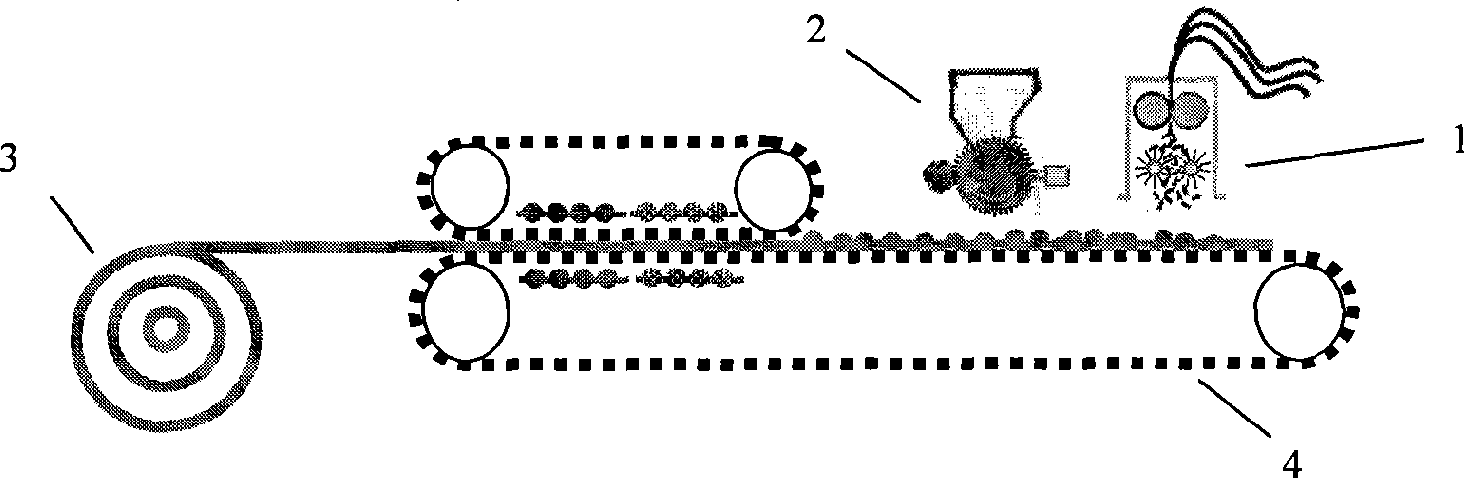

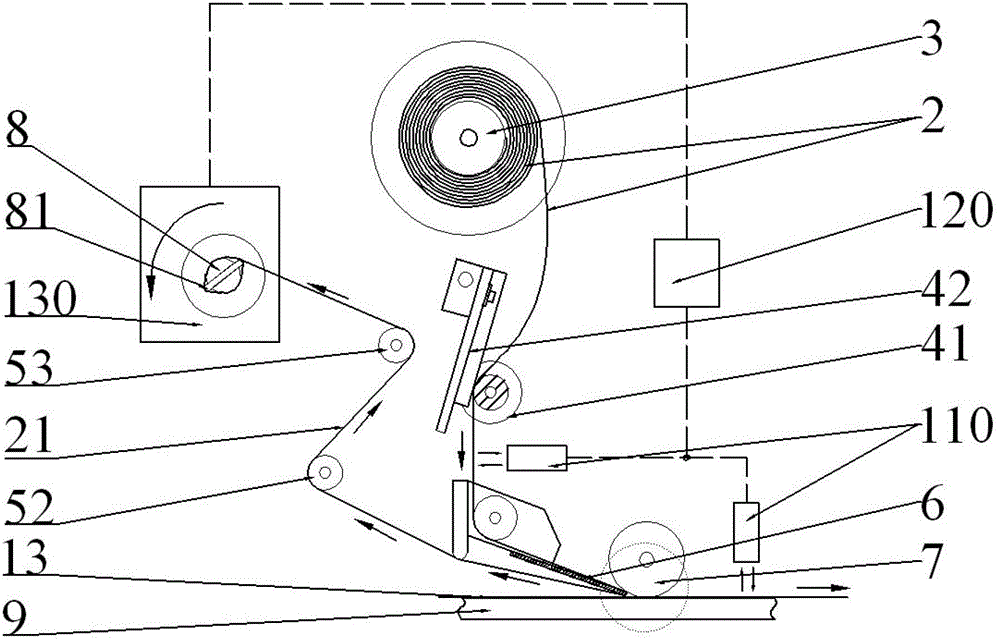

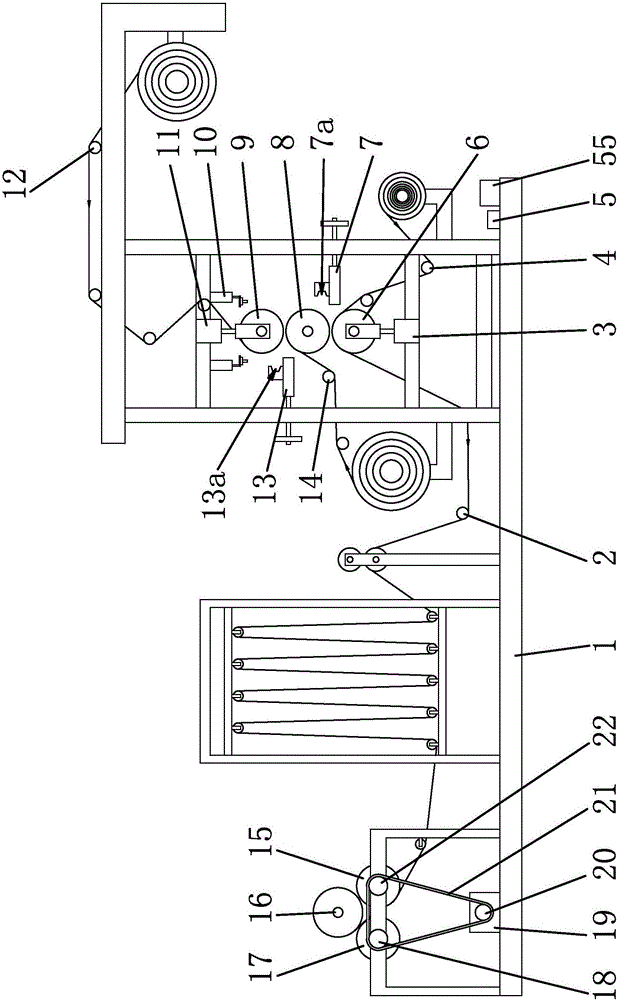

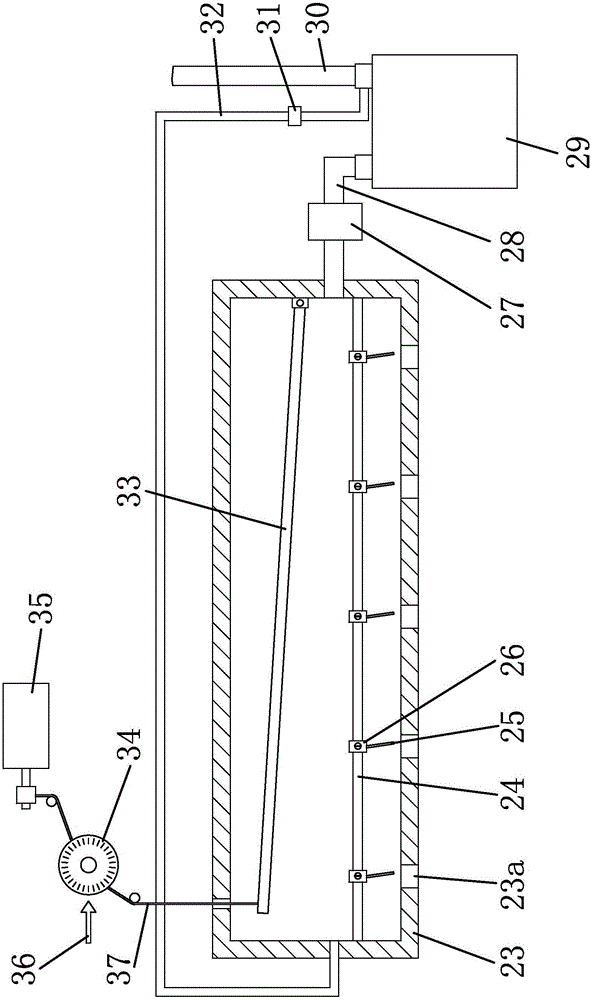

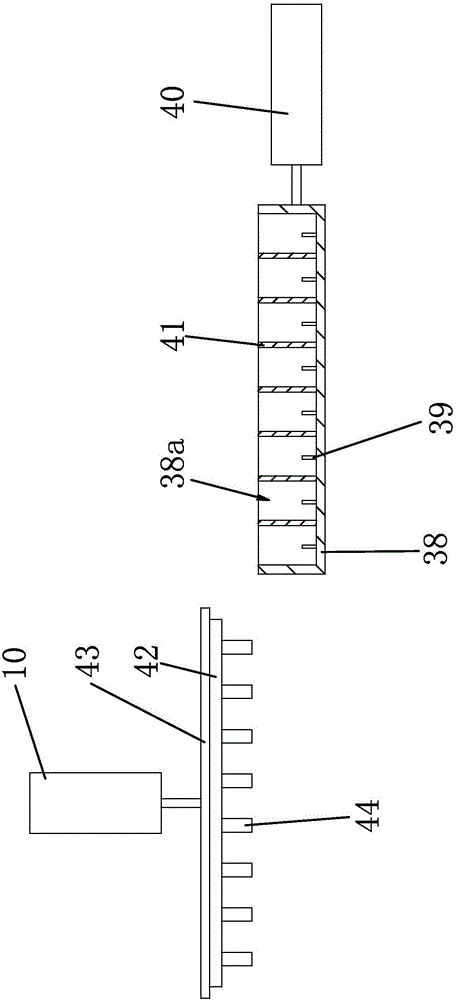

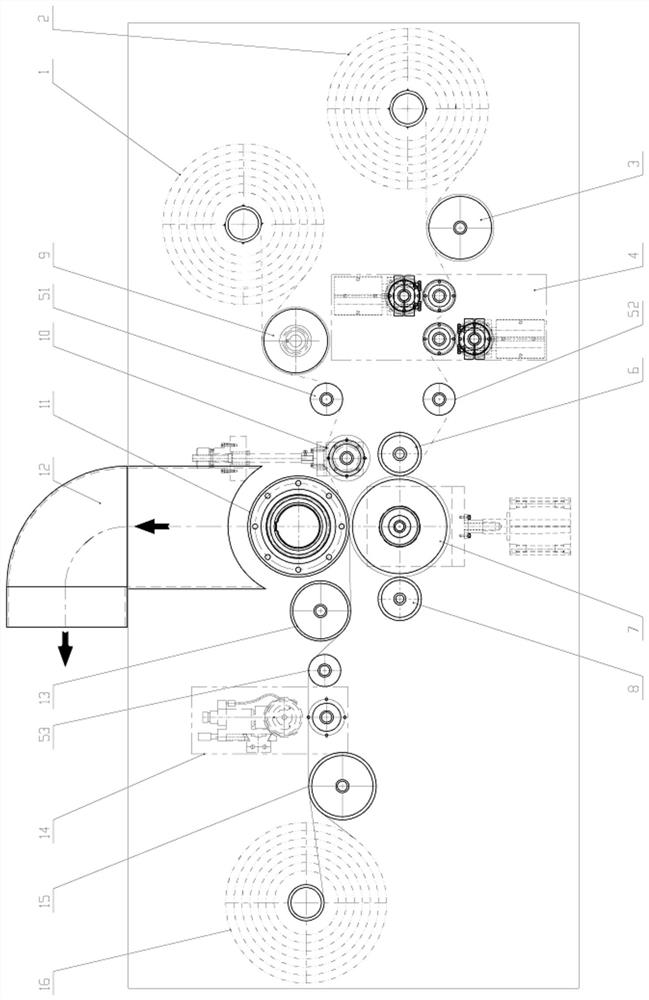

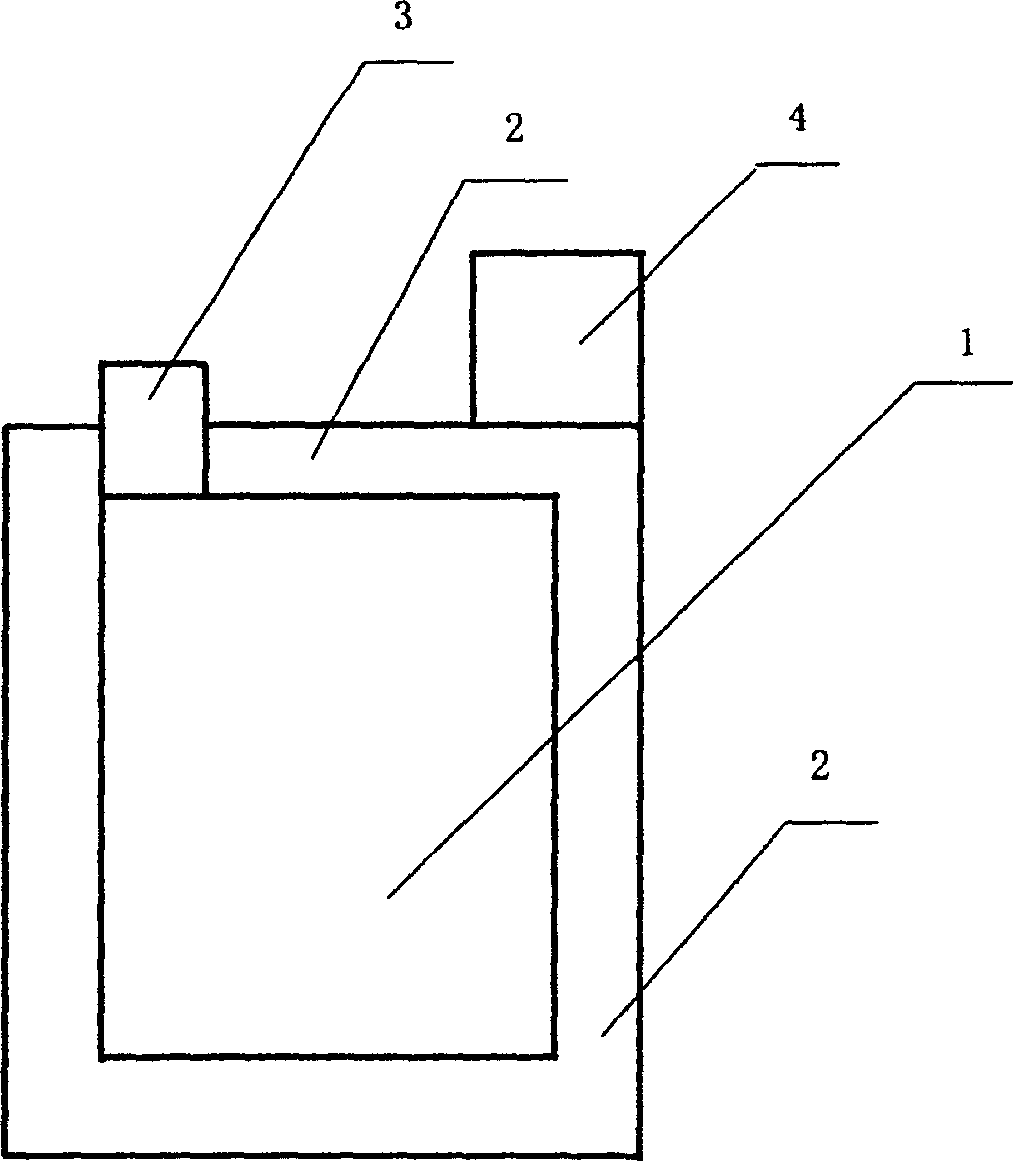

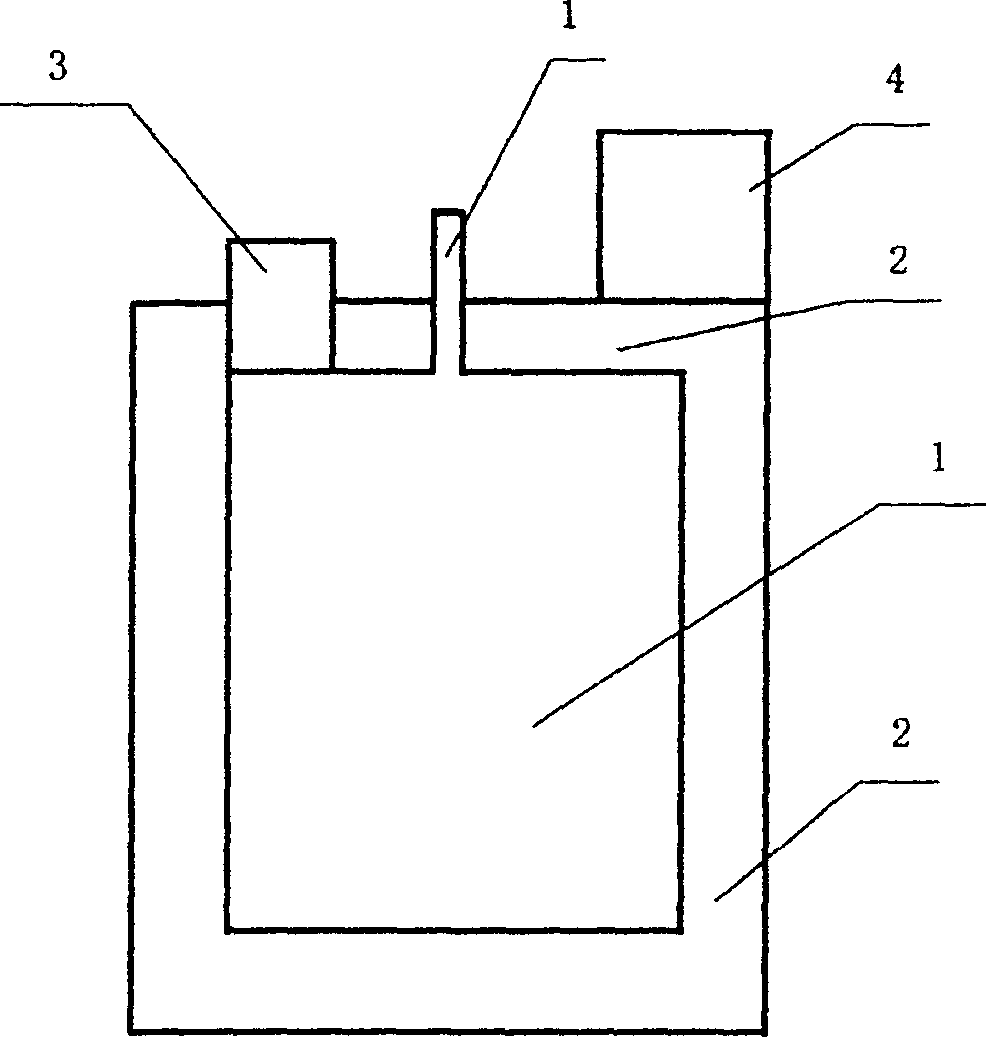

Labelling device

The invention relates to the technical field of mechanical equipment, and in particular relates to a labelling device. The labelling device is applied to splicing among a chip, a liner and a body paper in an electronic tag; the liner / chip is provided with an adhesive sticker layer, and the liner and the chip are sequentially adhered to a banded release paper tape, thus a self-adhesion label band is formed. The labelling device disclosed by the invention comprises a base platform used for transporting the body paper, an unwinding wheel used for placing a roll formed by the self-adhesion label band, a winding wheel used for rewinding the release paper tape which is stripped from the chip / liner as well as a tension device for the transport path of the release paper tape and a stripping plate which are sequentially restricted and arranged between the unwinding wheel and the winding wheel. The labelling device disclosed by the invention realizes automatic combination between an RFID (radio frequency identification) chip / liner and the body paper in an RFID electronic label production process. Combination speed is rapid, effect is good, production efficiency is greatly improved, and the labelling device can coordinate with the existing production line; and the labelling device disclosed by the invention has the advantages of a simple structure, reliable operation, low cost and high reliability and is convenient for adjusting, can be applied to production of the RFID electronic labels in different specifications and has good practical value.

Owner:MAXIM SMART MFG CO LTD

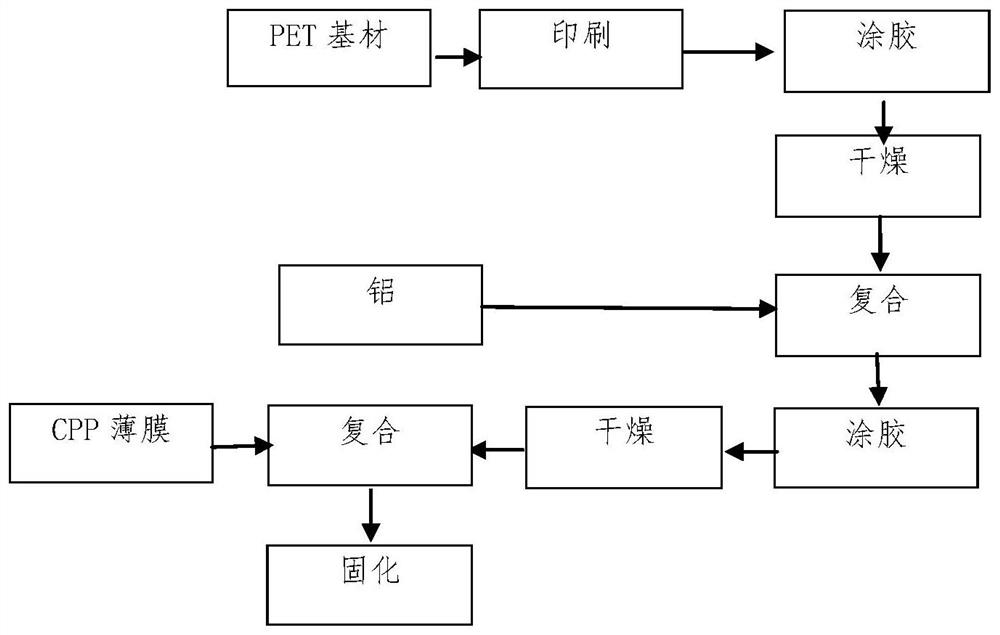

Manufacturing technology of aluminized paper for cigarettes

InactiveCN105178108AKeep the taste of smokingNot volatileFlexible coversWrappersManufacturing technologyAdhesive

The invention provides a manufacturing technology of aluminized paper for cigarettes. The method includes the following steps of manufacturing an original paper layer, manufacturing a stamping aluminum foil layer, manufacturing complex adhesive and applying the adhesive for recombination. The original paper layer is made of natural materials and free of harm to human bodies, and certain fragrance is achieved while the original smoking taste of the cigarettes is reserved; meanwhile, the complex adhesive is made of biological materials, and no harmful matter is volatilized; meanwhile, through the interleaving paper and aluminized paper composite method, the whole composite speed is high, full drying can be achieved, and the interleaving paper and aluminum foil can be tightly combined.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Production method of flame-retardant automotive roof fabric

ActiveCN106183332AAdvantages of production methodImprove flame retardant performanceSynthetic resin layered productsLaminationManufacturing engineeringFast speed

The invention provides a production method of flame-retardant automotive roof fabric. By the production method, the technical problems that existing production methods have excessively complex steps, manual operation is needed, production speed is low and the like are solved. The production method of the flame-retardant automotive roof fabric includes a, raw material purchase, b, surface layer production, and c, compounding. The production method has the advantage of high production speed.

Owner:ZHEJIANG ADIENT WANFANG TEXTILE TECH CO LTD

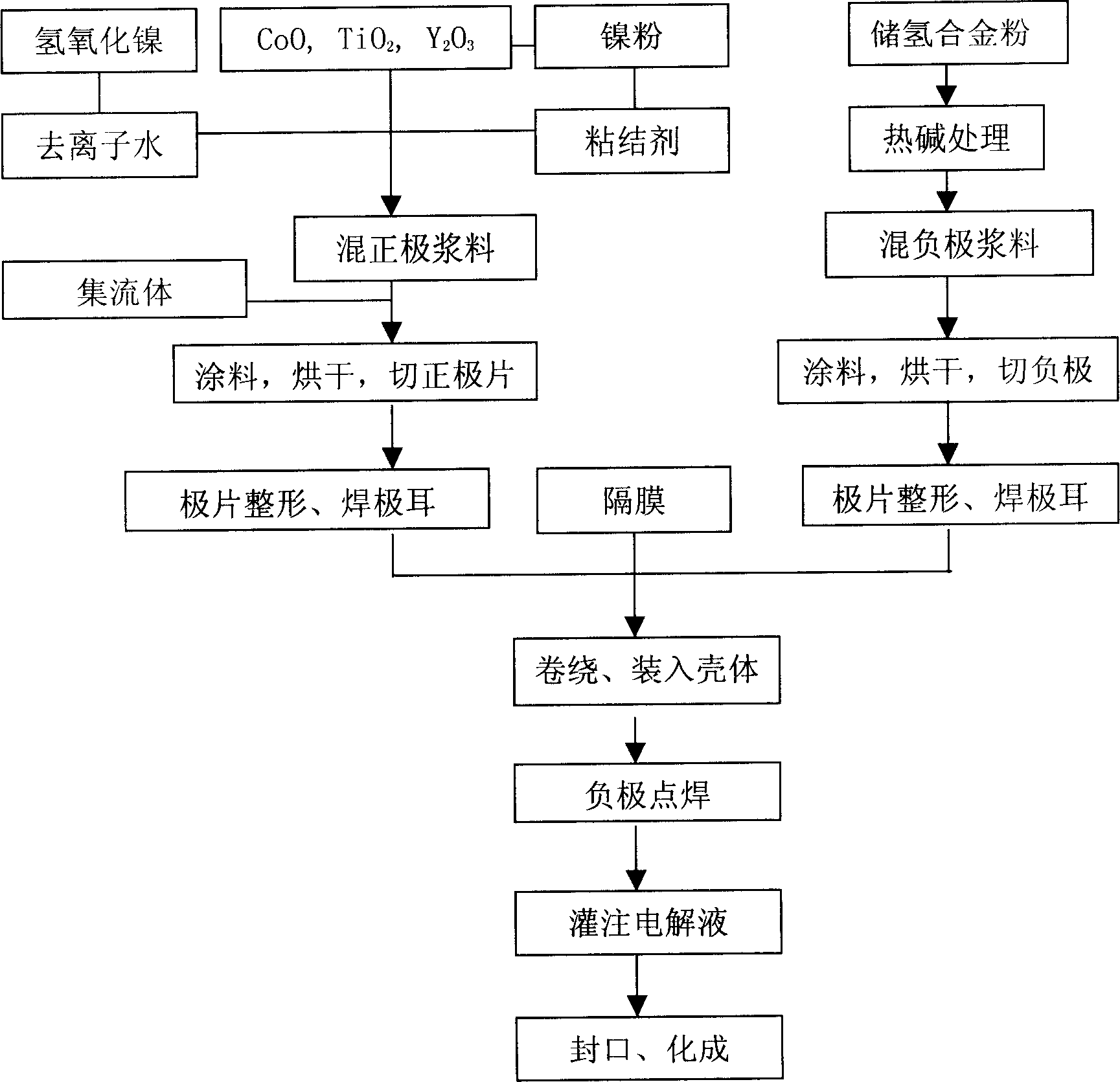

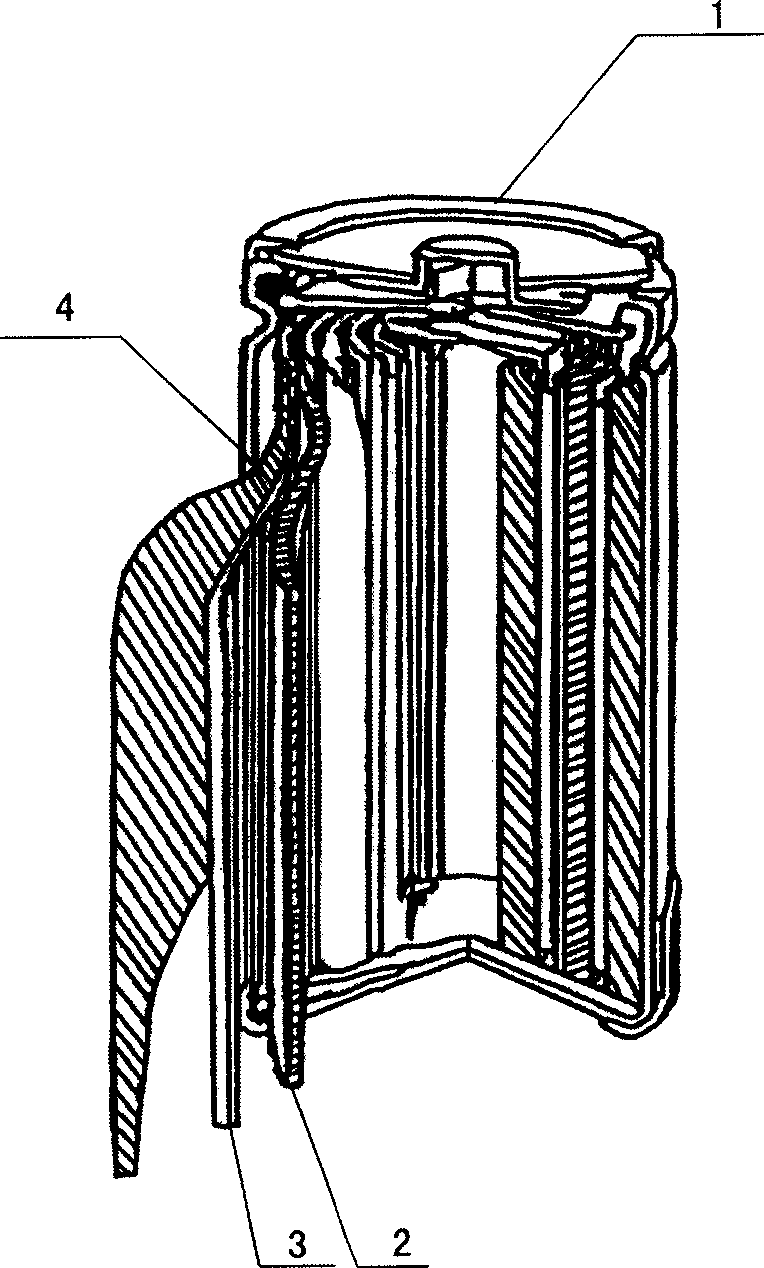

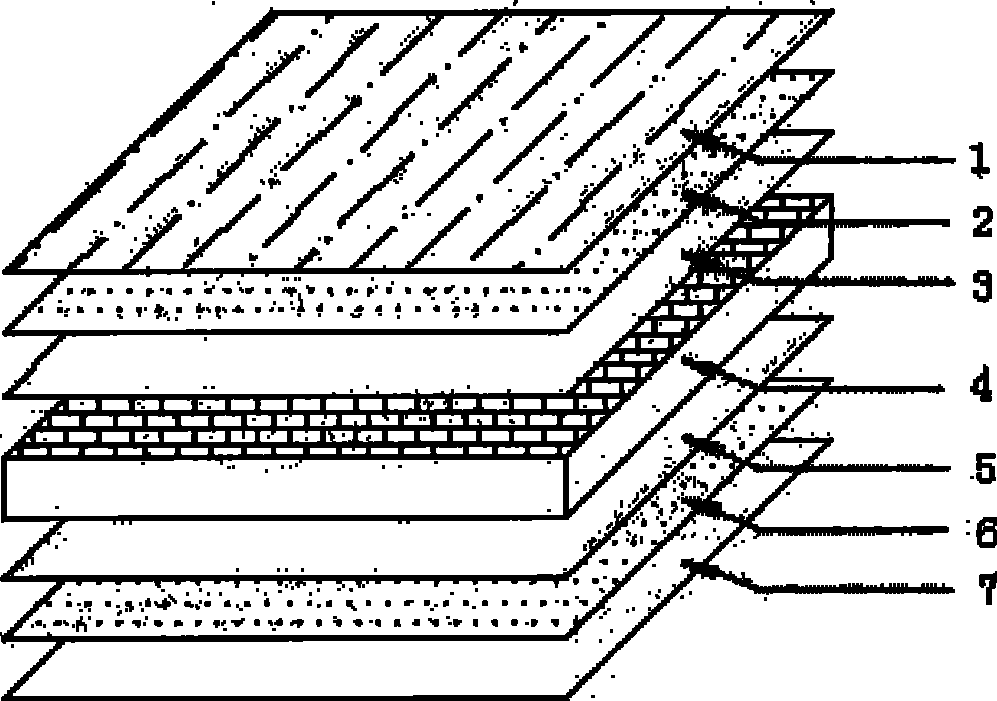

Columnar nickel hydrogen secondary battery and production thereof

InactiveCN1819320AComposite speedFast phase changeFinal product manufactureAlkaline accumulator electrodesNickel oxide hydroxideCurrent collector

In the battery shell there are pole pieces of anode and cathode. The anode paste is mainly composed of nickel hydroxide. In the supplementary materials there are CoO, TiO2, and Y2O2 as additive. The cathode paste is mainly composed of hydrogen storage alloy powder. The pastes are coated on current collector to form pole pieces of anode and cathode. The anode piece, diaphragm, and cathode piece are rolled to form cell core. The electrolyte is filled into the battery shell. The said cathode piece is longer than the one of anode in rolling direction, and is 1-4mm wider than the one of anode, so that the cathode piece in outmost layer contacts the inner wall of battery shell, and the bottom of cathode is bonded with the bottom of battery shell by welding.

Owner:赵兵 +1

Manufacturing method of multilayer composite board of polyurethane

InactiveCN101367287BEvenly distributedReduce energy consumptionSynthetic resin layered productsLaminationGlass fiberProduction line

The invention discloses a method for producing a polyurethane multilayered composite plate. The method comprises the following steps: (1)chopped glass fiber and hot melt rubber powder are scattered on a transmission caterpillar of a compounding machine and are subjected to heat pressing and compounding to form a film; and the film is cooled and coiled to obtain a rubber glass film; and (2) firstly, nonwoven fabric, the rubber glass film and an adhesive film in turn are unreeled, stacked and paved on a worktable of a composite production line from top to bottom; and secondly, a polyurethane rigid foam plate is placed; the adhesive film, the rubber glass film and a hot melt rubber film in turn are unreeled, stacked and paved on the polyurethane rigid foam plate from bottom to top and are subjected to heat pressing, compounding and cooling to obtain the polyurethane multilayered composite plate. The method can realize one-step compounding and molding of the polyurethane composite plate and has low consumption of the production line and high production efficiency; a production process using the rubber glass film as a strengthening material and the adhesive film as a cementing agent improves the bonding force between the strengthening material and a PU plate; and a prepared product has the advantages of strong rigidity, flat surface and stable quality and suitability for molding the roof of an automobile by a cold mould method or a dry method.

Owner:LIYANG SHANHU IND CO LTD

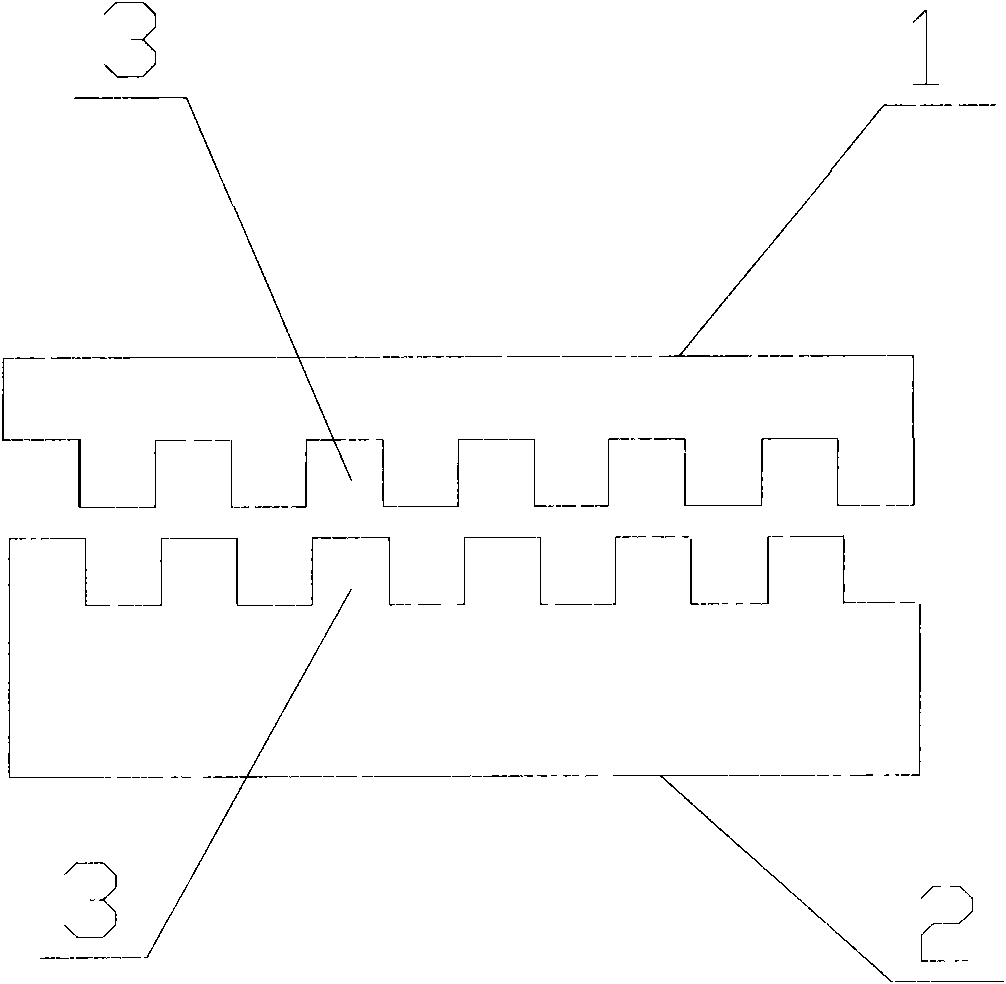

Manufacture method of metal composite board

InactiveCN101992568AReduce distortionSimple production processLamination ancillary operationsLaminationComposite strengthComposite plate

The invention discloses a manufacture method of a metal composite board, and relates to a manufacture process of the composite board, which comprises the following steps of: firstly, cleaning a composite surface of a base blank and a clad blank for removing surface impurities; secondly, manufacturing concave-convex lines or pressing concave-convex blocks on the composite surface of the base blank by using a die, making concave-convex lines or concave-convex blocks matched with the concave-convex lines or pressing concave-convex blocks on the composite surface of the base blank on the composite surface of the clad blank by using the die; and thirdly, mutually embedding and matching the base blank and the clad blank of the concave-convex lines or pressing concave-convex blocks together to be extruded to form a wedge structure which is not easy to separate so that the composite strength is higher. Meanwhile, compared with the traditional production process, the invention has the advantages of high production efficiency and high yield.

Owner:SICHUAN MCWELL TECH

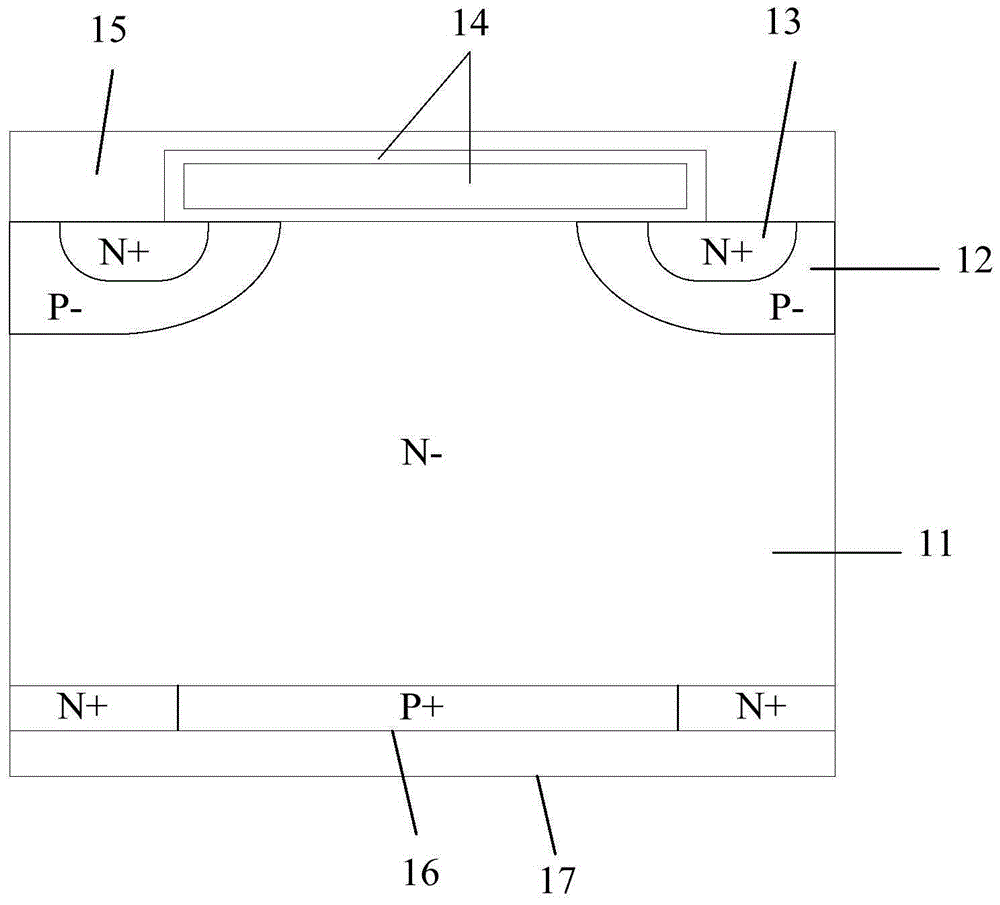

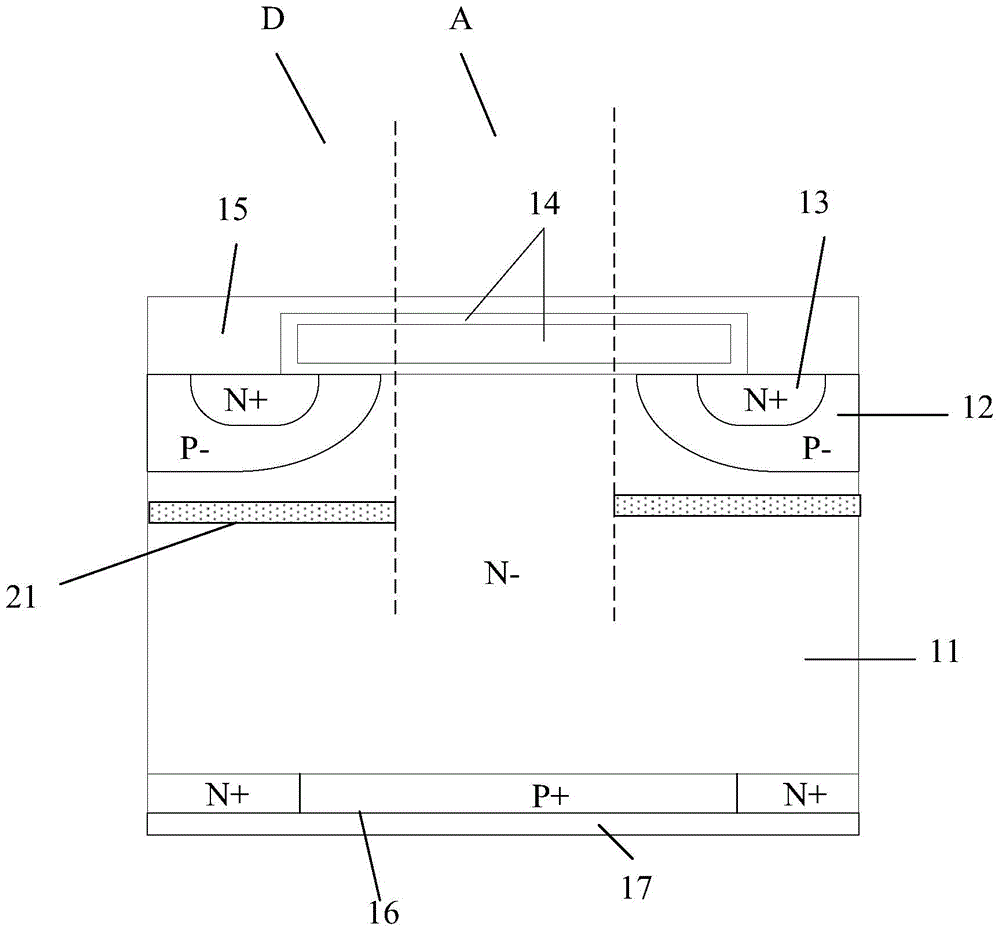

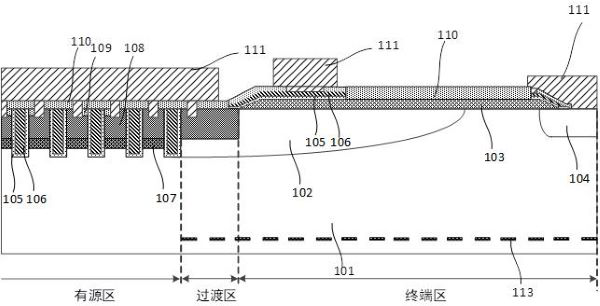

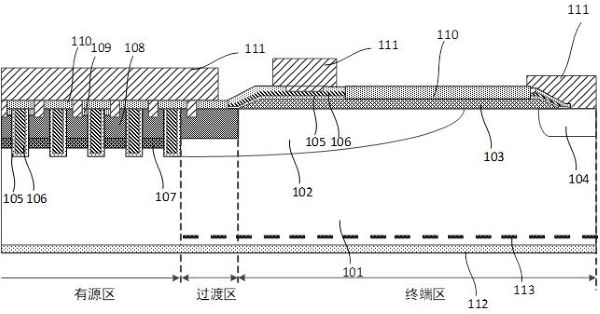

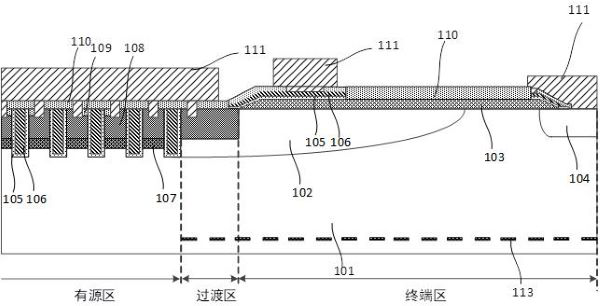

Reverse conducting-insulated gate bipolar transistor and fabrication method

InactiveCN106486536AReduce reverse recovery currentFast switching speedTransistorSemiconductor/solid-state device manufacturingCharge carrierReverse recovery

The invention relates to a reverse conducting-insulated gate bipolar transistor and a fabrication method thereof, and discloses a RC-IGBT (Reverse Conducting-Insulated Tate Bipolar Transistor) and a fabrication method thereof. The RC-IGBT comprises a substrate, a well region, an active region, a current collection region and a carrier low-lifetime thin layer, wherein the substrate is provided with a drift region, the well region is arranged in an upper surface of the substrate, the active region is arranged in the well region, the current collection region is arranged in a lower surface of the substrate, the carrier low-lifetime layer is arranged in the drift region, the upper surface of the substrate comprises an intermediate region and an edge region, the edge region encircles the intermediate region, the well region is arranged in the upper surface, corresponding to the edge region, of the substrate, the carrier low-lifetime thin layer is arranged under the well region, and the distance between the carrier low-lifetime thin layer and the well region is smaller than the distance between the carrier low-lifetime thin layer and the current collection region. In the RC-IGBT, The carrier low-lifetime thin layer is arranged under the well region, the carrier combination speed can be increased, hole injection of the well region on the drift region is reduced, a reverse recovery current of a FRD (Fast Recovery Diode) is further reduced, the reverse recovery time is further reduced, and thus, the switching speed of the RC-IGBT is increased.

Owner:SHANGHAI LIANXING ELECTRONICS +1

Steam-resistant solvent-free laminating adhesive and preparation method thereof

ActiveCN102604583BLow viscosityImprove heat resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides steam-resistant solvent-free laminating adhesive applicable to compound soft package, which comprises a component A and a component B. The component A is isocyanate terminated polyurethane polymer formed by reacting polyhydroxy compound and polyisocyanate terminated compound. The component B is formed by mixing more than one type of plant oil polyalcohol, curing accelerator and synthetic modifier. The polyhydroxy compound in component A is formed of polyester polyol and / or polyether polyol with more than two degrees of functionality and a molecular weight range of from 600-2000, and more than one type of plant oil polyalcohol. The curing accelerator in the component B is formed of small molecular polyalcohol with more than two degrees of functionality. The synthetic modifier is formed by reacting more than one type of silane coupling agent and polyalcohol. The steam-resistant solvent-free laminating adhesive is low in viscosity and fast in curing speed, has high peel strength after boiled in water at 100 DEG C, and is especially suitable for soft packages requiring long-term high temperature sterilization (such as soft packages for foods, drugs and baby products). The invention further provides a preparation method of the steam-resistant solvent-free laminating adhesive.

Owner:SOUTH CHINA UNIV OF TECH +1

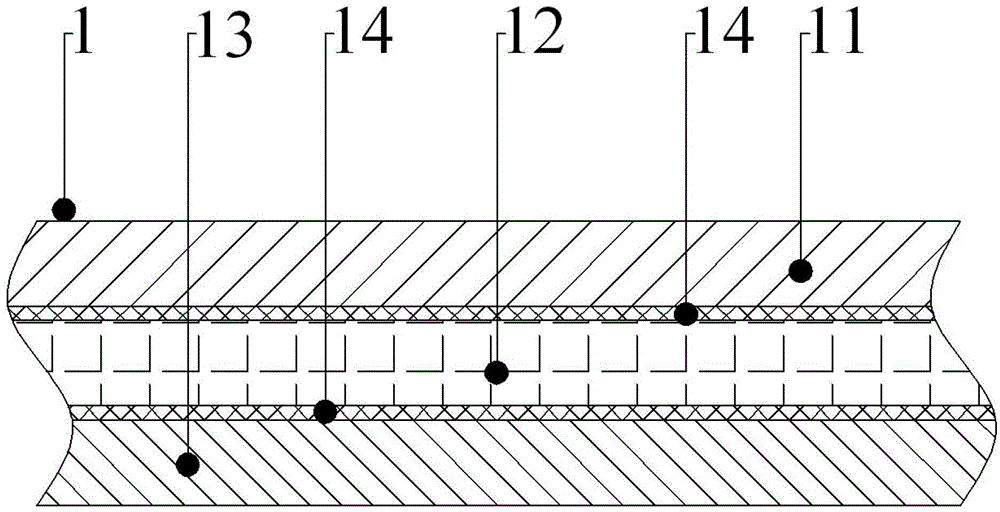

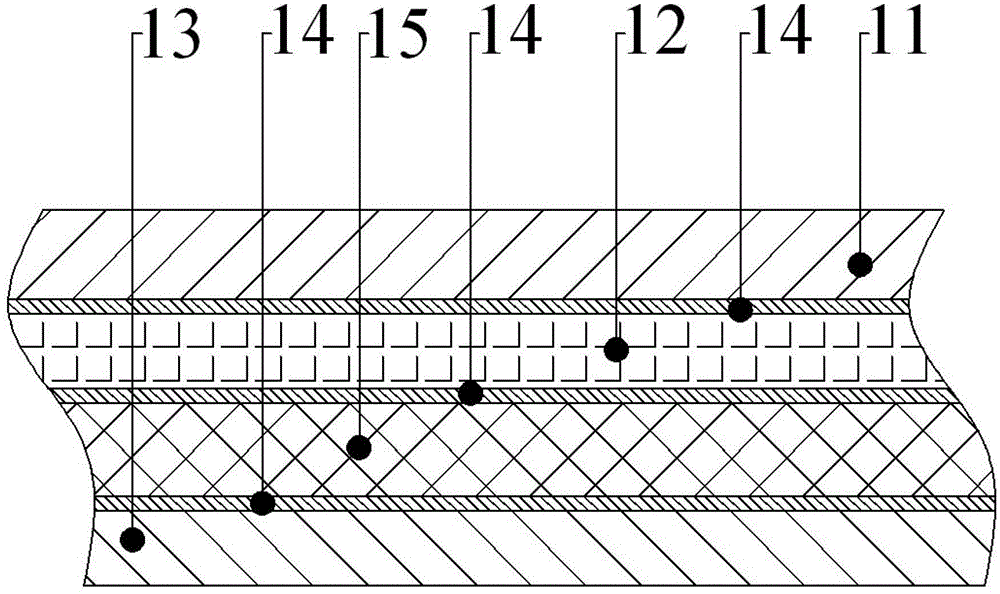

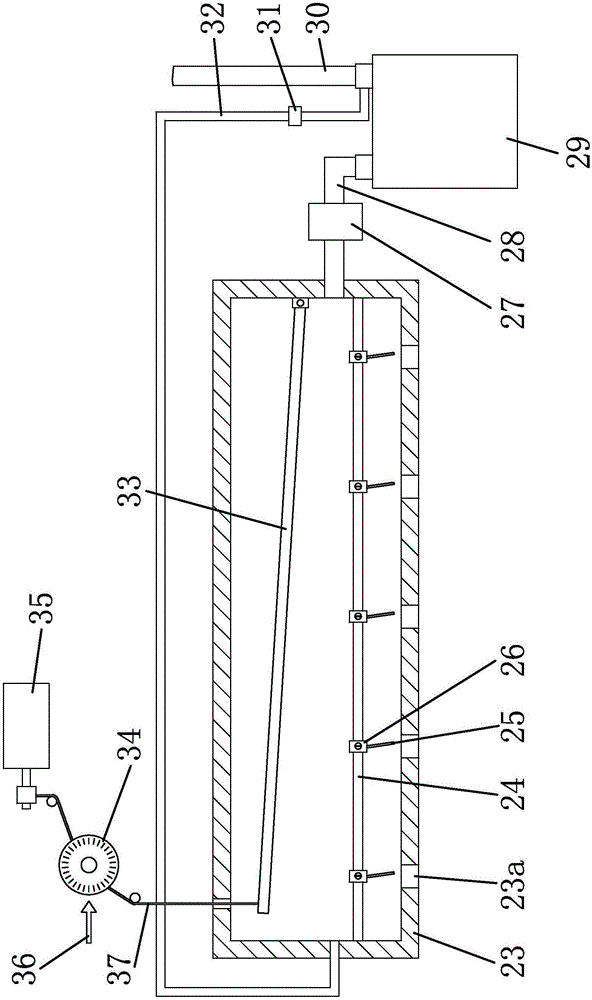

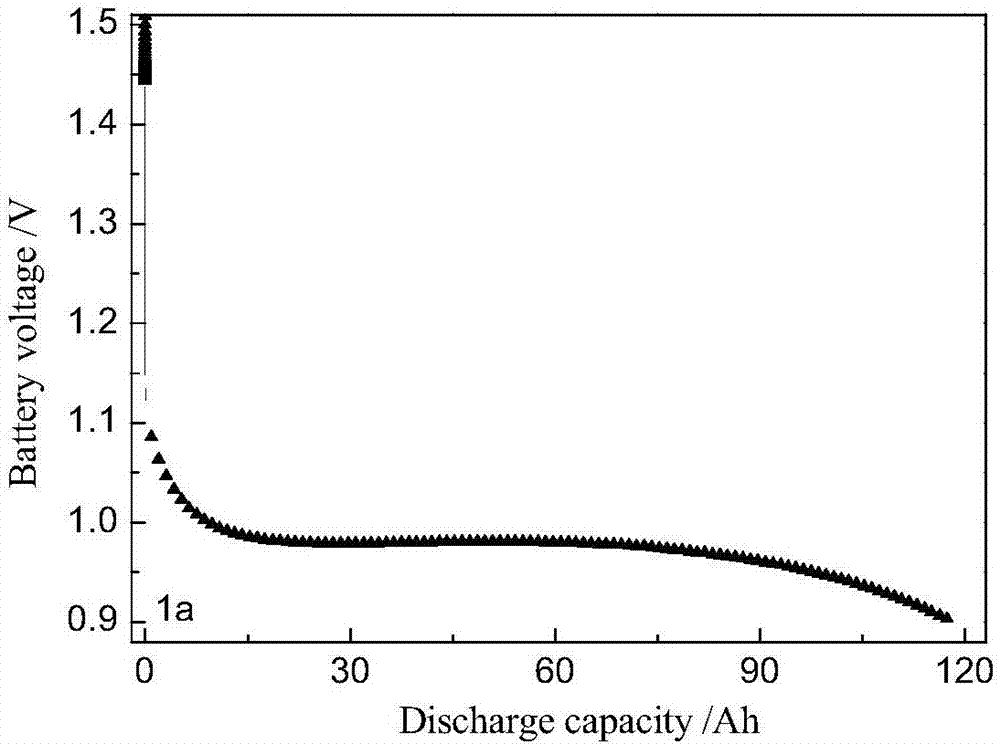

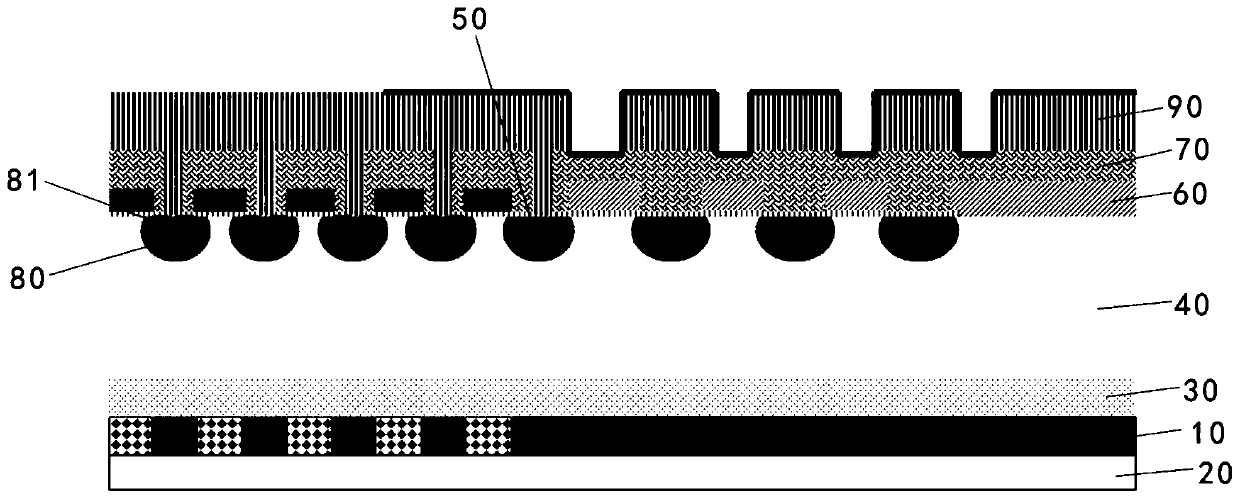

New rare earth power supply and preparation method thereof

ActiveCN107452918AFast transferAchieving charge and discharge capabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureRare earthEngineering

The invention relates to a new power supply, and in particular relates to a new rare earth power supply and a preparation method thereof. The new rare earth power supply comprises a battery case, wherein battery cells are contained inside the battery case, a spring board is arranged between adjacent battery cells, each battery cell comprises an anode-cathode component, one cathode pole piece is arranged at the two sides of the anode-cathode component respectively to form the battery cell, each anode-cathode component is composed of an anode pole piece packaged by a bag made from a diagram and the cathode pole pieces which are alternately laminated, and the cathode pole pieces are arranged at the two sides of each anode-cathode component; and an air chamber is arranged on the battery case, and a polyurethane piston core is arranged between the air chamber and the battery case. The new rare earth power supply provided by the invention has the advantages that the anode pole pieces and the cathode pole pieces are matched and combined, the spring boards maintain dynamic tightness of the pole pieces, the air chamber improves charging and discharging efficiencies, multiple conductive strips improve electron transfer speed, high current charging and discharging capability of a battery is realized, and long-time and high-frequency charging and discharging of a non-conventional current more than 500A can be met; the historic technical problem that heat dissipation speed is low is also solved. The invention also provides a preparation method of the new rare earth power supply, the technology is simple, and environmental friendliness is realized.

Owner:包头昊明稀土新电源科技有限公司

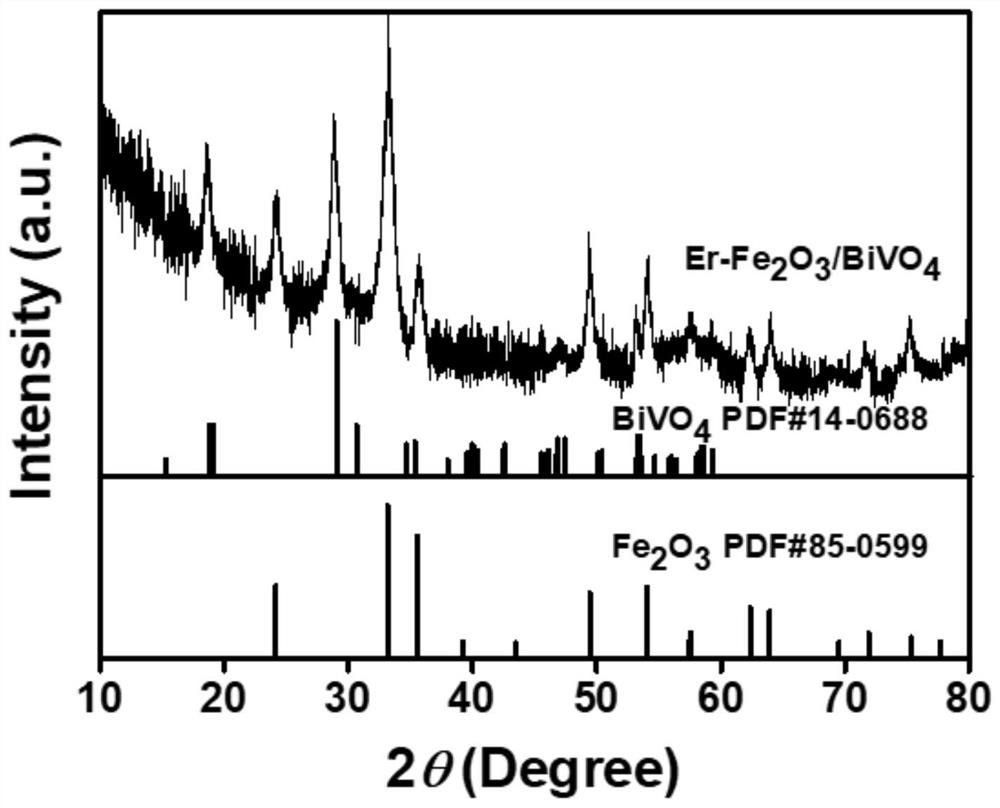

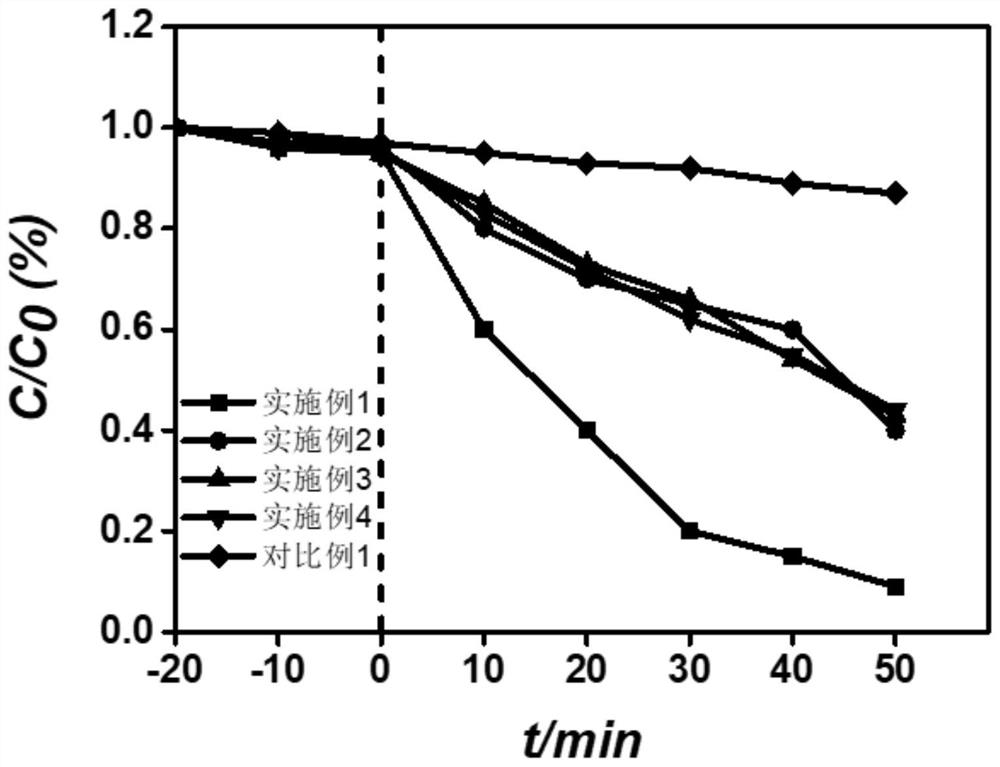

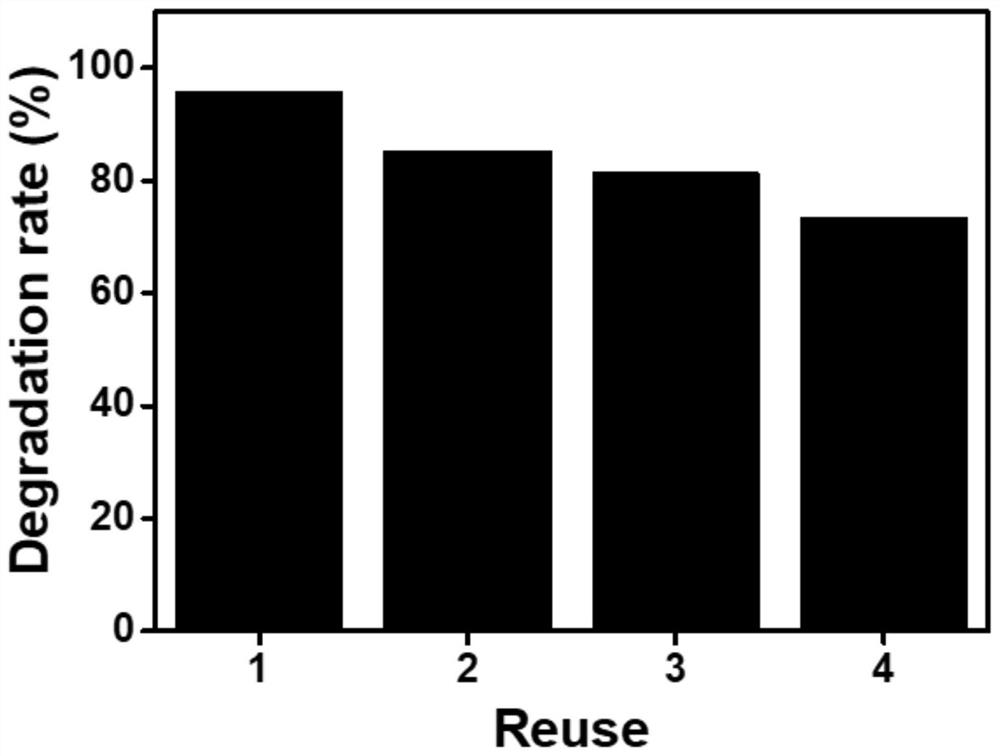

Er-Fe2O3/BiVO4 photocatalyst for degrading rhodamine B and preparation method thereof

InactiveCN112871179AEfficient separationEasy to separateWater/sewage treatment by irradiationWater treatment compoundsElectron holeCarrier capture

The invention discloses an Er-Fe2O3 / BiVO4 photocatalyst for degrading rhodamine B and a preparation method thereof. The method comprises the following steps of: (1) preparation of an Er-Fe2O3 precursor; (2) preparation of Er-Fe2O3; and (3) preparation of Er-Fe2O3 / BiVO4; the Er-Fe2O3 / BiVO4 photocatalyst is prepared through the three steps, the Er-Fe2O3 / BiVO4 photocatalyst is obtained by conducting composite modification on Er-doped Fe2O3 with a narrow forbidden bandwidth and BiVO4, more electrons and holes are generated, and the photocatalytic activity is remarkably improved. Er is doped into Fe2O3, so that the light absorption range of Fe2O3 can be expanded, the carrier excitation capability is improved, meanwhile, Er can become a carrier capture trap, the service life of Er can be prolonged, and the photocatalytic activity can be improved.

Owner:赵慧鸣

Making method of waterproof automobile ceiling fabric

ActiveCN106218034ANot easy to separateImprove product qualityFibre treatmentSynthetic resin layered productsSurface layerEngineering

The invention provides a making method of a waterproof automobile ceiling fabric. The technical problems of completes steps, manual operation needing, poor product quality and the like of an existing manufacturing method are solved. The making method of the waterproof automobile ceiling fabric comprises the following steps of (a) raw material purchase, (b) surface layer manufacturing and (c) compounding. The making method has the advantage of being good in product quality.

Owner:ZHEJIANG ADIENT WANFANG TEXTILE TECH CO LTD

A method for manufacturing a high-density tungsten carbide coated roller for a solvent-free composite machine

ActiveCN107699842BIncreased microhardnessImprove wear resistanceMolten spray coatingPorositySurface finish

The invention provides a manufacturing method of a high-density tungsten carbide coating roll for a solvent-free compound machine. Aiming at meeting the requirements for high wear resistance, low porosity and low friction coefficient of a coating roll for the solvent-free compound machine, a method for adding 5%-50% by weight of spherical WC particles with particle size being 30-100 mu m to spraying powder of sintered or agglomerated Ni-based WC, Co-based WC or Co-Cr-based WC and the like is adopted, high-speed spherical WC particles rebound instead of depositing in a coating during spraying,under the beating action after rebounding, the coating is more dense and low in porosity, coating glue is not prone to sticking and is easy to clean during using, and transfer rate is high; meanwhile,binding force between particles in the coating is increased under the action of repeated beating of the spherical WC particles, the particles are not prone to stripping during high-speed wearing, wear resistance is improved, and service life of the roll is prolonged. Porosity of a metering roll, a glue transfer roll and the coating roll, manufactured with the method, of the solvent-free compoundmachine is lower than 0.4%, surface smoothness is high, Ra is smaller than 0.08 mu m, wear resistance and transfer rate are high, and the service life is prolonged by 5 times or more.

Owner:GUANGDONG INST OF NEW MATERIALS +1

High-speed compounding and online peeling polyurethane transfer adhesive and preparation method thereof

InactiveCN109825239AHigh molecular weightImprove temperature resistancePolyureas/polyurethane adhesivesPolyesterPolyol

The invention discloses a high-speed compounding and online peeling polyurethane transfer adhesive which comprises a component A and a component B. The component A comprises, in weight percent, 30-70%of polymers A1, 1-10% of polymers A2, 20-60% of polyisocyanate, 0.5-2% of coupling agents and 0.1-1% of leveling agents, the polymers A1 is one of polyether polyol and polyester polyol or mixture ofthe polyether polyol and the polyester polyol, the functionality of the polyether polyol is 2, the polymers A2 is one of polyester polyol and polyether polyol or mixture of the polyester polyol and the polyether polyol, and the functionality of the polyester polyol is larger than or equal to 3. The component B comprises, in weight percent, 5-25% of amine chain extenders, 0.1-1% of amine catalystsand the balance water. The invention further provides a preparation method of the high-speed compounding and online peeling polyurethane transfer adhesive. The high-speed compounding and online peeling polyurethane transfer adhesive is used for production of transfer aluminized paper, high-speed compounding and online peeling can be achieved, improvement of production speed is facilitated, energyconsumption and production cost are reduced, and the adhesive has high bending resistance and good heat resistance and anti-sticking property and is safe and environmentally friendly.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

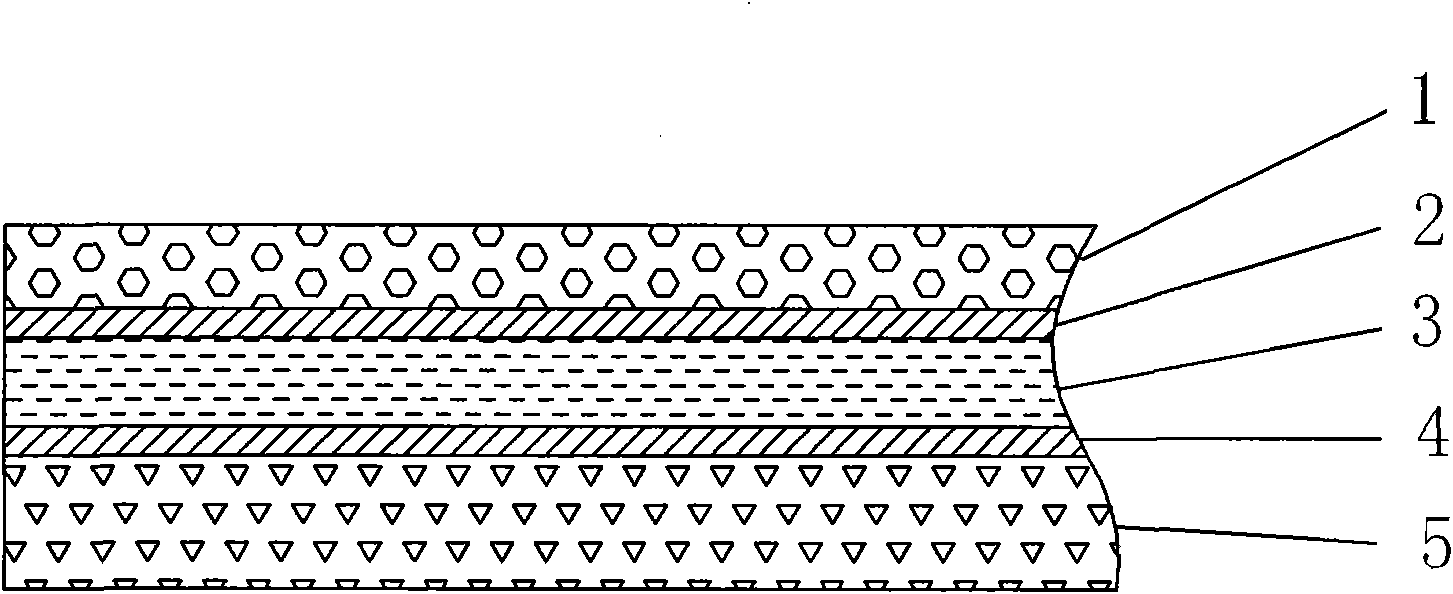

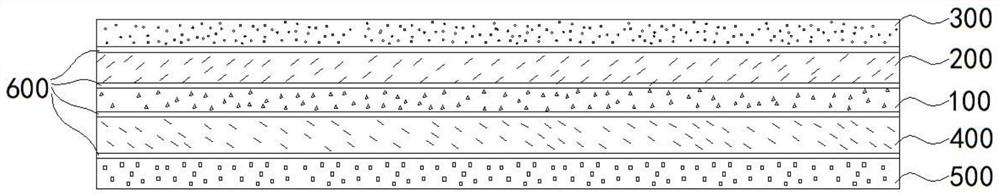

Multi-functional aluminum-plastic cloth composite film with layered structure and preparation method thereof

PendingCN113635627AComposite speedHigh composite strengthFlexible coversWrappersPolymer scienceAluminum foil

The invention discloses a multi-functional aluminum-plastic cloth composite film with a layered structure. The composite film comprises an aluminum foil layer. The upper surface of the aluminum foil layer is bonded with a thermoplastic polymer outer film layer, and the upper surface of the thermoplastic polymer outer film layer is bonded with a cloth base layer. A thermoplastic polymer inner film layer is adhered to the lower surface of the aluminum foil layer, and an anti-static polyethylene layer with an anti-static effect is adhered to the lower surface of the thermoplastic polymer inner film layer. The invention further discloses a preparation method of the aluminum-plastic cloth composite film with a layered structure. The invention provides the composition, the structural form and the manufacturing method of the multi-functional aluminum-plastic cloth composite film with a layered structure. The aluminum-plastic cloth composite film with a layered structure in the scheme is high in compounding speed and high in compounding strength, and the selection range of a base material and a barrier layer is wide. In addition, the aluminum-plastic cloth composite film with a layered structure in the scheme has excellent anti-static and moisture-resistant effects, and has a great application potential on products with high requirements on the anti-static effect and the water vapor transmission rate.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Reverse conduction field cut-off type IGBT (Insulated Gate Bipolar Transistor) and manufacturing method thereof

PendingCN110473913APromote conductionSmall pressure dropTransistorSemiconductor/solid-state device manufacturingElectric fieldInsulated-gate bipolar transistor

The invention provides a reverse conduction field cut-off type IGBT (Insulated Gate Bipolar Transistor). The reverse conduction field cut-off type IGBT comprises a substrate; the substrate is a P-typesubstrate; the back face of the P-type substrate is provided with a collector; the front face of the P-type substrate is provided with an electric field termination layer; one surface of the electricfield termination layer, which is far away from the P-type substrate, is provided with a drift region; P-type field limiting rings are arranged in the drift region; a plurality of P-type field limiting rings are provided; a field oxide layer and an oxide dielectric layer are arranged on the field limiting rings; P wells are formed in the front surface of the P-type substrate; N type emitters arearranged in the P wells; and the oxide dielectric layer is covered with a passivation layer. According to the reverse conduction field cut-off type IGBT provided by the invention, a manufacturing process is adjusted, and the service lives of carriers are prolonged; and therefore, the reverse conduction field cut-off IGBT has a high switching speed.

Owner:厦门芯达茂微电子有限公司

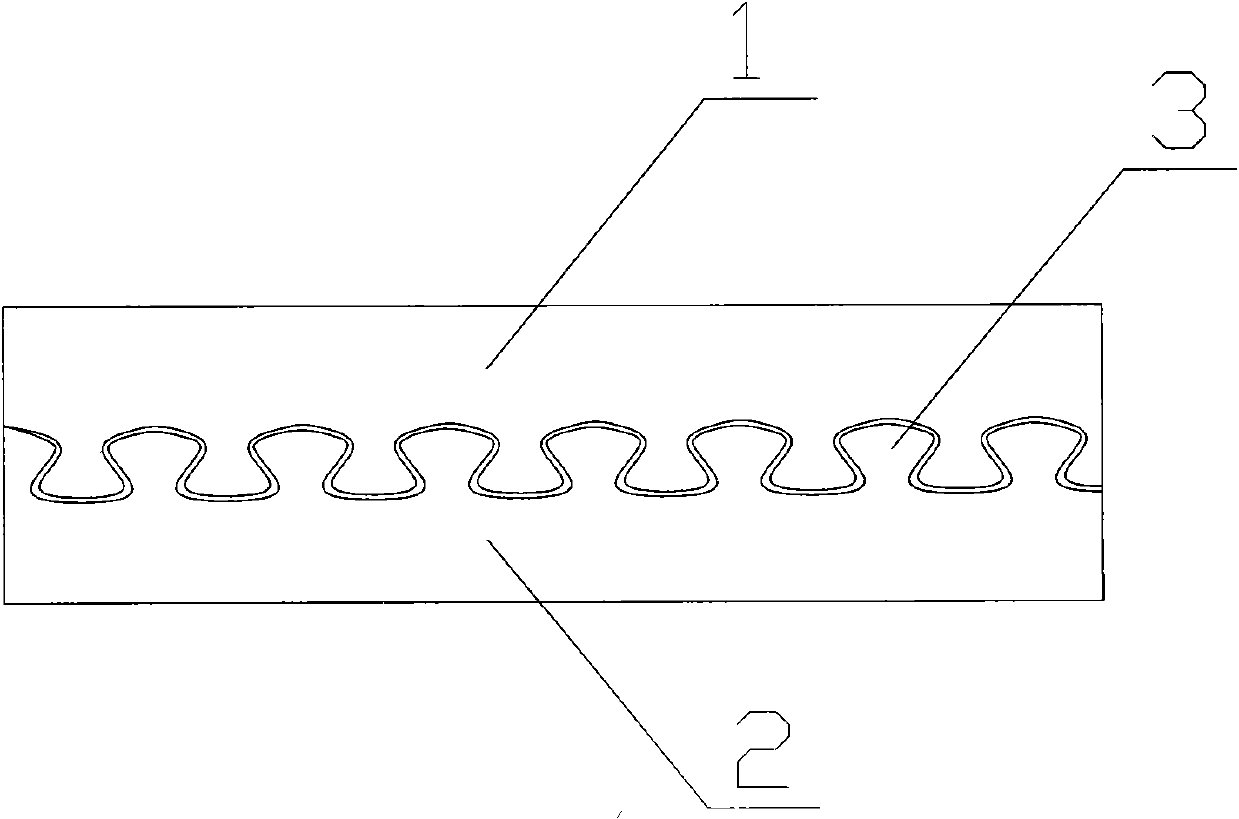

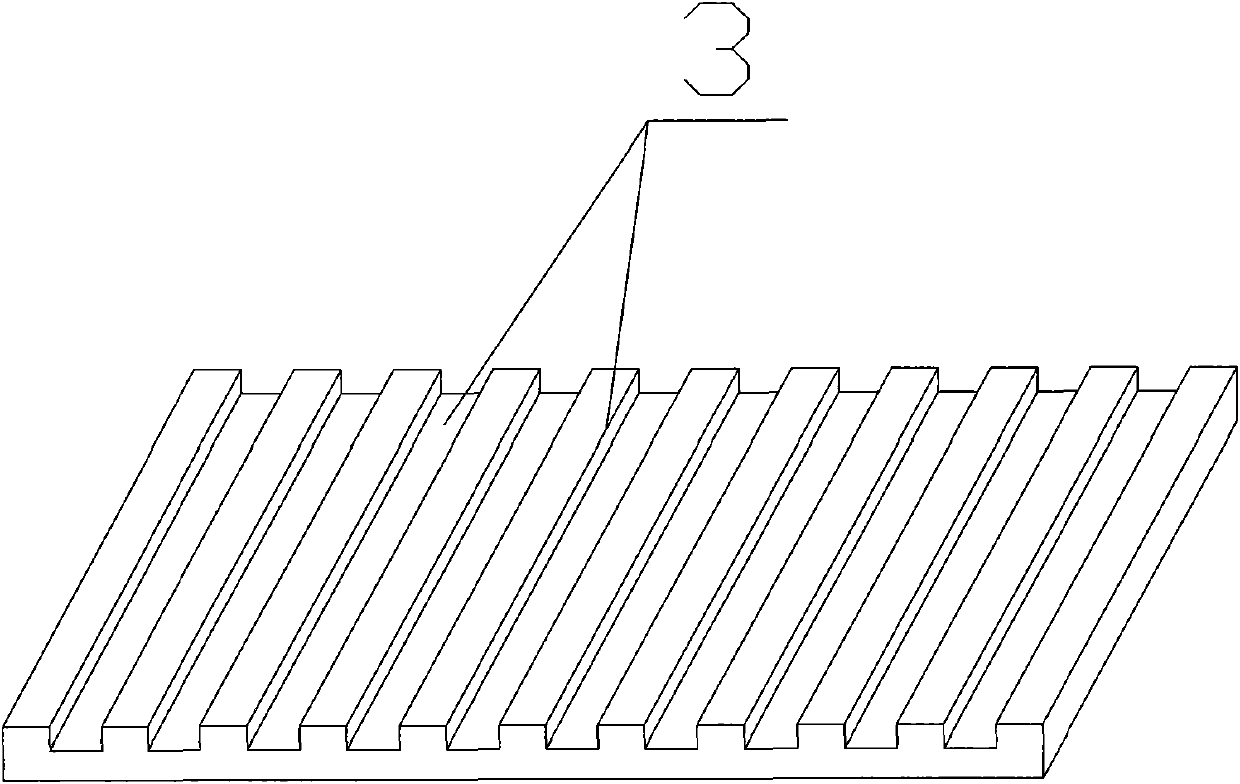

Hot melt adhesive for siphon plate and preparation method of hot melt adhesive

PendingCN114774027ASolve the problem of volatilitySolve the problem of recyclingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceHot melt

The invention discloses a hot melt adhesive for a siphon plate and a preparation method of the hot melt adhesive. The hot melt adhesive is prepared from the following raw materials: first EVA (Ethylene Vinyl Acetate) resin, second EVA resin, tackifying resin, Fischer-Tropsch wax and an antioxidant, wherein the content of VA in the first EVA resin is 25-30 wt%, and the content of VA in the second EVA resin is 15-20 wt%; the tackifying resin comprises a first tackifying resin with a softening point of 98-110 DEG C and a second tackifying resin with a softening point of 130-150 DEG C. The hot melt adhesive can improve the cohesiveness of the siphon plate, and has good chemical stability, aging resistance and ozone resistance. The preparation method of the hot melt adhesive comprises the following steps: mixing the Fischer-Tropsch wax and the oxidizing agent, adding the second tackifying resin and the first EVA resin, adding the first tackifying resin and the second EVA resin, heating and stirring to completely melt the raw materials, filtering, and granulating to obtain the hot melt adhesive for the siphon plate, so that environment-friendly, non-toxic, safe and efficient production is realized.

Owner:FOSHAN XINTAO NEW MATERIAL TECH

Preparation method of high strength composite type process glass

The invention discloses a preparation method of high strength composite type process glass. The preparation method comprises a glass substrate layer and a cladding layer, and a superheated metal liquid of the cladding layer is cast onto the main surface of the glass substrate layer so as to form a double-layer composite process glass together with the glass substrate layer; the cladding layer cancomprise 24% of aluminum, 16% of lead, 8% of zinc, 12% of copper, 15% of iron,7% of cobalt, 8% of nickel and their alloys; and bonding mechanism of the glass substrate layer and cladding layer alloy is fusion combination or diffusion combination, and the average thickness of the obtained composite type process glass is controlled within 6mm. The high strength composite type process glass is high in strength, stable in composite texture and wide in production range, the production process is convenient to control, low in production cost, high in efficiency and superior in product performance.

Owner:张家港伟宇工艺玻璃制品有限公司

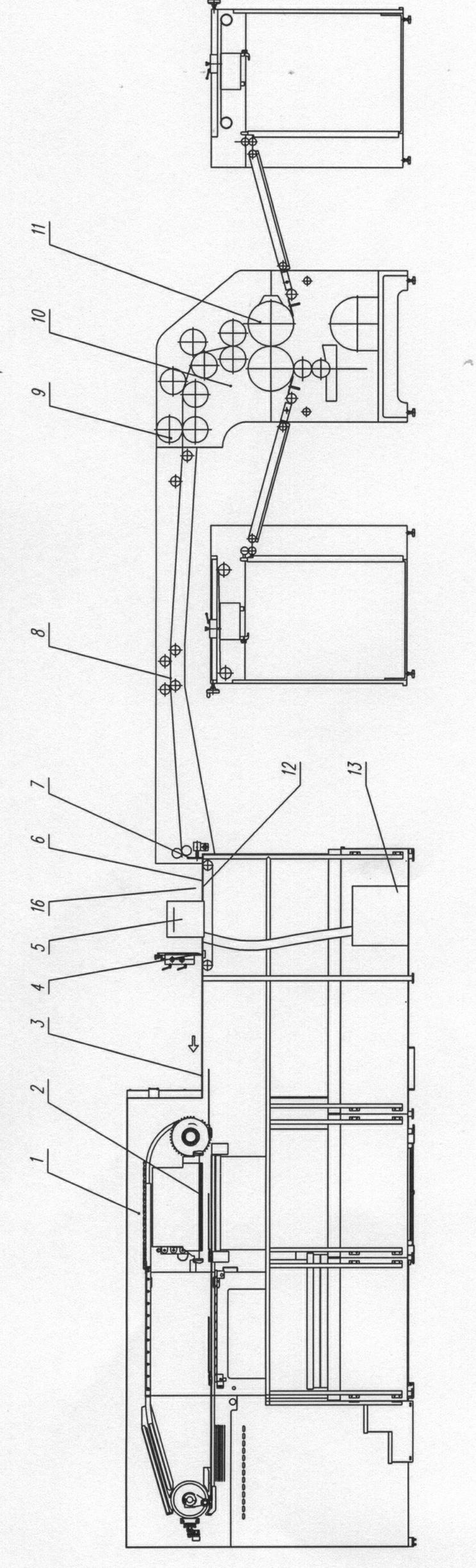

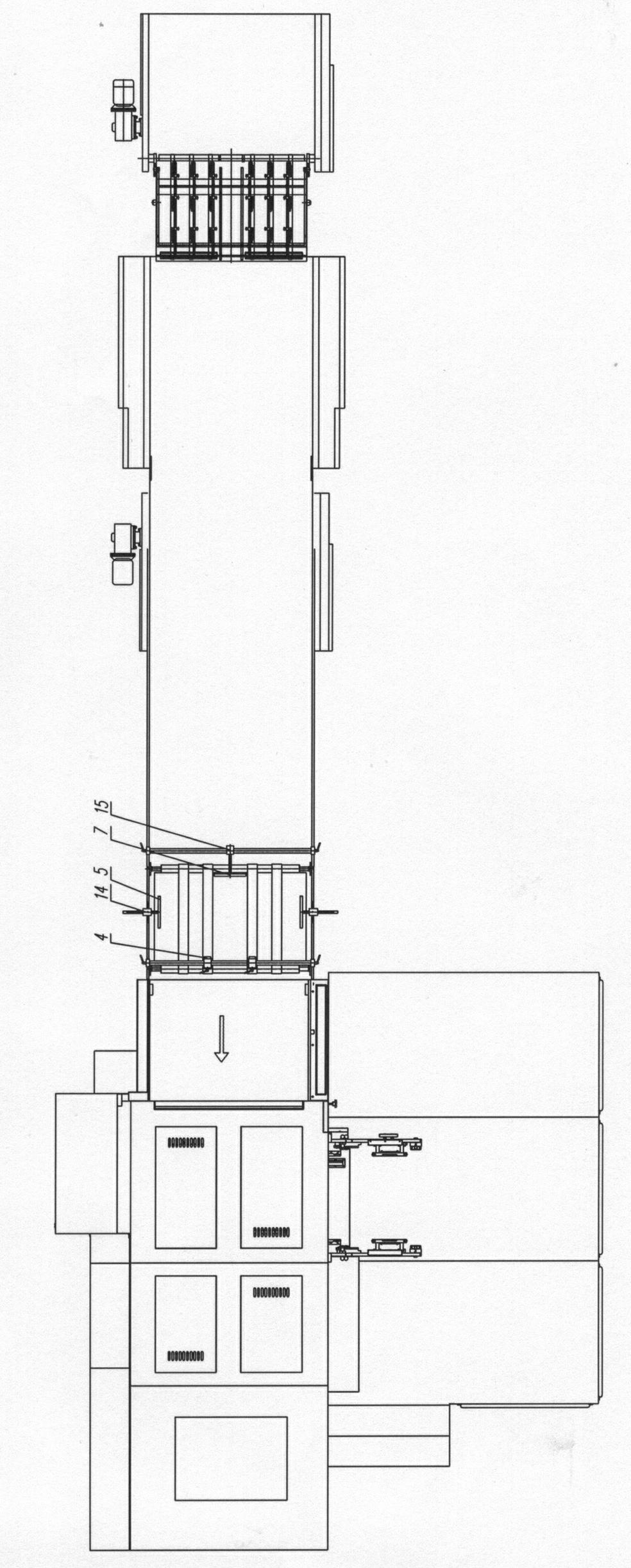

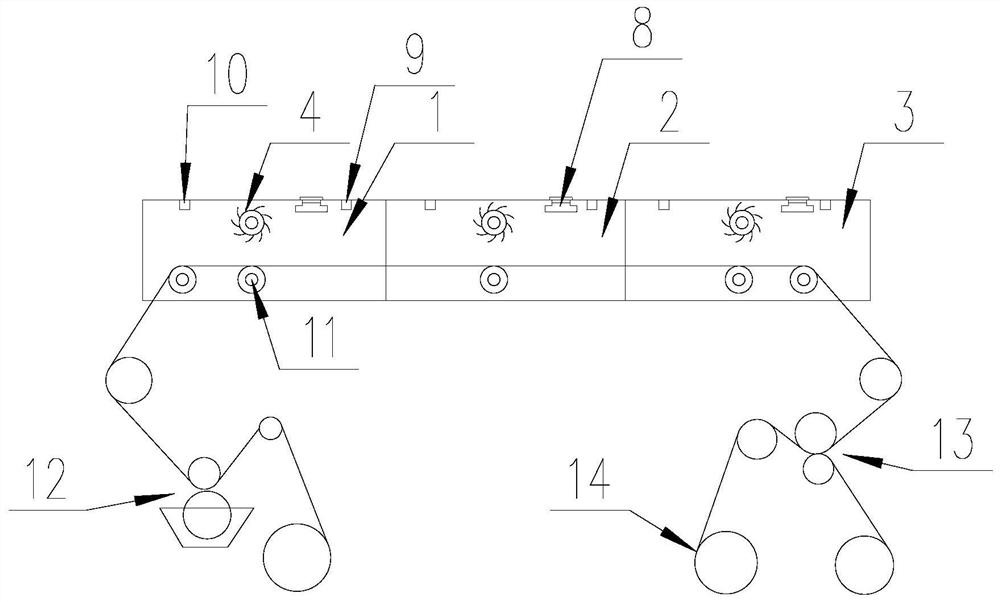

Laminating and die cutting integrated paperboard forming machine

InactiveCN102602058AReduce composite speedComposite speedMechanical working/deformationMetal working apparatusProgrammable logic controllerPaperboard

The invention discloses a laminating and die cutting integrated paperboard forming machine, which comprises a laminating unit and a die cutting unit, and is characterized in that a connecting table is arranged in front of the die cutting unit, a conveying belt is arranged among the connecting table and conveying rollers of the laminating unit and arranged on transmission wheels which are connected with a motor, an air suction and paper feeding device is arranged on the connecting table and comprises a paper storage and an air suction belt positioned below the paper storage, a slitter knife is arranged above the air suction belt, an optoelectronic switch arranged on the paper storage and the motor of the laminating unit are connected with a programmable logic controller. The paperboard forming machine integrating laminating and die cutting is higher in operating efficiency and lower in production cost.

Owner:WENZHOU QIDI MACHINERY

Inorganic environment-friendly plate and preparation method thereof

ActiveCN112851214AHigh strengthReduce manufacturing costSolid waste managementFirming agentAqueous solution

The invention relates to an inorganic environment-friendly board and a preparation method thereof, and relates to the technical field of environment-friendly boards, the inorganic environment-friendly board comprises 30-50 parts of coal gangue, 2-6 parts of cement, 0.2-0.4 part of a reinforcing agent, and 6-10 parts of a curing agent aqueous solution; the preparation method comprises the following steps: dissolving a curing agent in water according to a mass part ratio of (2-4): 100 to form a curing agent aqueous solution; uniformly mixing 30-50 parts by weight of coal gangue, 2-6 parts by weight of cement, 0.2-0.4 part by weight of a reinforcing agent and 6-10 parts by weight of a curing agent aqueous solution to obtain a mortar-like mixture; injecting the mortar-like mixture into a grid mold, trowelling, and carrying out pressure forming to obtain a prefabricated slab; and naturally curing the prefabricated plate to obtain the inorganic environment-friendly plate. The coal gangue is used as a main raw material, the compounding speed of the coal gangue and the cement is increased through the curing agent aqueous solution, the solidification forming time is shortened, the strength of the plate is improved through the reinforcing agent, the utilization rate of the coal gangue is increased, the production cost of the plate is reduced, and the formed plate is high in flexural and compressive strength.

Owner:长治市碳谷科技孵化器有限公司

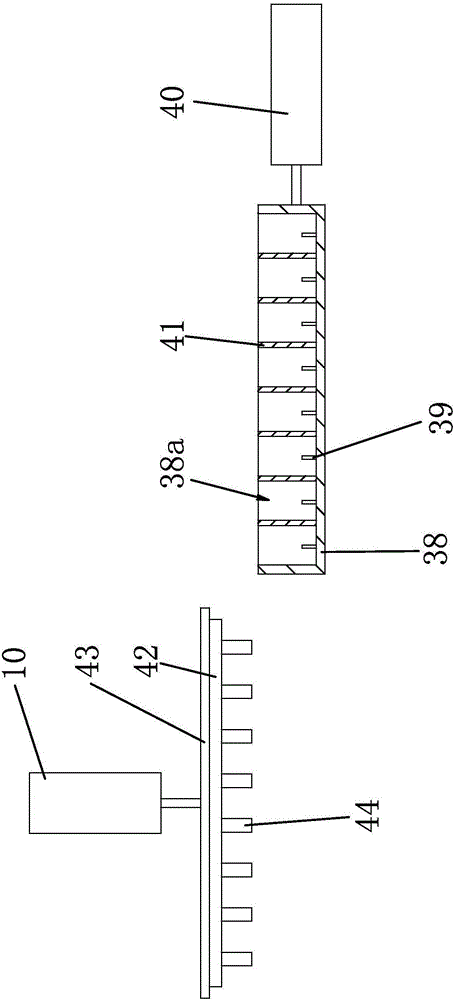

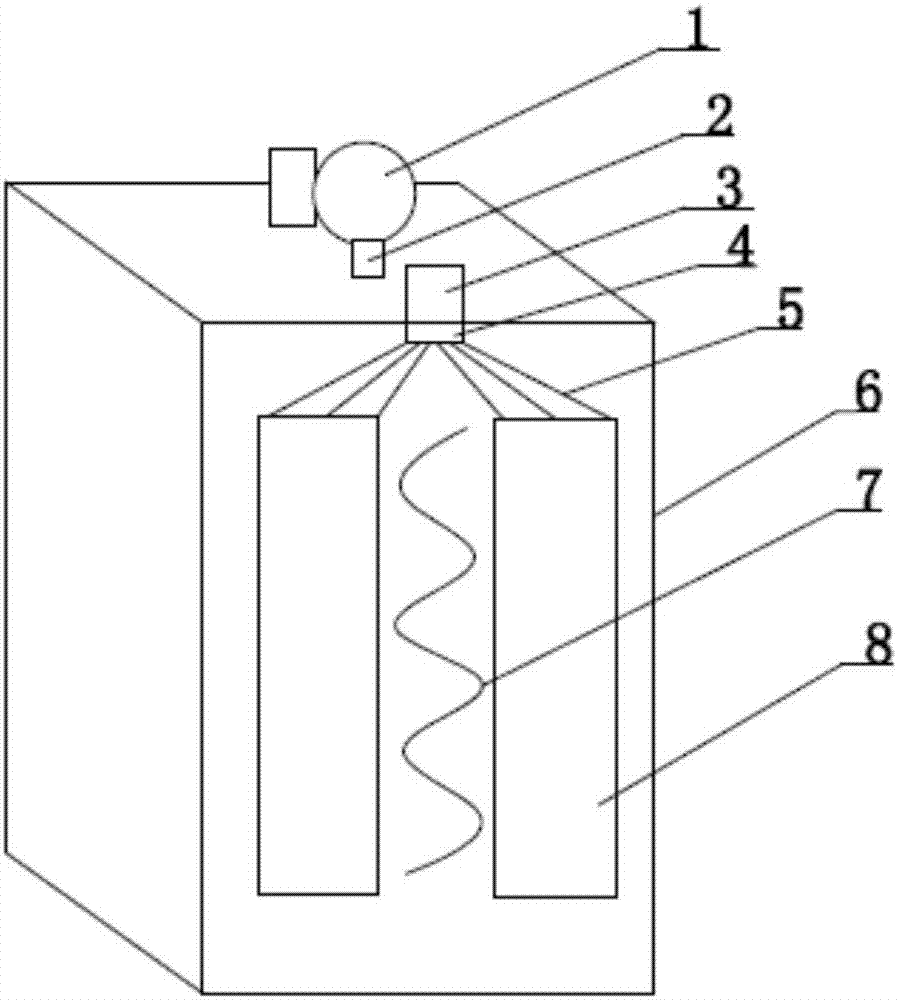

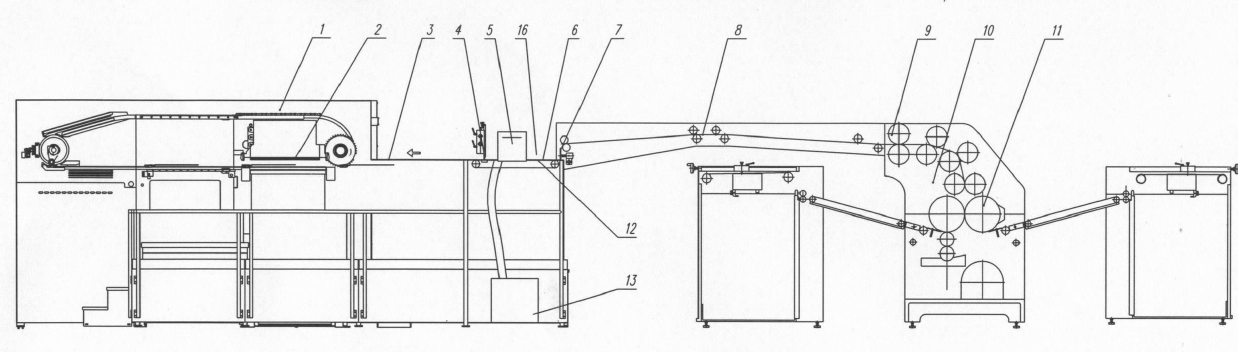

Adhesive composite device for multilayer composite heavy-duty packaging corrugated paper board

InactiveCN108001023ARealize structural compoundingComposite speedNon-macromolecular adhesive additivesCyclodextrin adhesivesPulp and paper industryHeavy duty

The invention discloses an adhesive composite device for a multilayer composite heavy-duty packaging corrugated paper board, and relates to the technical field of corrugated paper board processing. The adhesive composite device comprises an operating platform body; a horizontal conveying belt is arranged at the top of the operating platform body; feeding trough plates are arranged above the operating platform body; the feeding trough plates consist of a first-layer corrugated paper feeding trough plate, a second-layer corrugated paper feeding trough plate, a third-layer corrugated paper feeding trough plate and a surface paper feeding trough plate which are arranged in a staggered way through first struts and second struts; glue liquid pipes are transversely arranged between the second struts; a plurality of glue liquid nozzles which right face the horizontal conveying belt are uniformly arranged on the glue liquid pipes; a composite press roller is arranged at the downstream positionof the surface paper feeding trough plate; and a pressing channel for combining corrugated paper and surface paper is arranged between the composite press roller and the horizontal conveying belt. According to the device provided by the invention, the combination of the structure of three-layer corrugated paper and two-layer surface paper is automatically realized, and the corrugated paper board suitable for heavy-duty product packaging is prepared; and meanwhile, the composite speed of the corrugated paper board is improved, and the finished product quality of the corrugated paper board is ensured.

Owner:茆莉娟

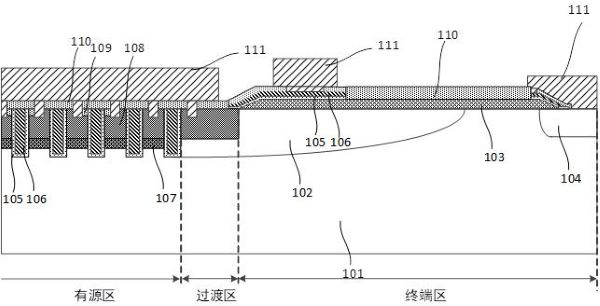

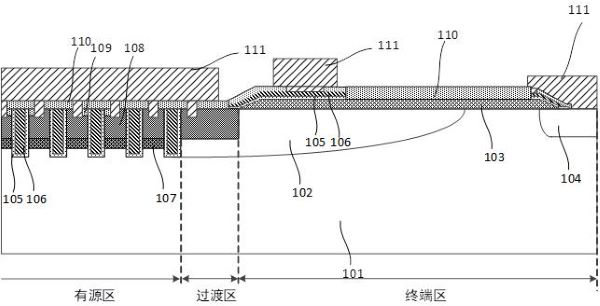

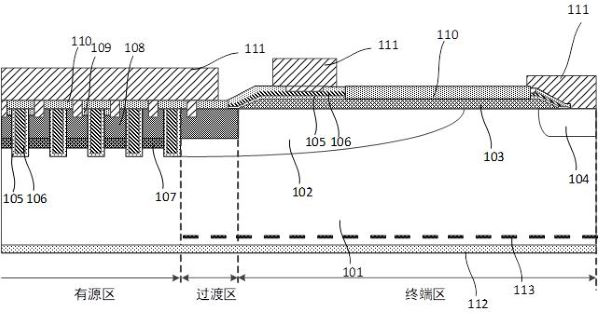

IGBT device and manufacturing method thereof

ActiveCN113571415AReduced hole lifetimeReduce emission efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesElectron holeChemical physics

The invention provides an IGBT device and a manufacturing method thereof. The IGBT device comprises a substrate, an oxygen ion defect layer, a collector region and a hydrogen ion doped region; the substrate comprises a first main surface and a second main surface which are opposite to each other, a front surface structure of the IGBT device is formed on the first main surface, and the IGBT device comprises an active region, a transition region and a terminal region; the oxygen ion defect layer is formed in the second main surface of the transition region and the terminal region; the collector region is formed on the second main surface of the substrate; the hydrogen ion doped region is formed in the second main surface of the substrate, the oxygen ion defect layer is located in the hydrogen ion doped region, and oxygen ions of the oxygen ion defect layer serve as adsorbents of the hydrogen ions, so that the doping concentration of the hydrogen ions in the hydrogen ion doped region is increased. When the IGBT device is switched on, the emission efficiency of the transition region and the terminal region is reduced, and when the IGBT device is switched off, the electron and hole recombination speed of the transition region and the terminal region is improved, so that the problem of current concentration in the transition region is effectively relieved, and the reliability of an IGBT chip is improved.

Owner:GTA SEMICON CO LTD

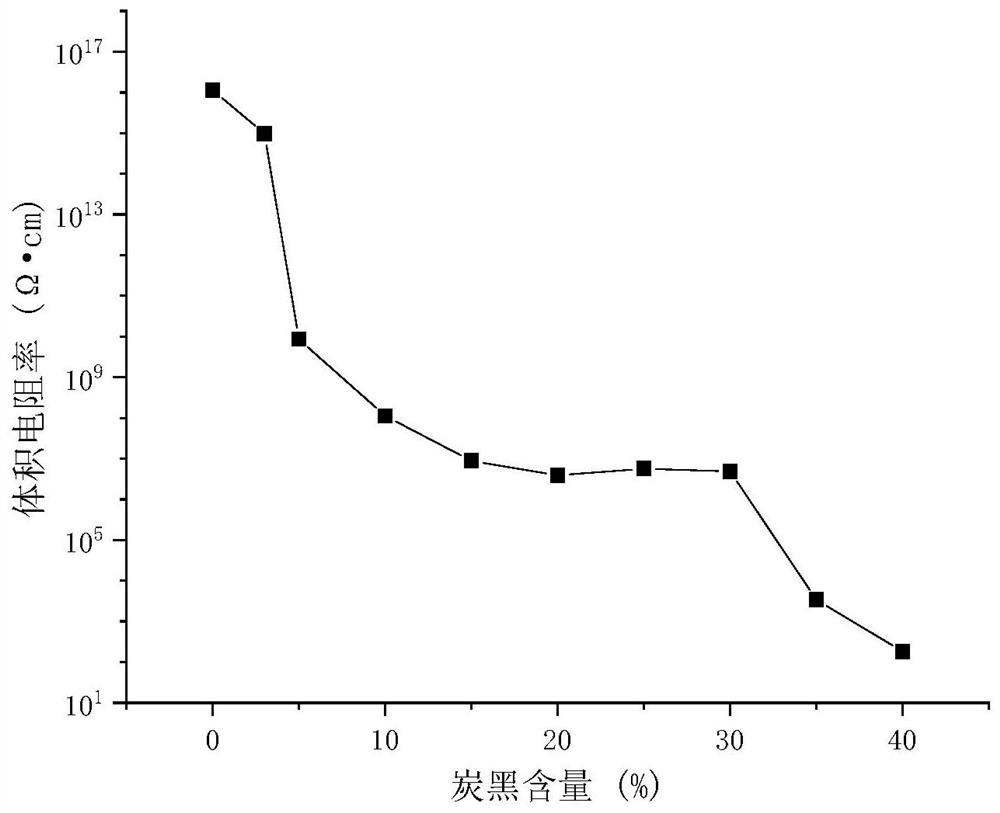

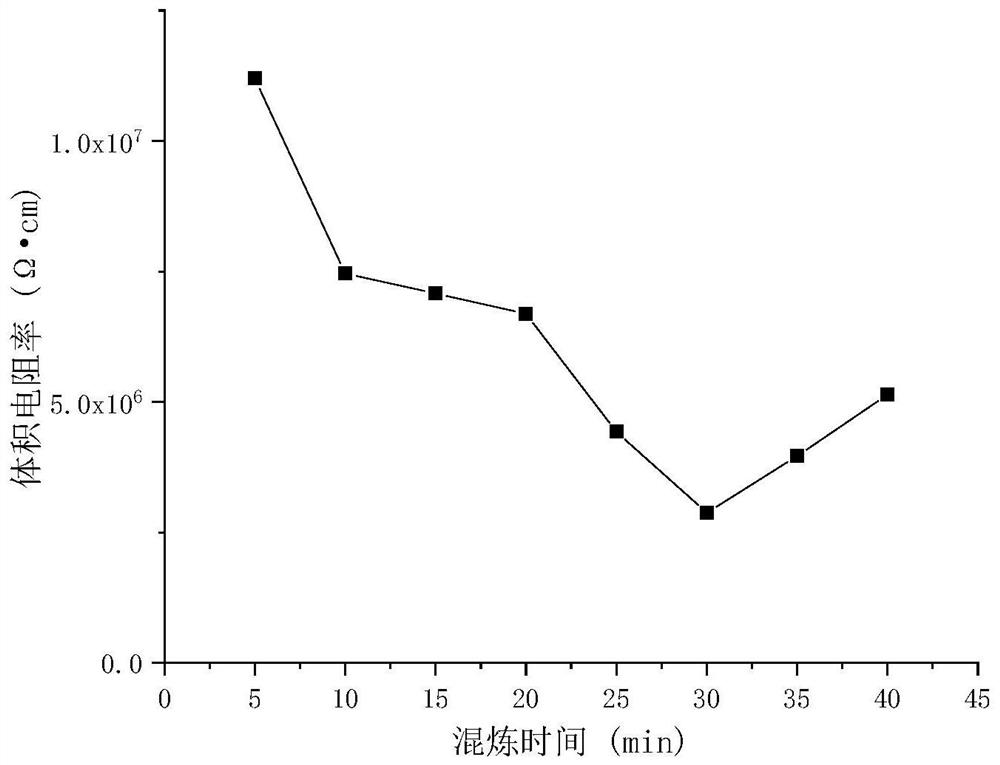

A kind of preparation method of lithium battery modified silicon-based negative electrode material

ActiveCN110752361BImprove toleranceLarge layer spacingNegative electrodesSecondary cellsCarbon layerAcrylonitrile

Owner:东营市东凯新材料技术研发有限责任公司

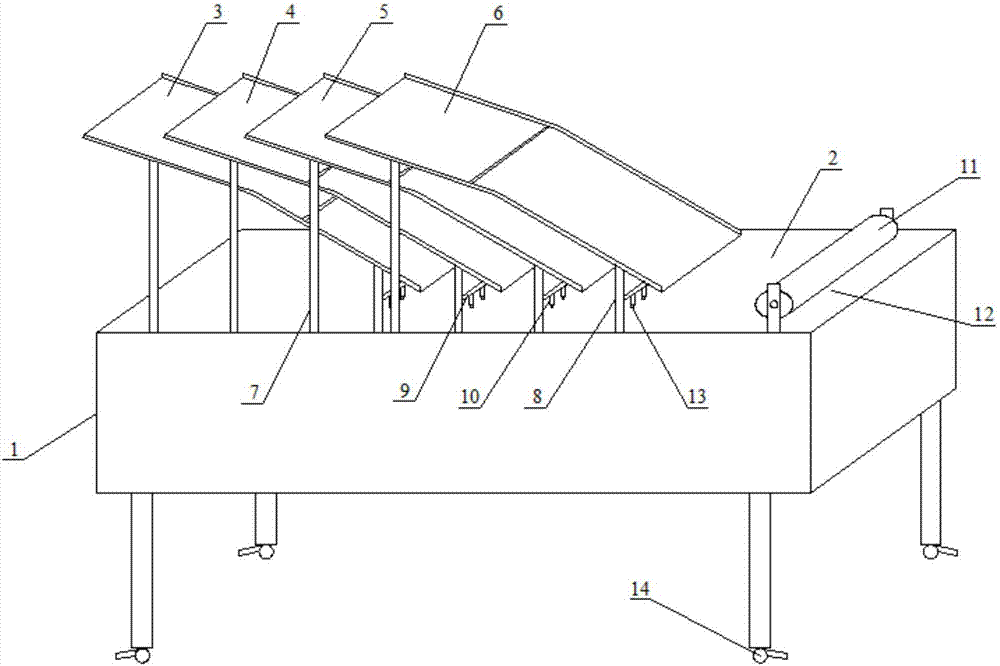

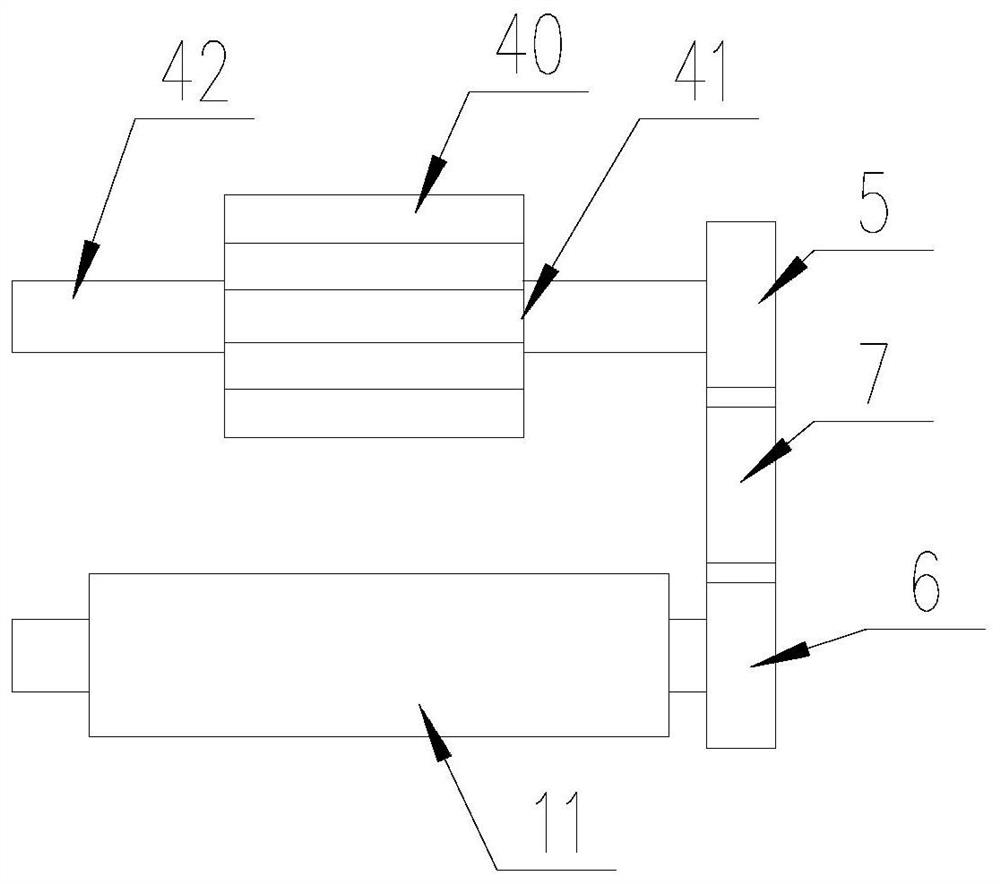

Release film compounding equipment and release film compounding production line

PendingCN113979170AControl compound temperatureReduce heat lossLaminationLamination apparatusProduction lineThin membrane

The invention discloses release film compounding equipment and a release film compounding production line. The release film compounding equipment comprises a rack; a first unwinding device, a second unwinding device, an infrared preheating roller, a high-temperature water preheating roller, a composite roller device, a heat supply system, a cooling roller, a third flattening roller, an edge cutting mechanism and a winding device are arranged on the rack; a thin film on the first unwinding device is preheated through an infrared preheating roller, a base film on the second unwinding device is preheated through a high-temperature water preheating roller, the preheated thin film and the base film are composited through the composite roller device to obtain a composite film, and the composite film bypasses the cooling roller and the third flattening roller, is subjected to edge cutting through an edge cutting mechanism and then is fed into the winding device to be wound. Aiming at the characteristics of the polyester composite release film, the production requirements of the novel polyester composite release film can be met, the release effect of the polyester composite release film is ensured, and meanwhile, the large-scale production of the novel composite release film is realized.

Owner:江苏金由新材料有限公司

A kind of inorganic environmental protection board and preparation method thereof

ActiveCN112851214BHigh strengthReduce manufacturing costSolid waste managementProcess engineeringAqueous solution

The application relates to an inorganic environmental protection board and a preparation method thereof, and relates to the technical field of environmental protection boards. The inorganic environmental protection board comprises: 30-50 parts of coal gangue, 2-6 parts of cement, 0.2-0.4 parts of a reinforcing agent, and 6- parts of an aqueous curing agent 10 parts; the preparation method includes: dissolving the solidifying agent in water to form a solidifying agent aqueous solution according to the mass ratio of 2-4:100; taking 30-50 parts of coal gangue, 2-6 parts of cement, and 0.2 parts of reinforcing agent by weight ‑0.4 part and 6‑10 parts of the curing agent aqueous solution, mixed uniformly to obtain a mortar-like mixture; after injecting the mortar-like mixture into a grid mold and smoothing, press-molding to obtain a prefabricated board; after natural curing of the prefabricated board, an inorganic Eco-friendly sheet. In the present application, using coal gangue as the main raw material, the compound speed of coal gangue and cement is accelerated by the curing agent aqueous solution, and the solidification molding time is shortened, and the strength of the board is increased by the reinforcing agent, which not only increases the utilization rate of coal gangue, but also reduces the production cost of the board. Moreover, the formed sheet has high flexural and compressive strength.

Owner:长治市碳谷科技孵化器有限公司

igbt device and its manufacturing method

ActiveCN113571415BReduced hole lifetimeReduce emission efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesElectron holeChemical physics

The invention provides an IGBT device and a manufacturing method thereof. The IGBT device includes: a substrate, the substrate includes opposite first main surfaces and second main surfaces, the first main surface is formed with a front structure of the IGBT device, and the IGBT device includes The active region, the transition region and the terminal region; the oxygen ion defect layer, formed in the second main surface of the transition region and the terminal region; the collector region, formed on the second main surface of the substrate; the hydrogen ion doped region, formed In the second main surface of the substrate, the oxygen ion defect layer is located in the hydrogen ion doped region, wherein the oxygen ions in the oxygen ion defect layer serve as adsorbents for hydrogen ions so as to increase the doping of hydrogen ions in the hydrogen ion doped region. impurity concentration. The present invention reduces the emission efficiency of the transition region and the terminal region when the IGBT device is turned on, and at the same time increases the recombination speed of electrons and holes in the transition region and the terminal region when the IGBT device is turned off, thereby effectively alleviating the current concentration problem existing in the transition region , Improve the reliability of the IGBT chip.

Owner:GTA SEMICON CO LTD

Alkaline accumulator

InactiveCN1243386CIncrease the number of particlesImprove composite effectAlkaline accumulatorsAlkaline accumulator electrodesInternal pressureEngineering

The invention relates to an alkaline accumulator. It includes positive pole, negative pole, insulator and shell. Area of the negative pole is larger than the area of the positive pole. Upper end of the negative pole is higher than the height of upper end of the positive pole. The relationship of areas between positive pole and negative pole is described by the formula: S(+)=aS(-) where a=0-1.0. The invented alkaline accumulator can lower internal pressure of battery, raise use rate of active material in pole and reduce incidence rate of battery short circuit.

Owner:CHUNLAN GROUP CORP

A composite film for liquid medicine packaging and its dry composite process

ActiveCN111941959BGood for volatilizationVolatile fastLamination ancillary operationsSynthetic resin layered productsComposite filmEngineering

The invention discloses a liquid medicine packaging composite film and its dry composite process, which solves the problem that in the existing dry composite process, due to incomplete solvent removal or moisture entering during the solvent removal process, the composite film is easily caused to foam and affect The binding force between the composite films and the problem of increasing solvent residues, the present invention includes: (1) open the dry composite machine and the induced draft fan, the movement of the guide roller drives the operation of the flow aid in the drying tunnel, and preheats the drying tunnel to make it reach Preset temperature; (2) Glue coating of the outer layer film; (3) After the glue coating is completed, the outer layer film enters the drying tunnel for solvent volatilization; (4) The outer layer film and the barrier layer film are combined to obtain the outer layer-barrier film intermediate product (5) heat-sealing layer film gluing; (6) after the gluing is completed, enter the drying tunnel for solvent volatilization; (7) compound the outer layer-barrier film intermediate product and the heat-sealing layer film to obtain a liquid drug packaging composite film . The invention has the advantages of fast solvent volatilization, good water removal in the drying tunnel and the like.

Owner:SICHUAN HUILI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com