Hot melt adhesive for siphon plate and preparation method of hot melt adhesive

A hot melt adhesive and siphon technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of poor wettability of non-polar materials, decreased adhesion performance, high surface tension, etc. To solve the problem of solvent volatilization and recovery, reduce the risk of poisoning, and achieve the effect of safe and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

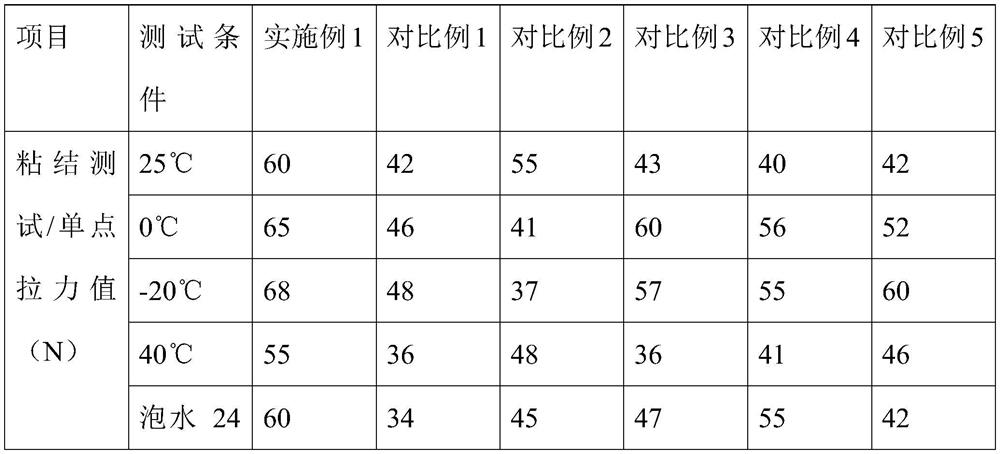

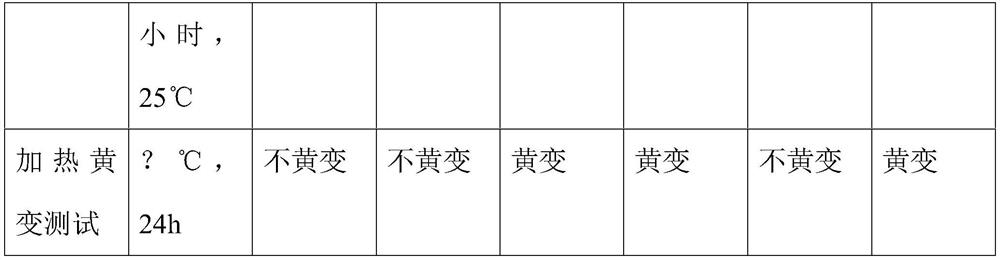

Examples

Embodiment 1

[0027] A hot melt adhesive for a siphon board, comprising the following raw materials by weight: 30 parts of the first EVA resin, 20 parts of the second EVA resin, 45 parts of tackifying resin, 5 parts of Fischer-Tropsch wax and 0.3 part of antioxidant;

[0028] Wherein, the VA content in the raw material used for the first EVA resin is 28wt%, and the first EVA resin is an EVA resin with a melt index of 145g / 10min; the VA content in the raw material used for the second EVA resin is 18wt%, and the second EVA resin has a VA content of 18wt%. The EVA resin is EVA resin with a melt index of 395; the tackifying resin is 15 parts of a first hydrogenated petroleum resin with a softening point of 100° C. and 20 parts of a second hydrogenated petroleum resin with a softening point of 150° C.

[0029] Specifically, the Fischer-Tropsch wax is Sasol Fischer-Tropsch wax H1. The antioxidant is antioxidant 1010.

[0030] The preparation method of above-mentioned hot melt adhesive for siphon...

Embodiment 2

[0036] A hot-melt adhesive for a siphon board, comprising the following raw materials by weight: 25 parts of the first EVA resin, 15 parts of the second EVA resin, 30 parts of tackifying resin, 6 parts of Fischer-Tropsch wax and 0.1 part of antioxidant;

[0037] Wherein, the VA content in the raw material used for the first EVA resin is 25wt%, and the first EVA resin is the EVA resin with a melt index of 155g / 10min and 395g / 10min with a mass ratio of 1:1; the raw material used for the second EVA resin The VA content is 15wt%, and the second EVA resin is an EVA resin with a melt index of 155g / 10min and 405g / 10min with a mass ratio of 1:1; the tackifying resin is 10 parts of the first EVA resin with a softening point of 98°C. Hydrogenated petroleum resin and 20 parts of a second hydrogenated petroleum resin having a softening point of 130°C.

[0038]Specifically, the Fischer-Tropsch wax is one or a mixture of two or more of Sasol Fischer-Tropsch Wax H1, Sasol Fischer-Tropsch Wax...

Embodiment 3

[0045] A hot-melt adhesive for a siphon board, comprising the following raw materials by weight: 35 parts of the first EVA resin, 25 parts of the second EVA resin, 50 parts of tackifying resin, 10 parts of Fischer-Tropsch wax and 1 part of antioxidant;

[0046] Wherein, the VA content in the raw material used for the first EVA resin is 30wt%, and the first EVA resin is an EVA resin with a melt index of 405g / 10min; the VA content in the raw material used for the second EVA resin is 20wt%, and the second EVA resin has a VA content of 20wt%. The EVA resin is an EVA resin with a melt index of 155 g / 10min; the tackifying resin is 20 parts of a first hydrogenated petroleum resin with a softening point of 110° C. and 30 parts of a second hydrogenated petroleum resin with a softening point of 150° C.

[0047] Specifically, the Fischer-Tropsch wax is Sasol Fischer-Tropsch wax SX-105. The antioxidant is antioxidant 1010.

[0048] The preparation method of above-mentioned hot melt adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com