Preparation method of zinc-copper-titanium alloy for corrosion prevention

A technology of copper-titanium alloy and titanium alloy, which is applied in the field of preparation of anti-corrosion zinc-copper-titanium alloy, can solve the problems of waste of zinc resources, insufficient corrosion resistance of zinc-copper-titanium alloy, etc., and achieve easy diffusion, shorten smelting time, and The effect of improving corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments.

[0020] A preparation method for anti-corrosion zinc-copper-titanium alloy, comprising the following steps:

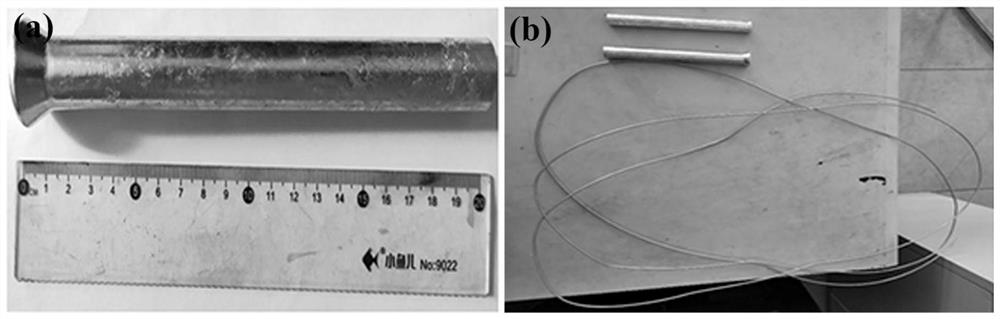

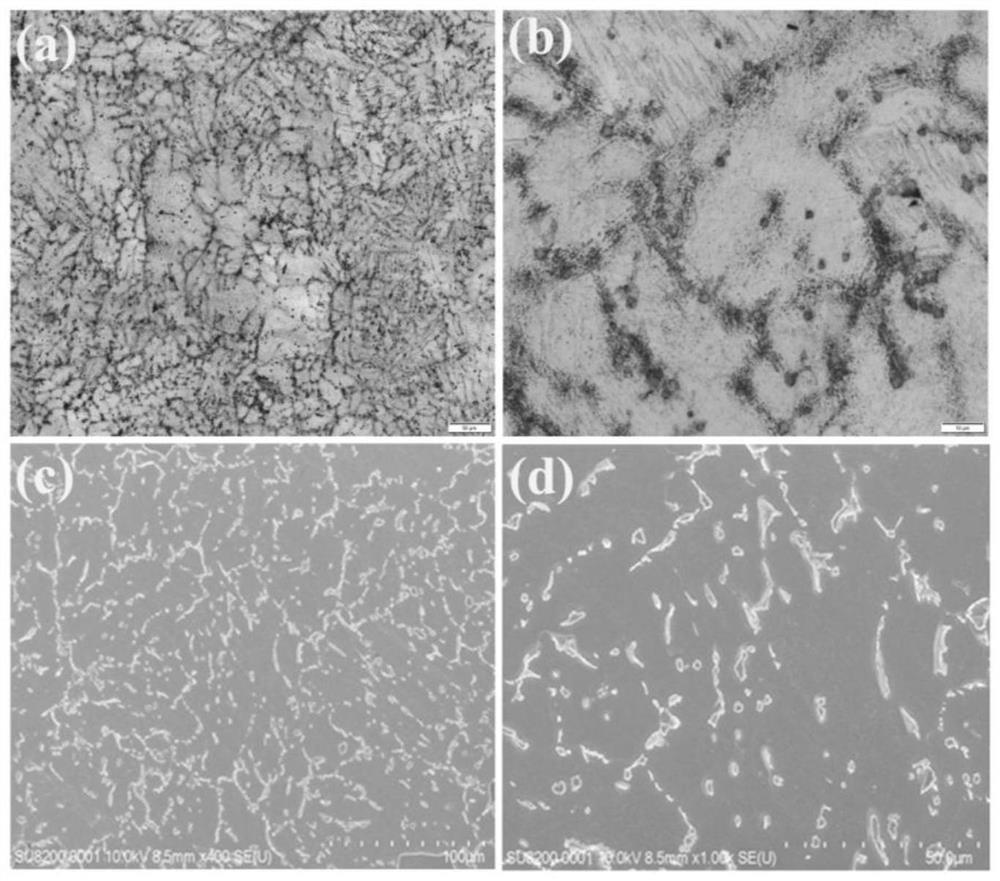

[0021] (1) Weigh the first-grade titanium sponge and pure copper block according to the mass ratio of 1:1, and melt them in an arc melting furnace. In order to ensure that the melting of each component is completely sufficient, it is best to ensure that the number of arc melting is more than 3 times , multiple times of melting under electromagnetic stirring conditions to produce copper-titanium alloy ingots;

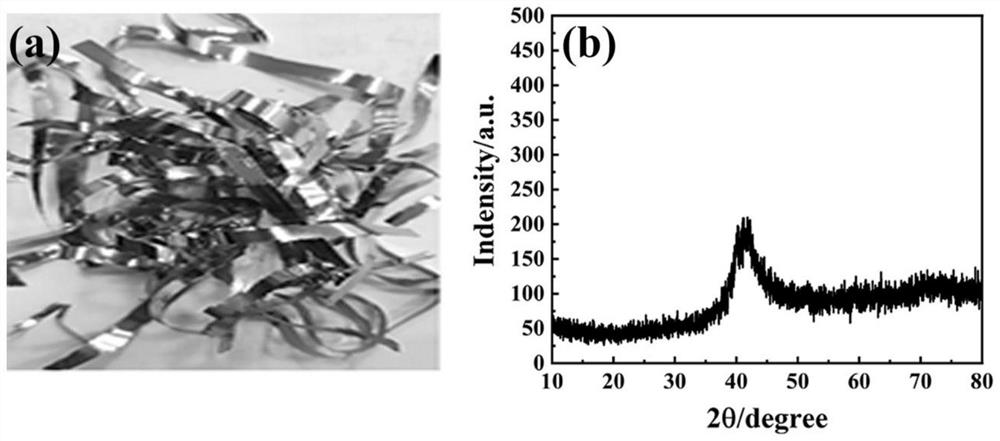

[0022] (2) The copper-titanium alloy ingot prepared in step (1) is subjected to single-roll spin quenching and rapid solidification. As the most optimal solution during operation, the rotation speed of the copper plate is not lower than 20m / s. If it is too low, it will make it difficult to grow amorphous. Prepare a copper-titanium alloy amorphous str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com