Composite material with high obstruction and high performance and preparation method thereof

A composite material and high-performance technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem that high barrier materials cannot meet the requirements, nylon fiber has low elastic modulus, and low temperature impact strength etc. to achieve excellent flexibility and elasticity, good mechanical properties, and high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

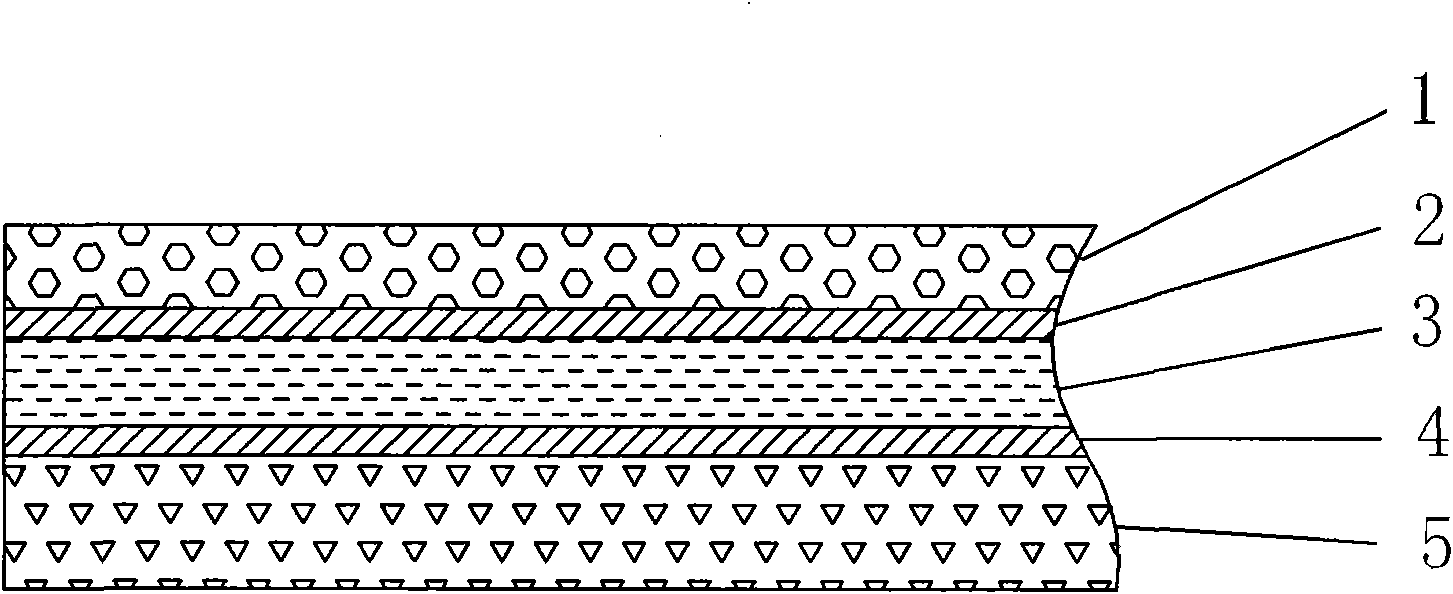

[0068] Such as figure 1 As shown, the high-barrier high-performance composite material of the present invention is composed of polyvinyl fluoride film layer 1, polyurethane adhesive layer 2, polyester aluminized film layer 3, polyurethane adhesive layer 4, aramid fabric Layers 5 are sequentially combined to form a laminated body.

[0069] Wherein, polyvinyl fluoride film is Tedlar film, and aramid fiber fabric is Kevlar fabric, adopts following method to prepare:

[0070] 1) The solid polyurethane adhesive particles are melted by a hot-melt adhesive machine, and the Tedlar film layer 1 and the polyester aluminized film layer 3 are combined on the hot-melt high-performance polyurethane adhesive through transfer gluing and composite rolling processes Together, the melting temperature of the hot melt adhesive machine is 70°C, and the glue amount of the high-performance polyurethane adhesive is 8g / m 2 , the composite rolling pressure is 1.0MPa, and the composite rolling temperat...

Embodiment 2

[0073] Such as figure 1 As shown, the high-barrier high-performance composite material of the present invention is composed of polyvinyl fluoride film layer 1, polyurethane adhesive layer 2, polyester aluminized film layer 3, polyurethane adhesive layer 4, aramid fabric Layers 5 are sequentially combined to form a laminated body.

[0074] The above-mentioned laminate is prepared by the following method:

[0075] 1) The solid polyurethane adhesive particles are melted by a hot-melt adhesive machine, and the polyvinyl fluoride film layer 1 and the polyester aluminized film layer 3 are bonded by the hot-melt high-performance polyurethane adhesive through transfer gluing and composite rolling. Composite together, where the melting temperature of the hot melt machine is 70°C, and the amount of glue applied by the high-performance polyurethane adhesive is 10g / m 2 , the composite rolling pressure is 1.0MPa, and the composite rolling temperature is 25°C; the thickness of the polyvin...

Embodiment 3

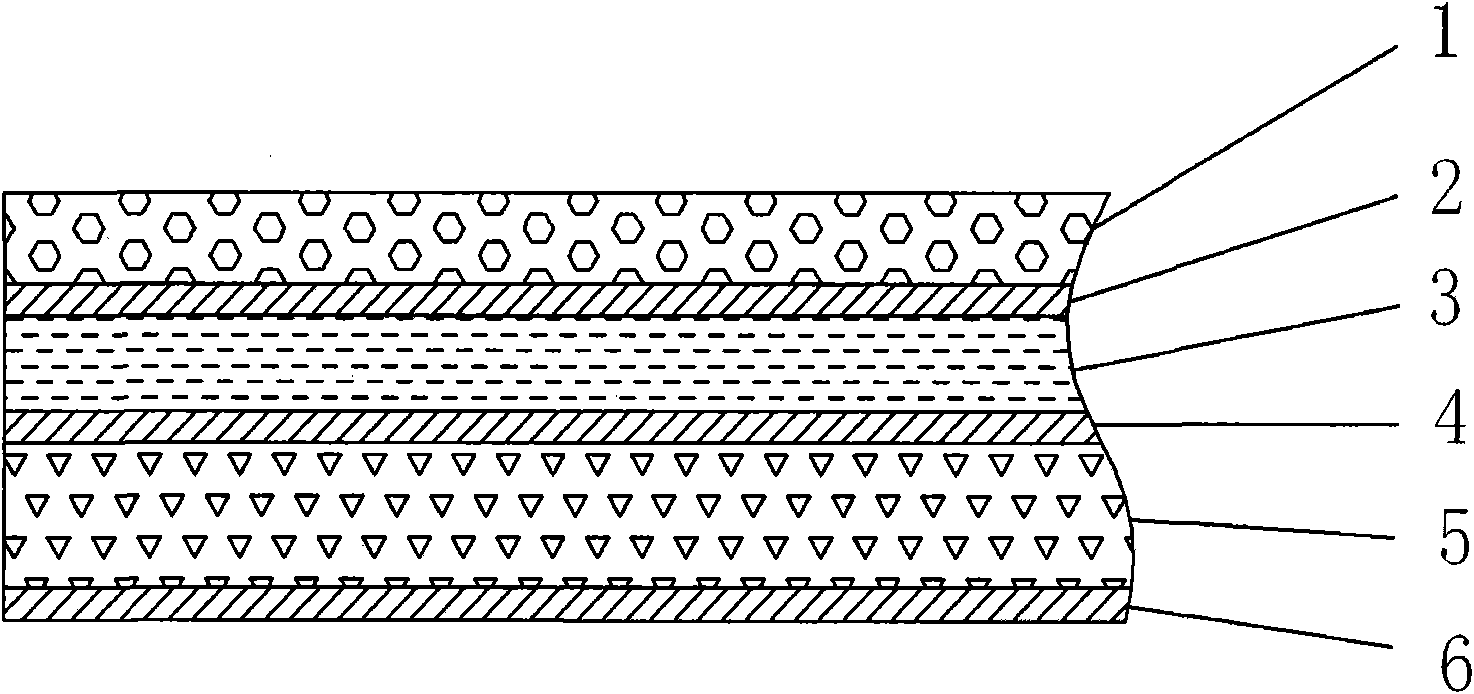

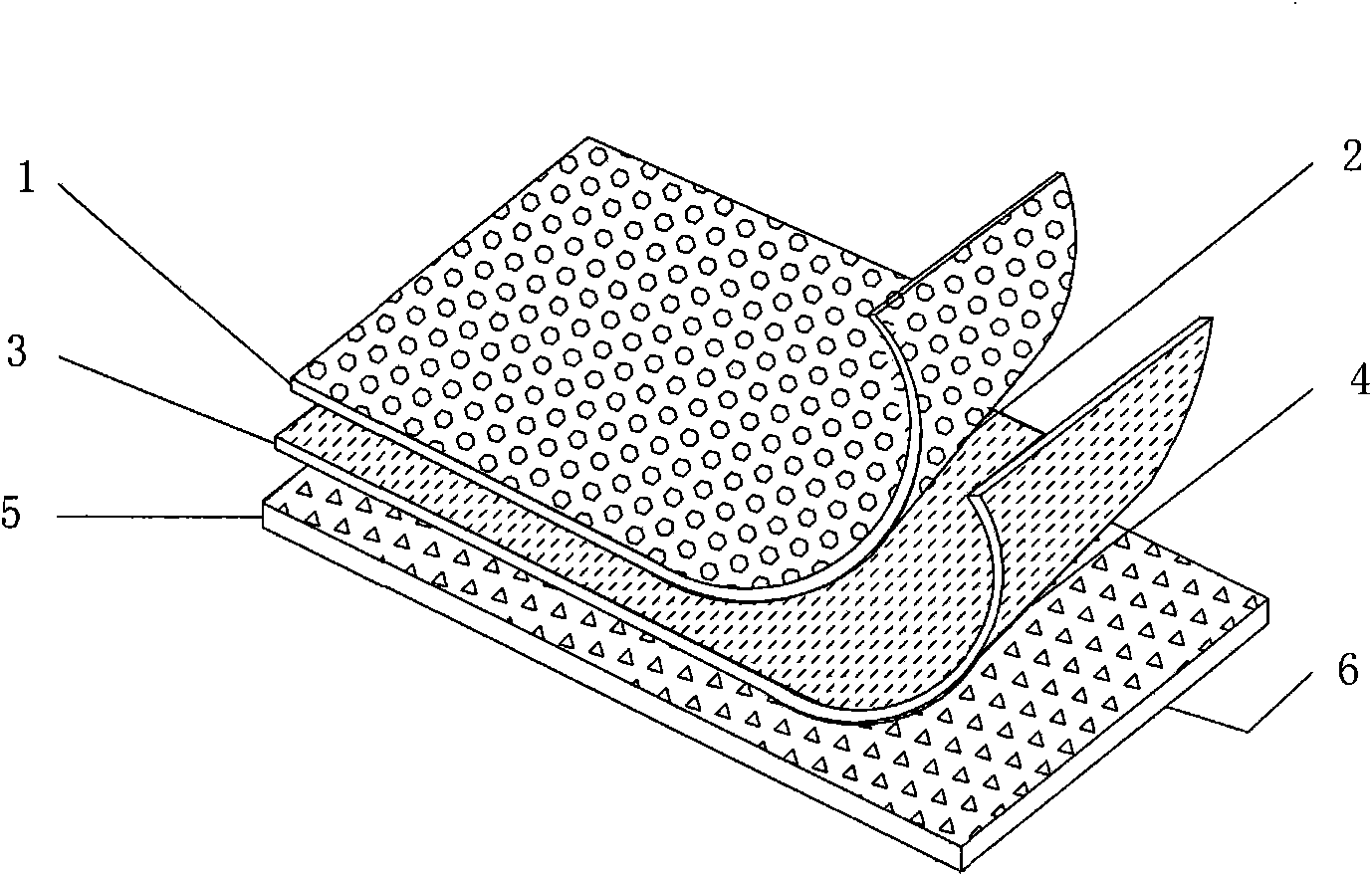

[0078] Such as figure 2 and 3 As shown, the high-barrier high-performance composite material of the present invention is composed of polyvinyl fluoride film layer 1, polyurethane adhesive layer 2, polyester aluminized film layer 3, polyurethane adhesive layer 4, aramid fabric Layer 5 and polyurethane coating 6 are sequentially combined to form a laminated body.

[0079] Wherein, polyvinyl fluoride film is Tedlar film, and aramid fiber fabric is Kevlar fabric, adopts following method to prepare:

[0080] 1) The solid polyurethane adhesive particles are melted by a hot-melt adhesive machine, and the Tedlar film layer 1 and the polyester aluminized film layer 3 are combined on the hot-melt high-performance polyurethane adhesive through transfer gluing and composite rolling processes Together, the melting temperature of the hot melt adhesive machine is 70°C, and the amount of glue applied by the high-performance polyurethane adhesive is 9g / m 2 , the composite rolling pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com