Making method of waterproof automobile ceiling fabric

A fabric and canopy technology, applied in chemical instruments and methods, vehicle components, lamination, etc., can solve the problems of complex manufacturing method steps and poor product quality, and achieve good product quality, fast compounding speed, and good smoke exhaust effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

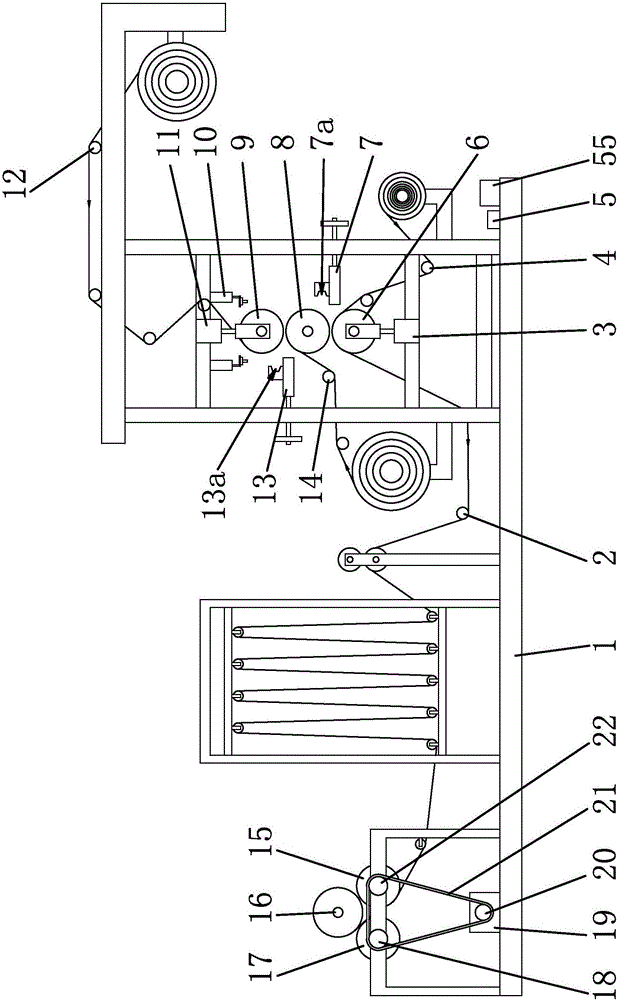

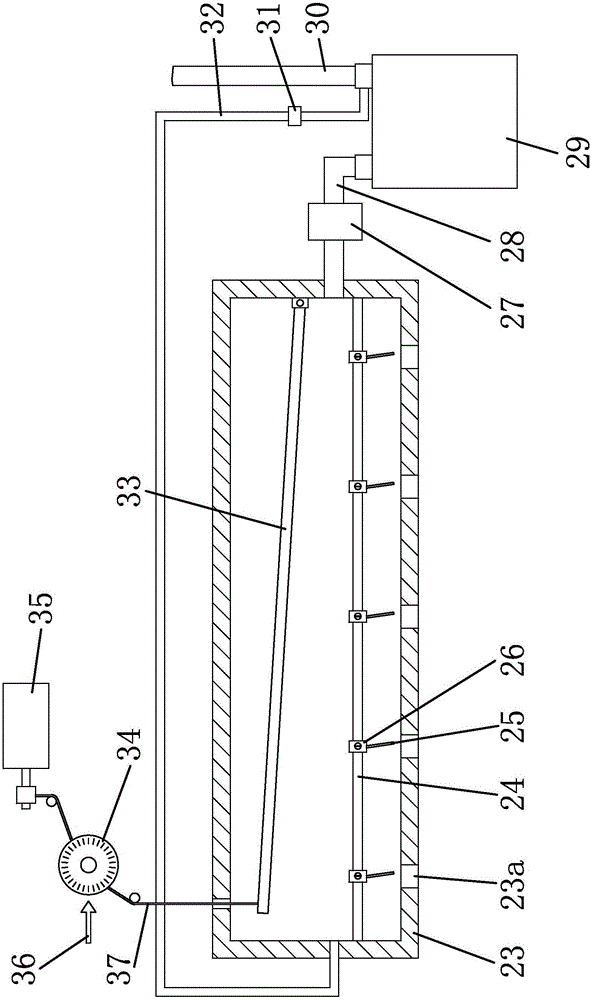

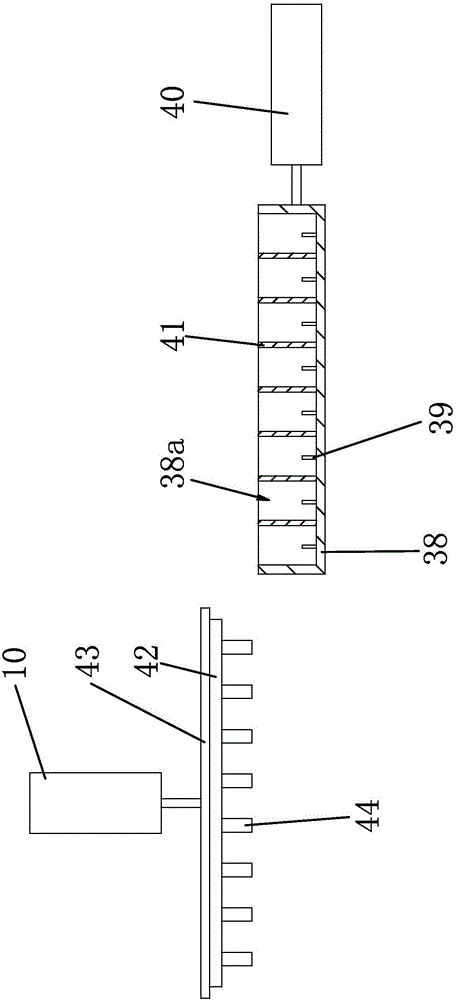

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0050] The preparation method of this waterproof car headliner fabric, this method comprises the following steps:

[0051] a. Outsourced raw materials: purchase the existing sponge on the market as the middle layer, and purchase the existing polyester non-woven fabric on the market as the inner layer;

[0052] b. Make the surface layer:

[0053] b1. Warping: the raw material yarn is evenly wound onto the pan head through the warping machine, and the raw material yarn is 90dtex cationic polyester filament and 70dtex ordinary polyester low elastic yarn;

[0054] b2. Weaving: the raw material yarn is bent into a loop through the warp knitting machine and interlaced to form a fabric;

[0055] b3. Washing: put the fabric into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com