Adhesive composite device for multilayer composite heavy-duty packaging corrugated paper board

A technology of corrugated cardboard and adhesive compounding, which is applied in the field of corrugated cardboard processing, can solve problems such as processing environmental pollution, achieve the effects of ensuring the quality of finished products, preventing formaldehyde release, and increasing the compounding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

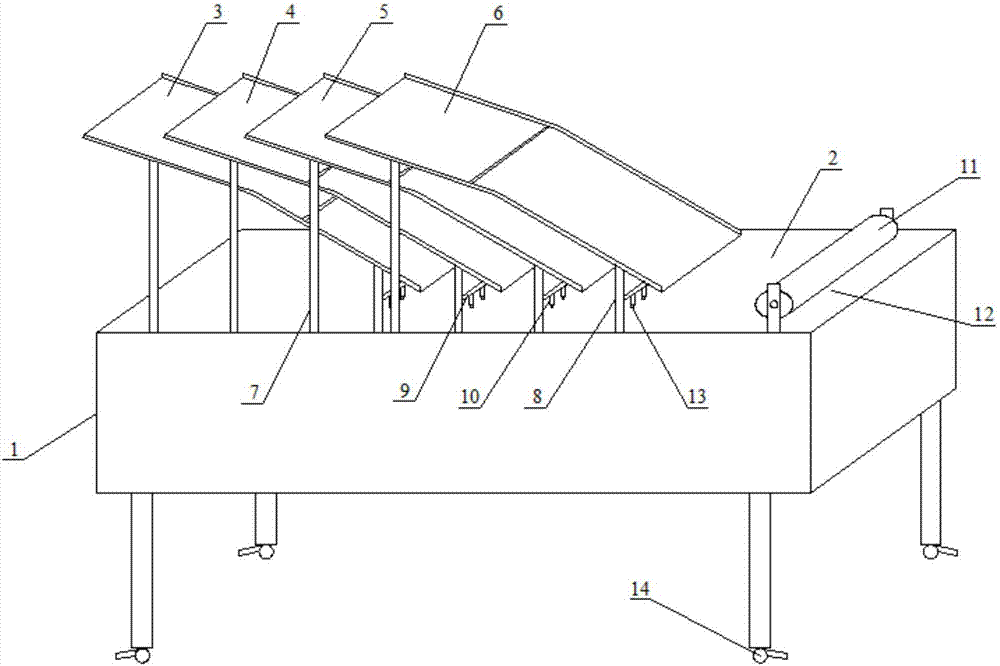

[0025] Such as figure 1 As shown, a multi-layer composite heavy-duty packaging corrugated cardboard gluing compound device includes an operation table body 1, a horizontal conveyor belt 2 is provided on the top of the operation table body, and a feed trough plate is provided above the operation table body. One layer of corrugated paper feeding channel board 3, the second layer of corrugated paper feeding channel board 4, the third layer of corrugated paper feeding channel board 5 and facial paper feeding channel board 6, the first layer of corrugated paper feeding channel The corrugated paper feed chute, the third layer of corrugated paper feed chute, and the facial paper feed chute are installed above the console body through the first pillar 7 and the second pillar 8 respectively, and glue is arranged horizontally between the second pillars Pipe 9, the glue pipe is evenly equipped with a plurality of glue nozzles 10 facing the horizontal conveyor belt, and a composite pressu...

Embodiment 2

[0027] Such as figure 1 As shown, a multi-layer composite heavy-duty packaging corrugated cardboard gluing compound device includes an operation table body 1, a horizontal conveyor belt 2 is provided on the top of the operation table body, and a feed trough plate is provided above the operation table body. One layer of corrugated paper feeding channel board 3, the second layer of corrugated paper feeding channel board 4, the third layer of corrugated paper feeding channel board 5 and facial paper feeding channel board 6, the first layer of corrugated paper feeding channel The corrugated paper feed chute, the third layer of corrugated paper feed chute, and the facial paper feed chute are installed above the console body through the first pillar 7 and the second pillar 8 respectively, and glue is arranged horizontally between the second pillars Pipe 9, the glue pipe is evenly equipped with a plurality of glue nozzles 10 facing the horizontal conveyor belt, and a composite pressu...

Embodiment 3

[0034] Such as figure 1As shown, a multi-layer composite heavy-duty packaging corrugated cardboard gluing compound device includes an operation table body 1, a horizontal conveyor belt 2 is provided on the top of the operation table body, and a feed trough plate is provided above the operation table body. One layer of corrugated paper feeding channel board 3, the second layer of corrugated paper feeding channel board 4, the third layer of corrugated paper feeding channel board 5 and facial paper feeding channel board 6, the first layer of corrugated paper feeding channel The corrugated paper feed chute, the third layer of corrugated paper feed chute, and the facial paper feed chute are installed above the console body through the first pillar 7 and the second pillar 8 respectively, and glue is arranged horizontally between the second pillars Pipe 9, the glue pipe is evenly equipped with a plurality of glue nozzles 10 facing the horizontal conveyor belt, and a composite pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com