Alkaline accumulator

A storage battery, alkaline technology, applied in the direction of alkaline storage batteries, alkaline storage battery electrodes, etc., can solve the problems of insufficient utilization of battery active materials, deterioration of battery sealing performance, affecting discharge capacity, etc., to improve gas recombination capacity, reduce The occurrence of battery short circuit and the effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment one: Positive pole is made: be to make Ni(OH) 2 , conductive agent, additives, and binders are composed of a slurry in a certain proportion, coated on the foamed nickel current collector, dried and rolled to form an electrode.

[0039] Negative electrode production: the hydrogen storage alloy, conductive agent, additive, and binder are composed of a slurry in a certain proportion, coated on the foamed nickel current collector, dried and rolled to form an electrode.

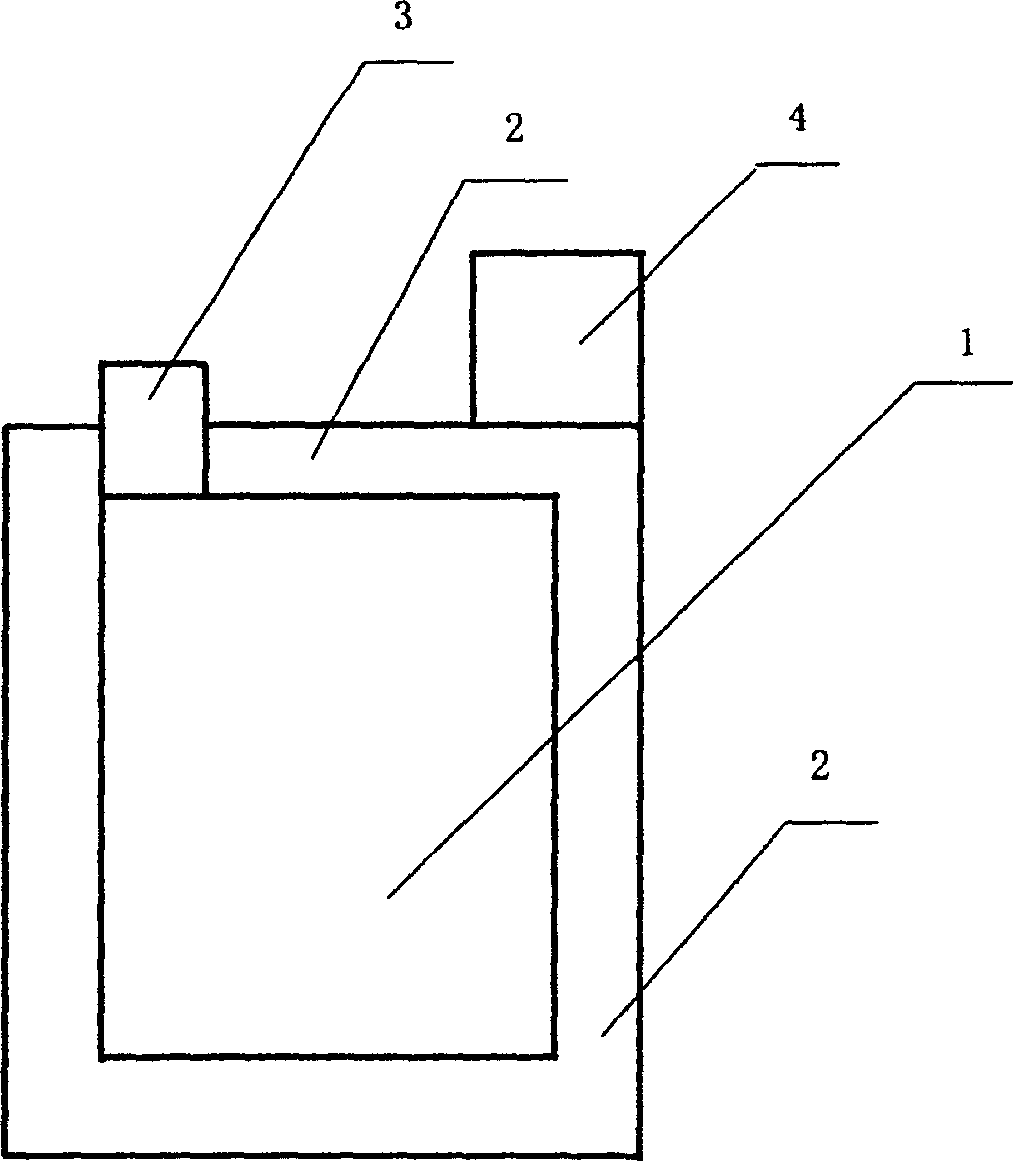

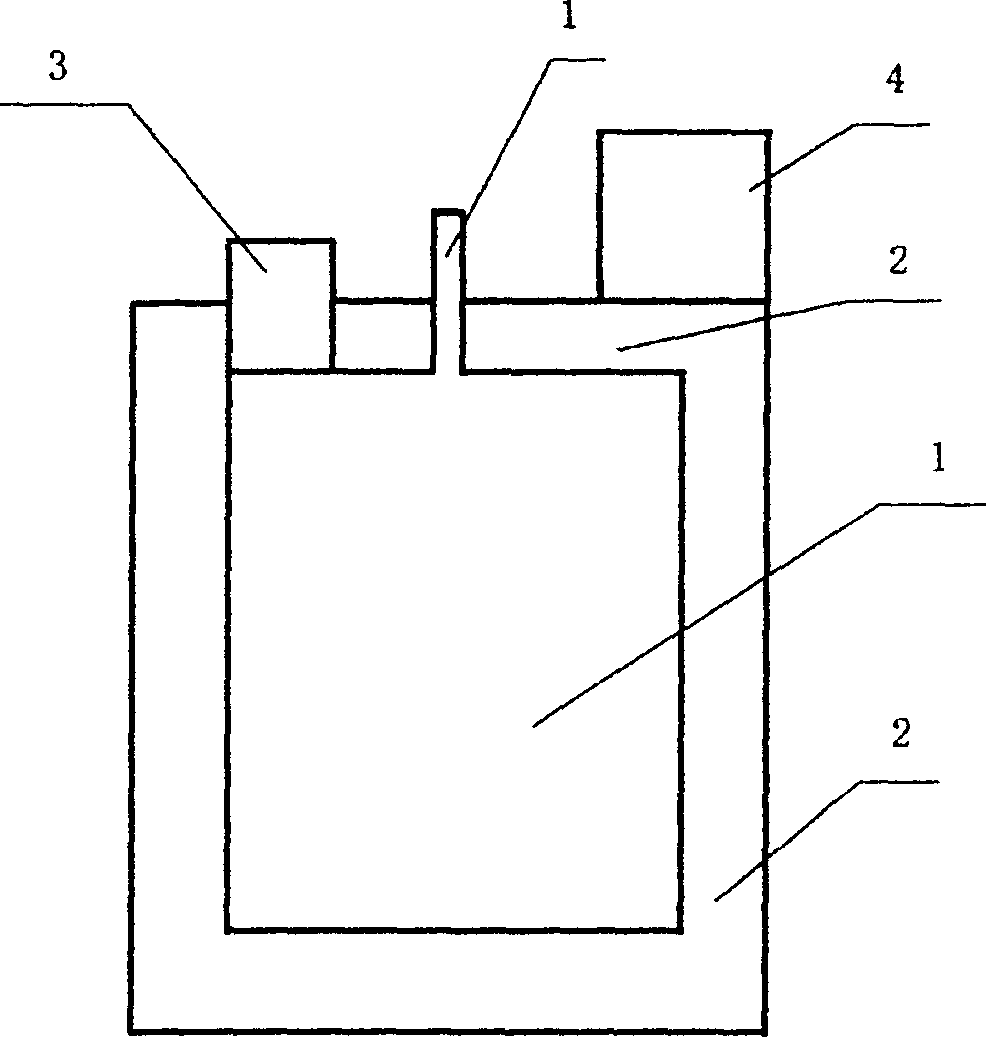

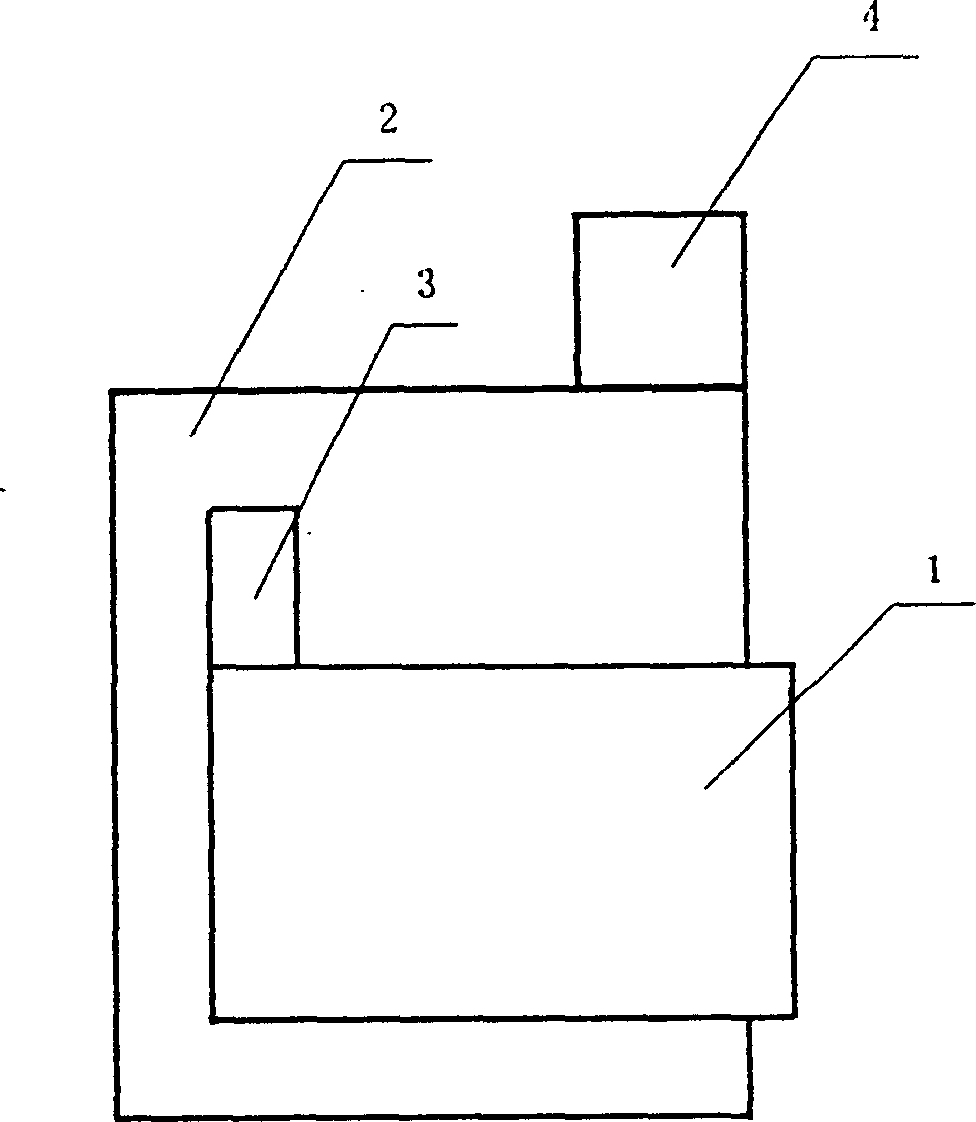

[0040] The production of the battery: wrap one of the above-mentioned positive and negative electrodes with a separator, and place the positive and negative electrodes overlapping each other. When the positive and negative electrodes are stacked, you can use figure 1 , figure 2 , image 3 or Figure 4 form, figure 1 The sides of the positive pole 1 do not exceed the sides of the negative pole 2, only the positive pole tab 3 is exposed, and the negative pole tab 4 is in the upper right corner...

Embodiment 2

[0041] Embodiment 2: The production of the positive and negative electrodes and the battery is the same as that of Embodiment 1. According to Table 2, when the value of b is constant, different values of c are used to compare the internal pressure after assembling the battery for 100 cycles. Wherein, the b value is the length coefficient value of the left and right sides of the positive and negative electrodes described in the claims.

[0042] With the structure of the present invention, the surface area of the negative electrode is greater than the surface area of the positive electrode, and the upper end of the negative electrode is higher than the upper end of the positive electrode, which can reduce the internal pressure of the battery by more than 60%, and the greater the coefficient value indicating the relationship between the positive and negative electrode area and the length of the left and right sides, the greater the internal pressure drop. Not obvious. It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com