A kind of high elongation rut400 vermicular graphite cast iron and its production process

A high elongation, vermicular graphite cast iron technology, applied in the direction of improving process efficiency, can solve the problems of reduced tensile strength, inability to meet the requirements of vermicular iron grades, etc., and achieves easy operation, high tensile strength, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

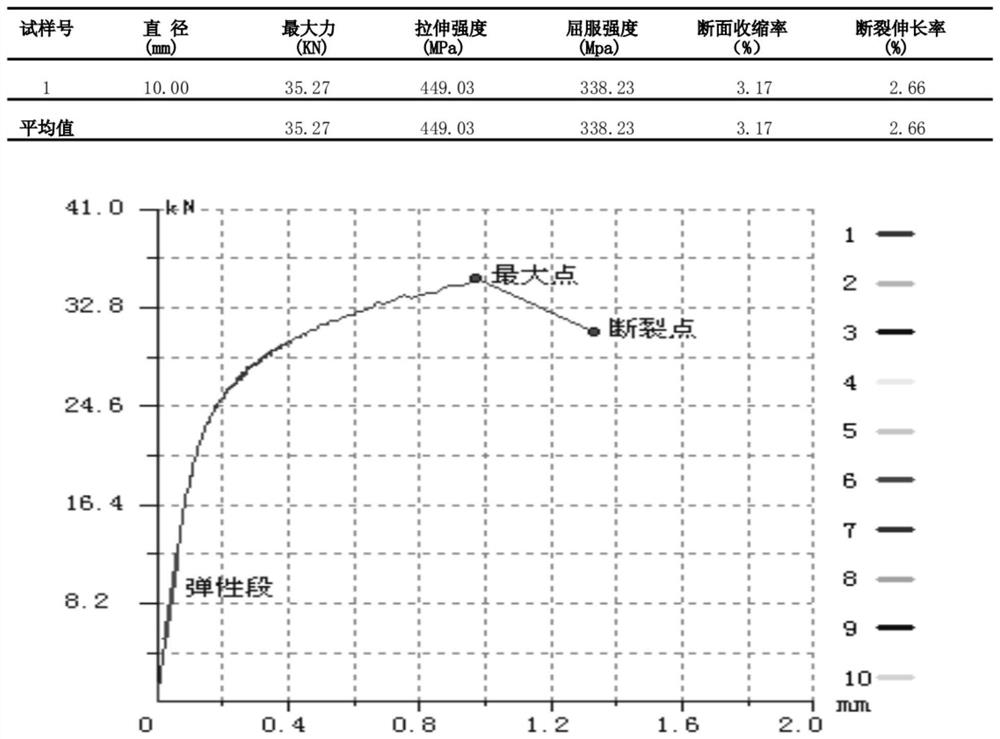

Image

Examples

Embodiment 1

[0041] (1) Ingredients Weighing raw materials for molten iron smelting:

[0042] The raw materials for hot metal smelting are composed of the following components by weight percentage: pig iron 0.715t, scrap steel 0.285t, ferrosilicon 3.5kg, recarburizer 4kg;

[0043] a. Pig iron is high-purity pig iron, and its composition mass percentages are as follows:

[0044] C(%) Si(%) Mn(%) P(%) S(%) Ti(%) ≥4.0 ≤0.4 ≤0.5 ≤0.025 ≤0.02 ≤0.03

[0045] The mass percentages of trace elements in pig iron are as follows:

[0046]

[0047] The balance is iron;

[0048] b. Scrap steel is carbon steel, and the mass percentages of the components are as follows:

[0049] C(%) Si(%) Mn(%) P(%) S(%) ≤0.3 ≤0.2 ≤0.3 ≤0.02 ≤0.015

[0050] The balance is iron;

[0051] c. The grade of ferrosilicon is FeSi75-B according to the GB2272-87 standard;

[0052] (2) Smelting molten iron

[0053] Put the molten iron smelting raw materials into an i...

Embodiment 2

[0071] (1) Ingredients Weighing raw materials for molten iron smelting:

[0072] The raw materials for hot metal smelting are composed of the following components by weight percentage: pig iron 0.72t, scrap steel 0.28t, ferrosilicon 3.4kg, recarburizer 4kg;

[0073] a. Pig iron is high-purity pig iron, and its composition mass percentages are as follows:

[0074] C(%) Si(%) Mn(%) P(%) S(%) Ti(%) ≥4.0 ≤0.4 ≤0.5 ≤0.025 ≤0.02 ≤0.03

[0075] The mass percentages of trace elements in pig iron are as follows:

[0076]

[0077] The balance is iron;

[0078] b. Scrap steel is carbon steel, and the mass percentages of the components are as follows:

[0079] C(%) Si(%) Mn(%) P(%) S(%) ≤0.3 ≤0.2 ≤0.3 ≤0.02 ≤0.015

[0080] The balance is iron;

[0081] c. The grade of ferrosilicon is FeSi75-B according to the GB2272-87 standard;

[0082] (2) Smelting molten iron

[0083] Put the molten iron smelting raw materials into the in...

Embodiment 3

[0101] (1) Ingredients Weighing raw materials for molten iron smelting:

[0102] The raw materials for hot metal smelting are composed of the following components by weight percentage: pig iron 0.718t, scrap steel 0.282t, ferrosilicon 3.5kg, recarburizer 4kg;

[0103] a. Pig iron is high-purity pig iron, and its composition mass percentages are as follows:

[0104] C(%) Si(%) Mn(%) P(%) S(%) Ti(%) ≥4.0 ≤0.4 ≤0.50 ≤0.025 ≤0.02 ≤0.03

[0105] The mass percentages of trace elements in pig iron are as follows:

[0106]

[0107] The balance is iron;

[0108] b. Scrap steel is carbon steel, and the mass percentages of the components are as follows:

[0109] C(%) Si(%) Mn(%) P(%) S(%) ≤0.3 ≤0.2 ≤0.3 ≤0.02 ≤0.015

[0110] The balance is iron;

[0111] c. The grade of ferrosilicon is FeSi75-B according to the GB2272-87 standard;

[0112] (2) Smelting molten iron

[0113] Put the molten iron smelting raw materials into an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com