Fabrication method of long-life titanium base electrode

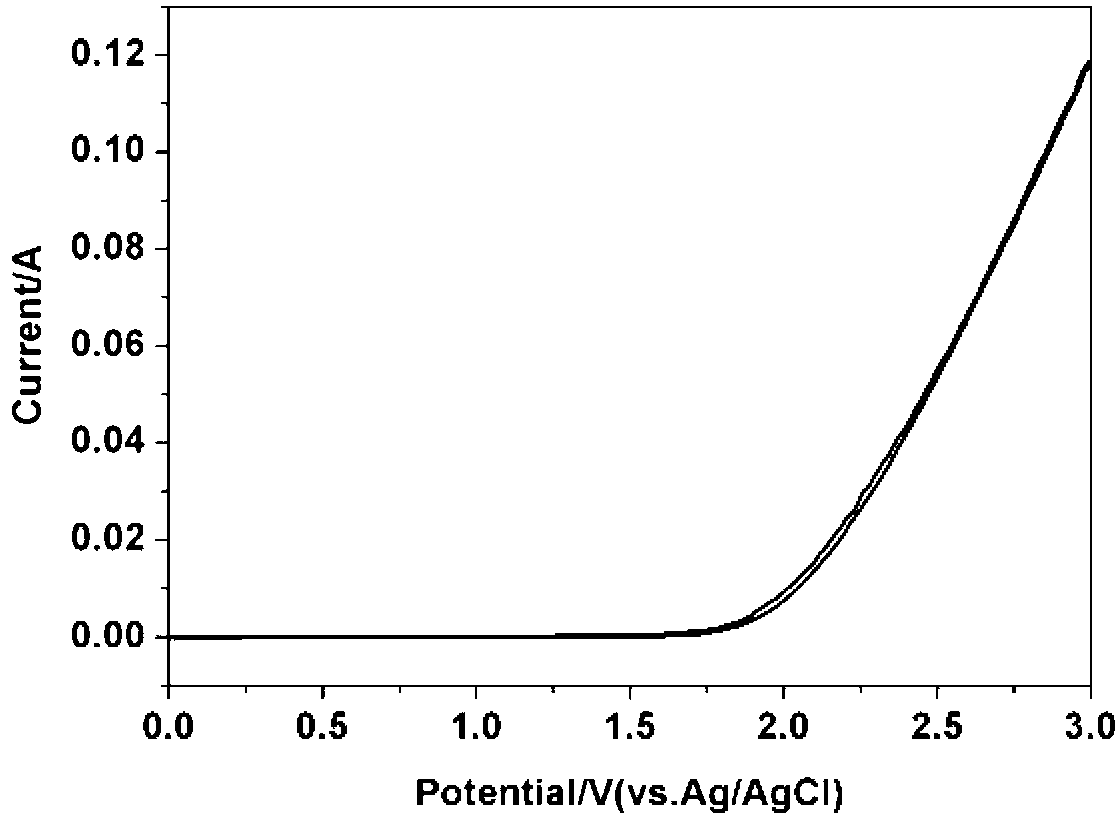

A long-life, titanium-based technology, used in electrodes, electrolysis processes, electrolysis components, etc., can solve problems such as the difficulty of preparing large-area uniform nanotubes, reducing the oxygen evolution potential of electrodes, affecting the use efficiency of electrodes and electrocatalytic activity, etc. It is convenient for industrialized large-scale production, high electrocatalytic activity, and the effect of realizing large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

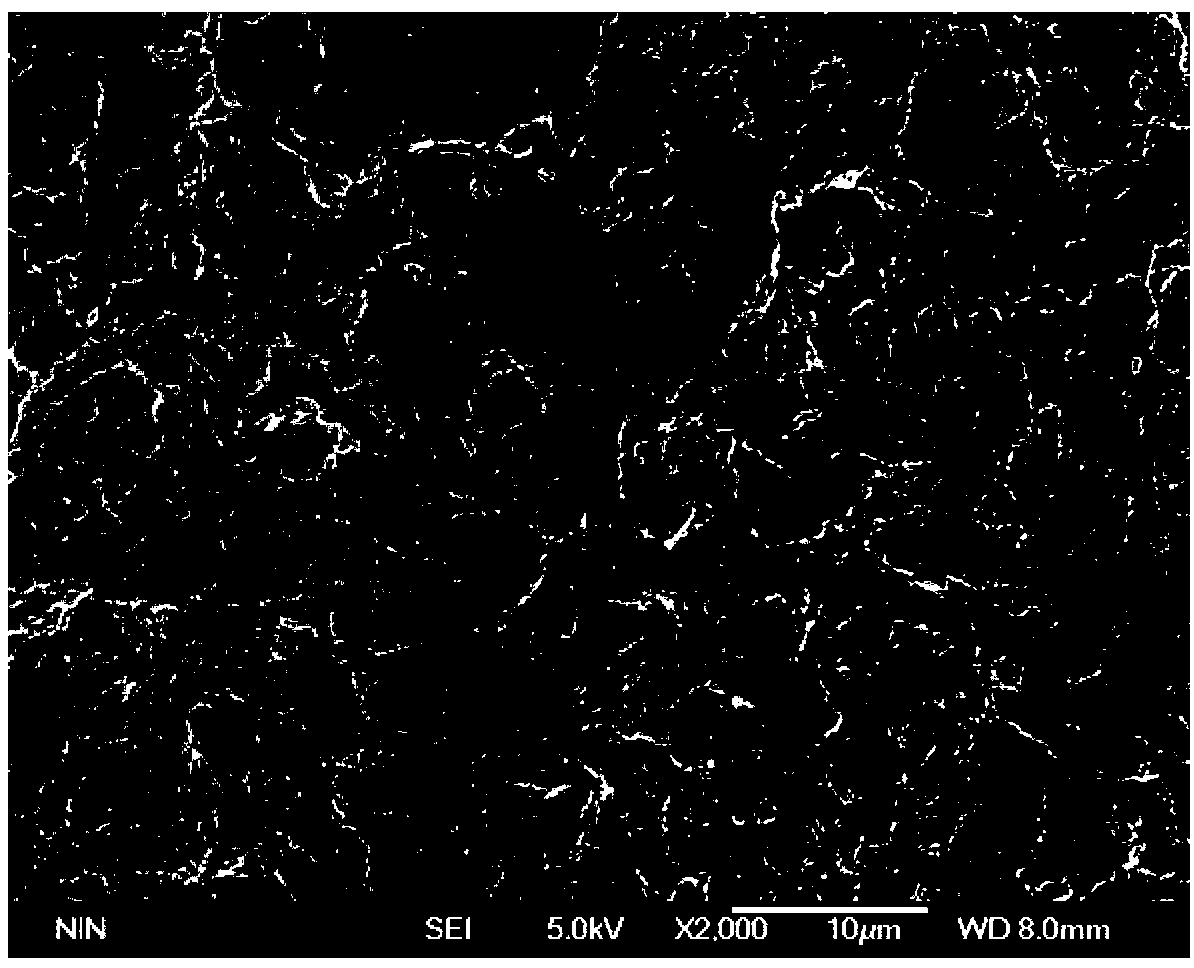

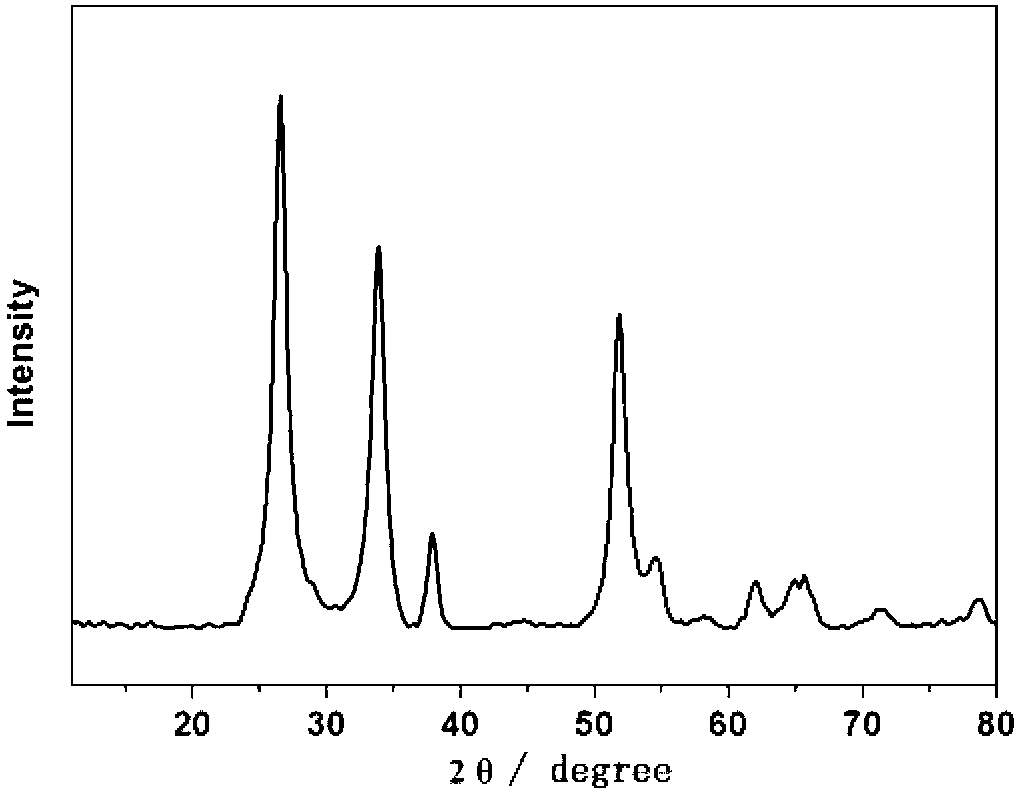

[0041] The preparation method of the long-life titanium-based electrode provided by the present invention uses impregnation, reduction, electrodeposition, and thermal oxidation to prepare a long-life and high oxygen evolution potential titanium-based tin dioxide electrode, which specifically includes the following steps:

[0042] 1) Preparation of titanium oxide layer on the surface of titanium substrate by dipping-thermal oxidation method

[0043] Polish the surface of the titanium substrate to smooth, remove oil with alkali, and clean it after oxalic acid etching. After drying, immerse the titanium substrate in the alcohol solution containing titanate, take it out after standing for a period of time, and heat and calcinate at 490-500°C for 0.5 -2h, a silver-gray titanium oxide intermediate layer is prepared.

[0044] 2) Reduction treatment is performed on the surface of the titanium oxide layer in a reducing atmosphere.

[0045] The titanium substrate prepared with the tita...

Embodiment 1

[0050] A method for preparing a long-life titanium-based electrode, comprising the following steps:

[0051] 1) Using the titanium sheet as the substrate, cut the titanium sheet into a size of 1.0cm×4.0cm with scissors, and polish the surface of the titanium sheet with 200-mesh coarse sandpaper and 40-mesh fine sandpaper successively to reveal the metallic luster;

[0052] Then heat and boil in the sodium hydroxide solution of 10% mass fraction concentration for 10min to remove oil;

[0053] Then heat the titanium sheet in a 10% mass fraction oxalic acid solution to slightly boil for 2 hours for acid etching, rinse with deionized water and place it in a 1% volume fraction oxalic acid solution for use;

[0054] Rinse the treated titanium sheet and dry it, then immerse the titanium sheet in the impregnation solution, the composition of the impregnation solution is 70% by volume of butyl titanate, 29% by volume of ethanol, and 1% by volume of nitric acid. After standing in the i...

Embodiment 2

[0062] A method for preparing a long-life titanium-based electrode, comprising the following steps:

[0063] 1) A titanium rod with a length of 55 cm and a diameter of 1 cm is used as the substrate, and the pretreatment steps of the substrate are the same as those in Example 1. Rinse the treated titanium rod and dry it;

[0064] Then immerse the titanium rod in the impregnation solution, the composition of the impregnation solution is 90% by volume of titanate, 9% by volume of ethanol, and 1% by volume of nitric acid. Heat and calcinate the impregnated titanium rod at 510°C for 0.5h in a muffle furnace to obtain a silver-gray titanium oxide layer.

[0065] 2) Pass dry high-purity hydrogen and high-purity ammonia into the reaction furnace at a ratio of 9:1 by volume, and reduce the titanium oxide layer prepared on the surface of the titanium substrate at 400-500 ° C under the condition of isolating oxygen Treat for 10-15 minutes.

[0066] 3) Using the titanium rod as the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com