Preparation method of high catalytic activity magnetic particle loading 2.5-dimensional anode

A technology with high catalytic activity and magnetic particles, applied in chemical instruments and methods, electrolytic inorganic material coating, electrolytic coating, etc. Infiltration and other problems, to achieve ideal removal efficiency and energy consumption, prolong electrode life, increase the effect of real catalytic area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

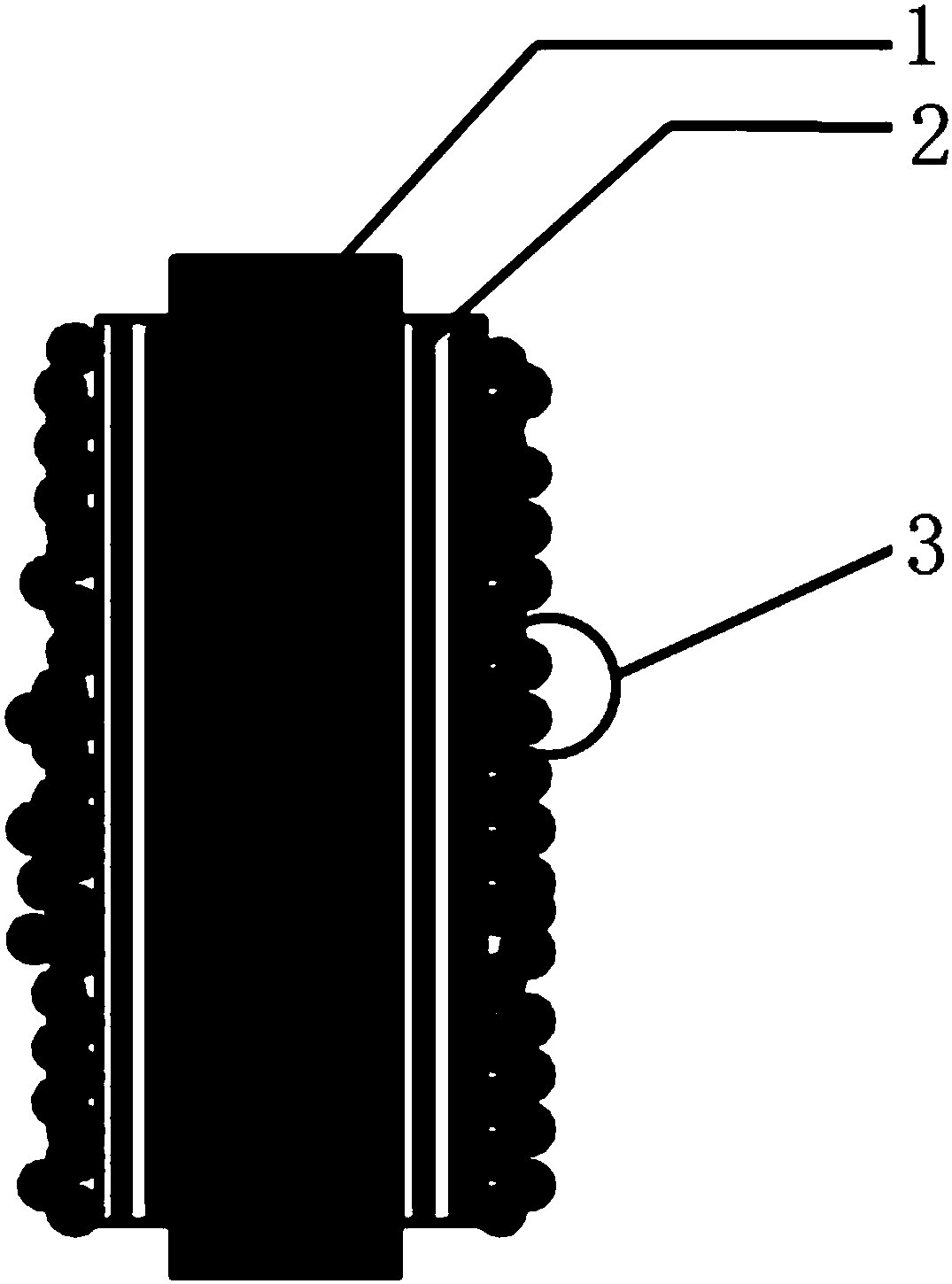

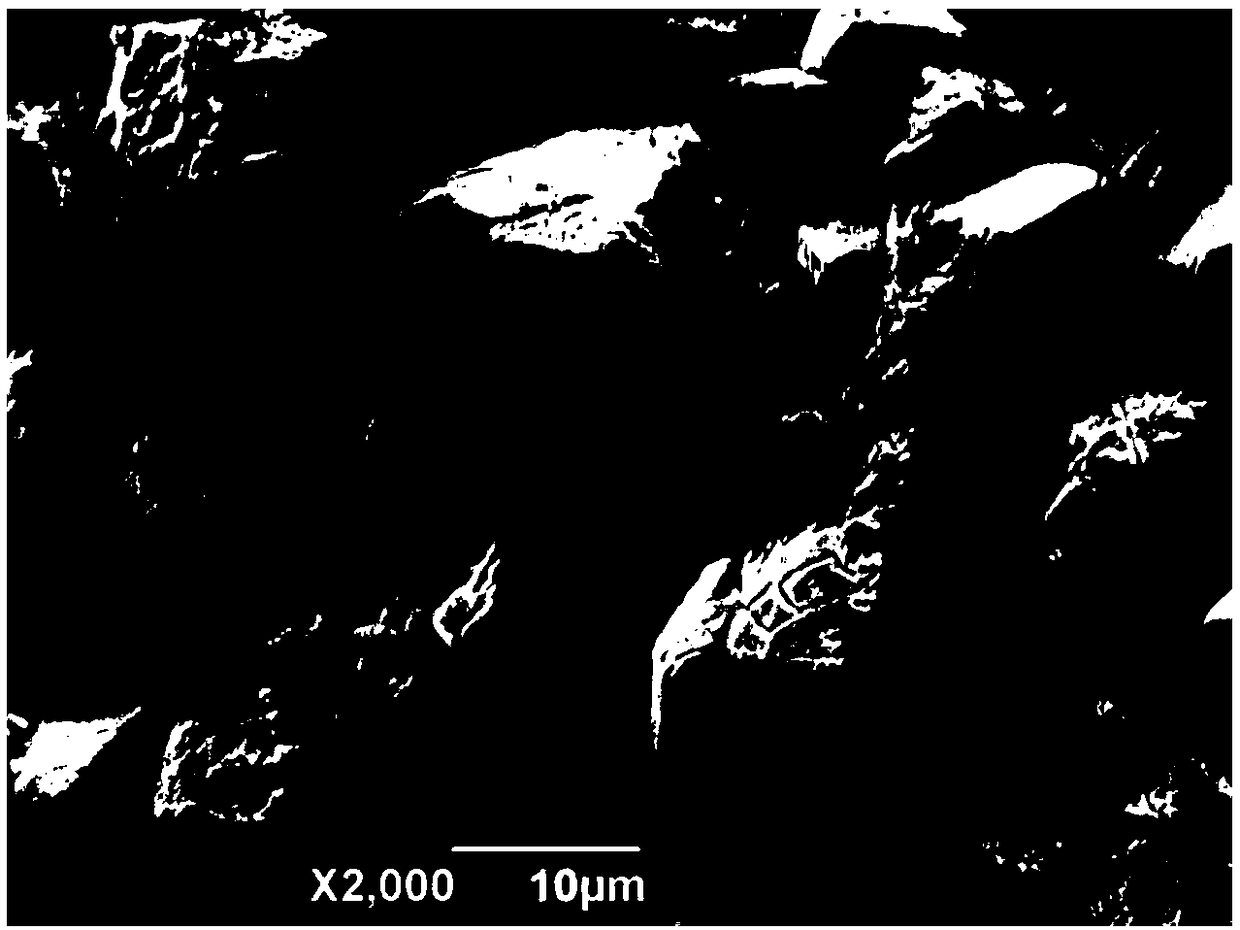

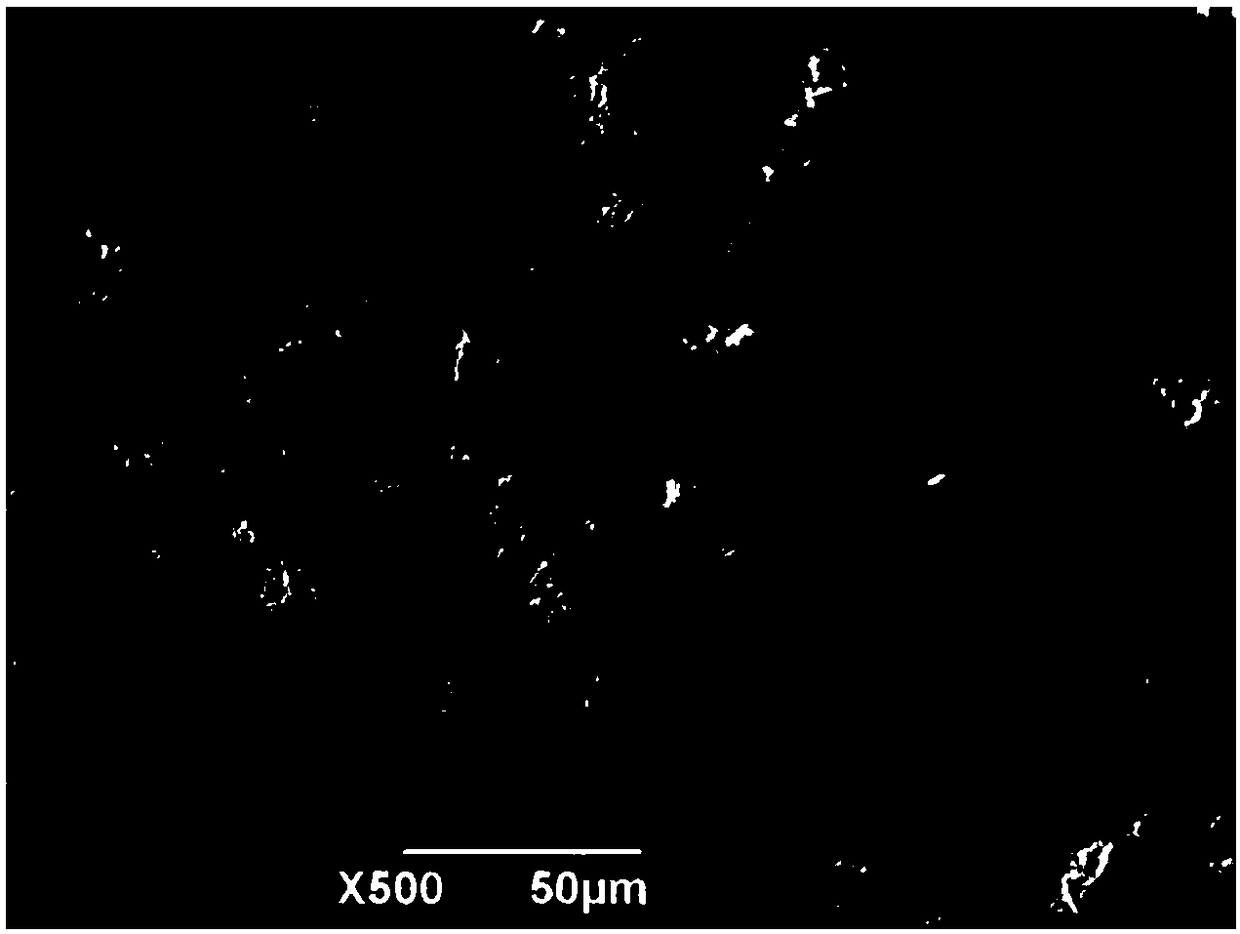

[0046] 1) By volume percentage, mix the tetrabutyl titanate of 64% volume fraction, the ethanol of 35% volume fraction and the nitric acid of 1% volume fraction, stir 10min, obtain pale yellow precursor solution, ferric iron tetroxide particles are mixed in Immerse in the light yellow precursor solution, the volume ratio of ferric oxide particles to the precursor solution is 1:1, heat under stirring until the precursor solution evaporates, the stirring time is 60min, and then put it into the muffle furnace for calcination at 300°C for 1.5h. A silver-gray titanium oxide layer is prepared on the surface of ferric oxide particles;

[0047] 2) Add tin tetrachloride and antimony trichloride to nitric acid to obtain a precursor solution. In the precursor solution, the concentration of tin tetrachloride is 1.0mol / L, the concentration of antimony trichloride is 0.1mol / L, and the concentration of nitric acid 0.1mol / L. Dip iron ferric oxide particles with a silver-gray titanium oxide l...

Embodiment 2

[0056] 1) By volume percentage, mix the tetrabutyl titanate of 40% volume fraction, the ethanol of 55% volume fraction and the nitric acid of 5% volume fraction, stir 20min, obtain light yellow precursor solution, ferric iron tetroxide particles are mixed in Immerse in the precursor solution, the volume ratio of ferric oxide particles to the precursor solution is 2:1, heat it under stirring until the precursor solution evaporates, the stirring time is 70min, and then put it into the muffle furnace for calcination at 250°C for 1.5h. A silver-gray titanium oxide layer is prepared on the surface of ferric oxide particles;

[0057] 2) Add tin tetrachloride and antimony trichloride to nitric acid to obtain a precursor solution. In the precursor solution, the concentration of tin tetrachloride is 1.0mol / L, the concentration of antimony trichloride is 0.1mol / L, and the concentration of nitric acid 0.1mol / L. Immerse the iron ferric oxide particles with a silver-gray titanium oxide la...

Embodiment 3

[0066] 1) By volume percentage, mix the tetrabutyl titanate of 50% volume fraction, the ethanol of 37% volume fraction and the nitric acid of 3% volume fraction, stir 10min, obtain light yellow precursor solution, ferric iron tetroxide particles are mixed Immerse in the light yellow precursor solution, the volume ratio of ferric oxide particles to the precursor solution is 1:1, heat under stirring until the precursor solution evaporates, the stirring time is 80min, and then put it into the muffle furnace for calcination at 350°C for 1.5h. A silver-gray titanium oxide layer is prepared on the surface of ferric oxide particles;

[0067] 2) Add tin tetrachloride and antimony trichloride to nitric acid to obtain a precursor solution. In the precursor solution, the concentration of tin tetrachloride is 1.0mol / L, the concentration of antimony trichloride is 0.1mol / L, and the concentration of nitric acid 0.1mol / L. Immerse the iron ferric oxide particles with a silver-gray titanium o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com