Sulfur-series medium-high entropy MAX phase solid solution material as well as preparation method and application of same

A technology of solid solution and powder materials, applied in the field of sulfur-based high-entropy MAX phase solid solution materials and their preparation, and MAX phase solid solution materials, can solve the problems of simple sulfur being volatile and unstable, difficult to synthesize, etc., and achieve good application prospects. The method is simple and easy, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another aspect of the embodiments of the present invention provides a method for preparing a sulfur-based medium-high entropy MAX phase solid solution material, comprising: providing ferrous sulfide as a high-temperature solid sulfur source;

[0036] React the mixture containing the ferrous sulfide, transition metal elemental substance and / or transition metal hydride and transition metal carbide at 1400-1800°C for 10-30 minutes to obtain the sulfur-based medium-high entropy MAX phase solid solution material, whose chemical formula is m 2 SC, where M includes any combination of three or more of Ti, Zr, Hf, V, Nb, and Ta.

[0037] In some embodiments, the preparation method specifically includes:

[0038] Mixing ferrous sulfide, transition metal elemental substance and / or transition metal hydride and transition metal carbide according to the molar ratio of (1.0~1.2):(1.9~2.1):(0.8~1) to obtain a mixture;

[0039] Using a spark plasma sintering system, raise the temperat...

Embodiment 1

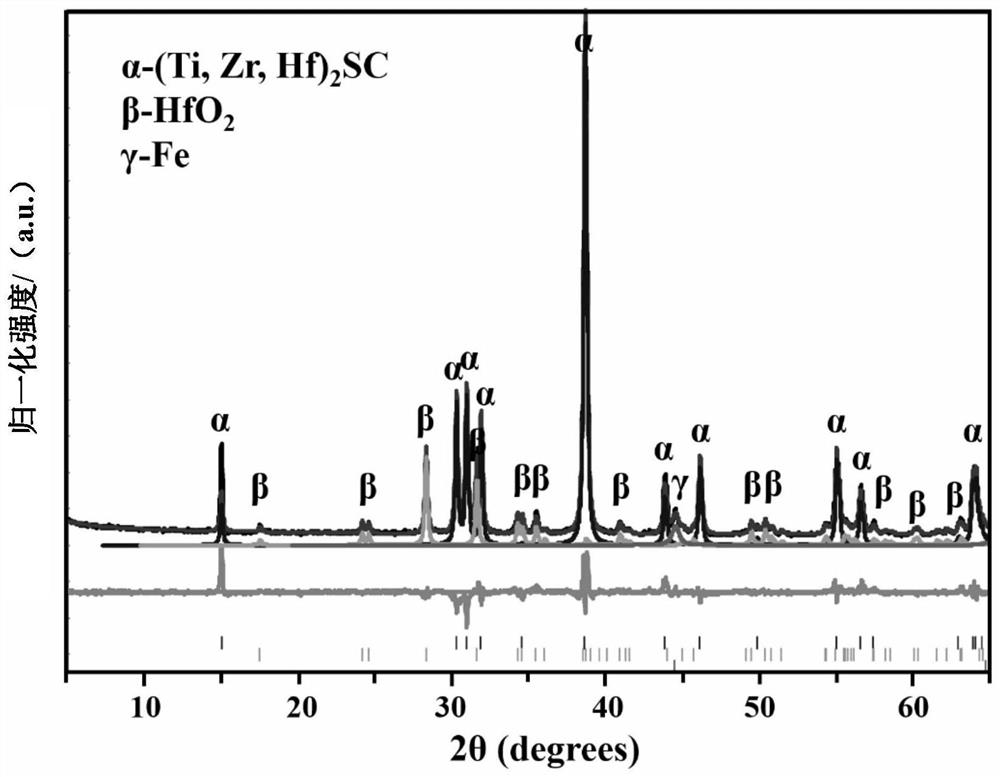

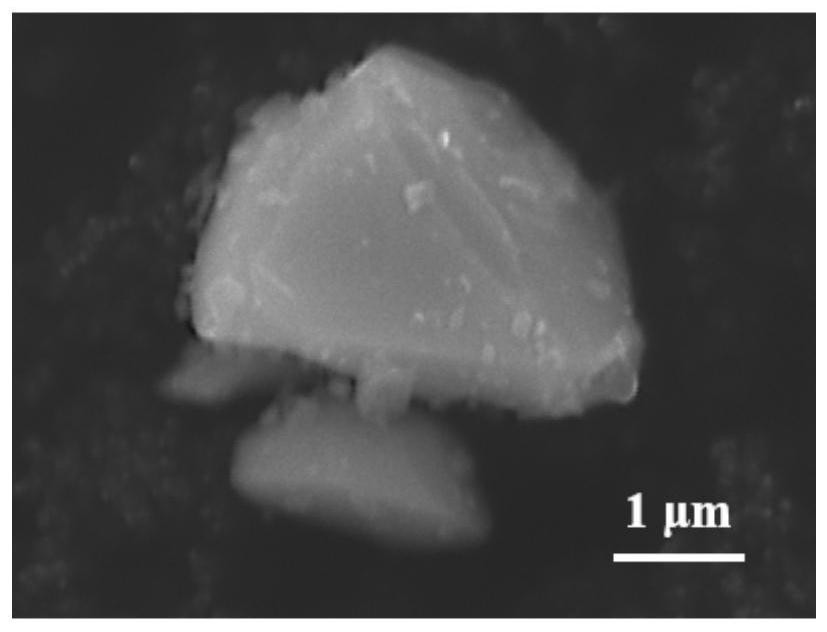

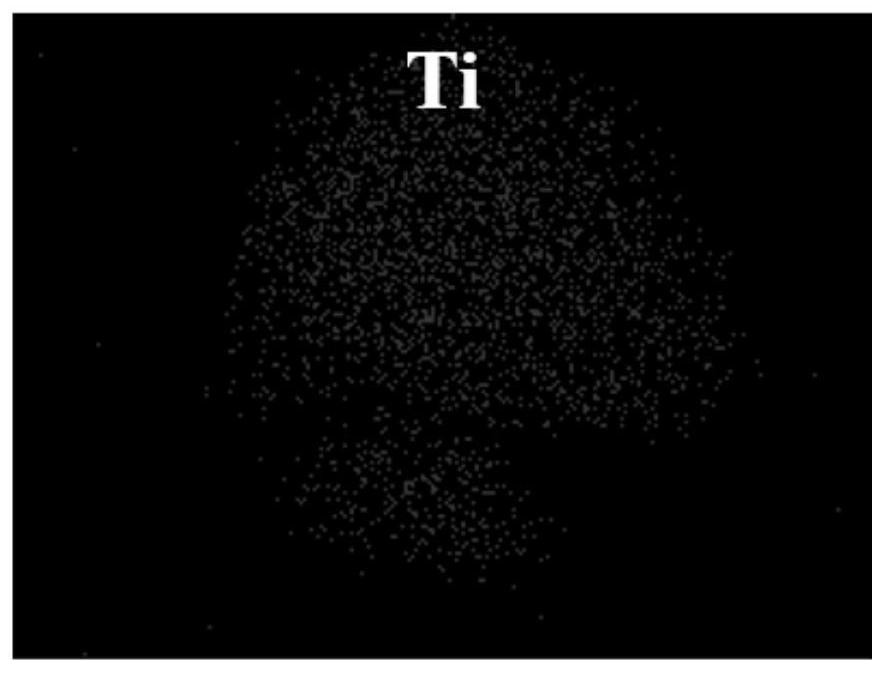

[0055] In this embodiment, the entropy MAX phase solid solution material in the sulfur series is (Ti, Zr, Hf) 2 SC. The preparation steps of the solid solution material are as follows:

[0056] (1) Choose titanium carbide, zirconium, zirconium carbide, hafnium hydride and ferrous sulfide as raw materials, according to TiC: Zr: ZrC: HfH 2 : The molar ratio of FeS is 2:1:1:2:3.2, mixed with alcohol as the medium for 30min during grinding, and dried in a vacuum oven. In this embodiment, if hafnium is easily oxidized, the use of hafnium hydride is beneficial to improve the purity of the target phase.

[0057] (2) Using a spark plasma sintering system, heat preservation at 1600°C for 20min at a heating rate of 50°C / min.

[0058] (3) The powder obtained in step (2) is crushed and ground to 300 mesh to obtain a precursor powder with uniform particle size distribution.

[0059] (4) Select dilute hydrochloric acid aqueous solution with a concentration of 3 mol / L as the etchant, etc...

Embodiment 2

[0065] In this embodiment, the sulfur-based high-entropy MAX phase solid solution material is (Ti, Zr, Hf, V) 2 SC. The preparation steps of the solid solution material are as follows:

[0066] (1) Choose titanium carbide, zirconium, hafnium hydride, vanadium carbide and ferrous sulfide as raw materials, according to TiC: Zr: HfH 2: The molar ratio of VC: FeS is 2:2:2:2:4.2, mixed with alcohol for 30min in the grinding process, and dried in a vacuum oven.

[0067] (2) Using a spark plasma sintering system, heat preservation at 1600°C for 20min at a heating rate of 50°C / min.

[0068] (3) The powder obtained in step (2) is crushed and ground to 300 mesh to obtain a precursor powder with uniform particle size distribution.

[0069] (4) Select dilute hydrochloric acid aqueous solution with a concentration of 3 mol / L as the etchant, etch at 50° C. for 2 days, and fully magnetically stir.

[0070] (5) Use polyvinylidene fluoride microporous filter membrane (PVDF, 0.45 μ m in por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lattice constant | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com