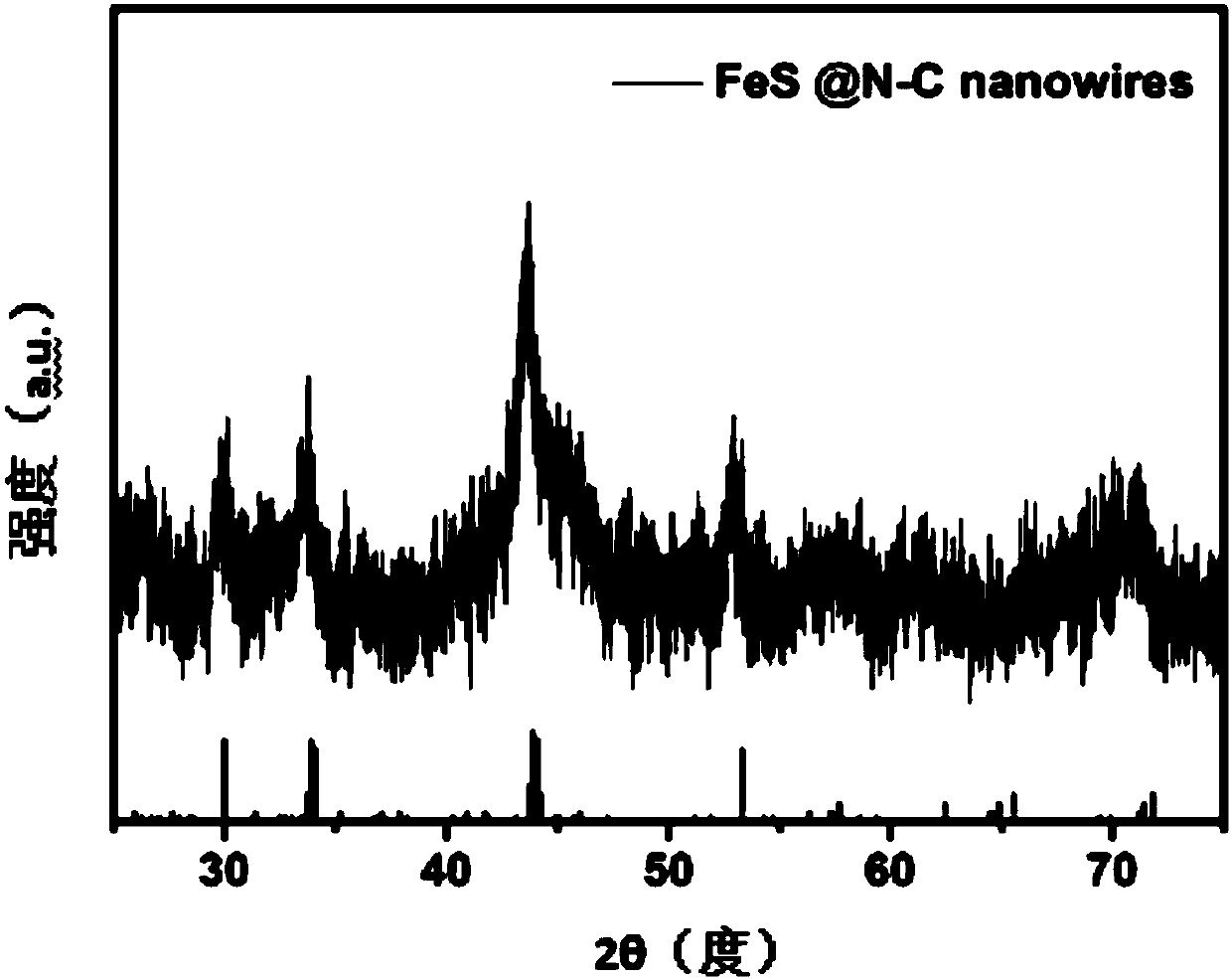

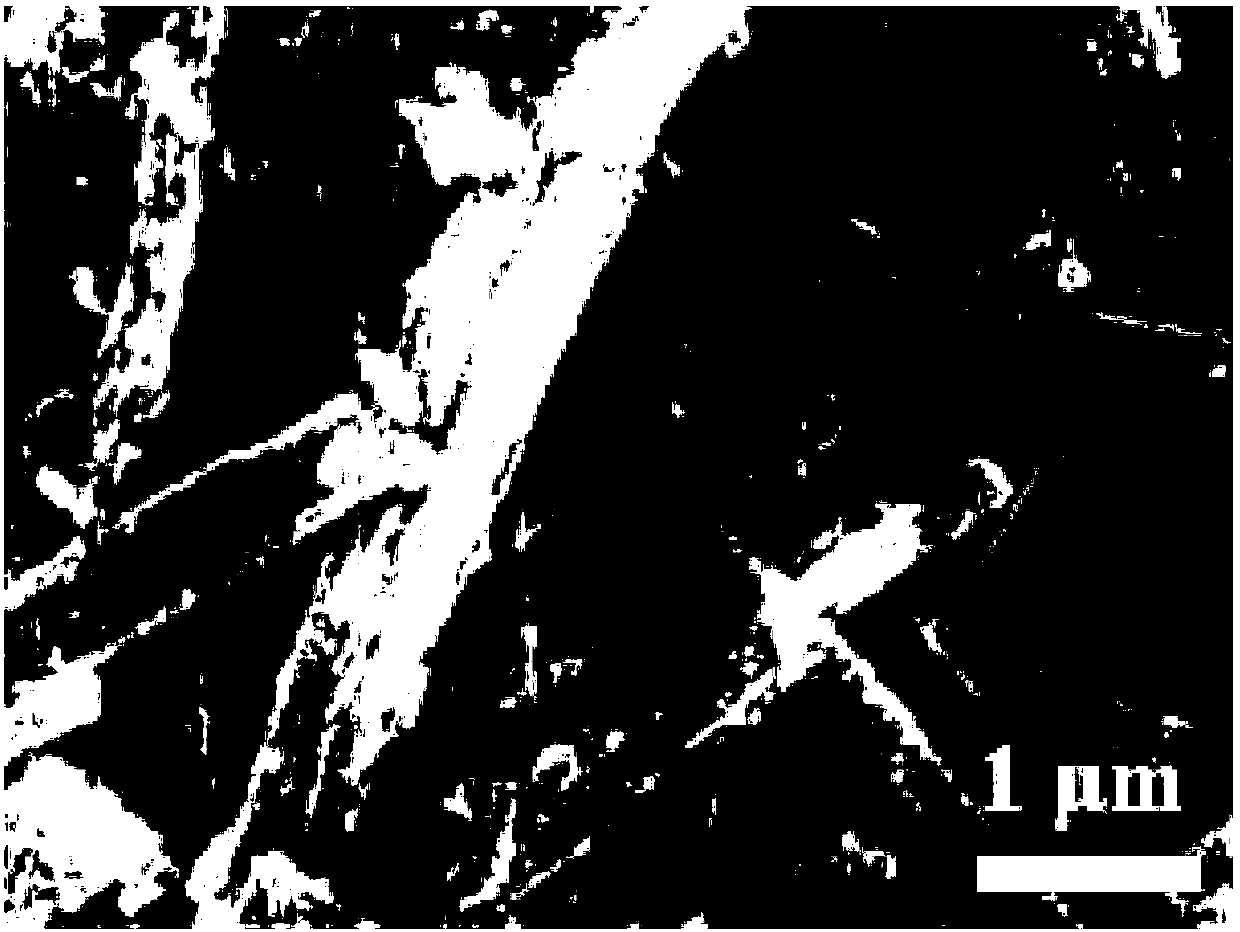

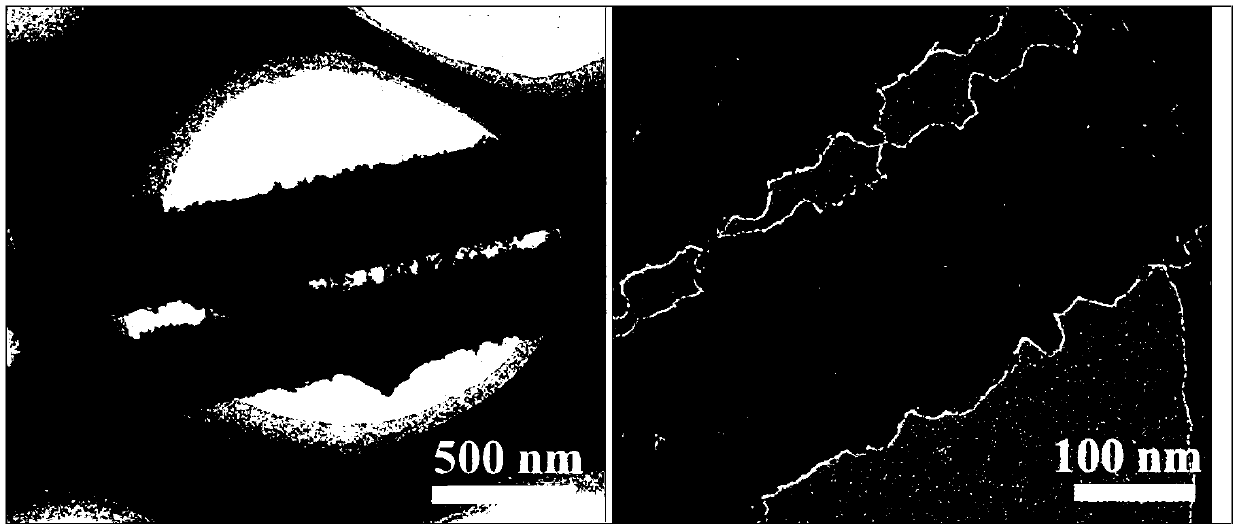

Porous ferrous sulfide nanowires and nitrogen doped carbon composite material and preparation method and application thereof

A ferrous sulfide, nitrogen-doped carbon technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of structural instability, high rate and long life limitation, and achieve low equipment requirements, high energy density, and shortened diffusion distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of porous ferrous sulfide nanowire and nitrogen-doped carbon composite material, it comprises the steps:

[0032] 1) Dissolve 1 mmol of ferrous sulfate heptahydrate in 25 ml of deionized water, and stir magnetically at room temperature until completely dissolved;

[0033] 2) Add 2 mmol of thioacetamide to the solution obtained in step 1), and stir magnetically at room temperature until completely dissolved;

[0034] 3) Add 5ml of ethylene glycol to the solution obtained in step 2), and stir at room temperature for 5 minutes;

[0035] 4) Add 5ml of ethylenediamine to the solution obtained in step 3), and stir at room temperature for 40 minutes;

[0036] 5) Transfer the solution obtained in step 4) into a 50mL reaction kettle, conduct a hydrothermal reaction at 180°C for 24 hours, take out the reaction kettle, and naturally cool to room temperature;

[0037] 6) The product obtained in step 5) is centrifuged, washed three times with deionized water...

Embodiment 2

[0042] 1) Dissolve 1 mmol of ferrous sulfate heptahydrate in 25 ml of deionized water, and stir magnetically at room temperature until completely dissolved;

[0043] 2) Add 2 mmol of thioacetamide to the solution obtained in step 1), and stir magnetically at room temperature until completely dissolved;

[0044] 3) Add 5ml of ethylene glycol to the solution obtained in step 2), and stir at room temperature for 2 minutes;

[0045] 4) Add 5ml of ethylenediamine to the solution obtained in step 3), and stir at room temperature for 50 minutes;

[0046] 5) Transfer the solution obtained in step 4) into a 50mL reaction kettle, conduct a hydrothermal reaction at 160°C for 24 hours, take out the reaction kettle, and naturally cool to room temperature;

[0047] 6) The product obtained in step 5) is centrifuged, washed three times with deionized water and absolute ethanol, and dried in an oven at 60-80°C to obtain the ferrous sulfide nanowire material precursor;

[0048] 7) The precurs...

Embodiment 3

[0051] 1) Dissolve 1 mmol of ferrous sulfate heptahydrate in 25 ml of deionized water, and stir magnetically at room temperature until completely dissolved;

[0052] 2) Add 2 mmol of thioacetamide to the solution obtained in step 1), and stir magnetically at room temperature until completely dissolved;

[0053] 3) Add 5ml of ethylene glycol to the solution obtained in step 2), and stir at room temperature for 5 minutes;

[0054] 4) Add 5ml of ethylenediamine to the solution obtained in step 3), and stir at room temperature for 45 minutes;

[0055] 5) Transfer the solution obtained in step 4) into a 50mL reaction kettle, and conduct a hydrothermal reaction at 200°C for 16 hours, take out the reaction kettle, and cool it down to room temperature naturally;

[0056] 6) The product obtained in step 5) is centrifuged, washed three times with deionized water and absolute ethanol, and dried in an oven at 60-80°C to obtain the ferrous sulfide nanowire material precursor;

[0057] 7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com